Plastics and Sustainability:

A Look Through the Lens of Natural Capital Costs

A new study by consultants Trucost shows the broader environmental advantages of plastics over alternative materials.

Previous Article Next Article

By American Chemistry Council (ACC)

Plastics and Sustainability:

A Look Through the Lens of Natural Capital Costs

A new study by consultants Trucost shows the broader environmental advantages of plastics over alternative materials.

Previous Article Next Article

By American Chemistry Council (ACC)

Plastics and Sustainability:

A Look Through the Lens of Natural Capital Costs

A new study by consultants Trucost shows the broader environmental advantages of plastics over alternative materials.

Previous Article Next Article

By American Chemistry Council (ACC)

Figure 1. Addition reaction mechanism showing styrene monomer polymerizing into polystyrene.

Figure 2.

Figure 3.

Note: This article continues the series of updates in Plastics Engineering from Plastics Make it Possible®, an initiative sponsored by America’s Plastics Makers® through the American Chemistry Council (ACC).

If a new material were found today that could reduce environmental costs compared to existing materials by nearly four times, imagine what a positive, disruptive force that would be. In the presence of such a force, traditional materials would progressively be set aside in the name of corporate and planetary sustainability.

Well, a new study provides insights for corporate decision makers, policy makers and environmentally minded people into just how disruptive plastics are from an environmental perspective.

Disruptive, that is, in a good way.

Recent Advances

We already know that plastics are replacing traditional materials, due in large part to their favorable strength-to-weight ratio that allows them to do more with less. We see that in numerous previous studies and market sectors.

Packaging – A study in the U.S. shows that if we were to replace plastic packaging with alternatives, we would dramatically increase the amount of packaging material. Alternatives would require four and a half times as much material by weight and increase the amount of packaging used by nearly 110 billion pounds yearly.

Building Materials – Plastics can help save a whole lot of energy over the lives of our homes and buildings. The energy saved by using plastic materials compared to alternative materials is approximately 467.2 trillion BTU of energy a year – that’s enough to meet the average annual energy needs of 4.6 million U.S. households.

Vehicles – Lightweight plastics and plastic composites comprise 50 percent of today’s vehicles by volume yet only 10 percent by weight, due to their strength-to-weight ratios. Reducing vehicle weight can significantly improve fuel efficiency, reducing both financial and environmental costs, while improving performance. As Ford Motor Co. notes: “Few innovations provide a more wide-ranging performance and efficiency advantage than reducing weight. All factors of a vehicle’s capabilities—acceleration, handling, braking, safety, efficiency—can improve through the use of advanced, lighter materials.”

But despite measurable advances in these and other areas, the often-accepted narrative around plastics is: they are more wasteful and have greater environmental impacts than traditional materials. Is this true? While every material has environmental costs, how do plastics actually compare to alternatives?

New Study

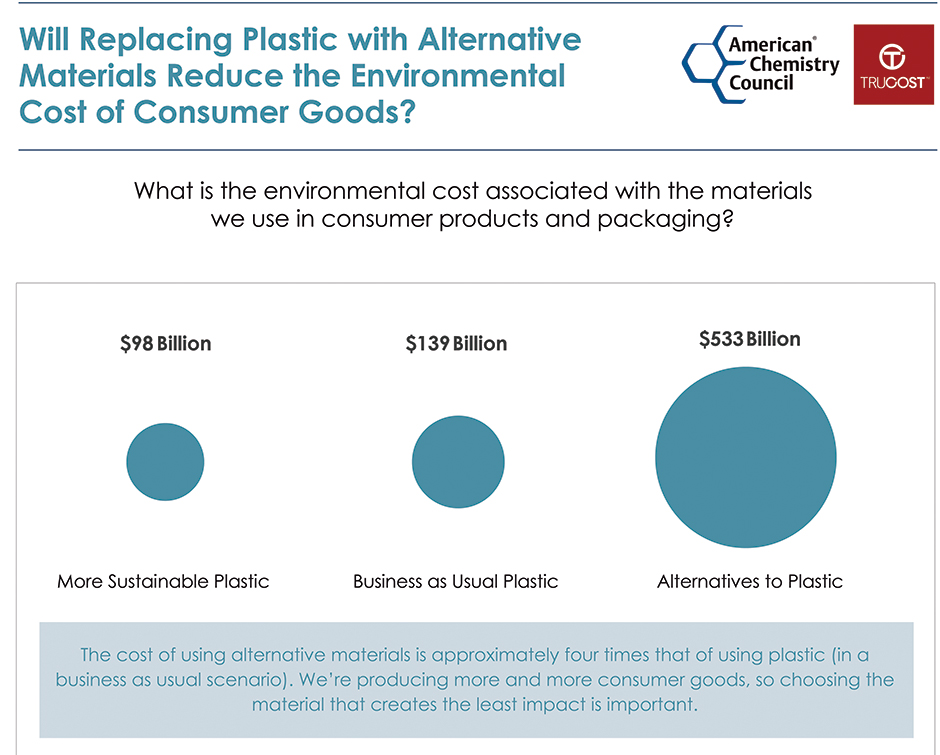

To answer this question, the American Chemistry Council commissioned an independent study by the environmental consulting firm Trucost PLC in London that looks at the broad environmental costs of using plastics in consumer goods compared to other materials.

This July 2016 study builds on a 2014 study, also by Trucost, commissioned by the United Nations Environment Programme (UNEP) called, “Valuing Plastics: The Business Case for Measuring, Managing and Disclosing Plastic Use in the Consumer Goods Industry.” That study found that the “total natural capital cost of plastic used in the consumer goods industry is estimated to be more than $75 billion per year.” The cost comes from a range of environmental impacts such as effects from marine litter and the loss of valuable resources when used plastics are sent to landfills rather than recycled.

What the 2014 study did not ask is: compared to what? Trucost’s new study, “Plastics and Sustainability: A Valuation of Environmental Benefits, Costs and Opportunities for Continuous Improvement,” provides that perspective. The report’s authors call it the largest natural capital cost study ever conducted for the plastics manufacturing sector.

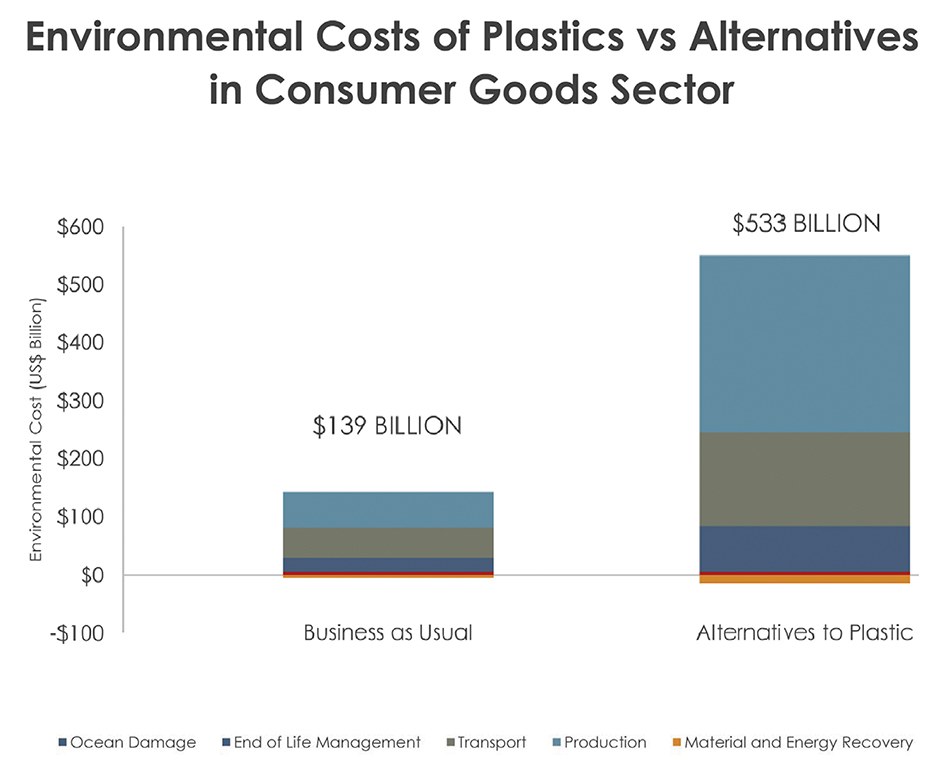

The new study expands upon the initial study by including transportation as part of the life cycle of products and packaging. Indeed, the study’s broader scope actually increased the estimated environmental cost of plastics from $75 billion to $139 billion per year.

Most notably, it compares the environmental cost of using plastics in consumer products and packaging to the cost of replacing plastics with alternative materials.

The findings? When compared to alternatives, the new study found that the environmental cost of using plastics is four times less than the costs of other materials. Substituting plastics in consumer products and packaging with alternatives that perform the same function would increase environmental costs from $139 billion to $533 billion annually (Figure 1).

Disruptive Findings

These results disrupt the commonly accepted narrative around plastics—the assumption that traditional materials have less environmental impact. In fact, these findings stand that assumption on its head.

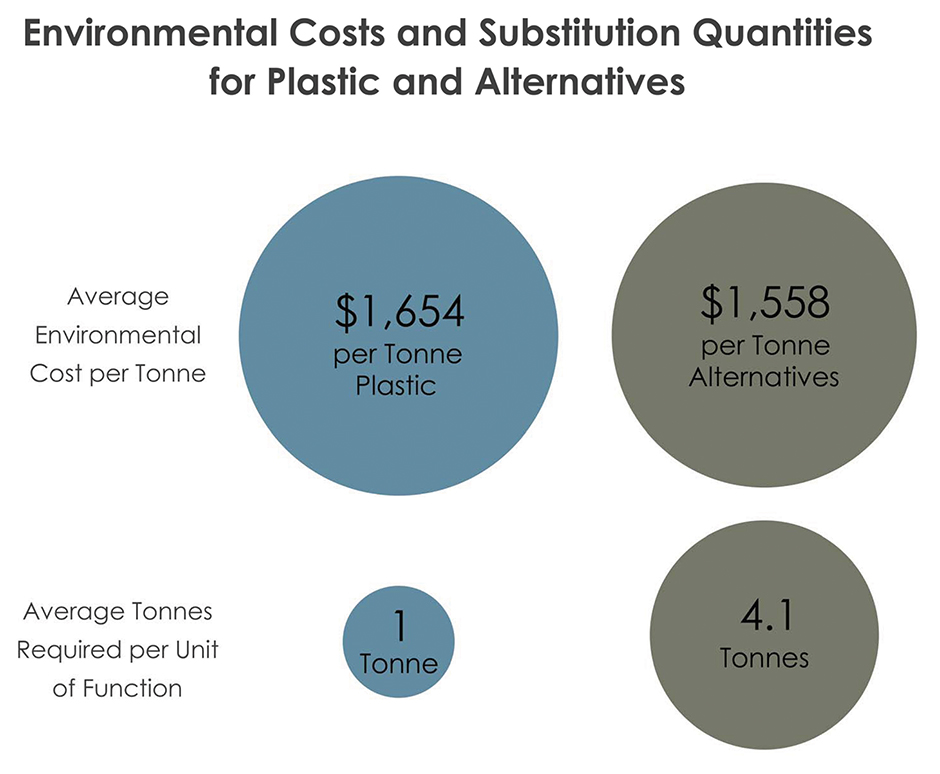

One of the likely reasons for these findings, as mentioned above, is the comparable strength-to-weight ratio of plastics. Alternative materials such as glass, tin, aluminum and paper can be viable alternatives to plastics in many consumer goods applications. But a greater amount of these alternative materials typically is needed to accomplish the same objective. Similar to the findings in the packaging study above, this new study finds that alternatives require four times more material by mass on average (Figure 2).

A good example: when Planters® replaced its glass jar for dry roasted peanuts with a recyclable plastic jar, the new label announced: “84% less packaging than glass jar by weight!” The company claims that the switch will result in a 25% reduction in trucks on the road to ship the same amount of nuts, along with saving millions of pounds in packaging and shipping materials.

In other words, using more material typically translates into higher environmental costs.

As it turns out, plastics are extremely efficient materials. Because they are both strong and lightweight, they allow us to do more with less in the 16 market sectors reviewed in the study … and in just about every aspect of modern living.

Now What?

Even though plastics have significantly less impact on the environment than alternatives, the study identifies numerous opportunities to reduce that impact. These steps include increasing the use of lower-carbon sources of energy upstream, adopting lower-emission transport modes, developing even more efficient plastic packaging, and increasing recycling and energy recovery to help address ocean litter and conserve resources. To help reduce plastics leakage into the marine environment, the study also highlighted the importance of expanding waste management infrastructure globally, particularly in Asia where other studies have determined 75% of marine litter originates.

The study also called for enhanced environmental leadership by the plastics industry, noting that the industry has “direct influence, or indirect influence via its supply chain management practices, over a significant share of the environmental costs of plastic use in consumer goods sector, and other sectors. Thus the industry is well positioned to play an enhanced leadership role in driving improvements in the environmental performance of the plastics value chain.”

This study represents the clearest and most comprehensive picture to date of the relative environmental costs and benefits of plastics compared to alternative materials. And by providing a path forward to further reduce these relative costs, the study provides insights for corporate decision makers, policy makers and environmentally minded people into how these disruptive materials can further contribute to sustainability.