New styrenic grades target gaskets and seals.

Graphic courtesy of PolymaxTPE

SmartKem’s truFLEX® semiconductor platform helps to enable flexible displays and electronics.

Photo courtesy of SmartKem

SmartKem’s truFLEX® semiconductor platform helps to enable flexible displays and electronics.

Photo courtesy of SmartKem

Makrolon SL polycarbonate sheet helped to remake this pedicab.

Photo courtesy of Covestro.

Makrolon SL polycarbonate sheet helped to remake this pedicab.

Photo courtesy of Covestro.

Automakers and tier suppliers are putting infrared systems to good use.

Photo courtesy of Heraeus Noblelight

Automakers and tier suppliers are putting infrared systems to good use.

Photo courtesy of Heraeus Noblelight

AI has rolled out its latest moisture analyzer.

Photo courtesy of Arizona Instrument LLC

AI has rolled out its latest moisture analyzer.

Photo courtesy of Arizona Instrument LLC

Conair says its latest system offers ‘a new approach to vacuum conveying.

Photo courtesy of Conair

Conair says its latest system offers ‘a new approach to vacuum conveying.

Photo courtesy of Conair

Science Campus at K 2016 to connect research & industry

Having met with a positive response at K 2013, the Science Campus at K 2016 in Düsseldorf, Germany, Oct. 19-26 will further intensify the dialogue between research and industry in an enlarged area and with an increased number of participating scientific organizations. Supplementing the presentations of universities and colleges, institutes and sponsoring organizations, the Science Campus will focus on the four key themes defined by the K 2016 Innovation Circle – a panel made up of experts from science and representatives of K’s Exhibitors Council.

The Science Campus enables exhibitors and visitors at K 2016 to gain a concentrated overview of scientific activities and findings in the plastics and rubber sector and promotes an exchange of experience between companies and universities. The participants at the Science Campus will be presenting pioneering materials and technologies and responding to the central challenges of polymer technology.

The discussion and communication will focus on the key themes: innovation drivers of global change focusing on resource efficiency; Plastics Industry 4.0; new materials and lightweight engineering, as well as on scientific training in macromolecular chemistry and plastics technology. Scientists of K 2016’s Innovation Circle and teams from their institutes will prepare the key themes and present them in different formats.

Expected to have a lasting impact on market development of the sector in the coming years, these themes will not only be the focus of the Science Campus at K 2016 but will also be reflected in the presentations of the exhibitors, the special show “Plastics Shape the Future” and the Innovation Compass.

At K 2016, more than 3,200 exhibitors from 60 nations will present their latest developments in the fields of machinery and equipment for the plastics and rubber industry, raw materials and auxiliaries, semi-finished products, technical parts, and reinforced plastics products. The eight-day fair is expected to attract some 200,000 trade visitors from all over the world.

New styrenic TPE grades offer seal integrity

PolymaxTPE introduces two styrenic TPE grades engineered to deliver low-compression-set performance expressly for gasket and seals application. These two new grades, P32-010 and P32-011, can replace TPV elastomers in a variety of applications that require high resilience for seal integrity, including gaskets, seals, valves, home appliances, and food packaging. What makes these new products stand out is their low compression set at elevated temperatures. Compression set is the measure of a material’s ability to recover from deformation. The lower the percentage, the better the material resists permanent deformation under a given deflection and temperature range.

“The development of new TPEs with low compression set for the seal industry reflects the focus of PolymaxTPE on R&D and its strategy of working proactively with customers”, noted Dr. Martin Lu, chief technology officer of PolymaxTPE. The two new grades score further points for their excellent tear strength, cold temperature flexibility, low odor, stability at high temperatures, and weather resistance. The raw materials used to manufacture these two grades are compliant with food-contact regulations. These materials can be used in stand-alone injection molding, extrusion applications, or bonded with polypropylene substrates.

SABIC to demonstrate “Chemistry that Matters™”

SABIC will showcase to K show visitors how “Chemistry that Matters™” is addressing global trends and the challenges in key industries with solutions to help create a better future for everyone. With a strong emphasis on sustainability, SABIC says that at this year’s event it will highlight its strong, collaborative approach with customers to jointly develop and produce global solutions, from concept to realization.

“Striving for a sustainable future means looking at business practices differently and being able to turn challenges into opportunities that add lasting business value,” said Abdulrahman Al-Fageeh, Executive Vice President - Polymers. “Our new organization brings us closer to customers, enabling us to offer sustainable solutions to the entire value chain and move further toward our vision to be a preferred world leader in chemicals.”

SABIC will feature new, sustainability-enabling materials and technologies it has developed. With the focus on key industry segments such as packaging, construction, healthcare, transportation, consumer goods and electronics, SABIC will display specific applications, such as renewable packaging, fuel-efficient transportation solutions, and easily constructed, reusable buildings. Stand visitors can gain deeper knowledge about these technologies through interactive, digital content.

The striking design of the stand will feature interior and exteriors walls constructed of SABIC’s LEXAN™ sheet, which is 50% lighter and 250 times more impact-resistant than glass. These materials help to reduce transport and labor costs, facilitate easy and fast installation, and provide excellent UV and fire resistance. The UV-protected outer surface offers long-term weatherability and its multiwall structure provides profound thermal insulation. With its inherent high impact resistance, clarity and durability, LEXAN™ sheet helps to maintain safety and a clear view in indoor applications.

Semiconductor material wins patent allowance in China

SmartKem, UK-based developer of the truFLEX® semiconductor platform for the manufacture of flexible displays and electronics, has had notification of patent allowance for its semiconductor material in China. This is a key market for the roll-out of its technology platform with display manufacturers across Asia.

Steve Kelly, CEO and founder of SmartKem, said: “Successful collaboration is crucial in helping China to become a key stakeholder and competitor in the global OLED display industry.

“As the Chinese OLED industry matures, China’s capabilities in both traditional and flexible OLED production will only increase as it turns its focus to designing and developing its own products rather than manufacturing someone else’s. There is a clear commitment to encourage high-tech research and development and there are benefits in place to incentivize innovation and high technological standards. Our new patent allowance places SmartKem in an excellent positon to consolidate and strengthen our existing position within the Chinese display sector with our ground-breaking semiconductor platform.”

The primary target applications include new wearable technologies, mobile devices, automotive, embedded, and transparent displays, but the technology is a key enabler for the many products that are helping to build the Internet of Things, such as gesture and touch control, fingerprint recognition and wide range of sensor applications.

“The global market for OLED and flexible OLED are set to grow rapidly in the next two to three years and we are very much focused on the industrialization and commercialization of our truFLEX® organic semiconductors to enhance and further strengthen our position in this sector. Patent allowance in key territories within Asia such as China is an important milestone in achieving wide-scale market adoption of our technology platform,” Kelly continued.

www.smartkem.com.

Clariant unveils new tools for stretch-blown PET bottles

Clariant announces availability of new blow-molding tools that can help customers evaluate how Clariant color and additive masterbatches perform in real-world applications. The new single-cavity tool, which is intended for reheat stretch blow molding of clear or colored PET polyester resins, produces a 12-oz (355-ml) round bottle with a long neck and curved sides. The design is intended to reflect current design trends for liquor bottles, but can also be used to evaluate wine, soft-drinks and other food and beverage containers, too.

“This new mold includes the details that customers told us they wanted in prototype tooling,” explains Peter Prusak, head of marketing for Clariant Masterbatches North America. “The tooling we’ve had in the past produced flask-shaped bottles, and the broad, flat panels were not as representative of the shapes that producers of liquor bottles and other beverage containers are looking for today.”

The tooling can be used to evaluate not only color, but also performance-enhancing additives and barrier properties, as well. Prusak says that the way plastic materials stretch to create a bottle’s shape can vary depending on the color and other ingredients in the compound. A resin/masterbatch combination that works well in one shape can develop cosmetic flaws or unacceptable physical properties in another. This is why it is so important to produce shapes that more accurately mimic the actual end-product containers.

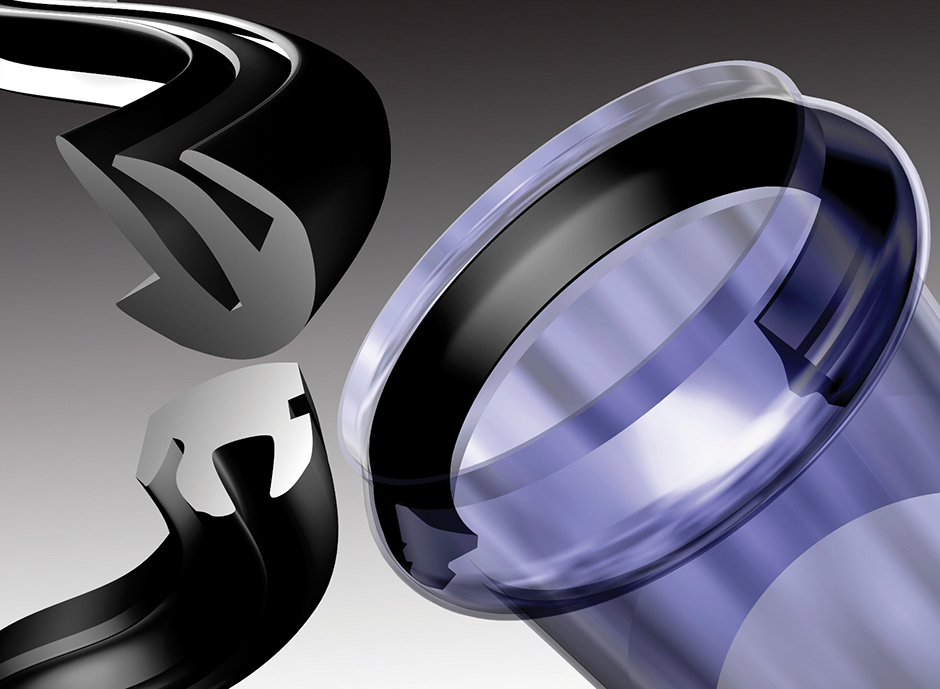

Covestro PC sheet helps new pedicab roll

Frustrated by equipment malfunctions and lack of options, Ben Morris, chief pedicab officer, Coaster Pedicab, set out to create the pedicab he believed the market was missing. Using feedback from its mechanics, professional drivers, passengers and the management team, the company began developing the next-generation pedicab. When they were finished, all that remained of the previous vehicle’s standard design was the three-wheel concept. With the design set, the team began its search for the ideal material to bring it to life. Lightweight and formable Makrolon® SL polycarbonate sheet from Covestro LLC fit the bill. Gauge selection, color and tint definition, fabrication, form, fit and function were all key drivers for this unique application.

“Other possible materials could not satisfy the needs of this demanding application,” said Justin Bruce, chief operating officer of Coaster Pedicab. “Fiberglass was too heavy, and other plastic materials prototyped could not withstand the abuse a pedicab endures. Makrolon® SL polycarbonate sheet, on the other hand, offers lighter weight, greater durability, higher impact strength and a brighter, cleaner look.

Makrolon® SL polycarbonate sheet is used for the pedicab siding and canopy, which provide structure, protection from the elements and a backing surface for applying advertisements. There are currently three models of Coaster Pedicabs on the market – Pro, Luxe and Luxe All Weather – all of which use Covestro’s polycarbonate sheet.

In addition to the material advantages provided by the polycarbonate sheet, Coaster Pedicab also benefited from the support offered by Covestro’s technical experts. “Covestro has a long history of supplying polycarbonate sheet to the transportation industry,” said Celeste Dunn, segment manager for transportation, polycarbonate sheet, for MS Global AG, a Covestro company. “Working with Coaster Pedicab resulted in an outstanding end product that exceeded everyone’s expectations.”

Infrared systems said to save time, money

Heraeus Noblelight plans to showcase at the K 2016 show how its optimally matched infrared systems help to form plastic automotive parts so efficiently that significant savings in time and energy result. In the same vein, global car parts supplier Faurecia has reduced cycle times by 20 seconds in the forming of dashboards by using infrared emitters from Heraeus, while car manufacturer Bentley relies on IR technology to ensure perfect fitting of roof liners in its luxury car bodies.

Faurecia uses carbon infrared emitters to form the dashboard of a car under heat, and coat it with a sound-proofing layer. Previously, the heat had been provided by a combination of metal foil emitters and steam, but this method was proving incapable of meeting the desired increased production speeds and was identified as the limiting factor in the overall production process. The plant was significantly improved by fitting carbon medium wave emitters. Carbon emitters transfer large amounts of energy very quickly, such that the company was able to dispense with the costly steam that had been used for pre-heating. The components to be molded are now heated directly in their molds. As a result, Faurecia was able to increase the heat-up rate by 16% and reduce the heating stage through-put time by about one-third from the previous time of 60 seconds.

Roof liners for Bentley cars consist of three components: a carrier fabric, an adhesive and a decorative leather facing piece. Ideally, this combined structure should maintain its integrity for the life of the vehicle. When Bentley introduced a new adhesive, which allows a fivefold increase in the bond strength of the materials being joined, it then had to look for a suitable heat source, as the new adhesive needed to be heated to an activation temperature of 65°C to maintain the process stage cycle time. The solution to the problem was provided by a custom-built, trim-handling system incorporating infrared emitters. Here, the carrier fabric is first sprayed with adhesive and the leather cladding is precisely fixed in a vacuum press. The infrared system then brings the adhesive up to the required 65°C in less than three minutes.

Songwon stabilizer targets automakers

Songwon recently launched its latest product for the automotive industry. The South Korean firm developed the new Songxtend® 2124 stabilizer specifically to meet the stringent demands of the automotive industry where weight and cost reduction are dominant factors.

Songxtend® 2124 stabilizer improves the long-term thermal stability of the short- and long-glass-fiber-reinforced polypropylene used in interior applications for molded parts, and can match the LTTS performance of 1000 h and beyond at 150°C. The new stabilizer contributes to making it possible for molded parts to be thinner and lighter while still having similar mechanical properties as unfilled parts.

Commenting on the new product, Thomas Schmutz, leader for Global Technical Service & Application Development, said: “Songxtend® 2124 demonstrates our drive to support the automotive industry. With this new addition, Songwon now offers a full range of stabilizers for unfilled, talc- and glass-filled PP. Providing a cost-efficient alternative to the existing products available, Songxtend® 2124 already has enabled one of Songwon’s global customers to reduce costs in its glass-fiber-reinforced PP application while exceeding 1000 h at 150°C, providing long-term thermal stability.”

Arizona Instrument introduces new moisture analyzer

Arizona Instrument LLC announces the Computrac® Vapor Pro® XL (VPXL) – its latest in a long line of accurate, reliable and easy-to-use moisture analyzers. The Vapor Pro® XL is a chemical-free, moisture-specific alternative to Karl Fischer titration. It features an upgraded heater, which increases the upper limit for testing temperatures to 300°C and allows for improved control over testing temperatures. The VPXL is also compatible with multiple sizes of sample vials and is equipped with stepped temperature testing capabilities for enhanced method development. From plastics to petroleum products, pharmaceuticals to chemicals, the VPXL is a good fit for a wide variety of applications.

The Vapor Pro XL is can be used in accordance with ASTM D7191-10: Standard Test Method for Determination of Moisture in Plastics by Relative Humidity Sensor, and ASTM D7546-15: Standard Test Method for Determination of Moisture in New and In-Service Lubricating Oils and Additives by Relative Humidity Sensor.

Conair to highlight vacuum-conveying system at K

The patent-pending R-PRO™ dense-phase vacuum-conveying system developed by Conair to minimize pellet fracturing, “angel hair,” and equipment wear caused by conventional dilute-phase conveying, will make its first appearance at a European trade show when K 2016 begins in October. Other innovations on display will include a new FLX-128 Plus conveying control, which now can be set up to operate the R-PRO system, a new Mobile Drying/Conveying (MDC) system with standard color touchscreen control interface, and several examples of equipment from Conair’s new MedLine® range of clean-room-ready auxiliaries.

The Resin Protection Conveying System (R-PRO™) is a new approach to vacuum conveying. Pellets move at slow speeds in dense slugs of material. This can be compared to conventional, high-speed, dilute-phase conveying, where pellets smear against the sides of aluminum tubing, deforming and creating long streamers or “angel hair” that can clog the system.

Consisting mainly of standard vacuum-conveying components, R-PRO results in slower flow and less resin damage without limiting throughput. It is cost-competitive and can even be retrofitted to existing systems, Conair says.