This is Not Your Father’s Automobile Industry

According to the SXSW ECO panel, cars are getting leaner and greener

Previous Article Next Article

By American Chemistry Council (ACC)

This is Not Your Father’s Automobile Industry

According to the SXSW ECO panel, cars are getting leaner and greener

Previous Article Next Article

By American Chemistry Council (ACC)

This is Not Your Father’s Automobile Industry

According to the SXSW ECO panel, cars are getting leaner and greener

Previous Article Next Article

By American Chemistry Council (ACC)

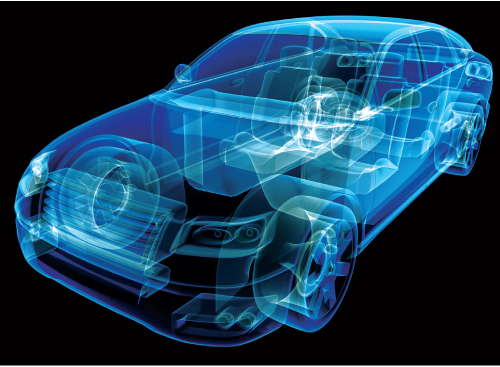

Cars today are about 50% plastics by volume (though only 10% by weight)—and this volume is expected to increase significantly.

The weight of many cars and trucks has actually been increasing with consumer demands for additional safety and interior features.

Note: This article continues a series of updates inPlastics Engineering from Plastics Make it Possible®, an initiative sponsored by America’s Plastics Makers® through the ACC.

Known for its wide-ranging music festival, South by Southwest® (SXSW) also organizes conferences and festivals in Austin, Texas, USA, on film, education, and interactive topics—as well as SXSW ECO, a conference focused on sustainability topics.

At the October 2015 SXSW ECO conference, the Plastics Make it Possiblecampaign helped organize a panel on sustainability and automobiles titled: “It’s a Sprint, Not a Marathon: the Race to 54.5.” As noted in the SXSW ECO program:

Automakers must increase fuel efficiency to 54.5 miles per gallon by 2025, a jump from 35.5 mpg by 2016. To achieve this, they are turning to new lightweight materials. Performance plastics and lightweight composites—such as carbon fiber-reinforced plastics used in Boeing’s Dreamliner—are up to 10 times stronger and 50 percent lighter than steel and 30 percent lighter than aluminum.

Why should car drivers care? Because all this “light weighting” will make for seriously strong and green cars. Cars will accelerate and stop faster, be more agile, be safer—plus become dramatically more fuel-efficient, significantly reducing emissions and lightening their environmental footprint. They also will get cooler and just more damn fun.

To discuss how U.S. autos can get leaner and greener in a decade, as well as the future of cars and mobility, Plastics Make it Possible invited four experts to participate on the panel from varying fields related to vehicles:

- a plastics/advanced materials maker, Scott Fallon, general manager of the Automotive Segment at SABIC;

- a former chief technical officer at Ford, Paul Mascarenas, now head of an international membership organization for automotive engineers;

- a government specialist in vehicle efficiency, Ray Bowman, from Oak Ridge National Labs; and

- the head of a renowned engineering school, Robert McMahon, president of Kettering University.

The message they brought to SXSW ECO: dramatically increased fuel efficiency can save natural resources, slash auto emissions, and save consumers money at the pump.

Some of the highlights and messages from the panel members include:

- Expect to see lots more plastics and composites in tomorrow’s cars. Why? These materials make possible big weight savings to help automakers improve fuel efficiency. They also have high energy absorption characteristics that can help improve strength and safety. Plus they provide more design freedom and allow consolidation of parts, which can reduce expense. Cars today already are 50% plastics by volume (and only

10% by weight)—and this volume is expected to increase significantly. - Also expect to see more plastics and composites in alternative powertrain vehicles such as electric cars. For example, plastics helped reduce the weight of the lithium-ion battery pack in the Nissan Leaf by 20%. Reducing the mass of an electric vehicle by 20% allows it to travel 20% further.

- Plastics are replacing glass in some windows. The Fiat 500L sports a plastic rear quarter window that is 35% lighter than its glass counterpart. In the Visio.M electric concept car under development in Germany, the all-plastic windows save 28 pounds (13 kg). And plastic’s superior thermal insulation reduces demand on the car’s HVAC system, extending the driving range by nearly 10 miles.

- But the all-plastic car is unlikely. Mixed material solutions are more likely, as plastics, aluminum, and steel combinations can deliver the safety and design features automakers need—and car owners demand. While plastics are displacing traditional materials in many vehicle components—even the engine—mixed-material cars are here to stay for the foreseeable future.

- The trend toward heavier cars must be reversed. Even though automakers have been increasing the use of lightweight plastics in their vehicles, the weight of many cars and trucks actually has been increasing with consumer demands for additional safety and interior features (like built-in TVs). Automakers are now reversing the trend, trying to balance customer expectations, regulatory standards, and affordability. This will require design efficiency, rightsizing, and material substitution—all leading to the use of more lightweight, strong materials, such as plastics reinforced with carbon fiber (typically referred to in the media as just “carbon fiber,” forgetting the essential plastics). Automakers have begun replacing heavier traditional materials with carbon fiber-reinforced plastics in the passenger cells, body panels, engine hoods—even wheels.

- While cars aren’t cheap, in some ways, they’re a bargain. According to government figures, the average cost per pound of today’s automobile—a modern engineering marvel with propulsion, safety, environmental, comfort, and entertainment systems—is about the same as round steak: $6. To keep cars affordable while increasing the use of pricier composites such as carbon fiber-reinforced plastics, material costs must come down, high-volume production processes must mature, material waste must decrease, and a skilled workforce must be trained. To meet these demands, automakers have invested heavily in carbon fiber-reinforced plastics technologies, and public-private partnerships are working to reduce the costs of composites and increase recycling opportunities.

- There is great demand for highly trained employees in the auto industry. For example, the demand for engineers in the auto industry (and elsewhere) is insatiable. According to its president, Kettering University’s placement rate for engineering graduates “vacillates widely” between 99 and 100%, with most graduates receiving three or more job offers.

- The modern car is a technological marvel. Autos are expected to advance even further as technologies allow them to communicate not only with the driver but with the automaker and other third parties that can monitor, measure, and improve the driver experience. That’s one reason the automobile industry is attracting the attention of tech giants. This definitely is not your father’s automobile industry.

While nobody knows exactly what cars will be like in 50 years, or even ten, the panel members speculated that the advent and acceptance of autonomous vehicles will usher in a new style of mobility, focused more on personal productivity and entertainment than physical driving. Perhaps. Or perhaps as cars get leaner and greener, car owners will want to experience that improved driving experience for themselves and not hand it over to a third party.

Regardless, the panel members made it clear that advanced materials such as plastics and composites will certainly be key to the future of automotive mobility.

Explore more about automotive plastics and sustainability at plasticsmakeitpossible.com.