Photo courtesy of Dow Chemical Company

Photo courtesy of Datacolor

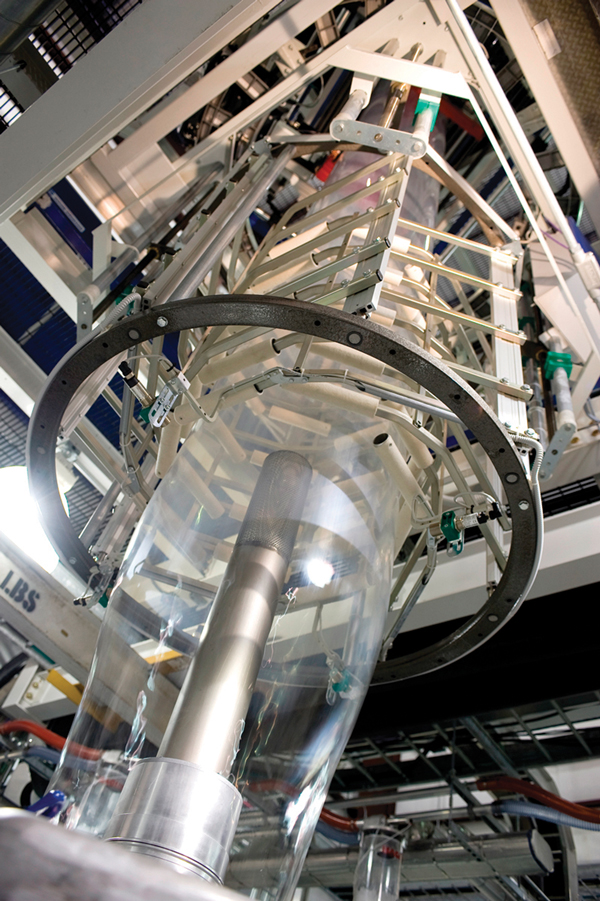

Photo courtesy of Guill Tool

Photo courtesy of Polymax Thermoplastic Elastomers

Photo courtesy of Rapid Granulator

Photo courtesy of Omegasonics

The Dow Chemical Company’s Packaging and Specialty Plastics business has announced the launch of Innate™

Precision Packaging Resins, a new family of resins that the company says offers “unprecedented performance levels to help customers address some of today’s most challenging packaging performance gaps.” Created from a patented molecular catalyst and advanced process technology, the resins offer a better stiffness-toughness balance, processing ease, and improved sustainability profiles.

“Innate resins were developed as a result of many discussions with converters and brand owners and careful analysis of the market trends,” says Diego Donoso, business president for Dow Packaging and Specialty Plastics.

The resins are designed to help define new market spaces and create new categories for everything from flexible food packaging to heavy-duty industrial shipping sacks. The company says they offer:

- excellent sustainability profiles due to their lightweighting potential;

- opportunities for new packaging efficiencies through material substitution;

- up to twice the abuse resistance in co-extruded films, compared to tested standard polyethylene resins on the market;

- film toughness without compromising stiffness and other key properties; and

- processing ease, with excellent bubble stability.

Datacolor, a global leader in color management solutions and color communication technology, has introduced its Datacolor® 800 and 500 series of spectrophotometers. The family of fully backward-compatible benchtops, complete with a new embedded processor and data storage, provides a platform for increased efficiency and color measurement confidence.

The Datacolor 800 family is the next generation of the “market’s only true close-tolerance spectrophotometer that ensures color can be communicated digitally,” the company says. Featuring a digital camera, the series is fully backward-compatible with the existing fleet of Datacolor 600spectrophotometers. Meanwhile, the Datacolor 500 family offers an economical option for a high-performance spectrophotometer with enhanced speed and advanced technology, while ensuring compatibility with the existing fleet of Datacolor 400instruments.

Both the 800 and 500 families feature a new color LCD screen that displays calibration status and instrument settings to allow for greater confidence in measurement results. Instrument accessibility has also been expanded with the introduction of an Ethernet port, allowing for the simultaneous connection of multiple computers.

Invista has launched its new Torzen® High Viscosity PA66 resins, as the company continues to develop a portfolio of engineered nylon resins aimed at solving today’s marketplace needs. The high-viscosity resins combine wear resistance with durability, and have good retention of molecular weight during processing—a distinct advantage for demanding processing methods.

“Through customer insights, we recognized a gap in the marketplace for a resin that brought toughness and wear resistance for a number of specialty applications, which are commonly known to be challenging during processing,” says Matt Osborne, Invista global business manager. “Our team was able to create multiple grades of different viscosities to help solve that challenge. Now injection molders, extruders, film producers, and compounders have a new option for these highly versatile products.”

Invista will target specialty applications such as monofilaments (brushes, fishing line), cast and high-strength multilayer films, stock shapes and rods, gears, chain tensioners, and rail isolators. The resins are also available as a compounding feedstock, the company adds.

Guill Tool has introduced Series 824, a co-extrusion crosshead designed for irrigation tubing with an emitter tool. Manufactured from stainless steel, this new crosshead features a balanced flow design with spiral technology that improves flow characteristics at all extruder speeds. Dual feed ports provide concentric compound flow, “while the splits flow from one extruder to feed the inside and outside layers via a manifold assembly.” Series 824 is adaptable to all popular extruders on the market currently, the company adds.

As Guill’s Bill Conley explains, “On this project, the customer challenged us with an application that required precise placement and bonding of preformed emitters within the extruded tubing without melting them in the crosshead. It was also necessary to process either a low-cost ‘ABA’ layer construction or single-layer construction within the same unit.”

With the Series 824, the customer realized cost reductions, better quality, less scrap, and more uptime in their process. The Guill “cool-tube” design prevented the emitter from melting in the head, and the overall unit mechanics allowed more rapid and easier changeover from a co-extrusion to a single layer, the company reports.

Polymax Thermoplastic Elastomers announced it has gained USP Class VI approval for a new TPE material designed for use in medical and biopharmaceutical applications. MT-1205I was developed to address the increasing demand for medical TPE tubing applications. This transparent elastomer is a high-purity compound with low leachables and extractables, required for ensuring patient safety.

MT-series materials have been approved for medical use due to their tactile feel, high level of transparency, kink resistance, and ability to withstand various sterilization methods like gamma ray, ethylene oxide, and steam. Medical-grade materials from Polymax are elastic, flexible TPE compounds available in a hardness range from 70 to 92 Shore ‘A’. They’ve passed cytotoxicity tests according to ISO 10993-5 and GB 14233 for medical use by the China Food and Drug Administration, the company adds.

“The addition of USP Class VI approval to our material certifications allows us to offer alternative solutions to the U.S. medical market for a variety of tubing and non-tubing applications,” states Tom Castile, Polymax vice president. “The unique properties of our newest material formulation provide a clear choice for medical device manufacturers who are looking for alternatives to PVC, natural rubber latex, and silicone.”

In September, the organization called Ocean Conservancy announced the global launch of Stemming the Tide: Land-based strategies for a plastic-free ocean, a “solutions-oriented report” created in partnership with the McKinsey Center for Business and Environment. The report outlines specific land-based solutions for plastic waste in the ocean, starting with the elimination of plastic waste leakage in five priority countries (China, Indonesia, Philippines, Vietnam and Thailand).

The report, “for the first time, outlines a specific path forward for the reduction, and ultimate elimination, of plastic waste in the oceans,” said Andreas Merkl, CEO of Ocean Conservancy. “The report’s findings confirm what many have long thought—that ocean plastic solutions actually begin on land.”

Eight million metric tons of plastic leak into the world’s ocean every year, and the amounts continue to grow. Without concerted global action, the report says there could be one ton of plastic for every three tons of fish by 2025, leading to massive environmental, economic, and health issues. With at least 80% of ocean plastic originating from land-based sources, the report’s findings propose a four-point solution for cutting leakage by 45% in the next ten years, dramatically reducing ocean plastic waste by 2025, with the ultimate goal of eradicating the issue by 2035.

“We’re committed to working toward a future of a plastic-free ocean,” said Jeff Wooster, global sustainability director of Dow Packaging and Specialty Plastics, a partner on the report. “Companies don’t make plastic with the intent of it ending up in the ocean, and we acknowledge the strong role industry must play in order to help eliminate ocean plastic waste by 2035.”

The report emphasizes the need for all approaches and solutions to be tailored at the regional level, specifically in the five priority countries identified, which account for half of all plastic leakage globally. While countries have made major improvements in curbing plastic leakage, greater global support is needed in these priority regions.

The report says the next ten years will be critical to effectively solve the problem of ocean plastic. To achieve success, it calls for a concerted global response driven by an international coalition of companies, governments and NGOs that will “catalyze commitments from political leadership, provide local ‘proofs of concept,’ provide waste management technology support, and prioritize the ocean plastic waste issue as part of the global policy agenda on the ocean and the environment.”

Size-reduction equipment specialist Rapid Granulator has launched the LBB 300 series, a granulator with a very low height for handling sheet and film scrap. The LBB (“low built base”) series is intended principally for use inline with a thermoforming unit, where its low height allows it to be located directly under the output conveyor, saving floor space.

The height of the LBB 300 series is just 600 mm (excluding the feeder) and it’s available in three widths: 900, 1200, and 1500 mm. The unit can be equipped with a roll-feed unit synchronized to the thermoforming line speed, or with a simple tray that collects skeletal frames as they fall from the line.

The modular granulator can also be configured to fit directly under a shredder to provide final size reduction, without the need for the conveyor belt used in common practice for connecting the two units. Rapid offers the LBB granulator in versions with various types of rotors and hoppers, depending on the application.

The compact design of the LBB 300 series means that it takes up very little extra space on the production floor. It’s designed to handle film and sheet up to 8-mm thick, depending on the material.

The series uses a “true scissors cutting action” to provide clean and precise cutting of sheet and film and high-quality regrind. Maximum throughput capacities range from 800 to 1200 kg/hr, and the output can be transported via a vacuum conveyor straight back into the production line for reprocessing.

On October 1st, Paulson Training Programs hosted a successful open house celebrating its new 9,000 ft2 (840 m2) training facility in Clearwater, Florida, USA. Multiple companies, industry associates, and individuals attended the four-hour event. Visitors met with expert instructors, toured classrooms, inspected injection molding machines, networked with colleagues, and reviewed simulation programs in the computer lab.

“In the three decades Paulson has been in business, the delivery of our training products has evolved from traditional classroom and textbooks to video tapes, to CDs, and now via internet-based training,” said Don Paulson, plastics pioneer and chairman/co-founder of Paulson Training Programs. “Having a dedicated training facility that combines classroom instruction with actual machines and a computer lab with our sophisticated and powerful simulation program allows us to offer a total solution to our customers.”

“Training and education is a core part of what SPE offers and is critical in closing the skills gap in today’s workforce challenges,” added Russell Broome, managing director of SPE. “Paulson’s new facility bolsters those efforts in spades and we’re happy to be here supporting their new initiative.”

Called the Paulson Plastics Academy Technical Center, the new facility will hold small class sizes of 16, with up to six computer stations in the computer lab that will offer the company’s complete library of online courses, as well as its injection molding simulation technology.

Consumer trends are impacting packaging markets around the world, according to “Global Packaging Trends,” a new report from PMMI, The Association for Packaging and Processing Technologies. The report shows three influencers making a mark in every region: growing awareness of health and wellness, recycling and environmental issues, and increasing disposable income and purchasing power.

“These trends are affecting packaging because they’re driving consumers’ purchasing choices,” says Jorge Izquierdo, PMMI vice president, market development. “Recyclability and reusability of packaging are dominant trends, and we’re predicting that will continue to be seen as PET and glass bottle usage increases.”

Packaging markets in the Middle East and Africa are anticipating 5.3% CAGR growth in volume, though forecasts for Western Europe and North America land at the other end of the spectrum, at 0.4% and 0.5%, respectively. The expansion in the Middle East and Africa “is the result of increasing exposure to modern lifestyles,” PMMI notes.

In the Asia-Pacific region, a forecast of 4.3% CAGR volume growth reflects increasing demand for PET bottles, particularly in the bottled water category, supporting health and wellness concerns.

Globally, the report notes that flexible plastic remains the dominant pack type, accounting for 29% of the market, while PET bottles (12% of the market) will be among the fastest growing segments, with 4.7% CAGR. Bottled water is expected to add 135 billion units through 2019, accounting for 54% of the absolute volume growth in PET bottle use.

Over the past 25 years, Herrmann Ultrasonics has grown from a small startup into an industry leader with a global presence in ultrasonic engineering. With this quarter-century of technical knowledge under its belt, the company opened its doors to potential customers and current customers for its first “Technology Day” on September 10th.

Over 150 customers were in attendance from around the world (some from as far away as Argentina) at its facility in Bartlett, Illinois, USA. The company’s abilities were on full display in seven informative workshops led by a team of Herrmann Ultrasonics and Herrmann Ultraschall specialists. Three additional workshops were held by guest speakers from Proto Labs, The Dow Chemical Company, and Clemson University.

“A proper understanding of ultrasonic technology by the customer allows us the ability to freely discuss the customers’ needs on a stronger platform and continuously provide efficient solutions,” said Thomas Herrmann, global CEO of the Herrmann group of companies. “Technology Day gives us the opportunity to not only educate but have an exchange of ideas.”

Customers in the plastic industry were encouraged to “get hands-on” with the company’s HiQ machine workshops. They were given parameters to obtain perfect weld results and were exposed to the benefits of infrared and high-speed cameras. These illustrate ultrasonic energy conversion into thermal energy, while micrographic analysis shows residual melt-layer thickness and melt flow in the weld-testing process.

Herrmann executive vice president and general manager, Uwe Peregi, added: “The day [was] a total success. Many new projects will be born from the proper understanding of what can be achieved with the use of ultrasonic engineering.”

Omegasonics announced that two of its cleaning units for the 3-D printing market now have CE Marking Certification, making them eligible for sale in the European Union.

The CE Marking signifies that Omegasonics’ SST4030

and 1900BT cleaning units comply with the essential requirements of relevant European health, safety, and environmental protection legislation. The systems enable 3-D printing companies to significantly reduce the time, labor, and costs associated with cleaning 3-D product

prototypes.

Compared to using a heated circulating bath washer or manual cutting to remove support material, which can take up to 24 hours, the SST4030 or 1900BT ultrasonic systems can reduce cleaning time by as much as 87%. In addition, because the machines are easily operated by one person, companies can experience as much as a 10:1 reduction in labor when they switch from manual cleaning.

The 20-gallon (76-liter) 1900 BT and the 187-gallon (708-liter) SST4030 units utilize precision ultrasonic technology to accurately and methodically remove support material—including ABS, polycarbonate, nylon 12, and Ultem™ resin—from 3-D printed prototype parts, regardless of the geometry or complexity, without damaging the part. They’re designed with all solid-state components and plug-and-play construction, and require no regular maintenance, the company adds.

“Due to 3-D printing’s rapid expansion into a variety of industries, the market for 3-D printing ultrasonic cleaning systems is growing considerably,” says Frank Pedeflous, president of Omegasonics. “More companies are recognizing the time and cost benefits of ultrasonic cleaning technology and the rapid return-on-investment it affords.”

In September, Emery Oleochemicals, a global producer of natural-based chemicals and the largest oleochemicals manufacturer in North America, celebrated its 175th anniversary in conjunction with the commercialization of its $50 million Bio-based and Recycled Content Polyols Plant.

The plant is described as the world’s first industrial-scale facility capable of utilizing scrap foam as feedstock to manufacture a new range of sustainable polyols. Additionally, by leveraging Emery Oleochemicals’ proprietary feedstock technology, the company is well-positioned to also provide performance bio-based polyols.

Combined, the bio-based and recycled-content polyols create a large portfolio of products suited for high-growth industries, such as automotive, furniture, major appliances, construction and coatings, adhesives, and sealants and elastomers. The sustainable products can address energy efficiency in buildings and reduce the amount of scrap foam dumped into landfills, the company explains.

A. Schulman, Inc., leading international supplier of high-performance plastic compounds, powders, and resins, announced that it was awarded the 2015 Bosch Global Supplier Award from Robert Bosch GmbH, an industry-leading engineering and electronics company headquartered in Germany.

Bosch recognized 58 suppliers from eleven countries in five categories including innovation, purchasing of indirect materials, raw materials and components, electronics and electromechanics, and mechanics. This is the 14th time that Bosch has given out global supplier awards, and it’s the 11th time A. Schulman has been awarded this honor from Bosch. The theme of this year’s award ceremony was “Power of Partnership—Connected Intelligence.”

A. Schulman supplies plastic resin to Bosch for use in a wide variety of industrial, automotive, and consumer goods applications, including connectors, housings, covers, sensors, fans, shrouds, and boxes.