New Study Helps Improve Peelable Seal in Film Packaging

Methodologies and testing scenarios led to an enhanced-barrier, lower-cost, downgauged film

Previous Article Next Article

By Dan Falla

Nova Chemicals, Sarnia, Ontario, Canada

New Study Helps Improve Peelable Seal in Film Packaging

Methodologies and testing scenarios led to an enhanced-barrier, lower-cost, downgauged film

Previous Article Next Article

By Dan Falla

Nova Chemicals, Sarnia, Ontario, Canada

New Study Helps Improve Peelable Seal in Film Packaging

Methodologies and testing scenarios led to an enhanced-barrier, lower-cost, downgauged film

Previous Article Next Article

By Dan Falla

Nova Chemicals, Sarnia, Ontario, Canada

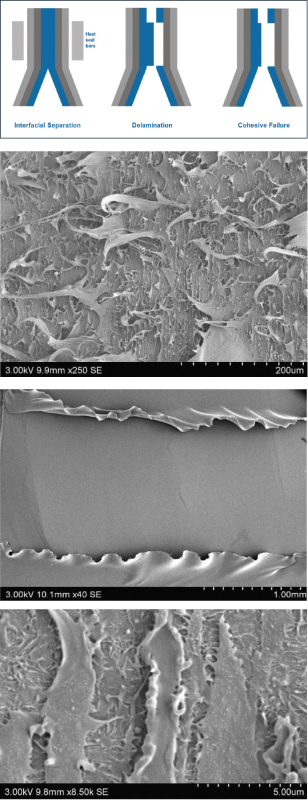

Figure 1: Peelable seal failure modes,2 with photos (from top) illustrating interfacial separation, delamination, and cohesive failure surfaces, respectively.

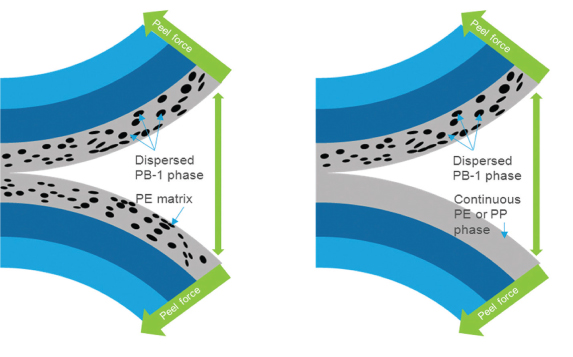

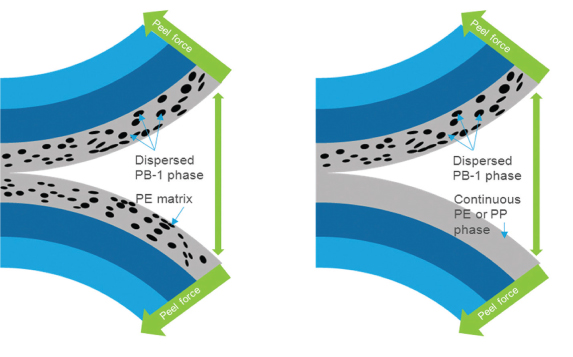

Figure 2: PB-1 peel mechanism: cohesive failure.

Figure 2: PB-1 peel mechanism: cohesive failure.

Table 1: Resins Used

Table 1: Resins Used

Many pouches or bags for dry goods, like cereal and crackers, are difficult to peel apart without tearing and damaging the bag. Consumer Reports magazine rated cereal bags as one of the five worst consumer packages, due to problems with opening.1

Most of these packages are three-layer coextruded blown films that are comprised of a peelable seal layer and a high-density polyethylene (HDPE) core layer. The thickness of the HDPE typically determines the moisture vapor transmission rate (MVTR) of the film. A low MVTR is important in order to maximize the shelf life of the product. Prompted by a need to better understand easy-open, peelable seal technology, a number of different seal formulations were evaluated, along with the MVTR properties of a high moisture barrier HDPE (sHDPE) compared to a conventional HDPE.

While previous studies have limited the qualitative measurement of peelability to the laboratory cold seal strength test, this study used a variety of methodologies and testing scenarios to simulate performance under real-world conditions, from the filling of material into a pouch to general packaging integrity. The results delivered an enhanced, lower-cost, downgauged film structure.

Fundamentals

Based on previous studies, there are three generally accepted peelable seal failure modes (Figure 1).2

- Interfacial separation:The separation occurs at the seal interface. The seal strength is dependent on the sealing temperature

- Delamination:The seal separates at an internal interface (between internal layers or between the inside layers). Sealing temperature is one of the significant variables in determining seal strengths; however, the thickness of the internal layer and adhesion between the internal layers also play major roles.

- Cohesive Failure:The structure separates within the seal layer. The peel seal material’s inherent strength determines the strength of the seal. The cohesive seal results in a smooth, clean peel surface and offers “whitening” of the seal with added built-in tamper evidence.3,4

Formulations Studied

Three types of polymeric resin systems were used in this study:

Polybutene-1 (PB-1) is a semi-crystalline, highly isotactic thermoplastic made from the polymerization of 1-butene using a Ziegler-Natta-type catalyst. It works by being incompatible with polyethylene. In the seal layer, it creates a layer with PB-1 islands in the PE matrix and results in cohesive failure of the seal (Figure 2).PB-1 is typically blended with 55% LDPE and 30% low seal-initiation LLDPE. PB-1 has more incompatibility with the LDPE than the LLDPE, hence the LLDPE should be chosen based on economics and the seal initiation temperature desired. Slip and antiblock agents may also be required.

Ethylene propylene peel polymer (EP) is a fully formulated copolymer that is commercially available. Seal failure may occur in a few ways: At lower temperatures, interfacial separation occurs at the seal/seal interface. At higher temperatures, the two seal layers “lock up,” and failure occurs when the seal delaminates from the core layers. The strength of the bond at the HDPE/seal interface is significantly high enough that care must be taken on the packaging line to use enough heat to “just seal” the package.

Ionomers are partially crosslinked ionomeric resins, and perform in peelable seal applications through delamination of the seal/seal interface.4 Much like the EP peel polymer, care must be taken to not seal at too high of a temperature, as seal lock-up is expected to occur, resulting in cohesive failure.

Table 1 shows the resins used to make the twelve film structures that were tested. (The films were fabricated using the three-layer Brampton Coex line at the Nova Chemicals Centre for Performance Applications.)

Experimental Methods

The films were subjected to the following physical tests at Nova Chemicals’ Centre for Performance Applications to determine their various properties:

- MVTR, using a Mocon test unit and 100% RH;

- dart impact, using ASTM D1709, Method A;

- film tear, using ASTM D1922;

- puncture, using a Nova Chemicals method;

- 1% and 2% secant modulus, using ASTM D882;

- tensile testing, using ASTM D882;

- hot tack strength, using the J&B Hot Tack test method—this simulates the filling of material into a pouch or bag by measuring the force required to separate a heat seal before the seal has had a chance to fully cool;

- heat seal strength, using a tensile tester model—this measures the force required to separate a seal after the material has cooled to 23°C (in this study, the sealed samples were allowed to age for two weeks prior to testing); and

- vertical form fill and seal (VFFS)—where the pouches were filled with 500 g of HDPE pellets to simulate the packaging of the product in commercial applications. (Pallet filled pouches were submitted to a leak detector test and drop test, while other pouches were emptied and aged for two weeks before being submitted to an end seal-strength test using a tensile tester. Air-filled pouches were also tested to determine the load the end seal failed at.)

Prior to the start of the project, samples of a commercial cereal liner were purchased at a local grocery store and tested to determine typical film properties. The analysis indicates that the film was a three layer co-extrusion with an EP peel polymer in the seal layer and two HDPE layers. Physical properties of the film have been added to analysis of this study. No VFFS work was done with the commercial film due to the small sample size. The heat seal curve of the film shows the classic curve expected for EP peel polymers.

Results

- The use of sHDPE was found to dramatically lower the MVTR of the films, versus a conventional HDPE. As expected, thicker films were also found to have lower MVTR. The films with sHDPE in the core had slightly lower dart impact properties than films made with HDPE.

- High film stiffness is a desirable attribute for faster packaging speeds. Films made with sHDPE in the core had higher 1% and 2% secant modulus. The results were almost 20% higher than those for the commercial film. Higher stiffness could allow the film to be downgauged while still maintaining stiffness relative to the competitive film. It may also allow the packaging line to run at a faster rate.

- Films made with the ionomer in the seal layer had the best overall physical properties, including impact resistance, and the highest machine-direction tear resistance—a desirable attribute once the bag is opened. The ionomer was also found to have the broadest peel-seal window along with the lowest peel force.

- Seal layer thickness did not appear to have a significant impact on the properties of the films tested.

- The amount of LDPE blended with the PB-1 was found to affect the end seal strength of the films. Higher amounts of LDPE resulted in lower seal strengths.

Conclusions

Overall, films made with either the ionomer or EP peel polymer in the seal layer and a barrier HDPE would produce an effective, peelable seal film with enhanced barrier properties. Also, the higher film stiffness with a barrier sHDPE would allow downgauging of the film.

References

1. “Oyster Awards.” Consumer Reports. March 2006.

2. Gibbons, J. “New Peelable Seal Technology for Easy-Open Packaging.” TAPPI PLACE Conference, Cincinnati, Ohio, 2006.

3. Doordan, M.M. (LyondellBasell). PB-1 Seal Peel Review. Equistar Chemicals, LP, 2012.

4. Hahm, D. “Easing Your Way to Reliable Peelable Seals” (whitepaper). DuPont Packaging & Industrial Polymers, 2011.

About the author… Dan Falla is a technical services specialist in Nova Chemicals’ food packaging group. Prior to joining the company in 2011, he worked for 27 years at Dow Chemical in food packaging and new business development, where his focus was on product innovation and support. Falla is also on the board of directors of SPE’s Flexible Packaging Division, where he serves as membership secretary and councilor. He holds more than 20 patents and has written more than 16 peer-reviewed articles.

Note: This article was based on a full-length study the author presented at ANTEC® Orlando 2015, “Peelable Seal Films with Enhanced Moisture Barrier Properties for Flexible Packaging Applications,” which is available from SPE customer service via U.S. 203-775-0471.