Too Valuable to Waste: Rethinking Plastics

Realizing the full value of plastics with “the 4 R’s”

Previous Article Next Article

By Steve Russell, Vice President Plastics Division, American Chemistry Council (ACC) Washington, D.C., USA

Too Valuable to Waste: Rethinking Plastics

Realizing the full value of plastics with “the 4 R’s”

Previous Article Next Article

By Steve Russell, Vice President Plastics Division, American Chemistry Council (ACC) Washington, D.C., USA

Too Valuable to Waste: Rethinking Plastics

Realizing the full value of plastics with “the 4 R’s”

Previous Article Next Article

By Steve Russell, Vice President Plastics Division, American Chemistry Council (ACC) Washington, D.C., USA

Steve Russell, ACC

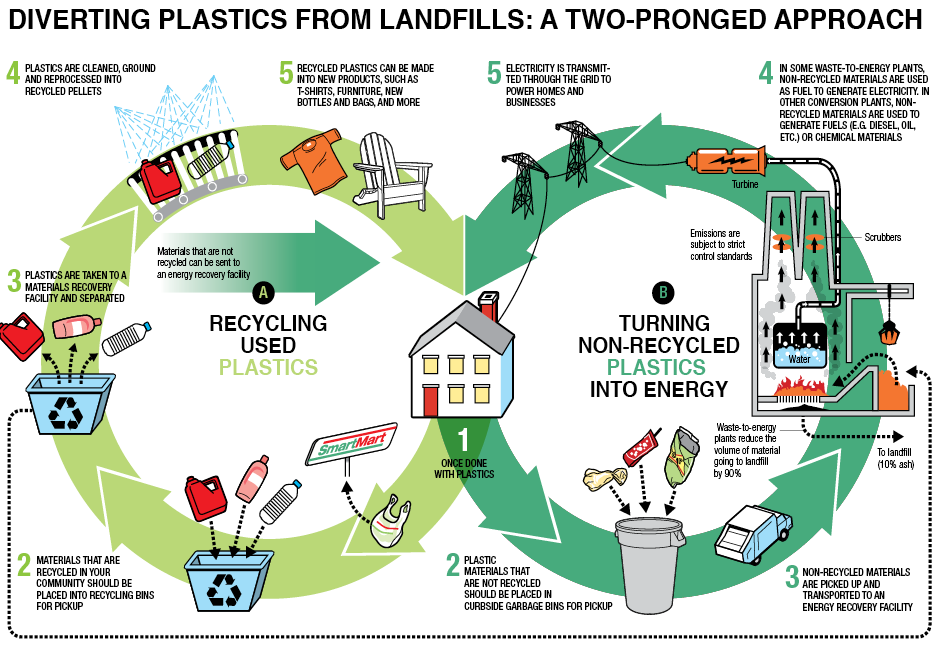

Diagram courtesy of ACC.

An event called Plasticity Forum gathers leaders who can learn and collaborate on sustainability issues surrounding plastics. During the most recent Plasticity event in New York, I had the opportunity to share ACC’s views on the roles plastics play in the global drive toward sustainability. Here’s a synopsis of that presentation.

In a relatively short period of time, plastics have become the “go to” material in many applications, for readily apparent reasons: they’re durable, adaptable, easy to produce, and in many cases more cost effective. That’s why today our shampoo bottles don’t shatter in the shower, our cars and trucks are made with lightweight materials to burn less fuel, our new homes are well insulated to save energy, and we can ship more goods with less packaging than ever before.

Plus, we’re in a time of incredible innovation. Our industry’s experts are working with their customers to:

- transform medicine with nano-scale devices and lifelike prostheses;

- deliver “smart packaging” that keeps food fresh longer and warns us when it’s spoiling;

- create lightweight polymer composites for aircrafts and cars; and

- even spice up world championship soccer games with a NASA-tested ball made from specialty plastics.

And while most plastics are made fromenergy sources, lifecycle data and analyses show that in most applications plastics actually save energy, when compared to available alternatives. A world without plastics would not just be less pleasant but also more wasteful.

But nobody wants a world where plastics fill up landfills or become litter. As a society, we need comprehensive, integrated approaches to manage our waste that allow us to benefit from incredible innovations in plastics without trashing our planet in the process.

That’s why ACC and plastics makers are focused on “the 4 R’s”: reduce, reuse, recycle, and recover.

The First R: Reduce

Plastics are all about source reduction, since they allow us to do more with less.

Let’s look at packaging. Recent life-cycle studies in Europe and the USA have shown that replacing plastic packaging with alternatives would:

- require four and a half times as much material by weight and increase the amount of packaging used by nearly one 110 billion pounds (50 billion kg);

- increase overall waste generation by 22%, equal to the weight of 169,000 Boeing 747 jumbo jets;

- increase energy use by 80%, equivalent to the energy from nearly 91 oil supertankers; plus

- result in 130% more global warming potential, similar to adding 15.7 million more cars to our roads.

These are really striking findings. Because of favorable strength-to-weight ratios, we can package more goods in plastics using less material. And consumer product companies are continually striving to make bottles and packaging lighter and thinner and finding innovative ways to reduce the amount of packaging for shipping and selling food and other goods.

This is not happening only in packaging. Automakers are increasingly turning to lightweight, tough plastics to help them reduce the weight of cars to improve fuel efficiency and meet CAFE standards. And the next big move will be to replace even more traditional materials with plastics reinforced with carbon fiber, as in the Boeing Dreamliner.

And in our homes and buildings, plastic building materials such as foam insulation are helping us save tremendous amounts of energy by providing superior insulation properties and by sealing the building “envelope.” Through a combination of options, including passive energy (such as solar) and modern plastic insulation, the next goal is “net zero” and “net positive” energy homes—homes where on-site energy production equals or exceeds on-site energy consumption. That is going to be a game-changer for energy use and greenhouse gas emission reductions.

The Second R: Reuse

Reuse is largely driven by how consumers use plastics, but companies are increasingly making plastics designed to be reused. Many brand owners are moving toward refillable products and concentrates that allow consumers to buy more product with less package, and consumers today have more opportunities to choose reusable packaging such as grocery bags, food containers, and beverage bottles.

The Third R: Recycle

Plastics are relatively new materials, and plastic recycling is even newer. So while we’re playing catch up, we’re catching up quickly, and there has been steady, year-over-year growth. Some examples:

- Nearly all Americans today can recycle plastic bottles.

- There are more than 18,000 places across the USA to recycle plastic bags and wraps.

- Nearly 31% of plastic bottles are recycled, not far behind glass containers at 34%.

- And more than one billion pounds of non-bottle plastic containers were recycled in 2013, which is triple the amount since just 2007.

To help increase these numbers, ACC works with coalitions of government, non-governmental organizations, brand companies, large retailers, and the recycling community to help consumers better understand how and what to recycle.

But the truth is we may never get to 100% recycling for plastics or any material. What do we do with those plastics that are not recycled? One of the truly counterproductive things our country has been doing for way too many years is treating used materials as garbage and burying them in landfills, which is a huge waste of valuable resources. This brings us to…

The Fourth R: Recover

The molecules that make up plastic products are a powerful source of energy. Non-recycled plastics can supply more than 15,000 BTU/pound (35,000 kJ/kg) in a facility that converts waste to energy. That’s more energy per pound than coal. Scientists at Columbia University found that converting all non-recycled plastics to energy could power 5.7 million homes.

Diverting all non-recycled municipal solid waste from landfills to waste-to-energy facilities could produce enough electricity to power nearly 14 million homes. That’s 12% of American households, powered solely from garbage. So as a nation we have a domestic source of energy that could power nearly 14 million homes every year. And we’re burying it.

While some U.S. communities are recovering energy from waste, other countries are far ahead of the USA. For example, there are more than four times as many waste-to-energy facilities in Europe than in the USA. And through aggressive recycling and recovery, Germany landfills only 1% of its waste.

But traditional waste-to-energy technology is only one way to recover the energy inherent in plastics. There also are promising new technologies that can turn plastics into fuels and other valuable materials, which can provide a source of readily available domestic energy. ACC is working with related industries across the country to jumpstart three emerging technologies:

- Plastics-to-oil technologies use pyrolysis to convert non-recycled plastics into oil that can be refined and used as fuel for cars and other vehicles. These technologies hold enormous promise: if all the non-recycled plastics in the USA were converted this way, we could create enough oil to fuel nine million cars for an entire year.

- Plastics also can be converted into a gas fuel that can be used to produce electricity or turned into liquid fuels and even raw materials such as chemicals for manufacturing. These technologies—called gasification—have not yet been fully commer- cialized the USA but are under development.

- Other technologies turns non-recycled plastics into engineered solid fuels that someday could be used just like coal at facilities that make steel and cement.

So the technology either exists or is in the works to recover the energy potential of non-recycled plastics from America’s waste stream.

Summing Up

Can we stop treating used plastics and other materials as waste and tap into their energy potential—instead of burying them in landfills? It will require changing how we as a nation think about and treat “waste,” as well as changing public policy so that energy recovery can play an integral role in our nation’s energy portfolio.

Plastics are inextricably tied to the global drive toward sustainability. As uses and applications of plastics expand, they enable energy savings and reductions in waste in our food packaging, our automobiles, our homes and buildings, and more. And once they reach their “end of life,” they become a large, untapped source of energy. It’s time to recognize and celebrate that.

Note: This article continues the series of updates in Plastics Engineering from Plastics Make it Possible®, an initiative sponsored by America’s Plastics Makers™ through ACC. For more information about statistics in this article and innovations in plastics, visit www.plasticsmakeitpossible.com or contact info@plasticsmakeitpossible.com.