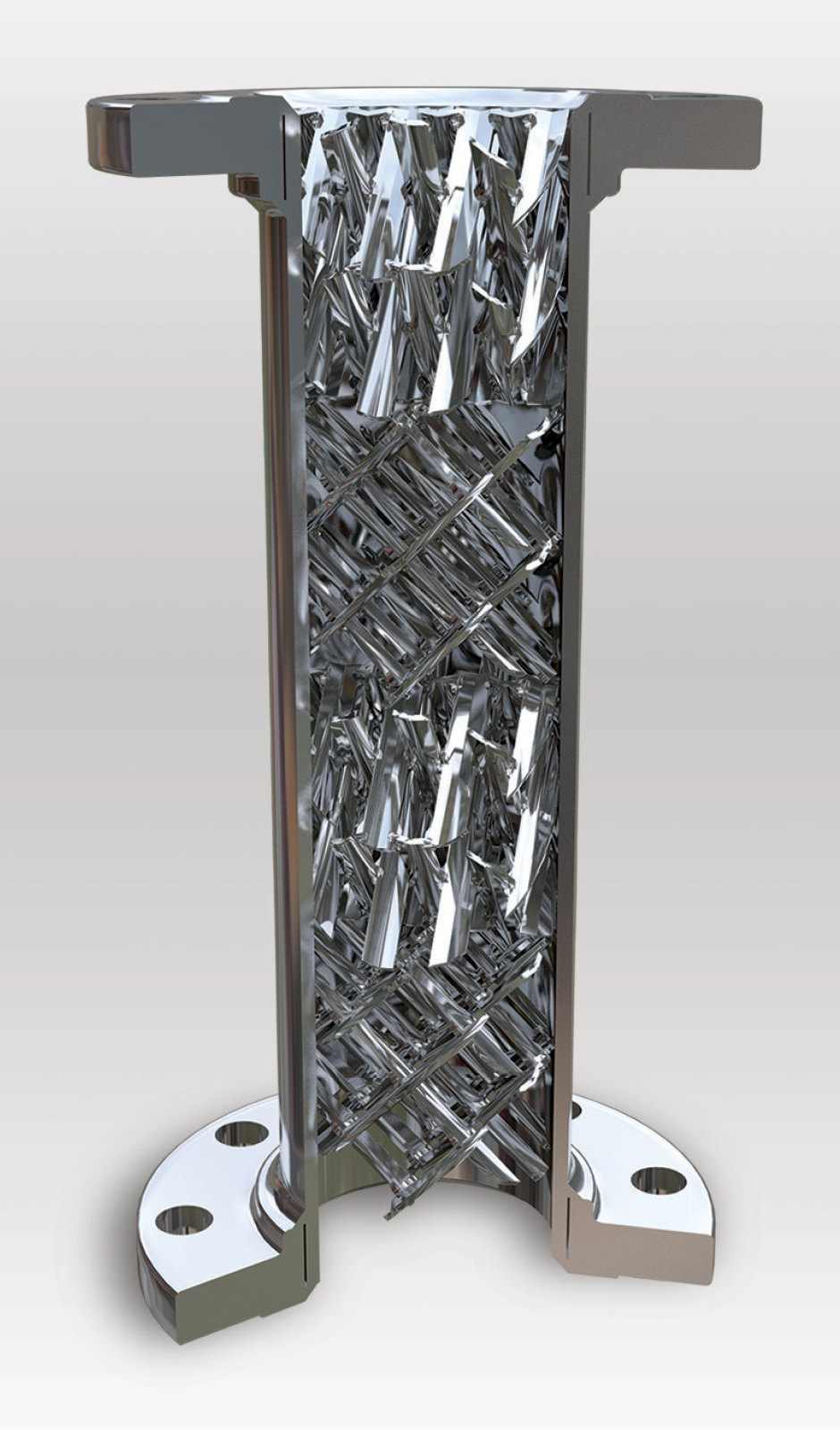

Photo courtesy of Chemineer

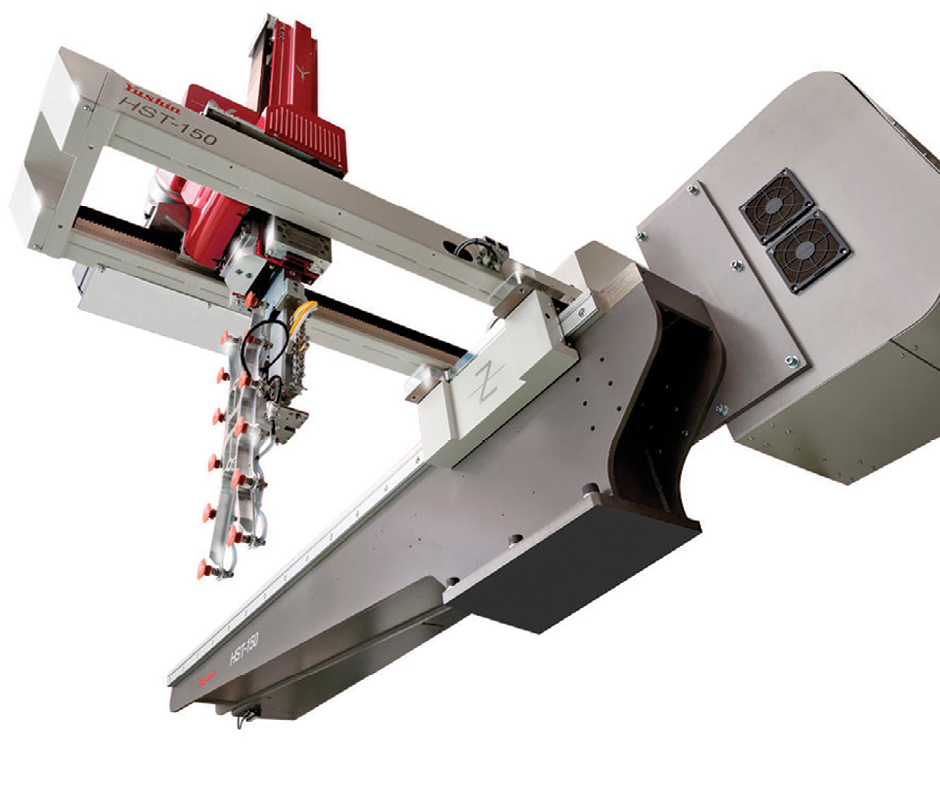

Photo courtesy of Yushin

Photo courtesy of Dow

Photo courtesy of Branson Ultrasonics

Jill Hesselroth (photo courtesy of Intek Plastics)

The Kenics™ Thermogenizer from Chemineer is a post-extrusion mixing device that provides color and additive distribution and uniform temperatures over a broad range of thermoplastics, including nylons, polyethylenes, styrenes, acrylics, cellulosics, and vinyl resins. Mixing is achieved by a stationary, helical Kenics Static Mixer element assembly, which induces flow divisions in the melt stream. This flow splitting combines with axial rotation of the stream, thus ensuring continuous transfer of material back and forth between the wall and the center of the stream.

Kenics Thermogenizers can be supplied with electrical band heaters and thermocouple ports for wall temperature control. Available in five different diameters, they install easily between the exit of an extruder and the accompanying die. Additional product features include production increases of 10 to 20%, elimination of temperature gradients created by extruders or other process equipment, better gauge control, consistent physical properties, quicker color changeovers, and better filler distribution, the company reports.

The organizing committee for the SPE Automotive Composites Conference & Exhibition (ACCE) issued its annual call for student scholarship applications and announced that the Michigan Economic Development Corp. (MEDC) is returning as a sponsor of two $2,000 historic SPE ACCE graduate scholarships (given annually since 2007), plus a $2,000 scholarship for an undergraduate or graduate student enrolled in a Michigan college/university (first given in 2013).

Applications for all three scholarships for the 2015-16 academic year are due July 20, and forms can be found at speautomotive.com/comp.htm. Winners will be selected from a pool of qualified applicants and announced in early August before this year’s SPE ACCE event.

“The State of Michigan is committed to ensuring that our auto industry has the pipeline of talent it will need for the future,” says Kevin Kerrigan, MEDC’s senior vice president, Automotive Office. “Michigan’s future as the global leader in automotive and manufacturing innovation and new technologies depends on engineering talent, and SPE’s Automotive Composites Conference and Exhibition focuses on both the current and future needs of Michigan’s most significant industry. Every dollar that we invest in these engineering scholarships is an investment in Michigan’s success in the future.”

Following its October 2014 announcement of a new, strategic partnership, A. Schulman, Inc. announced it would oversee the compounding and marketing of Initz Co., Ltd.’s Ecotran® polyphenylene sulfide (PPS) compounds. The offering is the culmination of the strategic partnership with the South Korean polymer producer.

A. Schulman is producing, selling, and distributing the Ecotran compounds in Europe, the Middle East, Africa, and the Americas. Initz is a joint venture of SK Chemicals Co., Ltd., Korea (66% of the shares) and Teijin Limited, Japan (34% of the shares).

“The combination of Initz’s know-how and A. Schulman’s global market access, manufacturing capabilities, and application development will support our customers in markets such as automotive, electronics, industrial, filtration, and coatings to meet and exceed their halogen-free industry standards,” says Marc Ollig, head of Product Management, Engineering Plastics. “Unlike other conventional PPS, Ecotran will enable them to differentiate their product offering and further strengthen their market position.”

Ecotran PPS is made with a new polymerization technology that eliminates residual chlorine in the product, which makes it purer than conventional PPS. This results in a halogen-free, eco-friendly, and low-emission product that has less outgassing during processing, decreasing the need for maintenance of molds and eliminating odors. Additional attributes include a brighter natural color, so new coloring opportunities will be possible.

Parts produced from Ecotran PPS can be exposed continuously at up to 240°C (460°F). The PPS is inherently flame retardant and achieves UL94 V-0 and 5VA classification. These properties allow it to be used in high-performance applications in the automotive, electronics, and industrial markets, where tolerance to high service temperatures and resistance to harsh environments are required, A. Schulman adds.

Attendees of NPE2015 saw a bigger Yushin booth, with double the number of injection molding machines of the last NPE show. In addition, the company presented more running work cells showing innovative applications of the operating robots than ever before. The 2012 booth highlighted the markets that are served with the broad Yushin product line. But this year, the focus was on the products and how they can be adapted to the specific needs of the attendee.

Yushin combined two robot families and downstream automation to mold, close, label, and pack medical marijuana vials. Atop a Toshiba EC250SX press, an RCII robot was fitted with two vertical main arms for part removal and transfer of these 40-dram (148-mL) vials to a closing station. After closing, a YC robot removed them from the closing station and presented them to a labeling station. Labeled vials were cased in reusable totes that circulated in a dual-level unstacking/restacking conveying system.

Building on the success of the London 2012 Olympic Games experience, the innovative artificial turf based on The Dow Chemical Company’s polyethylene and polyurethane technologies will be the official playing surface for hockey competitions during the Rio 2016 Olympic Games, at the Deodoro Olympic Park. Dow, the Official Chemistry Company of the Olympic Games, is working once again with Polytan STI, a global manufacturer and supplier of outdoor and indoor sports surfaces, to deliver a higher-performing, more reliable, and faster artificial turf for the world’s best hockey players in Rio.

Two pitches and one warm-up area at Deodoro, as well as two additional pitches to be built at the Federal University of Rio, will benefit from a comprehensive playing surface that consists of specific high-performing materials formulated together in multiple layers. The surface system is designed to deliver enhanced durability for increased pitch life and a consistent field-of-play throughout the busy Olympic competition schedule.

The internationally certified artificial turf system offers colorability, enabling customized aesthetics and design for the playing surface. London 2012 marked the first Olympic hockey competition in history to be played on blue and pink turf. The blue color enabled players, officials, spectators, and the media to keep their eyes on the ball more easily, because it provided a high level of contrast against the yellow ball and white lines.

Beyond the Olympic athletes, citizens of Rio will largely benefit from the innovative playing surfaces to be installed in Deodoro, as the park will remain as one of the main legacy projects for the city after the Games have concluded. Dow says it and its customer plan to donate material to support the construction of the Deodoro pitches and enable the long-term use of the fields.

Branson Ultrasonics, a business of Emerson, introduced a new addition to its 2000X series of Ultrasonic Assembly Systems at NPE2015. The new 2000Xc ultrasonic welding system combines consistent high quality welds with the process control needs of today’s manufacturing environment. The 2000Xc locks in the welding process with fully electronic welder settings, hierarchical password protection, and Ethernet connectivity access.

The company says the system offers secure process controls and detailed weld data to meet the global compliance, traceability, and security needs of today’s medical, automotive, business, and consumer electronics markets. The security feature helps to ensure compliance with medical manufacturing regulations, including ISO 13485 and FDA 21 CFR part 11. The Branson 2000Xc can be adapted to automation systems or used as a stand-alone complete system in an assembly cell.

The new system features the capability to weld by time, energy, peak power, ground detect, collapse, or absolute. The weld pressure, hold pressure, down speed, and rapid traverse are electronically programmable with a process change audit trail. There are no operator accessible controls, Branson says—ensuring validated processes remain unchanged.

With just a couple weeks to go before the registration deadline on May 31, K 2016, The “World’s No. 1 Trade Fair for Plastics and Rubber,” is experiencing strong demand for exhibit space. All 19 halls will again be fully booked, and some 3,000 exhibitors will offer a complete overview of the plastics and rubber world market. Companies from all continents have already registered to present their innovations in various exhibit categories over the week of October 19–26, 2016, at the fairgrounds in Düsseldorf, Germany.

“Due to its unparalleled range of products and the unmatched internationality of exhibitors and visitors, the trade fair is in a class of its own worldwide,” states Werner M. Dornscheidt, president and CEO of Messe Düsseldorf. “It is the place where key decisions for products, processes, and problem-solving are made, and it points the way forward for the entire industry for the coming years.

“We are delighted that demand for exhibition space is again extremely strong. The companies from the plastics and rubber sector know that they can look forward to an excellent platform for their business success every three years in Düsseldorf.”

The presentations of the exhibitors at K 2016 will be complemented by a special show illustrating the possible uses of plastics and their diversified properties today as well as in the future. This special show will be organized by the German plastics industry under the auspices of PlasticsEurope Deutschland and Messe Düsseldorf.

Another highlight of the K 2016 ancillary program will be the Science Campus—a forum for research and teaching. In this special zone, institutes, universities, and other higher-education institutions will present their latest scientific findings in the field of plastics and rubber and help to strengthen the dialogue between research and industry, explains Messe Düsseldorf.

Intek Plastics, Inc., a plastics extruder providing high-quality, precisely engineered, customer-specific products, has named Jill Hesselroth as Chief Executive Officer to lead the company as it continues to expand its business. Hesselroth brings a broad mix of business management leadership, inspiration, operational experience, and a passion for customer care to Intek. President Mike Kinning and Chief Operations Officer Steve Glienke will remain in their current roles as part of the executive team.

In her career, Hesselroth has served as a leader in several manufacturing companies, including Gillette, Andersen Corp., St. Jude Medical, Zimmer, and most recently Nortech Systems. Hesselroth has supported Habitat for Humanity on numerous builds and The Salvation Army as a past Red Kettle campaign chairperson and current campaign volunteer. She has a bachelor’s degree in accounting from the University of Minnesota and holds certifications from the University of Kentucky, College of Engineering in Lean Systems, and Stanford Executive Education, in Influence and Negotiations; and she is certified in production and inventory management (CPIM) and Project Management (CPM).

“I am honored and excited to be joining Intek at this time,” Hesselroth said. “The opportunities for continued success are excellent, and I look forward to leading the Intek team to make them a reality. Building further on Intek’s success is a challenge I accept with confidence, determination, and fierce ambition. I am passionately committed to reinforcing the company’s commitment to place our customers at the center of everything we do. The bar I set for myself and my team is high.” www.intekplastics.com