From Pellet to Part in Florida

NPE2015 and ANTEC® Orlando presented innovations covering the gamut of processes, from 3-D printing to part assembly

Previous Article Next Article

By Michael Tolinski

From Pellet to Part in Florida

NPE2015 and ANTEC® Orlando presented innovations covering the gamut of processes, from 3-D printing to part assembly

Previous Article Next Article

By Michael Tolinski

From Pellet to Part in Florida

NPE2015 and ANTEC® Orlando presented innovations covering the gamut of processes, from 3-D printing to part assembly

Previous Article Next Article

By Michael Tolinski

Nearly all seats were filled for the ANTEC Orlando 2015 plenary talk on additive manufacturing given by Heinz Gaub of Arburg.

SABIC’s carbon fiber-reinforced compounds were used in 3D-printing Local Motors’ Strati vehicle using the BAAM printer from Cincinnati Inc. (photos courtesy of SABIC).

BASF’s Ultrasim analysis tool was used to create this all-plastic shopping cart from Bemis Manufacturing (photo courtesy of BASF).

Entek’s QC3-43MM co-rotating twin-screw extruder was designed with customer input, the company says (photo courtesy of Entek)..

At NPE, SPE’s “Linky” character (promoting The Chain networking site) raided Milacron’s booth for samples of the company’s Klear Cans, a clarified PP alternative to metal cans (Klear Cans photo courtesy of Milliken & Co.).

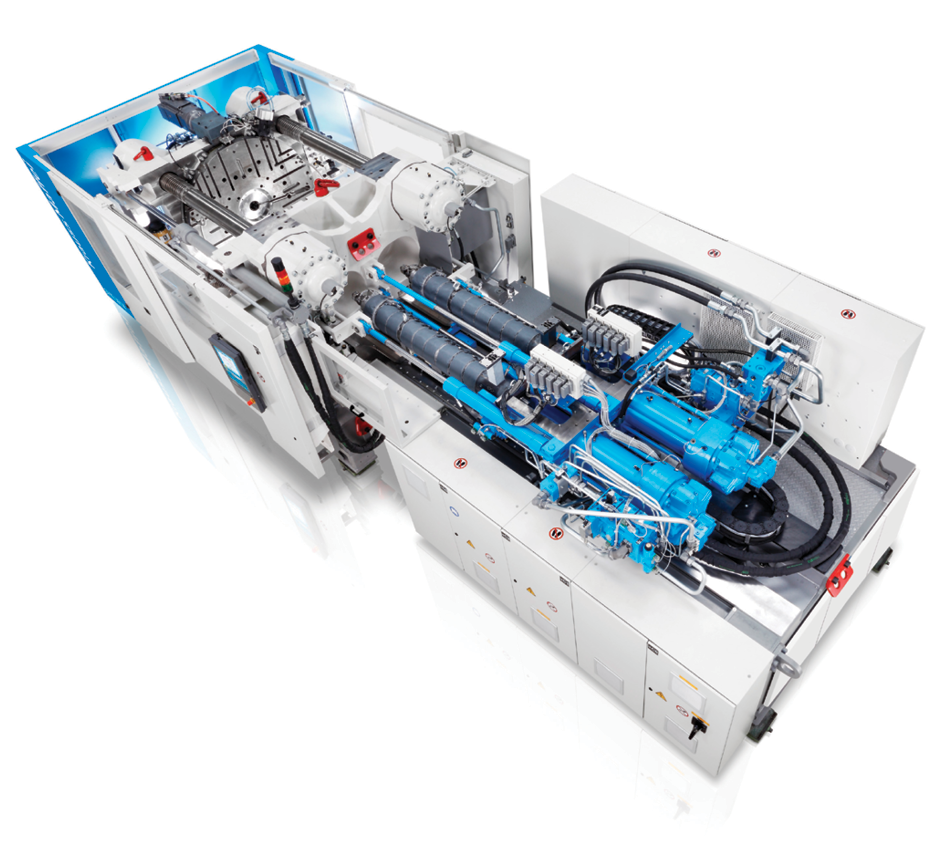

KraussMaffei GXH multi-injection molding machines have parallel horizontal injection units, helping to eliminate “dead corners” in hot runners, the company says (image courtesy of KraussMaffei).

AEC’s Trident™ GS modular chiller has five parallel circuits combining for up to 600 tons of chilling capacity (photo courtesy of ACS Group).

Brown Machine’s Elite Series trim presses have a “Drop Away” release allowing easier tool changes and maintenance (photos courtesy of Brown).

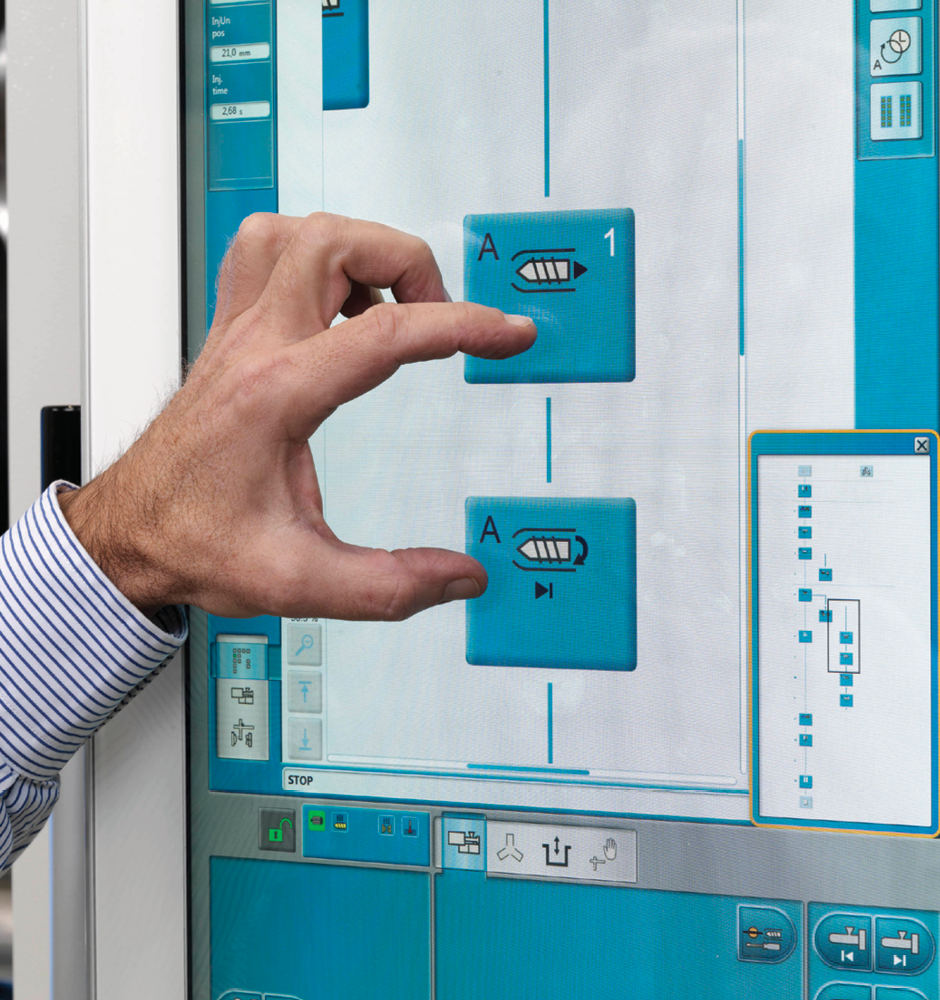

More machine control interfaces are supporting smartphone-style swiping and dragging gestures (as shown in this photo of the Multitouch touchscreen from KraussMaffei).

TPEs at NPE

Makers of thermoplastic elastomers were prominently displaying new grades at NPE—in increasingly diverse applications. Here are just a few examples:

- Offering TPEs for engineering applications, Kraiburg TPE is increasing its manufacturing capacity in the USA (with new production in Buford, Georgia). The company has broken into the automotive window seal market with high-flow Thermolast® grades; these work with low cavity pressures, helping prevent the window glass from breaking during encapsulation.

- For softer and more consumer-oriented applications, Star Thermoplastics offers a range of TPE hardnesses and grades, including “ultra-clear” StarClear® materials in durometers of 3 to 50 Shore ‘A’.

- PolyOne presented its Versaflex™ VDT vibration-damping TPE for overmolding applications in power tools, sporting goods, and appliances, in which the TPE is said to enhance end-user comfort.

- And Styrolution exhibited clear, flexible medical tubing made using Styroflex®, a styrene-butadiene block copolymer “with the properties of a thermoplastic elastomer,” the company says.

Winners “for Life”

The second annual SPE Plastics for Life™ parts competition once again pitted award-winning part designs from various SPE design competitions against each other in one “best of the best” brouhaha. Actually, the voting was orderly and peaceful, as 20 industry judges picked winners in four categories (plus an overall winner) while over 150 attendees voted for a People’s Choice Award. The Grand Award went to the single collimator LED automotive headlamp lens molded for the Ford 2015 F-150. Here a Bayer MaterialScience Makrolon® optical grade of polycarbonate was used with a multi-shot mold. The complex part reportedly provided a $5 per vehicle cost savings. Other winners took home awards for specific “Life” categories:

- “Protecting Life”: The MAXx Rescue Backboard, a heavy-gauge, twin-sheet pressure-formed part with thermoforming-based features such as molded-in strap pins for securing patients.

- “Quality of Life”: The Nissan GT-R vehicle decklid made from carbon-fiber reinforced plastics in the form of a compression-molded prepreg with woven continuous fiber; it reportedly offers a 40% weight savings compared to an aluminum decklid.

- “Improving Life”: Triangular-profile PET bottles designed to nest together as a four-pack, allowing shipping and shelf-space savings. The bottles are molded in an Amsler Equipment two-cavity WAE L22x stretch blow molder.

- “Sustaining Life”: A lightweight expanded polypropylene FoamCore® parking stop molded by Pinnacle Plastic Products, using a process that combines blow molding and steam chest molding.

- The People’s Choice Award went to a bowling pin elevator, a twin-sheet thermoformed TPO enclosure tough enough to be used for collecting and re-setting bowling pins. This steel-to-plastic conversion reportedly reduces downtime, maintenance costs, and pin jams. Meanwhile, awards were handed out for SPE poster presentations by students/young professionals, who this year used electronic screens to present their posters:

- The first-place graduate award: Anvit Gupta and Xi Yu of the Univ. of Massachusetts–Lowell, for “Process-Property Relationship During Wire Coating Extrusion.”

- The first-place undergraduate award: Abigail Gilmore and Kierstyn Williams, Penn State Erie, the Behrend College, for “Determining Processability of Recycled Fillers in Polypropylene Resin.”

- And the Ken J. Braney International Award: Vida Poursorkhabi of the Univ. of Guelph, Canada, for “Characterization of Carbonized Electrospun Lignin Fibers.”

The “Plastics for Life” Grand Award winner: the LED automotive headlamp lens (at left) for the Ford 2015 F-150.

Amidst all the deal-making and recycled-plastics fashion shows and the like at NPE in March were serious technical innovations presented at both NPE and ANTEC Orlando. And although sometimes it seemed like all eyes were focused on developments in 3-D printing, other innovations addressed every step of plastics processing and production.

Nanotech Aloft

And there are good reasons to innovate: Polymeric materials still have a lot of jobs left to take on, especially in aerospace, according to ANTEC plenary speaker Michael Meador, manager of the Nanotechnology Project in NASA’s Game Changing Development Program.

Meador’s talk focused on uses of nanotechnology—especially nanocomposites—in current and future space missions. He looked back at the original goals of the U.S. National Nanotechnology Initiative laid out in the year 2000 by President Clinton. They concerned using nanotech in nanomanufacturing, nano-electronics, solar energy, and sensors. At that time Clinton noted the benefits of “developing materials that are ten time stronger than steel but a fraction of the weight”—which relates to what Meador and his teams have concentrated on since then.

For example, aerogels—they’re highly porous solids which are very good for insulation, but silica aerogels “are not mechanically robust,” he said. So researchers are using nanotechnology to create polyimide aerogels that are tough enough for use in “deflatable decelerators” used to slow spacecraft descents.

Another project is developing lightweight carbon nanotube composites having strength properties that are closer to those of a theoretically ideal composite—that is, one with properties of an individual nanotube particle itself. Meador said one goal is to create nanotubes in forms similar to those of standard carbon fibers used in current aerospace manufacturing processes, while offering much higher properties.

Additive Manufacturing Matures

Multiple presentations and exhibits in Orlando showed how 3-D printing and additive manufacturing methods are turning into practical—maybe even essential—tools for plastics professionals.

The talk that drew perhaps the biggest audience was the Tuesday ANTEC plenary speech by Heinz Gaub of Arburg. Many things are driving additive manufacturing development, said Gaub: more customized and personalized products, shorter product cycles, and increased product variations.

Gaub made a strong distinction between the terms “3-D printing” and “additive manufacturing” (AM). He defined 3-D printing as “a more simple process for [making] geometric parts,” compared to AM, which makes fully functional parts. Arburg’s Freeformer system leans more towards AM, since it builds up parts with molten droplets of actual injection molding production resins, creating parts with properties near those of the molded versions (see also February’s Plastics Engineering, p. 12, for a full report on this and related AM/3-D developments at NPE).

Arburg’s AM activities started in 2005. “We would start producing small droplets of liquid plastic” and placing them on a surface, Gaub recounted, describing the droplets as being like 3-D “pixels” whose placement could be controlled. A couple years later, the company began to build layered structures with this proto-Freeformer technology and filed its first patent.

In 2014, “We did a pilot production run for some key customers”—important because Arburg considered customer feedback key information for Freeformer commercialization, Gaub said. Based on the feedback, Freeformer machines were prepared for series production starting in March of this year.

Material Progress, in 3-D

As AM matures, people are looking at it more critically. Steve Wright of Eastman Chemical Co. may have delved into a little controversy with his talk at ANTEC’s “Super Session” on AM/3-D printing. Wright said more people have been thinking about the odors and VOC emissions produced by fused-filament 3-D printing, especially since the printers are often used in confined spaces and, increasingly, schools and homes.

Wright showed that both VOCs and nanoparticles can be emitted. Even though the emissions may not reach regulatory limits, “printing should always be done in a well-ventilated work area following the printer manufacturer’s instructions for safe operation,” he advised.

Given the issues with odor, Eastman introduced a low-odor, high-strength material option for 3-D printing—its Amphora™ 3D polymer. It’s been combined with 20% carbon fiber in filament form and offered under Helian Polymers’ ColorFabb brand for extrusion-based 3-D printing. The resulting ColorFabb XT-CF20 is said to offer functional strength, stiffness, and aesthetics.

Meanwhile, SABIC is releasing 3-D printable and functional materials in a big way, literally. With its LNP™ Thermocomp™ carbon fiber-reinforced compounds, the company used the Big Area Additive Manufacturing (BAAM) printer from Cincinnati Inc. to print the “world’s first” 3D-printed car, Local Motors’ Strati.

“SABIC is formally committing to the 3-D printing industry,” emphasizing “synergies” between materials and machines for printing stronger parts, said Thierry Materne, vice president, Technology & Innovation for SABIC Innovative Plastics, at an NPE press conference.

Innovations: From Pellet to Assembly

Apart from additive manufacturing, NPE exhibitors had plenty to offer for practically every step of plastics-related manufacturing. Below is just a sampling of the highlights.

Selecting Material

Surprises are usually unwelcome in product development planning—especially failures from choosing the wrong material. Thus BASF presented its Ultrasim® analysis tool for predicting a material’s performance in an application with “90-95% accuracy.” Used for structural applications like those that require fiber-reinforced plastics, the company says the tool can account for the influence of the injection molding process while studying a part’s static and impact loads, vibration and acoustics, and fatigue and creep.

“Ultrasim technology optimizes the overall design process,” said Mark Minnichelli, director of technical development at BASF. Besides minimizing part mass and costs, the tool is useful in metal-to-plastic conversions. “We’re working with engineers who are used to designing with steel and aluminum,” Minnichelli added at a press event.

He referenced a collaboration with Bemis Manufacturing Co. to design and produce an all-plastic shopping cart design using Ultrasim. With the right gating developed for injection molding, the cart’s structural element reportedly allows it to support an 1100-lb (500-kg) static load and a 600-lb (270-kg) moving load at 6 miles per hour (10 km/hr).

Compounding

For developing compounds and short production runs, Coperion presented the redesigned ZSK 26 Mc18 twin-screw laboratory extruder. The extruder is mobile, holding all auxiliary drives and heating and cooling systems in one integrated cabinet. It reportedly supplies increased torque (15 Nm/cm3) and a higher throughput range from 20 to 400 lb/hr (9-180 kg/hr). (The company will also be presenting the STS Mc11, a “next generation” of compounding extruders, at Chinaplas this month.)

Meanwhile, Entek offered its QC3-43MM co-rotating twin-screw extruder. It was designed with the input of Entek’s compounder customers, resulting in key added features, the company says. For example, changeovers are aided by a self-alignment feature that allows screws to be installed only in the correct way. The extruder also has an increased screw OD/ID for compounding challenging formulations.

Controls include enhanced graphics, a recipe library, trending software, and web connectivity allowing remote troubleshooting. “For now, the QC3-43MM is the only Entek twin-screw extruder with these new features, but we will phase in these design changes to our other machines as well,” says the company’s John Effmann.

Injection Molding

Milacron showed off several injection molding developments at NPE, but perhaps the most colorful was the Klear Can, produced on a Ferromatik Milacron 280 press in 8-second cycles. The clarified polypropylene container is co-injected with EVOH, which serves as a barrier layer allowing 2-5 years of food shelf-life. The Can is meant to compete with metal food cans, in the same canning lines and retort (132°C) treatments. Its PP is clarified with Milliken’s Millad® NX™ 8000 additive (this additive is also now being used for thermoforming clear PP, reports Milliken).

But showing off the food inside isn’t the only feature of the Can. During shipment and use, it reportedly will resist dents and other kinds of handling damage that are common with metal cans. And it has “a proprietary false foot design that prevents can deformation during retort,” reports Milacron. Klear Cans are also 40-50% lighter than metal cans, reducing transportation costs and emissions.

“Combined with its exceptional light weight and improved durability and recyclability, the Klear Can promises to change the way shelf-stable foods are marketed,” said Milacron’s Russell Bennett. The concept is being brought before focus groups after NPE, from which Bennett said he anticipated receiving positive feedback.

Multi-component injection molding was one focus of KraussMaffei’s at the show. The company’s GX series of machines allow the molding of up to four different combinations of colors and/or materials in a part. The five variations of the GX twin-platen injection molding machine, in the medium clamping force range, have an optional integrated servo-electric-driven turntable for rotating the mold.

The GXH variant has parallel horizontal injection units. “Using the horizontal arrangement, the melt is guided directly into the respective mold-half,” says Paul Caprio, president of Krauss-Maffei Corp. in the USA. “This way, so-called dead corners in the hot runner are reduced.” Other machines in the GX series have lateral or vertical injection units.

Cooling the Process

With above-average temperatures in Orlando that week, staying cool might’ve been on some people’s minds. AEC, an ACS Group company, announced a new central chiller, the Trident™ GS Series. The compact, modular unit has individual circuits providing 50 to 120 tons of chilling capacity (175-422 kW). The unit can be expanded to match customers’ needs, offering up to five parallel circuits for a maximum of 600 tons of chilling.

Each parallel circuit contains all of the necessary components and programming allowing it to take over as the master unit at any time, the company says, reducing the time for integration and setup. The chiller also has an integrated strainer that can be removed manually and cleaned with minimum downtime, as the company demonstrated at NPE.

Trimming & Part Handling

Looking further down the line, Brown Machine LLC introduced its LS Elite Series servo-driven horizontal trim press, which reportedly allows greater speeds (175 strokes per minute or more), “solid and smooth” operation, longer tool life, and faster changeover times (less than 30 minutes).

Regarding this last point, Brown’s Jim Robbins demonstrated the press’s “Drop-Away Connecting Rod Release,” which opens up the moving platen further than the press stroke for faster die-set changeovers. Quick tool changes are important, said Robbins, especially since there are fewer packaging operations that run dedicated trim lines; more color changes, part numbers, and materials now mean more tool changes.

The feature is also said to be particularly helpful for maintaining die-sets that trim shallow components on a short stroke, typically meaning that with the platen fully open, there’s little room between the punch and dies. The Drop-Away release retracts the moving platen more, providing more space for maintenance.

For handling injection-molded parts, three new lines of robots from Sepro America are meant to serve large injection presses (800-5,000 tons). Moreover, “We’ve added five- and six-axis products in all size ranges, in-mold labeling solutions, a dual-arm unit, a servo sprue-picker, and new, user-friendly controls,” says Jean-Michel Renaudeau, CEO of the Sepro Group in France.

Some of the new robots feature enhanced technologies; others just offer what’s needed. The company’s “Strong Line,” for example, is meant to make “three-axis servo speed and precision available to molders who have applications that require simple pick-and-place functionality,” the company says. At its NPE press event, the company’s Jim Healy stressed Sepro’s willingness to fit robots to both new and old molding machines, of any brand and any application.

Controlling it All

Process controls and the human-machine interface were major emphases of equipment makers at NPE. Some companies pointed to their smarter touchscreens, like Siemens’s IFP widescreen flat-panel monitors that allow “five-finger operator input” and are said to recognize various operator gestures—including accidental touches of the screen.

New touchscreen controller displays recognize smartphone-type dragging and swiping gestures, like in KraussMaffei’s new molding machine controller. “Displays can be controlled through gestures with two or more fingers,” says Günther Grimm, head of Software and Control Technology at KM. “These include swiping movements, and spreading your fingers to zoom.”

And there are more remote machine interface options being made available using the Web or, now, smartphones—in quest of a goal of “remote everything,” as Wittmann Battenfeld president Dave Preusse termed it at a press conference. The company described its WiBa QuickLook app as a simple and quick way to check the status of injection molding machines and robots via smartphone (the app links to Wittmann R8.3 robot software and Wittmann Battenfeld Unilog B6 control systems).

The user makes a status request by phone, and the app delivers a “manageable” amount of data, the company says—like the most important current parameter settings for a molding machine and one or several robots (users must go to the production cell controller itself to make adjustments).

Assembly

As plastics parts get more sophisticated, so will the assembly methods required to join them. 3M is making a concerted effort in this area with its new “Assembly Solutions” initiative, which helps engineers find alternatives to mechanical fasteners, welds, and rivets. The company has rated adhesives and tapes across critical design characteristics, so engineers can determine the best options to consider for their unique design or process criteria.

Adhesives and tapes can simplify assembly and reduce costs and supply engineering advantages beyond bonding, like sealing. Applications include joining panels to frames or stiffeners to panels, large-surface lamination, trim or gasket attachment, and encapsulation.

The initiative is targeting the needs of design and product engineers. “They are the decision makers on how to [join] materials together,” said Mark De La Forest, Structural Adhesives manager for 3M’s Industrial Adhesives and Tapes Division. More and more “within the plastics industry,… [molders] have become assemblers.”

Recycling Scrap

And at the end of the line, there’s scrap to be reclaimed. For this, Cumberland (an ACS Group brand) introduced the Combi-shredder, which combines a shredder and granulator in a single unit. The shredder is stacked directly onto the granulator, and shredded scrap is directly discharged to the granulator, with the units’ speeds synchronized for throughputs of up to 700 kg/hr. The company stresses that the concept conserves floor space and reduces downtime for transferring material, since large parts and purgings are put in the shredder and come out as regrind.