Maschinen- und Anlagenbau Schulz GmbH will celebrate its 10th anniversary at K 2016 by rolling out a new machine design for its extruder and melt filter series. Photo courtesy of MAS

Yumix, a Texas maker of cocktail brands, wants to shake up the sector with this 2-part, snap-fit PET bottle that allows users to mix their own drinks. Photo courtesy of Plastic Technologies Inc

Yumix, a Texas maker of cocktail brands, wants to shake up the sector with this 2-part, snap-fit PET bottle that allows users to mix their own drinks. Photo courtesy of Plastic Technologies Inc

Sweden’s Rapid Granulator is ‘opening its heart’ to make its Raptor Series of shredders easier to clean and maintain. Photo courtesy of Rapid Granulator

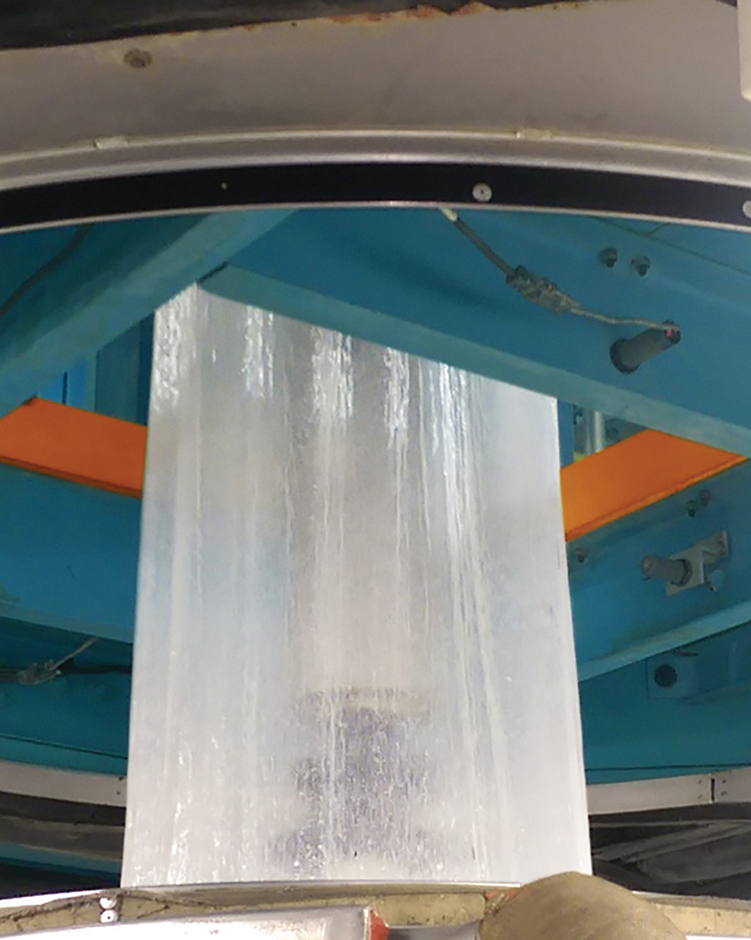

Sun Plastech’s newest ASACLEAN purging compound — UF2 grade — can be used by blown and cast film extruders, as well as injection molders. Photo courtesy of ASACLEAN

Wittmann Battenfeld will showcase its medical micromolding technology prowess at November’s Compamed show in Düsseldorf, Germany. Photo courtesy of Wittmann Battenfeld

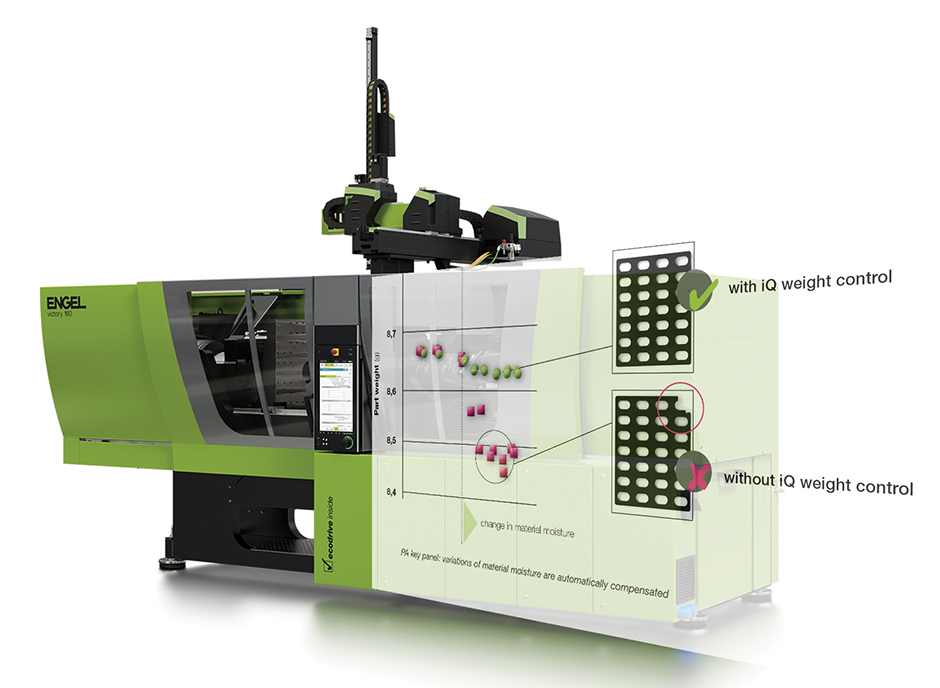

Engel says its iQ weight control software helps boost molding precision and productivity. Photo courtesy of Engel Group

Huntsman Advanced Materials believes that adding graphene to its Araldite® epoxy resins may help to advance the market for nanocomposites. Photo courtesy of Huntsman Advanced Materials

MAS to Unveil its Latest Extrusion & Melt Filter Technology

To mark its 10th anniversary, Austrian extrusion machinery manufacturer Maschinen- und Anlagenbau Schulz GmbH will introduce a new machine design for its extruder and melt filter series at K 2016. The conical, co-rotating, twin-screw extruder is designed specifically for plastics manufacturers and compounders to develop formulas in a scientifically oriented manner and produce them in very small volumes. MAS says the machine’s large feed opening and gentle plasticization process make it suitable for all extrusion applications that require a high degree of thermal and mechanical polymer protection. This is especially the case for recycling and compounding applications, as well as for film extrusion.

MAS introduced the CDF continuous melt filter in 2011. Its design allows customers to effectively process highly contaminated materials and help increase extruder capacity. The basic concept of the filter is a rotating screen combined with a continuous scraper system, which lifts the contamination from the screen surface and discharges it through an auger. In its latest iteration, the filter system is now equipped with a new pneumatic scraper. This allows a higher degree of adjustability for the stable performance of the system. Further features of the latest filter generation include optimized melt channels as well as changes to the heating system to heating plates and bands, which improves the heating coefficient.

Yumix Cocktails Use 2-Compartment, Snap-Fit PET Package

Austin, Texas-based brand owner Yumix LLC wanted to give adult consumers a great tasting cocktail that they can mix themselves anywhere, anytime. That led it to work with Plastic Technologies Inc. (PTI) of Holland, Ohio, and develop a two-compartment package—with the bottom container snapping into the base of the larger top bottle. The Clasper™ bottle—engineered by PTI —combines two polyethylene terephthalate (PET) containers and a shrink label, and has yielded a disruptive new cocktail line that is both portable and shelf-stable.

The bottom of the bottle holds 50 ml of premium alcohol and features a heat-applied, aluminum-foil seal. The main bottle holds 6.5 ounces of hot-filled, shelf-stable juice and is topped by a 38 mm polypropylene closure. The shrink-label graphics add visual appeal and also include usage instructions.

The Clasper™ bottle concept is the brainchild of Yumix founder Alex Garner. After having gained experience working with fresh juices for a major beverage company, it occurred to him that adding alcohol to those juices would be a perfect companion for adults on a warm day. He wanted the product to be portable, while also taking the guesswork out of cocktail mixing to help the consumer consistently achieve a great flavor profile.

“I knew from my experience that if we tried to premix the juice and alcohol, the enzymes in the juice would quickly alter the taste. You would then have to add preservatives and sweetener, which would alter the flavor profile. That’s not what we wanted to do and that’s why we expended significant effort to develop the right package. The end result has been driven by our quality goals,” Garner explained.

Yumix entered soft launch distribution in Texas this month with three flavors— strawberry lemonade with vodka, cosmopolitan with vodka, and pink grapefruit with vodka. The brand offers consumers a 12- to 18-month shelf life and will retail between $3.99 and $4.99, depending on the market. Plans are already under way to add more flavors. Yumix is planning for wider, national distribution in 2017.

Rapid Introduces New ‘Open-Hearted’ Plastic Shredders

Size-reduction technology specialist Rapid Granulator is introducing a new family of shredders for plastics: The Raptor Series. These modularly designed units feature a world-first with their “open-hearted” design. The design of the Raptor enables quick and direct access to the shredder rotor and cutter chamber, which simplifies the cleaning and service process. The front door, hinged on the side, provides unrestricted access to the rotor and to the screen, which is mounted in the door. Once the front door is open, the shredder hopper mounted on a rear hinge can be tilted back.

“The Raptor Series is a shredder and granulator hybrid with the shredder’s heavy-duty cutting technology combined with granulator features such as Rapid’s ‘open-hearted’ design that makes it super-easy to operate, service and clean,” says Rapid Global Sales and Marketing Director Bengt Rimark. “The Raptor Series has been developed with 100% focus on every single detail that is of importance for plastic processors, to create simplicity and a minimum cost of ownership. As we develop and manufacture both granulators and shredders, we make sure that the machines are tailored for each other and that we can provide complete recycling systems, direct from Rapid.”

The machine can be in a completely open position in less than one minute after it has stopped running. Once open, all fasteners are accessible from the outside using air-driven tools. The access made possible by the design makes any contamination immediately visible. And, Rapid claims, this ease and speed of cleaning and maintenance serves to lower the cost of ownership of the Raptor Series.

ASACLEAN™ Wants to Purge Your Plastics Packaging Machinery

Sun Plastech Inc., part of Asahi Kasei Group, has introduced a new UF2 grade purging compound in its ASACLEAN™ product range. It is targeting the new product for thermoplastic blown and cast film extrusion applications, as well as injection molding. Like all ASACLEAN products, this latest grade is said to enable faster changeovers for reduced equipment downtime, thereby increasing productivity and helping plastics manufacturers to save money.

Plastics processors are always looking to accomplish fast color and material changes, and to effectively remove color and carbon contamination from their machines. Sun Plastech recommends UF2 grade purging compound for color changes, material changes, hot-runner cleaning and shutdown/sealing.

It can be purged through a die without removing it, can effectively remove gels and contamination that is not carbonized, and has excellent compatibility with PE resins.

For blown film applications, UF2 grade purging compound also helps manufacturers “hold the bubble,” minimizing downtime to increase productivity. For blow molding application, UF2 helps hold the parison, according to the manufacturer.

A Sun Plastech customer recently performed a cost-savings analysis of an extrusion polyethylene color change on a machine with a 4.5” die and a barrel capacity of 50 pounds, where black polyethylene was being replaced with natural polyethylene for the next run. Using ASACLEAN’s UF2 grade instead of the customer’s usual “next resin” purging method, resulted in a clear reduction of machine downtime due to faster changeover and less wasted material. Overall, the firm claims, the customer reduced its costs by 65%, resulting in annualized savings of more than $23,000.

Wittmann Battenfeld to Present Cleanroom Medical Micromolding

Wittmann Battenfeld has been well established in medical technology for a number of years, offering injection molding machines — specifically, the all-electric EcoPower series and the MicroPower series — for cleanroom manufacturing. Last year, the Torrington, Conn.-based company concentrated its medical technology activities in a separate group, to better enable it to offer expert counseling and project planning for medical technology applications for micro injection molding. The firm now has also examined and validated its servo-hydraulic SmartPower series at the company’s in-house cleanroom test center.

At the Nov. 14-16 Compamed 2016 show, Wittmann Battenfeld plans to demonstrate its medical expertise with a machine designed for small and micro parts from its MicroPower series. The company says this machine series stands out for its cost efficiency, high speed, and process reliability. Thermally homogeneous melt is injected via a two-step, screw-and-plunger injection unit with shot volumes ranging from 0.05 to 4 cm3. This makes it possible to turn out top-quality parts with extremely stable production with short cycle times. At the show, Wittmann Battenfeld plans to use a MicroPower 15/10 and assembly injection molding in a cleanroom environment to produce the carrier parts of a “lab-on-a-chip,” which serves to analyze blood particles.

The machine that will be on display comes as a full-fledged, clean-room production cell, equipped with a rotary disk, parts removal handling device, a Wittmann Drymax Micro dryer, and integrated quality inspection by image processing, as well as a cleanroom module, which produces class 6 clean air, according to the ISO 14644-1 standard.

Emerson Gets Big & Complex with its Branson GLX-3 Laser Welder

Branson Ultrasonics, a business of Emerson, says its new GLX-3 laser welder delivers clean, high-speed welding of large-format plastic parts with more complex geometries to meet the growing needs of automotive, appliance, medical, filtration, and other applications that require particulate-free welds with superior aesthetic quality.

The new GLX-3 welder incorporates advanced features, including Branson’s patented Simultaneous Thru-Transmission Infrared (STTIr) process, which heats, melts, and joins the entire weld line of two or more parts simultaneously. Compared to scan or trace laser welding processes, which must travel the entire length of the weld line to accomplish heating, Branson’s STTIr results in a significantly faster weld cycle on large parts, and more precise melt of the weld line.

The GLX-3 welder is designed for large-format parts that require greater laser and clamping power. It offers an expansive high-speed, servo-driven lift table with a high overhead clearance, capable of accommodating single- or multi-cavity tooling with combined weights of up to 500 kg. The GLX-3 offers four levels of laser power, a wider range of clamping force, plus closed-loop, clamp-force control to meet the most demanding parts-welding requirements.

The GLX-3 is designed for easy use, with a 12-inch, color human-machine interface (HMI) screen based on a common global IPC architecture that simplifies training, setup, adjustment and diagnostics. The HMI software can accommodate up to 99 different users with configurable access rights and password-protected logins. Both welders are housed in compact, Class 1, laser-safe enclosures that meet CE, ISO and ANSI norms, with twin front doors that contain 3.5mm thick, laser-safe glass for process viewing.

A dedicated safety PLC running Branson’s advanced Logic Control System manages the machine’s functions and safety aspects. This automatically synchronizes door, lift-table and tooling activities to minimize weld cycle times while maintaining process safety. Integral chillers that are linked to roof-mounted heat exchanger-dehumidification units provide process cooling for the GLX-3 welder.

Engel Applies its iQ to Hydraulic Injection Molding Machines

Simply using a precise injection molding machine will not achieve molded parts of a consistently high quality shot by shot. Even minor changes in ambient conditions or in raw materials and wear can have an effect and require that parameters be readjusted. The iQ weight control software from Austria’s Engel Group now makes it possible to automatically recognize deviations and compensate for them in the same shot in hydraulic injection molding machines such as, for example, the Engel victory and Engel duo. Taking such action helps to boost productivity and actively prevent rejects.

To achieve this, the software analyzes the pressure profile in real time during the injection process and compares the measured values with a reference cycle. The injection profile, switchover point and the post injection pressure are adjusted to the current conditions for every shot, which keeps the injected volume constant during the entire production run.

Engel uses the prefix iQ to denote intelligent, decentralized assistance systems that enable injection molding companies to optimize their productivity, efficiency, quality and flexibility. Decentralized intelligence is a key feature of the continually self-optimizing smart factory, the goal of Industry 4.0, which will be a focus of the upcoming K 2016 trade fair in Germany (and where Engel will occupy Stand C58 in Hall 15).

Engel’s answer to the new challenges of this development is inject 4.0. This comprehensive program already offers numerous products and solutions for all three parts of the smart factory – smart machine, smart service and smart production – and the company is adding new ones continuously.

Huntsman Exploring Graphene-Enhanced Nanocomposites

Huntsman Advanced Materials is researching opportunities for developing graphene-enhanced composite solutions, with a view to incorporating graphene into its Araldite® epoxy resins. It says it expects that such applications will significantly advance the market for nanocomposites. Ultralight yet immensely tough, graphene is stronger than steel but incredibly flexible. It also conducts electricity better than copper and can act as a barrier that not even helium can pass through. A myriad of unprecedented attributes has seen this material rapidly gain acceptance as a key enabler in a growing number of applications.

The renewable energy, automotive and medical sectors, in particular, have been quick to investigate uses of the material. Improved photovoltaic cells benefit from its excellent conductivity and transparency, stronger car tires last longer due to its improved heat dissipation, and pioneering research suggests that the placement of graphene on the internal surfaces of intravenous catheters will improve the efficacy of chemotherapy treatments.

Established processing technologies that are energy- and materials-efficient make polymer composites an ideal area for innovation, as one of the simplest and most effective ways of realizing graphene’s potential is in combination with existing products. Initial results have shown that Araldite® graphene-reinforced resins offer greater dimensional and thermal stability in addition to improved impact resistance, properties that through further investigation could offer major performance benefits.

David Hatrick, European Technology Director of Huntsman Advanced Materials, said, “We continue to make good progress in collaborative developments and have been particularly impressed with the improvements already made in the areas of thermal, electrical and mechanical performance.”