Ecosystems, IoT & the Future of Product Design

The rise of smart devices is reshaping how products are being developed

Previous Article Next Article

By Robert Grace

The Internet already has revolutionized just about everything — how we communicate, shop, travel, consume entertainment, and more. Now it is about to reshape how we design and develop products. And anyone involved in that process will be affected.

What’s driving this change? In a phrase — the Internet of Things. The IoT is the digital, wireless network that increasingly is interconnecting devices, machinery and humans, and making “dumb” products “smart” and connected. This is creating vast new opportunities for brand owners and product developers to learn about how people actually use their products in real time, and adapt future designs accordingly.

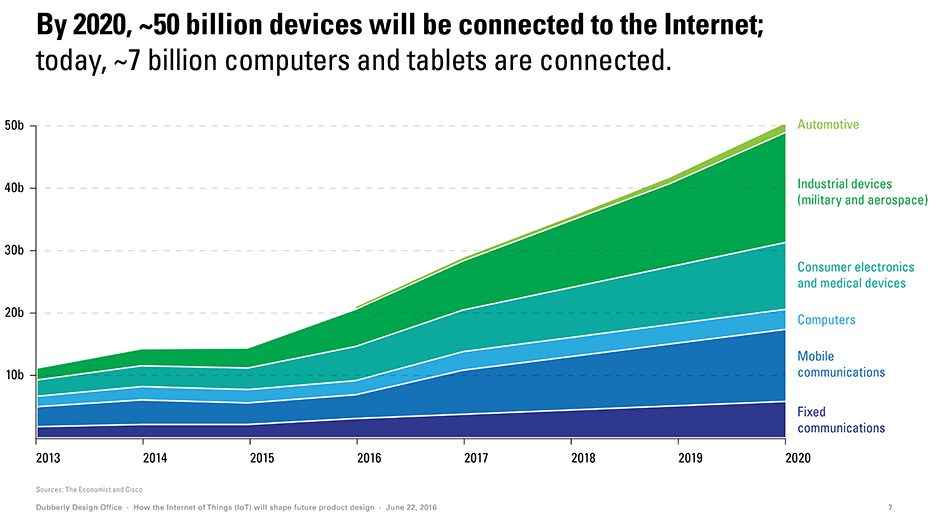

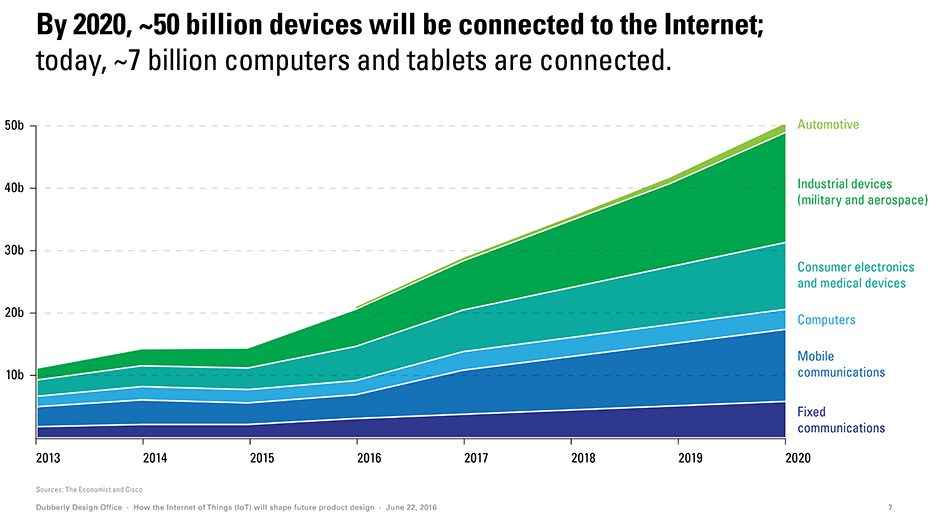

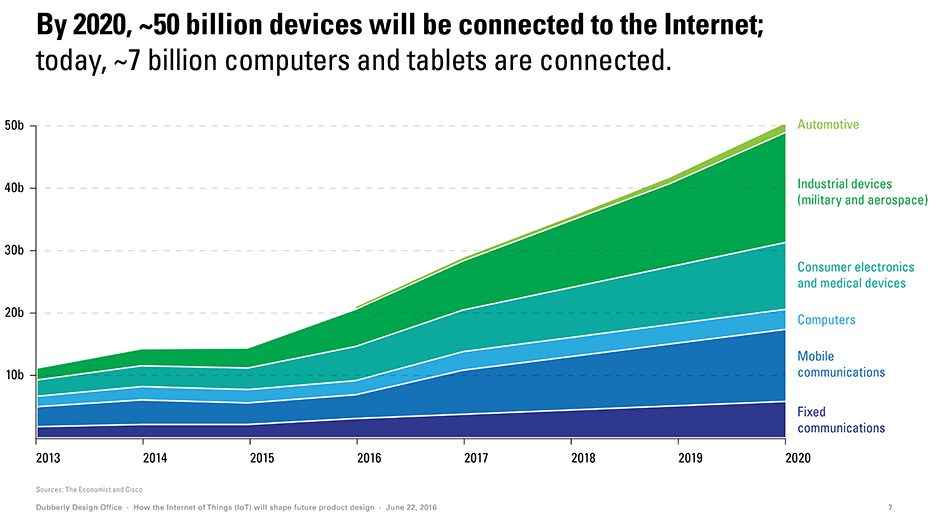

Cisco Internet Business Solutions Group has predicted that by 2020 some 50 billion devices – including phones, computers, appliances, vehicles and various types of machines — will be digitally connected to the Internet (see Figure 1).

Figure 1. Sources: The Economist and Cisco (image courtesy of Dubberly Design Office)

From a design perspective, these so-called smart devices and other consumer goods will need to continue to be stylish, safe, powerful, durable, cost-effective, miniaturized and sustainable – often all at the same time. But they also will eventually cease to stand alone. They are becoming part of a platform or system, and eventually of a “system of systems,” which is changing everything.

That means, explains Stephen B. Wilcox, founder and principal of the Philadelphia-based consultancy Design Science, that, “As designers, we’re no longer going to be designing products; we’re going to be designing adaptive systems. That means systems that have been designed from the beginning to naturally change as a function of data received from the users.”

Wilcox spoke in detail about these trends in his June 22 presentation at the inaugural SPE Design in Plastics 2016 conference (www.4spe.org/designinplastics), held at the Rhode Island School of Design in Providence. He gave credit for much of the information in his talk to his partner Hugh Dubberly, a former Apple manager who now is principal of his own consultancy, Dubberly Design Office, in San Francisco.

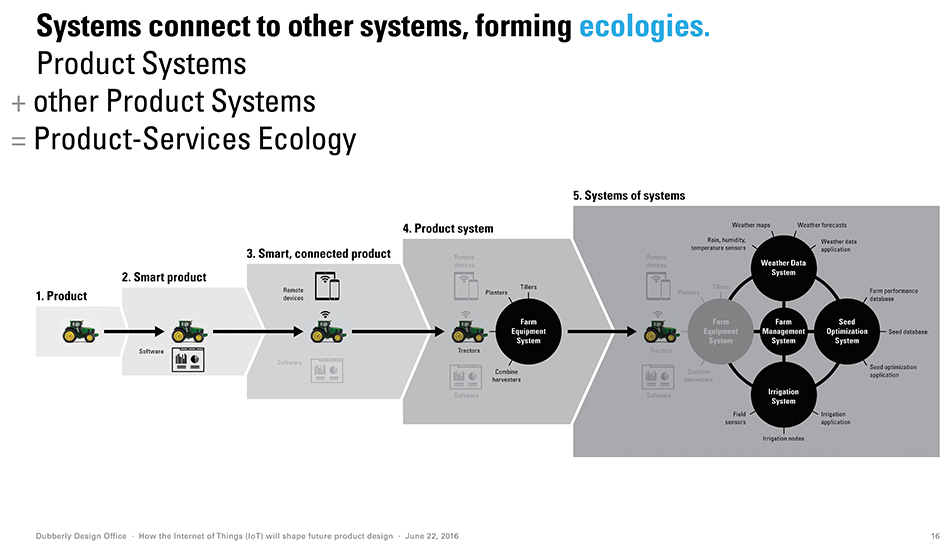

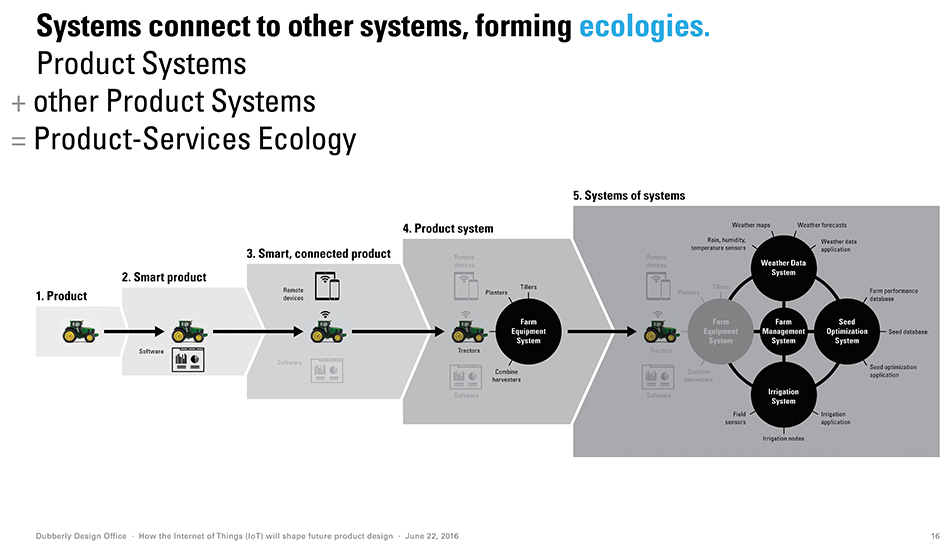

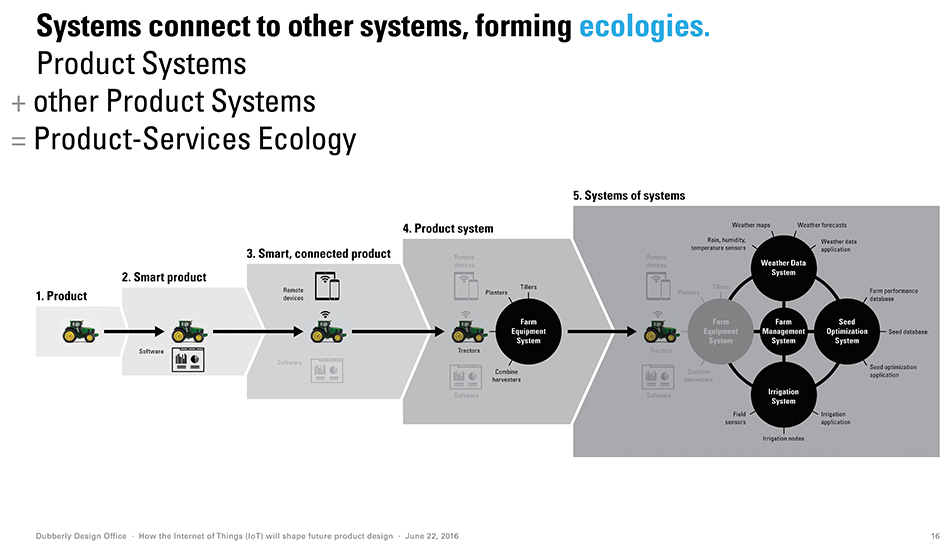

“We start with a product and we end up with a ‘system of systems’,” Wilcox continued. “Services are connecting to integrated systems, forming ‘product service ecologies’ — networks of products, services, people and their interaction.” Let’s look at some real-life examples.

Plowing fertile new ground

Early farming implements were pulled by horses, and then power was built into the tractor. More recently, tractors began adding “intelligence,” in the form of embedded microchips. Citing a 2014 Harvard Business Review article by Harvard professor and economist Michael E. Porter, Wilcox referred to what has now become a farm equipment system. The new generation of tractors incorporates sensors and wi-fi and is interconnected via the cloud to the tiller, to the harvester, to the planter — which allows the farmer to start making intelligent decisions (see Fig. 2).

Figure 2. Sources: Michael Porter and Harvard Business Review (image courtesy of Dubberly Design Office)

“The type of furrow that you plow with the tractor determines a setting in the planter, and you don’t have to do this anymore by brute force. Those settings are automatic, because the various devices are connected to each other. Now the harvester knows when the planter planted the seeds, etc.

“The next step, and we’re not there yet,” Wilcox noted, “but this is what we’re predicting: Take that complex farm equipment system, and connect that to other complex systems, so now you have a system of systems. You have a weather system that sends data that helps you to make decisions about when you harvest. You have an irrigation system that is impacted by what you planted, a seed optimization system, and so forth.”

Take, for example, modern vineyards, he said. Sensors attached to each grapevine detect temperature and humidity. Data is transmitted from the vines to a repeater, and then to the cloud. The winemaker now has a database, which allows him or her to do microharvesting, and to know exactly when to harvest each individual vine. This is happening now, Wilcox noted.

Rolling down the highway, intelligently

There are 60-100 sensors in the typical consumer automobile, Wilcox said, and that’s expected to double in the next few years. There are, on average, 30 microprocessors in your automobile; some have as many as 100, and the number is constantly increasing.

When those sensors are connected to the Internet, you have a “smart, connected” vehicle. This intelligence allows you to optimize fuel use, braking and the like. You can gather and store data, take external input of data, and communicate what’s happening with that device to other sources.

And speaking of driving — consider Uber. The ride-sharing service is a great example of platform, and a disruptive technology. You may think of it primarily as an app on your smartphone, but it’s an entire ecology.

Dubberly suggests that venture capitalists won’t even put up money for stand-alone apps anymore. They’re looking for these types of platforms. Last December, the market valued Uber at $62 billion, and Wilcox noted that in mid-June, Uber raised another $26 billion in capital.

Why? Because, he suggests, Uber’s ultimate goal is to put UPS and Federal Express out of business. They intend eventually to get rid of their drivers and replace them with self-driving cars and drones. And this platform they’re creating will become the primary means of delivering goods, as well as transporting people. At least that’s their objective.

When Barbie talks back

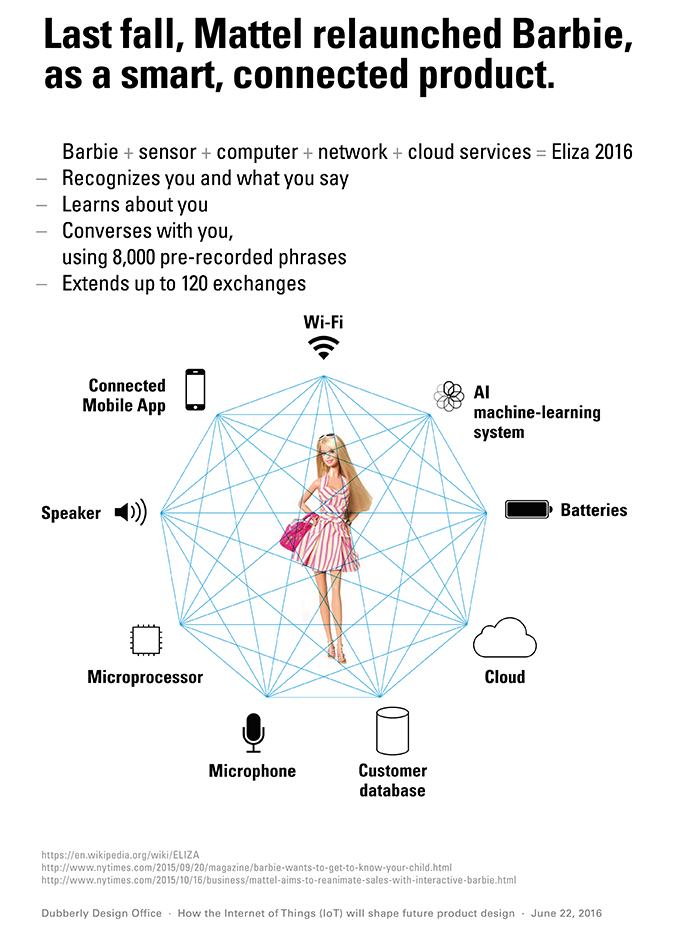

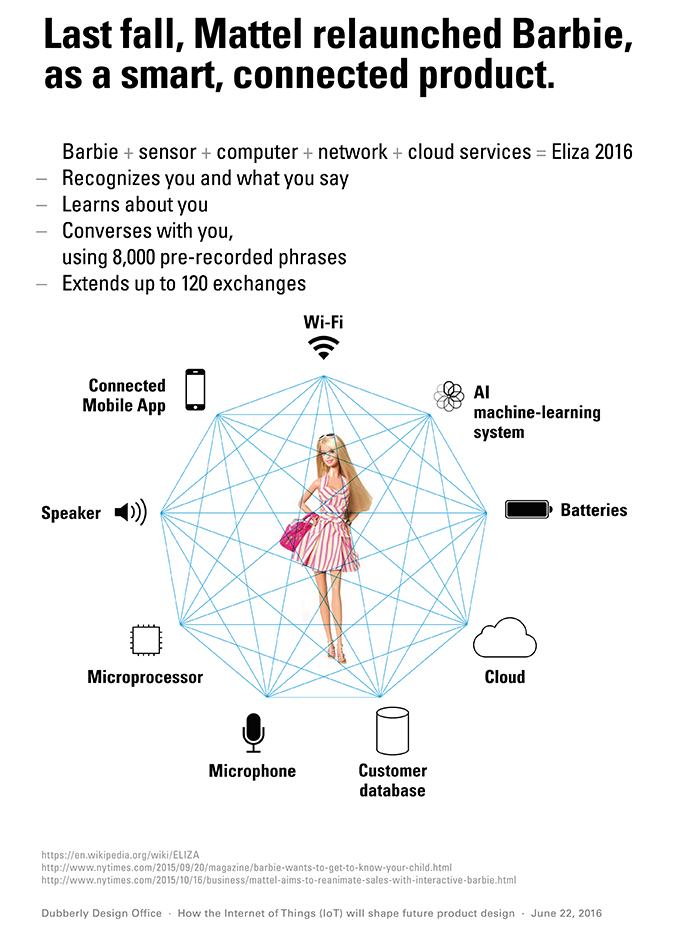

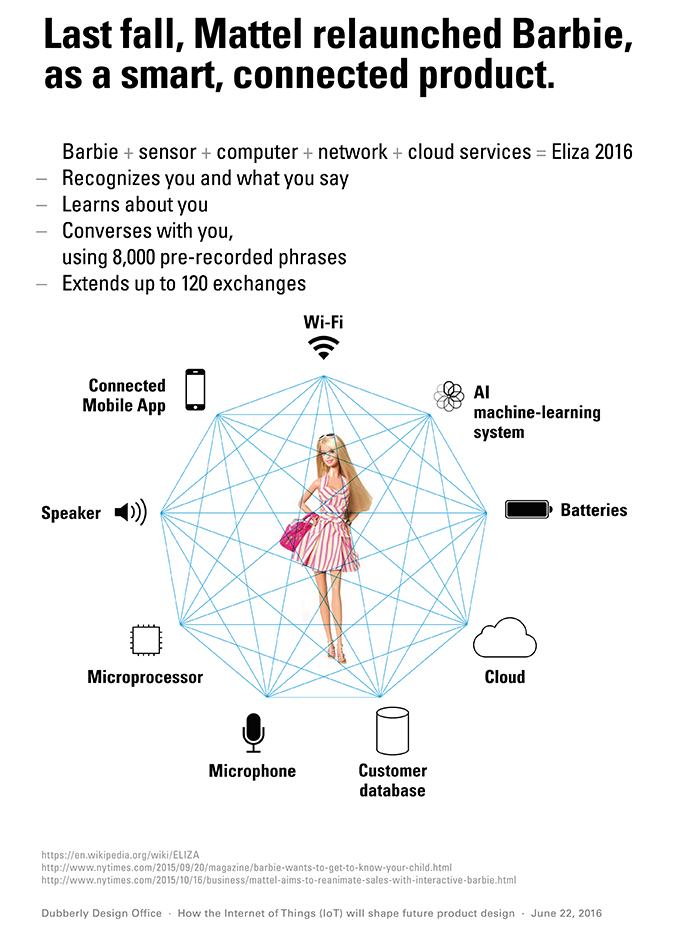

The Barbie doll, at a glance, would appear to be a classic example of a stand-alone product. Well, that is all changing, too.

Last fall, U.S. toymaker Mattel Inc. relaunched Barbie as a smart, connected product (see Fig. 3). She includes a sensor, and is connected to the cloud. She learns about you and your habits when you play with her, detects what you say to her (with machine learning) and can repeat something back, appropriately, using 8,000 pre-recorded phrases.

Figure 3. Image courtesy of Dubberly Design Office.

“If you connect Barbie with a CRM (customer relationship management) system,” Wilcox said, “you can imagine Barbie saying to its owner, ‘Mary, I see your birthday’s coming up soon, you know I have a little sister that I think would really be nice.’ Some of this is a little scary, but this is where we’re headed.”

CRM, he noted, has moved from being an outsourced service to being the core upon which businesses such as Uber are built. “They know where you are, they know what you need, and they send you things. The CRM is what you’ve got to sell.”

The pros and cons of Big Data

So all these sensors and interconnected smart products mean that brand owners and manufacturers now have access to a torrent of data about how customers use their products. What is one to do with all that information, and how will it impact future product design and development?

TEAMS Design USA CEO Paul Hatch has some strong views about this. Hatch, a Chicago-based British designer who 18 years ago launched the U.S. arm of Germany’s TEAMS Design, shared his thoughts in an interview at the recent Industrial Designers Society of America international conference in Detroit.

“The active groups in IoT at the moment tend to be the technologists and business deal-makers. There’s big money invested in this space. But designers and design engineers have a big opportunity that they’ve not yet grasped. From an industrial design standpoint, with IoT, we can get very intelligent, real-time data.”

Back in the 1980s, he noted, someone coined the phrase “garbage in, garbage out” as it relates to data management. And he sees the same thing happening today. Companies and brands are starting to collecting tons of data — but often with no plan or purpose. One of Hatch’s current missions is to drive the collection of quality data.

“What we’re measuring through the product is how it’s interacting with a human. What we get from that are insights into how someone is doing something, so that in the next version, we do it better, more efficiently. This allows us to create an MVP, or ‘minimally viable product’.” The aim is to strip away all the other features and functions that you could add to a product, and just focus on the core function, thereby saving cost and producing a better user experience.

“From an engineering standpoint,” Hatch said, “this makes a lot of sense. But how do we find out what that core functional ability is? IoT gives us that chance. Now we can track how people are actually using things.”

Take a connected kitchen blender as an example. When a person uses this device, or any smart device, the goal is to ensure they are having a good experience, since that generates better quality data.

Designing in user options

“To ensure we’re maximizing the experience,” explained Hatch, “we first of all should design the object using UX (user experience) design methods, which make the experience itself the focal point to all discussions during development and helps to provide a more user-centric result. Secondly, we want to provide options for the user, or customizability — that way, the user is making a choice in how they interact with the product and we can find out this preference, with tracking, and explore further with the next design.”

The owner of that data will gain insights and potential competitive advantages over those that don’t gather or properly analyze it.

Hatch suggests that creators of physical products take a page from the book of software developers and others in the user-interface world. But that requires a distinct change in mindset. Designers and brand owners should view their physical products as a beta version. It’s not sold as a beta, he stressed — it’s sold as a quality blender that’s going to make you a great smoothie.

But those involved with developing the product need to think of it as being just the first step on the way to creating the better blender.

“The thinking now is that we launch the best we can, under the constraints we have at the moment, and hopefully there will be another generation — perhaps with a different feature or two. But we don’t usually think of what we launch as being unfinished. It’s not that the consumer purchasing or using it should think of it as unfinished in any way, it’s just that we should put into it options that will tell us whether our hypotheses for the next version are correct or not.”

Think of it, Hatch urges, as a human experiment. “In essence, we’re doing a live experiment on 10,000 users. In that blender we should be including different ways of interacting with it — say, turning it on by lifting the lid, or by gesturing above it. And we can see if people stumble across those features, and start using them on a daily basis, or if they go back and forth.”

Additionally, he said, factor in the user demographics, to see, for example, if people over 50 like the traditional on/off switch, and if those under 20 prefer waving at the device or using an app to turn it on. “Then,” Hatch said, “we might learn that we need to make two different blenders, which will be intuitive for that demographic. We need to offer redundant options and features, because we need to find out preferences.”

Justifying the higher price

But, the engineering and marketing departments ask, won’t adding multiple features like this make the product more expensive?

Yes, says Hatch, and that creates a challenge, but one that is well worth striving to overcome. One is asking the consumer to pay more, he recognizes, when the ultimate beneficiary of these features is the company, via the data it collects, and not the user.

“We need to cover the additional cost by using design to create more value. You shouldn’t just make a blender and add a chip to it; you should change the experience. When this new blender comes to the market, it needs to clearly be different. It might be different physically — it might be modular, so you can follow up with an extra device that the customer can add to it later, like an upgrade. There is evidence that there’s demand for these more game-changing objects.”

Hatch acknowledges that it’s much easier to update software than hardware, but product developers need to start creating objects that have some potential adaptation built into them. “The true value isn’t on selling more Gen 1 blenders, the true value is in the data that you get from that Gen 1. It could even be a loss leader, because the value of that data is huge. Quality data is liquid gold.

“The whole thing is a very hard sell,” he admits. “We’re swimming upstream, and I’m telling people to swim upstream. It takes a lot more effort, and a lot more strategy.”

A majority of companies very likely will choose to float downstream instead. Their products may become cheaper and simpler and find a niche in the market. But the problem is that they’ll be part of the old system, and without intelligent monitoring of user habits, those companies soon will find themselves at a distinct market disadvantage, compared to their competitors.

A change in mindset required

All involved in adopting this new approach to product development must make some other changes, as well, according to Hatch. Designers and engineers now usually follow a given product right up until launch time, and then hand it off to the marketing and sales departments. But it’s no longer just about completing and launching a product, and then moving on. In many ways, in this new environment, the launch is just the beginning. The product lives on. A blender, for example, may be in use for the next three to five to 10 years, and continue to provide valuable user data through its lifetime.

“We may continue to supplement that product with additional features,” Hatch said, “and instead of saying goodbye to the product when it goes off the shelf, we continue the journey with that user. That’s a whole different mindset now.”

So, how will this trend impact those in the product-development trenches? Engineers and designers potentially can have the biggest impact when it comes to ensuring the product’s makers get quality data, according to Hatch. “They are the only ones in a position to straddle the divide between marketing and technology, to be able to bring the pieces together.”

Wilcox added: “I’m totally biased, but I’m very optimistic. … The designer’s the one, in this interdisciplinary society, who communicates with the marketing person and the engineer and the financial people, etc. Who else has that sort of broad education, and who else can illustrate other people’s ideas?

“So, maybe designers won’t be figuring out where the bosses are anymore — maybe that’ll be done automatically. But I think the designer’s role is going to remain central to this whole process.”

Dubberly, in a recent email interview, shared his views on this, as well.

“We will still need people to design individual products,” he said. “However, an increasing portion of products will also be smart and connected. That will create opportunities for designers and engineers to design and manage systems. Defining APIs (application program interfaces) and services will become increasingly important, as will taking a platform approach – creating systems on which others can build.

“Designers will move from almost exclusively designing physical artifacts,” Dubberly continued, “to also creating tools, services and situations that enable others to design. In a sense, the professional designer will become a meta-designer. And because feedback is so important, a crucial new role for designers will be designing feedback systems and determining what data their teams will need in order to improve products rapidly.”

Wilcox added: “As I see it, there’s a shift happening from the need for expertise on molding, air flow, etc., to the need for expertise on designing whole systems that are adaptive, that collect and use information, and on software, in general. I recommend a book called ‘The Zero Marginal Cost Society,’ by Jeremy Rifkin. It’s two years old now, but still quite remarkable in the way it puts all this into context.”

This shift, suggests Wilcox, “puts a premium on various flavors of systems engineering. To use an analogy, it’s the difference between a world where doctors are experts on specific parts of the body to a world where doctors are experts on the maintenance of health.”

Dubberly, meanwhile, noted that product development teams are growing and becoming more diverse. He says communication and facilitation skills are becoming more important than ever, along with skills in data analytics, machine learning and data visualization.

He sees the relationship that designers have with the people who use their products changing, as well. “In many ways, an industrial-era designer had little choice other than to send products into the world and hope they did well. This was a one-way, broadcast model; feedback was minimal and infrequent. Information-era designers are increasingly establishing conversations with customers. Web-based applications receive feedback continuously every day, (e.g., information about what buttons customers click).

“Smart connected products are very similar,” he added. “Continuous feedback means continuous change and optimization — Google’s continuous beta will become more common in hardware. This means designers will increasingly be concerned about designing conversations with customers.”

Companies need to adapt to the changes being wrought by the IoT, Wilcox noted.

“I work mainly on medical devices,” he said. “Even my clients who make simple, ordinary stuff like syringes and auto-injectors, they’re all struggling to adapt to this new world. Syringes are being designed so that, when it’s used, it sends a signal so your healthcare professional knows exactly when you used that device. So now we have a database that both the doctor and the patient have access to.

“We started off by designing a syringe. Now that syringe has become an interface for the patient, an interface for the healthcare professional, and a database in the cloud, often accessed on a cell phone.”

This whole complex network requires a different skill set and a different infrastructure. “My clients are seeing that they can’t stay in the basic syringe business, even if they want to, because how can you compete when your competitor now has an adaptive system that tells him about compliance, does automatic billing, etc.? You just can’t sell a stand-alone product,” he said.

“The Internet of Things signals a larger cultural shift,” Wilcox and Dubberly suggest — “from the Industrial Age to the Information Age, and a corresponding shift in the nature of products, from the design of objects, to the design of adaptive systems orchestrating experiences.”

How do you think the IoT will change future product development and the role of the engineer? Tell us in The Chain at: http://bit.ly/future_product_design

Ecosystems, IoT & the Future of Product Design

The rise of smart devices is reshaping how products are being developed

Previous Article Next Article

By Robert Grace

The Internet already has revolutionized just about everything — how we communicate, shop, travel, consume entertainment, and more. Now it is about to reshape how we design and develop products. And anyone involved in that process will be affected.

What’s driving this change? In a phrase — the Internet of Things. The IoT is the digital, wireless network that increasingly is interconnecting devices, machinery and humans, and making “dumb” products “smart” and connected. This is creating vast new opportunities for brand owners and product developers to learn about how people actually use their products in real time, and adapt future designs accordingly.

Cisco Internet Business Solutions Group has predicted that by 2020 some 50 billion devices – including phones, computers, appliances, vehicles and various types of machines — will be digitally connected to the Internet (see Figure 1).

Figure 1. Sources: The Economist and Cisco (image courtesy of Dubberly Design Office)

From a design perspective, these so-called smart devices and other consumer goods will need to continue to be stylish, safe, powerful, durable, cost-effective, miniaturized and sustainable – often all at the same time. But they also will eventually cease to stand alone. They are becoming part of a platform or system, and eventually of a “system of systems,” which is changing everything.

That means, explains Stephen B. Wilcox, founder and principal of the Philadelphia-based consultancy Design Science, that, “As designers, we’re no longer going to be designing products; we’re going to be designing adaptive systems. That means systems that have been designed from the beginning to naturally change as a function of data received from the users.”

Wilcox spoke in detail about these trends in his June 22 presentation at the inaugural SPE Design in Plastics 2016 conference (www.4spe.org/designinplastics), held at the Rhode Island School of Design in Providence. He gave credit for much of the information in his talk to his partner Hugh Dubberly, a former Apple manager who now is principal of his own consultancy, Dubberly Design Office, in San Francisco.

“We start with a product and we end up with a ‘system of systems’,” Wilcox continued. “Services are connecting to integrated systems, forming ‘product service ecologies’ — networks of products, services, people and their interaction.” Let’s look at some real-life examples.

Plowing fertile new ground

Early farming implements were pulled by horses, and then power was built into the tractor. More recently, tractors began adding “intelligence,” in the form of embedded microchips. Citing a 2014 Harvard Business Review article by Harvard professor and economist Michael E. Porter, Wilcox referred to what has now become a farm equipment system. The new generation of tractors incorporates sensors and wi-fi and is interconnected via the cloud to the tiller, to the harvester, to the planter — which allows the farmer to start making intelligent decisions (see Fig. 2).

Figure 2. Sources: Michael Porter and Harvard Business Review (image courtesy of Dubberly Design Office)

“The type of furrow that you plow with the tractor determines a setting in the planter, and you don’t have to do this anymore by brute force. Those settings are automatic, because the various devices are connected to each other. Now the harvester knows when the planter planted the seeds, etc.

“The next step, and we’re not there yet,” Wilcox noted, “but this is what we’re predicting: Take that complex farm equipment system, and connect that to other complex systems, so now you have a system of systems. You have a weather system that sends data that helps you to make decisions about when you harvest. You have an irrigation system that is impacted by what you planted, a seed optimization system, and so forth.”

Take, for example, modern vineyards, he said. Sensors attached to each grapevine detect temperature and humidity. Data is transmitted from the vines to a repeater, and then to the cloud. The winemaker now has a database, which allows him or her to do microharvesting, and to know exactly when to harvest each individual vine. This is happening now, Wilcox noted.

Rolling down the highway, intelligently

There are 60-100 sensors in the typical consumer automobile, Wilcox said, and that’s expected to double in the next few years. There are, on average, 30 microprocessors in your automobile; some have as many as 100, and the number is constantly increasing.

When those sensors are connected to the Internet, you have a “smart, connected” vehicle. This intelligence allows you to optimize fuel use, braking and the like. You can gather and store data, take external input of data, and communicate what’s happening with that device to other sources.

And speaking of driving — consider Uber. The ride-sharing service is a great example of platform, and a disruptive technology. You may think of it primarily as an app on your smartphone, but it’s an entire ecology.

Dubberly suggests that venture capitalists won’t even put up money for stand-alone apps anymore. They’re looking for these types of platforms. Last December, the market valued Uber at $62 billion, and Wilcox noted that in mid-June, Uber raised another $26 billion in capital.

Why? Because, he suggests, Uber’s ultimate goal is to put UPS and Federal Express out of business. They intend eventually to get rid of their drivers and replace them with self-driving cars and drones. And this platform they’re creating will become the primary means of delivering goods, as well as transporting people. At least that’s their objective.

When Barbie talks back

The Barbie doll, at a glance, would appear to be a classic example of a stand-alone product. Well, that is all changing, too.

Last fall, U.S. toymaker Mattel Inc. relaunched Barbie as a smart, connected product (see Fig. 3). She includes a sensor, and is connected to the cloud. She learns about you and your habits when you play with her, detects what you say to her (with machine learning) and can repeat something back, appropriately, using 8,000 pre-recorded phrases.

Figure 3. Image courtesy of Dubberly Design Office.

“If you connect Barbie with a CRM (customer relationship management) system,” Wilcox said, “you can imagine Barbie saying to its owner, ‘Mary, I see your birthday’s coming up soon, you know I have a little sister that I think would really be nice.’ Some of this is a little scary, but this is where we’re headed.”

CRM, he noted, has moved from being an outsourced service to being the core upon which businesses such as Uber are built. “They know where you are, they know what you need, and they send you things. The CRM is what you’ve got to sell.”

The pros and cons of Big Data

So all these sensors and interconnected smart products mean that brand owners and manufacturers now have access to a torrent of data about how customers use their products. What is one to do with all that information, and how will it impact future product design and development?

TEAMS Design USA CEO Paul Hatch has some strong views about this. Hatch, a Chicago-based British designer who 18 years ago launched the U.S. arm of Germany’s TEAMS Design, shared his thoughts in an interview at the recent Industrial Designers Society of America international conference in Detroit.

“The active groups in IoT at the moment tend to be the technologists and business deal-makers. There’s big money invested in this space. But designers and design engineers have a big opportunity that they’ve not yet grasped. From an industrial design standpoint, with IoT, we can get very intelligent, real-time data.”

Back in the 1980s, he noted, someone coined the phrase “garbage in, garbage out” as it relates to data management. And he sees the same thing happening today. Companies and brands are starting to collecting tons of data — but often with no plan or purpose. One of Hatch’s current missions is to drive the collection of quality data.

“What we’re measuring through the product is how it’s interacting with a human. What we get from that are insights into how someone is doing something, so that in the next version, we do it better, more efficiently. This allows us to create an MVP, or ‘minimally viable product’.” The aim is to strip away all the other features and functions that you could add to a product, and just focus on the core function, thereby saving cost and producing a better user experience.

“From an engineering standpoint,” Hatch said, “this makes a lot of sense. But how do we find out what that core functional ability is? IoT gives us that chance. Now we can track how people are actually using things.”

Take a connected kitchen blender as an example. When a person uses this device, or any smart device, the goal is to ensure they are having a good experience, since that generates better quality data.

Designing in user options

“To ensure we’re maximizing the experience,” explained Hatch, “we first of all should design the object using UX (user experience) design methods, which make the experience itself the focal point to all discussions during development and helps to provide a more user-centric result. Secondly, we want to provide options for the user, or customizability — that way, the user is making a choice in how they interact with the product and we can find out this preference, with tracking, and explore further with the next design.”

The owner of that data will gain insights and potential competitive advantages over those that don’t gather or properly analyze it.

Hatch suggests that creators of physical products take a page from the book of software developers and others in the user-interface world. But that requires a distinct change in mindset. Designers and brand owners should view their physical products as a beta version. It’s not sold as a beta, he stressed — it’s sold as a quality blender that’s going to make you a great smoothie.

But those involved with developing the product need to think of it as being just the first step on the way to creating the better blender.

“The thinking now is that we launch the best we can, under the constraints we have at the moment, and hopefully there will be another generation — perhaps with a different feature or two. But we don’t usually think of what we launch as being unfinished. It’s not that the consumer purchasing or using it should think of it as unfinished in any way, it’s just that we should put into it options that will tell us whether our hypotheses for the next version are correct or not.”

Think of it, Hatch urges, as a human experiment. “In essence, we’re doing a live experiment on 10,000 users. In that blender we should be including different ways of interacting with it — say, turning it on by lifting the lid, or by gesturing above it. And we can see if people stumble across those features, and start using them on a daily basis, or if they go back and forth.”

Additionally, he said, factor in the user demographics, to see, for example, if people over 50 like the traditional on/off switch, and if those under 20 prefer waving at the device or using an app to turn it on. “Then,” Hatch said, “we might learn that we need to make two different blenders, which will be intuitive for that demographic. We need to offer redundant options and features, because we need to find out preferences.”

Justifying the higher price

But, the engineering and marketing departments ask, won’t adding multiple features like this make the product more expensive?

Yes, says Hatch, and that creates a challenge, but one that is well worth striving to overcome. One is asking the consumer to pay more, he recognizes, when the ultimate beneficiary of these features is the company, via the data it collects, and not the user.

“We need to cover the additional cost by using design to create more value. You shouldn’t just make a blender and add a chip to it; you should change the experience. When this new blender comes to the market, it needs to clearly be different. It might be different physically — it might be modular, so you can follow up with an extra device that the customer can add to it later, like an upgrade. There is evidence that there’s demand for these more game-changing objects.”

Hatch acknowledges that it’s much easier to update software than hardware, but product developers need to start creating objects that have some potential adaptation built into them. “The true value isn’t on selling more Gen 1 blenders, the true value is in the data that you get from that Gen 1. It could even be a loss leader, because the value of that data is huge. Quality data is liquid gold.

“The whole thing is a very hard sell,” he admits. “We’re swimming upstream, and I’m telling people to swim upstream. It takes a lot more effort, and a lot more strategy.”

A majority of companies very likely will choose to float downstream instead. Their products may become cheaper and simpler and find a niche in the market. But the problem is that they’ll be part of the old system, and without intelligent monitoring of user habits, those companies soon will find themselves at a distinct market disadvantage, compared to their competitors.

A change in mindset required

All involved in adopting this new approach to product development must make some other changes, as well, according to Hatch. Designers and engineers now usually follow a given product right up until launch time, and then hand it off to the marketing and sales departments. But it’s no longer just about completing and launching a product, and then moving on. In many ways, in this new environment, the launch is just the beginning. The product lives on. A blender, for example, may be in use for the next three to five to 10 years, and continue to provide valuable user data through its lifetime.

“We may continue to supplement that product with additional features,” Hatch said, “and instead of saying goodbye to the product when it goes off the shelf, we continue the journey with that user. That’s a whole different mindset now.”

So, how will this trend impact those in the product-development trenches? Engineers and designers potentially can have the biggest impact when it comes to ensuring the product’s makers get quality data, according to Hatch. “They are the only ones in a position to straddle the divide between marketing and technology, to be able to bring the pieces together.”

Wilcox added: “I’m totally biased, but I’m very optimistic. … The designer’s the one, in this interdisciplinary society, who communicates with the marketing person and the engineer and the financial people, etc. Who else has that sort of broad education, and who else can illustrate other people’s ideas?

“So, maybe designers won’t be figuring out where the bosses are anymore — maybe that’ll be done automatically. But I think the designer’s role is going to remain central to this whole process.”

Dubberly, in a recent email interview, shared his views on this, as well.

“We will still need people to design individual products,” he said. “However, an increasing portion of products will also be smart and connected. That will create opportunities for designers and engineers to design and manage systems. Defining APIs (application program interfaces) and services will become increasingly important, as will taking a platform approach – creating systems on which others can build.

“Designers will move from almost exclusively designing physical artifacts,” Dubberly continued, “to also creating tools, services and situations that enable others to design. In a sense, the professional designer will become a meta-designer. And because feedback is so important, a crucial new role for designers will be designing feedback systems and determining what data their teams will need in order to improve products rapidly.”

Wilcox added: “As I see it, there’s a shift happening from the need for expertise on molding, air flow, etc., to the need for expertise on designing whole systems that are adaptive, that collect and use information, and on software, in general. I recommend a book called ‘The Zero Marginal Cost Society,’ by Jeremy Rifkin. It’s two years old now, but still quite remarkable in the way it puts all this into context.”

This shift, suggests Wilcox, “puts a premium on various flavors of systems engineering. To use an analogy, it’s the difference between a world where doctors are experts on specific parts of the body to a world where doctors are experts on the maintenance of health.”

Dubberly, meanwhile, noted that product development teams are growing and becoming more diverse. He says communication and facilitation skills are becoming more important than ever, along with skills in data analytics, machine learning and data visualization.

He sees the relationship that designers have with the people who use their products changing, as well. “In many ways, an industrial-era designer had little choice other than to send products into the world and hope they did well. This was a one-way, broadcast model; feedback was minimal and infrequent. Information-era designers are increasingly establishing conversations with customers. Web-based applications receive feedback continuously every day, (e.g., information about what buttons customers click).

“Smart connected products are very similar,” he added. “Continuous feedback means continuous change and optimization — Google’s continuous beta will become more common in hardware. This means designers will increasingly be concerned about designing conversations with customers.”

Companies need to adapt to the changes being wrought by the IoT, Wilcox noted.

“I work mainly on medical devices,” he said. “Even my clients who make simple, ordinary stuff like syringes and auto-injectors, they’re all struggling to adapt to this new world. Syringes are being designed so that, when it’s used, it sends a signal so your healthcare professional knows exactly when you used that device. So now we have a database that both the doctor and the patient have access to.

“We started off by designing a syringe. Now that syringe has become an interface for the patient, an interface for the healthcare professional, and a database in the cloud, often accessed on a cell phone.”

This whole complex network requires a different skill set and a different infrastructure. “My clients are seeing that they can’t stay in the basic syringe business, even if they want to, because how can you compete when your competitor now has an adaptive system that tells him about compliance, does automatic billing, etc.? You just can’t sell a stand-alone product,” he said.

“The Internet of Things signals a larger cultural shift,” Wilcox and Dubberly suggest — “from the Industrial Age to the Information Age, and a corresponding shift in the nature of products, from the design of objects, to the design of adaptive systems orchestrating experiences.”

How do you think the IoT will change future product development and the role of the engineer? Tell us in The Chain at: http://bit.ly/future_product_design

Ecosystems, IoT & the Future of Product Design

The rise of smart devices is reshaping how products are being developed

Previous Article Next Article

By Robert Grace

The Internet already has revolutionized just about everything — how we communicate, shop, travel, consume entertainment, and more. Now it is about to reshape how we design and develop products. And anyone involved in that process will be affected.

What’s driving this change? In a phrase — the Internet of Things. The IoT is the digital, wireless network that increasingly is interconnecting devices, machinery and humans, and making “dumb” products “smart” and connected. This is creating vast new opportunities for brand owners and product developers to learn about how people actually use their products in real time, and adapt future designs accordingly.

Cisco Internet Business Solutions Group has predicted that by 2020 some 50 billion devices – including phones, computers, appliances, vehicles and various types of machines — will be digitally connected to the Internet (see Figure 1).

Figure 1. Sources: The Economist and Cisco (image courtesy of Dubberly Design Office)

From a design perspective, these so-called smart devices and other consumer goods will need to continue to be stylish, safe, powerful, durable, cost-effective, miniaturized and sustainable – often all at the same time. But they also will eventually cease to stand alone. They are becoming part of a platform or system, and eventually of a “system of systems,” which is changing everything.

That means, explains Stephen B. Wilcox, founder and principal of the Philadelphia-based consultancy Design Science, that, “As designers, we’re no longer going to be designing products; we’re going to be designing adaptive systems. That means systems that have been designed from the beginning to naturally change as a function of data received from the users.”

Wilcox spoke in detail about these trends in his June 22 presentation at the inaugural SPE Design in Plastics 2016 conference (www.4spe.org/designinplastics), held at the Rhode Island School of Design in Providence. He gave credit for much of the information in his talk to his partner Hugh Dubberly, a former Apple manager who now is principal of his own consultancy, Dubberly Design Office, in San Francisco.

“We start with a product and we end up with a ‘system of systems’,” Wilcox continued. “Services are connecting to integrated systems, forming ‘product service ecologies’ — networks of products, services, people and their interaction.” Let’s look at some real-life examples.

Plowing fertile new ground

Early farming implements were pulled by horses, and then power was built into the tractor. More recently, tractors began adding “intelligence,” in the form of embedded microchips. Citing a 2014 Harvard Business Review article by Harvard professor and economist Michael E. Porter, Wilcox referred to what has now become a farm equipment system. The new generation of tractors incorporates sensors and wi-fi and is interconnected via the cloud to the tiller, to the harvester, to the planter — which allows the farmer to start making intelligent decisions (see Fig. 2).

Figure 2. Sources: Michael Porter and Harvard Business Review (image courtesy of Dubberly Design Office)

“The type of furrow that you plow with the tractor determines a setting in the planter, and you don’t have to do this anymore by brute force. Those settings are automatic, because the various devices are connected to each other. Now the harvester knows when the planter planted the seeds, etc.

“The next step, and we’re not there yet,” Wilcox noted, “but this is what we’re predicting: Take that complex farm equipment system, and connect that to other complex systems, so now you have a system of systems. You have a weather system that sends data that helps you to make decisions about when you harvest. You have an irrigation system that is impacted by what you planted, a seed optimization system, and so forth.”

Take, for example, modern vineyards, he said. Sensors attached to each grapevine detect temperature and humidity. Data is transmitted from the vines to a repeater, and then to the cloud. The winemaker now has a database, which allows him or her to do microharvesting, and to know exactly when to harvest each individual vine. This is happening now, Wilcox noted.

Rolling down the highway, intelligently

There are 60-100 sensors in the typical consumer automobile, Wilcox said, and that’s expected to double in the next few years. There are, on average, 30 microprocessors in your automobile; some have as many as 100, and the number is constantly increasing.

When those sensors are connected to the Internet, you have a “smart, connected” vehicle. This intelligence allows you to optimize fuel use, braking and the like. You can gather and store data, take external input of data, and communicate what’s happening with that device to other sources.

And speaking of driving — consider Uber. The ride-sharing service is a great example of platform, and a disruptive technology. You may think of it primarily as an app on your smartphone, but it’s an entire ecology.

Dubberly suggests that venture capitalists won’t even put up money for stand-alone apps anymore. They’re looking for these types of platforms. Last December, the market valued Uber at $62 billion, and Wilcox noted that in mid-June, Uber raised another $26 billion in capital.

Why? Because, he suggests, Uber’s ultimate goal is to put UPS and Federal Express out of business. They intend eventually to get rid of their drivers and replace them with self-driving cars and drones. And this platform they’re creating will become the primary means of delivering goods, as well as transporting people. At least that’s their objective.

When Barbie talks back

The Barbie doll, at a glance, would appear to be a classic example of a stand-alone product. Well, that is all changing, too.

Last fall, U.S. toymaker Mattel Inc. relaunched Barbie as a smart, connected product (see Fig. 3). She includes a sensor, and is connected to the cloud. She learns about you and your habits when you play with her, detects what you say to her (with machine learning) and can repeat something back, appropriately, using 8,000 pre-recorded phrases.

Figure 3. Image courtesy of Dubberly Design Office.

“If you connect Barbie with a CRM (customer relationship management) system,” Wilcox said, “you can imagine Barbie saying to its owner, ‘Mary, I see your birthday’s coming up soon, you know I have a little sister that I think would really be nice.’ Some of this is a little scary, but this is where we’re headed.”

CRM, he noted, has moved from being an outsourced service to being the core upon which businesses such as Uber are built. “They know where you are, they know what you need, and they send you things. The CRM is what you’ve got to sell.”

The pros and cons of Big Data

So all these sensors and interconnected smart products mean that brand owners and manufacturers now have access to a torrent of data about how customers use their products. What is one to do with all that information, and how will it impact future product design and development?

TEAMS Design USA CEO Paul Hatch has some strong views about this. Hatch, a Chicago-based British designer who 18 years ago launched the U.S. arm of Germany’s TEAMS Design, shared his thoughts in an interview at the recent Industrial Designers Society of America international conference in Detroit.

“The active groups in IoT at the moment tend to be the technologists and business deal-makers. There’s big money invested in this space. But designers and design engineers have a big opportunity that they’ve not yet grasped. From an industrial design standpoint, with IoT, we can get very intelligent, real-time data.”

Back in the 1980s, he noted, someone coined the phrase “garbage in, garbage out” as it relates to data management. And he sees the same thing happening today. Companies and brands are starting to collecting tons of data — but often with no plan or purpose. One of Hatch’s current missions is to drive the collection of quality data.

“What we’re measuring through the product is how it’s interacting with a human. What we get from that are insights into how someone is doing something, so that in the next version, we do it better, more efficiently. This allows us to create an MVP, or ‘minimally viable product’.” The aim is to strip away all the other features and functions that you could add to a product, and just focus on the core function, thereby saving cost and producing a better user experience.

“From an engineering standpoint,” Hatch said, “this makes a lot of sense. But how do we find out what that core functional ability is? IoT gives us that chance. Now we can track how people are actually using things.”

Take a connected kitchen blender as an example. When a person uses this device, or any smart device, the goal is to ensure they are having a good experience, since that generates better quality data.

Designing in user options

“To ensure we’re maximizing the experience,” explained Hatch, “we first of all should design the object using UX (user experience) design methods, which make the experience itself the focal point to all discussions during development and helps to provide a more user-centric result. Secondly, we want to provide options for the user, or customizability — that way, the user is making a choice in how they interact with the product and we can find out this preference, with tracking, and explore further with the next design.”

The owner of that data will gain insights and potential competitive advantages over those that don’t gather or properly analyze it.

Hatch suggests that creators of physical products take a page from the book of software developers and others in the user-interface world. But that requires a distinct change in mindset. Designers and brand owners should view their physical products as a beta version. It’s not sold as a beta, he stressed — it’s sold as a quality blender that’s going to make you a great smoothie.

But those involved with developing the product need to think of it as being just the first step on the way to creating the better blender.

“The thinking now is that we launch the best we can, under the constraints we have at the moment, and hopefully there will be another generation — perhaps with a different feature or two. But we don’t usually think of what we launch as being unfinished. It’s not that the consumer purchasing or using it should think of it as unfinished in any way, it’s just that we should put into it options that will tell us whether our hypotheses for the next version are correct or not.”

Think of it, Hatch urges, as a human experiment. “In essence, we’re doing a live experiment on 10,000 users. In that blender we should be including different ways of interacting with it — say, turning it on by lifting the lid, or by gesturing above it. And we can see if people stumble across those features, and start using them on a daily basis, or if they go back and forth.”

Additionally, he said, factor in the user demographics, to see, for example, if people over 50 like the traditional on/off switch, and if those under 20 prefer waving at the device or using an app to turn it on. “Then,” Hatch said, “we might learn that we need to make two different blenders, which will be intuitive for that demographic. We need to offer redundant options and features, because we need to find out preferences.”

Justifying the higher price

But, the engineering and marketing departments ask, won’t adding multiple features like this make the product more expensive?

Yes, says Hatch, and that creates a challenge, but one that is well worth striving to overcome. One is asking the consumer to pay more, he recognizes, when the ultimate beneficiary of these features is the company, via the data it collects, and not the user.

“We need to cover the additional cost by using design to create more value. You shouldn’t just make a blender and add a chip to it; you should change the experience. When this new blender comes to the market, it needs to clearly be different. It might be different physically — it might be modular, so you can follow up with an extra device that the customer can add to it later, like an upgrade. There is evidence that there’s demand for these more game-changing objects.”

Hatch acknowledges that it’s much easier to update software than hardware, but product developers need to start creating objects that have some potential adaptation built into them. “The true value isn’t on selling more Gen 1 blenders, the true value is in the data that you get from that Gen 1. It could even be a loss leader, because the value of that data is huge. Quality data is liquid gold.

“The whole thing is a very hard sell,” he admits. “We’re swimming upstream, and I’m telling people to swim upstream. It takes a lot more effort, and a lot more strategy.”

A majority of companies very likely will choose to float downstream instead. Their products may become cheaper and simpler and find a niche in the market. But the problem is that they’ll be part of the old system, and without intelligent monitoring of user habits, those companies soon will find themselves at a distinct market disadvantage, compared to their competitors.

A change in mindset required

All involved in adopting this new approach to product development must make some other changes, as well, according to Hatch. Designers and engineers now usually follow a given product right up until launch time, and then hand it off to the marketing and sales departments. But it’s no longer just about completing and launching a product, and then moving on. In many ways, in this new environment, the launch is just the beginning. The product lives on. A blender, for example, may be in use for the next three to five to 10 years, and continue to provide valuable user data through its lifetime.

“We may continue to supplement that product with additional features,” Hatch said, “and instead of saying goodbye to the product when it goes off the shelf, we continue the journey with that user. That’s a whole different mindset now.”

So, how will this trend impact those in the product-development trenches? Engineers and designers potentially can have the biggest impact when it comes to ensuring the product’s makers get quality data, according to Hatch. “They are the only ones in a position to straddle the divide between marketing and technology, to be able to bring the pieces together.”

Wilcox added: “I’m totally biased, but I’m very optimistic. … The designer’s the one, in this interdisciplinary society, who communicates with the marketing person and the engineer and the financial people, etc. Who else has that sort of broad education, and who else can illustrate other people’s ideas?

“So, maybe designers won’t be figuring out where the bosses are anymore — maybe that’ll be done automatically. But I think the designer’s role is going to remain central to this whole process.”

Dubberly, in a recent email interview, shared his views on this, as well.

“We will still need people to design individual products,” he said. “However, an increasing portion of products will also be smart and connected. That will create opportunities for designers and engineers to design and manage systems. Defining APIs (application program interfaces) and services will become increasingly important, as will taking a platform approach – creating systems on which others can build.

“Designers will move from almost exclusively designing physical artifacts,” Dubberly continued, “to also creating tools, services and situations that enable others to design. In a sense, the professional designer will become a meta-designer. And because feedback is so important, a crucial new role for designers will be designing feedback systems and determining what data their teams will need in order to improve products rapidly.”

Wilcox added: “As I see it, there’s a shift happening from the need for expertise on molding, air flow, etc., to the need for expertise on designing whole systems that are adaptive, that collect and use information, and on software, in general. I recommend a book called ‘The Zero Marginal Cost Society,’ by Jeremy Rifkin. It’s two years old now, but still quite remarkable in the way it puts all this into context.”

This shift, suggests Wilcox, “puts a premium on various flavors of systems engineering. To use an analogy, it’s the difference between a world where doctors are experts on specific parts of the body to a world where doctors are experts on the maintenance of health.”

Dubberly, meanwhile, noted that product development teams are growing and becoming more diverse. He says communication and facilitation skills are becoming more important than ever, along with skills in data analytics, machine learning and data visualization.

He sees the relationship that designers have with the people who use their products changing, as well. “In many ways, an industrial-era designer had little choice other than to send products into the world and hope they did well. This was a one-way, broadcast model; feedback was minimal and infrequent. Information-era designers are increasingly establishing conversations with customers. Web-based applications receive feedback continuously every day, (e.g., information about what buttons customers click).

“Smart connected products are very similar,” he added. “Continuous feedback means continuous change and optimization — Google’s continuous beta will become more common in hardware. This means designers will increasingly be concerned about designing conversations with customers.”

Companies need to adapt to the changes being wrought by the IoT, Wilcox noted.

“I work mainly on medical devices,” he said. “Even my clients who make simple, ordinary stuff like syringes and auto-injectors, they’re all struggling to adapt to this new world. Syringes are being designed so that, when it’s used, it sends a signal so your healthcare professional knows exactly when you used that device. So now we have a database that both the doctor and the patient have access to.

“We started off by designing a syringe. Now that syringe has become an interface for the patient, an interface for the healthcare professional, and a database in the cloud, often accessed on a cell phone.”

This whole complex network requires a different skill set and a different infrastructure. “My clients are seeing that they can’t stay in the basic syringe business, even if they want to, because how can you compete when your competitor now has an adaptive system that tells him about compliance, does automatic billing, etc.? You just can’t sell a stand-alone product,” he said.

“The Internet of Things signals a larger cultural shift,” Wilcox and Dubberly suggest — “from the Industrial Age to the Information Age, and a corresponding shift in the nature of products, from the design of objects, to the design of adaptive systems orchestrating experiences.”