Breakthroughs for Creating New Designs with Modern TPEs

With the right design and processing guidelines, new thermoplastic elastomers can take on more challenging applications

Previous Article Next Article

By Rob Banning

Breakthroughs for Creating New Designs with Modern TPEs

With the right design and processing guidelines, new thermoplastic elastomers can take on more challenging applications

Previous Article Next Article

By Rob Banning

Breakthroughs for Creating New Designs with Modern TPEs

With the right design and processing guidelines, new thermoplastic elastomers can take on more challenging applications

Previous Article Next Article

By Rob Banning

TPE cable grommets provide flexible seals to protect wire and automotive electronics in a car body. They offer high flexibility and good mechanical properties over a wide temperature range; excellent resistance to ozone and weathering; fast, cost-effective processing over competitive products; and excellent adhesion with conventional hard components. (Photo courtesy of Polymax Thermoplastic Elastomers.)

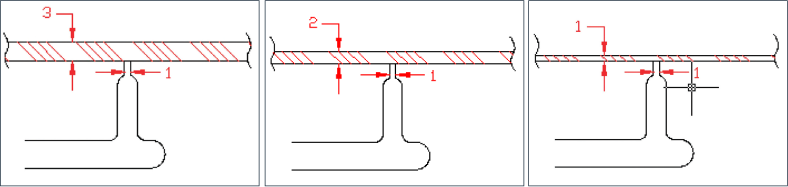

Three examples of gating to achieve flow with low-viscosity materials: Left, gate diameter 1/5 to 1/3 of wall thickness; center, gate appropriate only for most viscous TPEs (like conventional TPUs); and right, gate far too large (for all TPEs).

The medical industry provides many excellent examples of the use of specialty TPEs as alternatives to traditional materials. For example, medical grade TPEs in plunger seals are alternatives to rubber seals in single-use syringes. The seal helps to optimize plunger movement for accurate dosage control and ease of injection. (Photo courtesy of Polymax Thermoplastic Elastomers.)

[Ed. note: The following continues a series of expert-authored articles written exclusively for PE; for additional questions and guidance about this topic, contact the consultant-author directly using the information at the end of the article.]

The universe of thermoplastic elastomers (TPEs) usage among product end-users and custom thermoplastic processors has continued to grow steadily over the past 35 years. Today, custom processors are focusing sales efforts to raise TPE component value (and resulting profits) through new designs and new material combinations, to solve problems and improve the final components’ aesthetics and performance.

As processors and end-users continue to collaborate effectively in solving OEM challenges, the range of truly new TPEs for new products has steadily expanded the performance envelope. The specific uses of carefully selected TPEs, including proper finished product design, best tooling details, and appropriate material combinations, provide a platform for success for new molded and extruded components.

The range of component solutions using modern TPEs as a key element has continued to expand, especially through effective use of:

- insert and two-shot injection molding;

- co- and tri-extruded profiles; and

- dual-layer integral extrusion blow molded goods.

These three methods are the focus of this article. As we begin to explore how to most effectively combine TPEs with commodity and engineering thermoplastics, a very brief review of the performance range of modern TPE compounds is also offered.

The Expanding TPE Universe

Today, new specific TPE compounds can offer the following range of elastomeric performance to expand the value of new designs for finished components:

- effective heat aging up to 150°C for hose, automotive, and industrial components;

- peak temperature performance up to 163°C for short-term exposure in low-stress molded and extruded components;

- reliable low compression set and stress relaxation in seals and gaskets, for performance up to 100°C in continuous use;

- bond strength greater than 20 lb./linear inch (3.6 kg/cm) in more than 15 specific alternative thermoplastic/TPE combinations, in substrates for two-layer co-processing for extruded and molded articles;

- outstanding colorability and UV stability of TPE compounds, as proven in a broad variety of automotive, consumer, and building and construction industry components over the past two decades; and

- reliable high tear strength, especially in modern copolyester (COPE), thermoplastic polyurethane (TPU), and highly customized styrenic block copolymer (SBC) TPE alloys for components with high toughness requirements.

- And for components requiring an excellent range of chemical resistance, proper selection among TPU, thermoplastic vulcanizate (TPV), and COPE TPEs will fill this requirement.

The above list is clearly not comprehensive, but it provides a brief overview of available component performance, as TPEs have passed the annual sales volume of $5.2 billion worldwide.

Key Questions When Considering TPEs

End-users typically drive trends and specific component needs and requirements, and answering the following seven key questions can help provide options in using a selected TPE in a new finished article, relative to the integrated thermoplastic process techniques:

1. What is the available geometry to drive higher bond levels between the TPE compound and thermoplastic substrate? Increased surface area can raise the total strength between the elastomer and plastic sections in the component.

2. What are the most important design aspects for insert and two-shot molding? They include:

- the best gating location for the individual part and tool design;

- proper TPE selection for optimum bonding to the substrate;

- using mechanical interlocks between the plastic substrate and TPE sections to increase total bonding area;

- proper process control for the selected TPE (especially management of shear rate in the first stage pressure);

- avoiding long TPE flow paths with L/T ratios exceeding 150:1; and

- selecting optimum molding and tooling process to match the part volume requirements.

3. What are the peak temperatures the final molded component must endure? The TPE and thermoplastic should be selected as a combined pair to ensure proper peak heat capability and long-term heat aging in applications requiring high-temperature durability.

4. In the selection of final product design and tooling to accommodate the optimized bond strength, have proper flow length and resulting L/T ratios been considered, as well as the gating and venting in the two-shot (or insert) molded design, to reliably achieve the desired bond effect? Most normal venting should be cut between 0.0008” and 0.001” (0.020-0.025 mm). It is recommended that there be full peripheral vents where possible in the designs.

Other tool design rules of thumb include:

- Consider a two-shot process selection vs. insert molding for annual volumes over 150,000.

- Consider the use of mechanical interlocks where critical performance in bond reliability is required.

- Carefully examine gating strategy to maintain flow geometry at L/T < 150:1.

- Pick truly compatible plastic/TPE material combinations.

- For thin-wall plastic substrates, be sure the plastic substrate is properly supported to ensure proper flow of the TPE at the end of flow.

- Consider use of surface texture techniques to add value to the finished overmolded component.

- For TPE surface coverage exceeding 180°, clearly evaluate the parting line strategy in injection mold tooling during the part design process.

- Avoid wall thickness differences of less than 4:1 in the molded TPE thickness sections.

- To avoid sinks, TPE wall thickness should be between 0.030” and 0.225” (0.76-5.7 mm).

- And finally, TPEs have high shrinkage rates; this can sometimes result in warpage of the substrate at thicker overmolded TPE sections.

5. What are the gate location considerations for molded TPE surfaces?

- Always gate at the thickest TPE cross section.

- Optimize the gate type for part geometry and cosmetic component preferences.

- The gate orientation to the component wall should be customized.

- Typically you should not gate near core pins, to minimize melt flow obstruction.

- Gates can be used in combination with added flow channels to ensure minimal molded-in stress.

- You may not want to make the gate perpendicular (at a 90° angle), which can cause a “jetting” surface effect.

- Consider the exact gate location with respect to resultant knit lines.

- Mold-filling analysis may be appropriate for complex geometries.

- Avoid long flow paths (>200:1 L/T).

6. Have all performance aspects of the TPE/thermoplastic pair been considered? The most important aspects include:

- effective bonding with the targeted thermoplastic substrate;

- toughness requirements for the surface and body of the part;

- coefficient of friction (COF) requirements for the elastomeric surface to meet consumer preferences;

- temperature range (low to high) capabilities of plastic and TPE materials;

- UV resistance to maximize useful lifetime of the component to meet OEM needs; and

- low-temperature performance requirements, particularly in rugged, high-toughness articles.

7. As the performance range and specialty alloys of TPEs has expanded so greatly over the past 15-20 years, what processing performance of the elastomer compounds must be considered for injection molding, vs. profile extrusion, vs. integral blow-molded parisons? A TPE’s melt rheology in the finished compound can be precisely adjusted to match the needs of most thermoplastic processes by the majority of the leading global TPE compounders.

New Horizons for TPEs

During the design phase of new product innovation, the traditional delineation of TPE compounds’ performance has significantly changed—for more design choices and higher TPE product value. The traditional separation of SBC-based alloys vs. styrene-ethylene-butylene styrene (SEBS) vs. TPV vs. TPU vs. COPE TPEs has greatly changed. These changes have occurred primarily through new alloys, by combining two or more elastomeric feedstocks with two or more thermoplastic polymers. These new alloys have helped drive TPEs into new components requiring highly defined component performance and aesthetics, including:

- low taste/odor in applications requiring contact with food and consumable liquids;

- higher-temperature applications to meet system requirements;

- higher elastomer tear strength at reduced TPE hardness levels (even down to 50-55 Shore ‘A’ specialty alloys);

- high levels of bond adhesion to a broad variety of thermoplastic substrates;

- highly precise levels of both static and kinetic COF in the elastomeric surface for proper component aesthetics; and

- flowability into very thin cross sections in profile extrusions, blown film, two- and three-layer blow molding, and thin-wall injection molded articles.

The recommendations to optimize a component’s final value should involve the design team with the fabrication experts working together as early as possible. These combined inputs will drive more precise design and fabrication options to help the TPE suppliers and part fabricators provide an optimized TPE early in the process.

Proper usage of TPEs offers a continued expansion of highly effective finished product differentiation. Innovation can truly drive effective material integration in new designs. A couple of the key questions to ask in order to spur innovation include:

(A.) What combination of component functions does the finished component need to deliver? Functions might include:

- strong gas-barrier properties, which can be coupled with the cost effectiveness of commodity thermoplastics;

- nearly any type of desired soft-touch/soft-grip aesthetics, which can be generated using seven major established families of melt-bondable TPEs from more than ten major established TPE material suppliers; and

- huge gains in component toughness, which can be achieved through combinations of engineering thermoplastics with very tough/very high tear-strength TPEs.

Meanwhile, molded thermoplastic composites offer huge gains in stiffness to replace metal-based designs. These can be coupled with commodity thermoplastics and even bondable TPEs to achieve very high bond levels. New thermoplastic composites offer much greater bond strength with SBC-based elastomers to provide very high toughness and longevity with the bonds. Many of these TPE substrates bond with new thermoplastic composites and greatly exceed traditional bond levels with common commodity thermoplastics.

And new plastics and elastomers offer highly specific and attractive gas-barrier properties in multi-material-based components through blow molding, injection molding, and blown film.

(B.) What improved aesthetics can the new designs deliver? Using all material options from before, new designs using blow-molded, extruded or injection-molded components offer an incredible range of color and texture, stiffness and modulus, outside surface durometer and COF, electric conductivity, weatherability/UV resistance, and color stability.

Quite literally, designers have more tools for controlling a component’s shape, form, and function than ever before. Processors and material suppliers offer an incredible broad spectrum of solutions to successfully execute designs in new consumer components. This approach can be utilized with specific polymers from the engineering thermoplastics, commodity thermoplastics, and highly melt-bondable TPE technologies currently available.

About the Author:

Rob Banning is founder and managing partner of Trimax LLC (www.trimaxllc.net), a consulting firm for the plastics industry based in St. Louis, Missouri, USA. Prior to founding Trimax in 1994, he served as the global automotive marketing manager for Monsanto/Advanced Elastomer Systems’ Santoprene TPVs. He can be reached via e-mail at Trimax@i1.net or by phone at U.S. +1 314-954-0518.