The Role of Plastics Compounding for Injection Molding

Some of the complexities of compounding are demystified in this overview

Previous Article Next Article

By Mark Rosen1 and Arash Kiani2

1Corex Design Group, Franklin Lakes, New Jersey, USA 2Compound Engineering Solutions Inc., Clifton, New Jersey

The Role of Plastics Compounding for Injection Molding

Some of the complexities of compounding are demystified in this overview

Previous Article Next Article

By Mark Rosen1 and Arash Kiani2

1Corex Design Group, Franklin Lakes, New Jersey, USA 2Compound Engineering Solutions Inc., Clifton, New Jersey

The Role of Plastics Compounding for Injection Molding

Some of the complexities of compounding are demystified in this overview

Previous Article Next Article

By Mark Rosen1 and Arash Kiani2

1Corex Design Group, Franklin Lakes, New Jersey, USA 2Compound Engineering Solutions Inc., Clifton, New Jersey

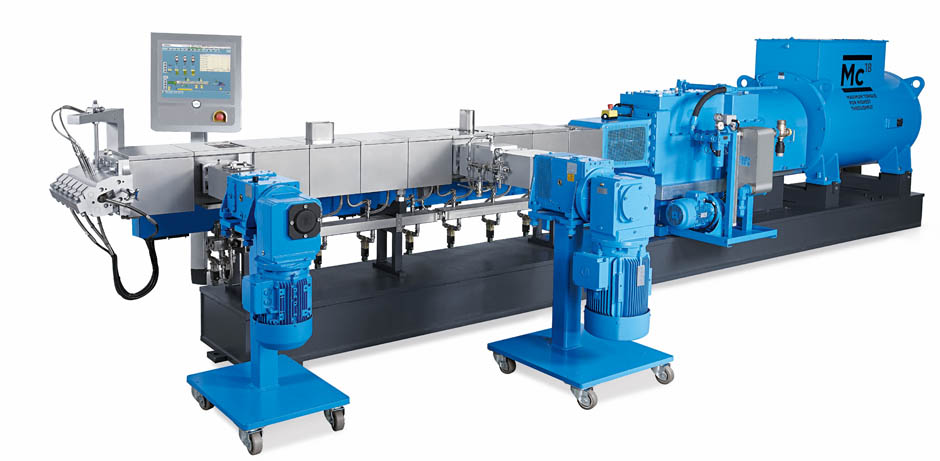

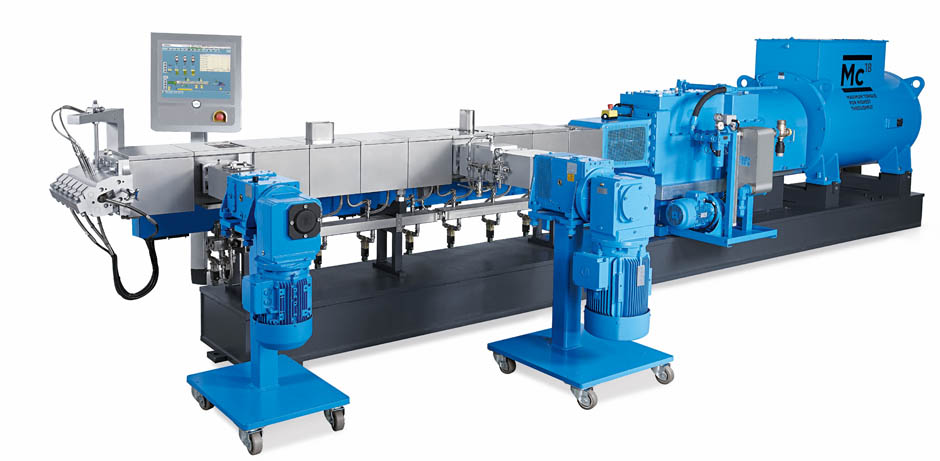

An example of a high-throughput twin-screw compounding extruder, the Coperion ZSK 82 Mc18 series (image courtesy of Coperion).

An example of a high-throughput twin-screw compounding extruder, the Coperion ZSK 82 Mc18 series (image courtesy of Coperion).

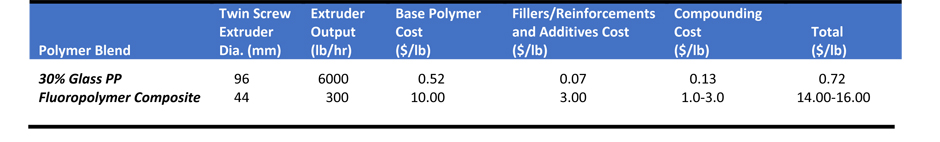

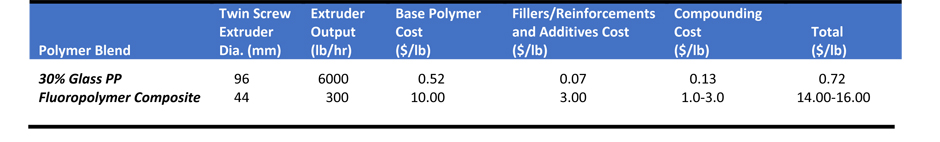

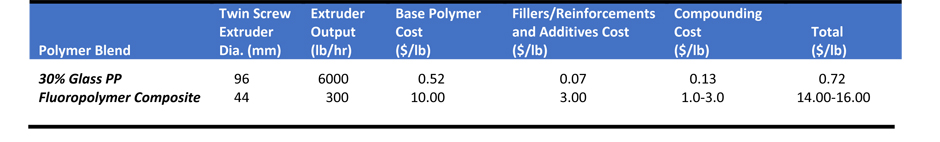

Cost Analysis of Different Polymer Compounds

Cost Analysis of Different Polymer Compounds

Cost Analysis of Different Polymer Compounds

[Note: To consult with the authors, see their contact information at the end of the article.]

In this article we will introduce the topic of plastics material compounding and custom compounding. For many of us in the plastics industry this topic can be a bit of a mystery. There are a countless number of different commercial plastics grades and formulations available today. In addition, there’s an endless number of different blends of materials and additives which can be custom compounded to improve the performance, appearance, and cost benefits over existing commercial products. However, for most smaller and mid-sized companies, finding experts or custom compounders with this specialty can be difficult. As a result, many new product development teams are missing this key expertise.

Although the plastics industry is huge (the third-largest industry in North America), only a small fraction of workers are involved in material formulations and compounding. As such, few understand this topic well. In this article, we’ll introduce some of the key concepts of material compounding and describe the roles of material compounders in successful plastics programs.

A Brief History of Compounding

Plastics compounding technology has its origins as an extension of rubber compounding. In late 1800s and early 1900s, machine builders in Germany and England (Werner & Pfleiderer Inc. and Banbury) developed machinery for rubber compounding. The majority of the development of recent thermoplastics has its roots in research work during World War II by companies such as Union Carbide, which developed new synthetic rubbers and thermoplastics to support the war effort.

Modern compounding technology was developed in the early 1950s by Paul Erdminger of Bayer Corp. He developed a special three-lobe co-rotating twin screw design whereby the elements were completely self-wiping. This work was commercialized by the Werner & Pfeiderer Corp. (“W&P,” currently Coperion). The main difference between these machines and the previous single screw and Banbury type extruders was the flexibility of the design.

DuPont developed a mechanical description of the geometry of self-wiping twin screw extruders in the 1970s. This work was fundamental to understanding the nature of the material flow in co-rotating twin screw extruders. W&P engineers further developed the co-rotating twin screw by developing a two-lobe design which allowed for larger surface area.

Twin screw extruders are generally described by two variables, Do/Di (outer diameter to inner diameter) and Md/A3 (specific torque over centerline distance cubed). Over the years the value of Md/A3 has increased from 3 to 20. Machines also are running at much higher RPM, depending on the application. In essence, a 45-mm latest-generation twin screw has a throughput capacity of a 1970s (160-mm) twin screw extruder.

Single screws are drag and pressure building devices. The feed rate is dictated by the screw speed and the restriction at the end of the extruder (namely the die plate and the screen changer). In general, the extruders were air cooled, and they were used mainly for melting and homogenizing the polymer. The initial use of single screw extruders was at the end of the polymer reactors, to take powder discharged from the reactor and add stabilizers prior to pelletizing the material.

Using twin screw extruders, process engineers had “Lego-like” building-blocks sets whereby the screw elements could be put together. However, the infinite possibilities in the way twin screw extruders can be put together provides opportunities and challenges.

In the 1990s, Arash Kiani (co-author of this article) and his co-workers at Krupp Werner & Pfliederer (Coperion) developed advanced modeling techniques to understand the fluid mechanics of the flow in twin screw extruders. The simulation tools allowed engineers to pick optimal machine conditions for a given compounding task. But even with the advances in simulation, the setup of compounding extruders remains an art which is augmented by science.

The Effect of Fillers & Additives on End Properties & Cost

The development of filled or reinforced compounds (CaCO3-filled, talc-filled, and glass-filled PP, for example) increased the use of twin screw extruders as the means of taking base polymer and modifying the product. The addition of fillers was initially done at the feed throat of the extruders, similar to the general practice on a Banbury or FCM (Farrel continuous mixer). However, over time it was learned that changing the feed location could result in increased physical properties. Another advantage of adding the filler downstream is to reduce the wear on the extruder, since the filler will be introduced into the already molten polymer downstream, and lower stresses are imparted.

Fillers extend the range of products that are normally available from resin producers. A filler can increase certain physical properties (flexural, tensile, and impact properties), and, depending on the type of the filler used, sometimes it can also reduce the cost of the resin used by the molder.

In general, fillers with an aspect ratio of 10/1 increase the flex modulus and can reduce the cost of the finished resin. High-aspect-ratio fillers can increase the tensile properties of the finished compound. New developments by filler producers have produced high-aspect-ratio talc and CaCO3 so the possibility of producing products with excellent properties using standard fillers has increased.

Large compounders can produce these filled products using very large extruders, and, due to their buying power, have large categories of products that can fulfill the needs of the majority of injection molders. Compounders can pick the right filler (talc, CaCO3, glass, cellulose) for the application based on specific needs of the molder.

Other exotic fillers such as natural fibers (cellulose, hemp, rice husks, etc.) are being used to increase the “green” content of the finished product. It’s interesting to note that specific compounding expertise is required for processing these fibers to achieve good dispersion and optimal properties.

Other fillers such as nanoclay or nanotalc are being used to increase physical properties while at the same time reducing specific gravity, compared to traditional fillers. These fillers are much harder to distribute into the matrix due to the fact that very small, hard particles have to be broken up into nano-size particles and distributed in the polymer matrix.

What are the Types of Compounders in the Industry?

Large compounders

Large compounders have portfolios of products to meet customer needs. These compounders have developed products based on different resins with various fillers, reinforcements, or additives. The products are sometimes developed to meet a specific customer specification such as in automotive bumper fascia. These standard products are off-the-shelf products that can be purchased by injection molders. Large compounders also provide color masterbatch and other masterbatches that allow the molder to increase the range of their product by coloring products or adding “special effects” at the molding machine.

Toll compounders

Toll compounders are essentially guns for hire and provide services to other compounders or custom compound formulas for molders. Some compounders provide large-volume tolling to major compounders. Smaller specialty compounders provide advanced custom development for the majors, or can work with molders to solve their molding problems.

Specialty compounders

Twin screw extruder manufacturers have a specific setup for a given compounding task (like for glass additions, carbon black dispersion, etc.). In general, compounders work together with twin screw machine manufacturers to buy an optimized setup for their application and dedicate their line to running a so-called optimized process.

However, the dynamics of the industry requires modification of the line depending on new products or applications. This requires in-house expertise to modify the setup and use an optimized “Lego” model. This is where specialty compounders have an edge over resin producers, due to the fact that they process more varied products and have better in-house expertise than material producers. It’s interesting to note that material producers usually utilize a specialty compounder to kick-start a project or optimize a project that has run into trouble at their own plants.

Specialty toll compounders provide rapid development that bypasses the layers of management that big compounders have. The product development and optimization of even relatively low-volume compounds (50,000-1,000,000 lb or 20,000-450,000 kg) can be done together with these specialty compounders.

Tolling costs

he cost of a product will depend on the cost of the formulation, output rate of the line, and volume of the run (see table). The compounder can charge from $200 to $600/hr processing fee on lines that have output rates from 100 to 10,000 lb/hr (45-4500 kg/hr), depending on the processing.

In summary, the cost of compounding depends on the complexity of the setup and the type of extruder that is used. For example, for large-scale compounding of PP with glass fiber, the processing/tolling cost will be as low to $0.10 to $0.15/lb, while a specialty fluoropolymer that needs to be run on an Inconel-lined twin screw at a much lower rate may cost $1 to $3/lb.

Keys to Success

When developing new plastic products, it’s important to understand the role of optimizing the plastics formulation for the application. Many plastics professionals do not have much experience with plastics compounding and, as a result, tend to rely on the recommendations of plastics materials suppliers. In many cases, the use of a custom-compounded material allows for a molded product with superior performance and cost benefits over commercially available grades.

Specialty compounders can work with different polymers, reinforcements, fillers, and additives to optimize the performance, aesthetics, and cost of a material for a specific application. Understanding the role of material formulations and working with the right material development partner are keys to success in the competitive marketplace of the plastics industry.

About the authors…

Mark Rosen is founder of Corex Design Group (www.corexdg.com), an award-winning plastics consulting firm consisting of plastics industry veterans available

to assist companies with design, engineering, analysis, and technical marketing. He can be reached via e-mail at mrosen@corexdg.com or by phone at +1 201-970-9188.

Dr. Arash Kiani (pictured) is president of Compounding Engineering Solutions Inc. (compounding.us). He has over 30 years of experience in the compounding area. From 1989 to 1999, he worked at Coperion, heading the simulation R&D team in the USA and Germany, and since 1999 he’s run his own compounding company in New Jersey, providing tolling and development services to major material producers. He can be reached at kiani@compounding.us or +1 973-818-8185.