The Robots Are Coming

Actually, robots have been here for some time, as far as injection molding companies are concerned, but they’re certainly increasing in number and capabilities

Previous Article Next Article

By Jon Evans

The Robots Are Coming

Actually, robots have been here for some time, as far as injection molding companies are concerned, but they’re certainly increasing in number and capabilities

Previous Article Next Article

By Jon Evans

The Robots Are Coming

Actually, robots have been here for some time, as far as injection molding companies are concerned, but they’re certainly increasing in number and capabilities

Previous Article Next Article

By Jon Evans

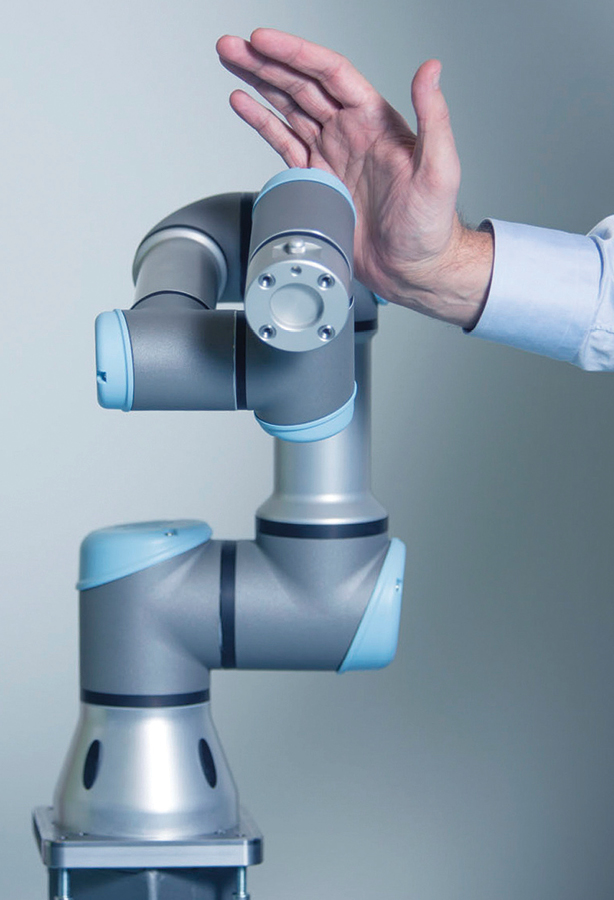

Robots are becoming handier. Instead of being restricted to safety enclosures, collaborative robots from Universal Robots can operate alongside humans because of built-in safety programming that automatically stops the robot’s operation when it encounters obstacles (photo courtesy of Universal Robots).

The 7X Line of five-axis robots from Sepro use servo motors to power movement and a system control that can integrate positional information from all five servo encoders (image courtesy of Sepro).

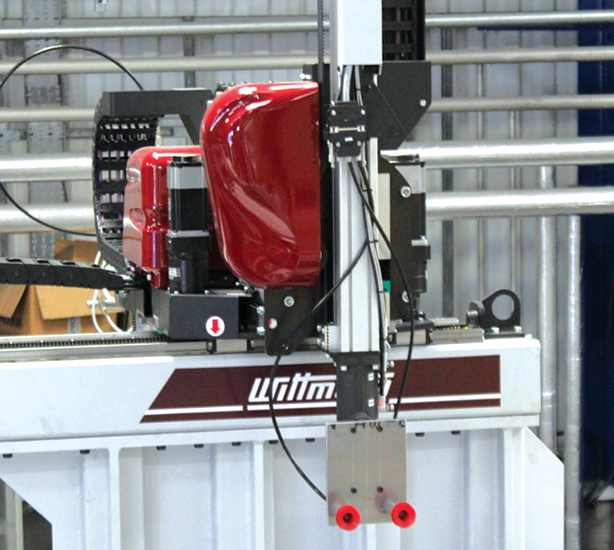

Wittmann’s control system can link injection molding machines with several peripheral devices, including robots (photo courtesy of Wittmann Group).

According to the U.S. Robotic Industries Association, sales of robots to the plastics and rubber sector in North America increased by 25% in 2014, making it the second-fastest-growing industrial sector for robotics after automotive. This substantial growth is also being replicated at the level of individual companies. French company Sepro, which develops robots specifically for injection molding applications, had its best-ever year in 2014, with sales of almost €80 million ($84 million), while its U.S. business, Sepro America, saw sales increase by 26%. Meanwhile, the Austrian company Wittmann Group, which develops injection molding machines and robots to go with them, is currently expanding its robot production capacity at both its headquarters in Vienna and its U.S. facility in Torrington, Connecticut, with completion planned by January 2016.

This growth in the use of robots by injection molders is obviously partly being driven by the general upturn in the economy, especially in the USA, and the associated growth in the plastics sector since 2011. But it’s also being driven by technical advances in the robots being developed for injection molding applications; although they remain essentially mechanical arms, these robots are becoming faster, more dexterous, more precise, and more connected. This means they can take on more and more of the repetitive but intricate tasks that previously had to be performed by human workers, freeing up these workers for more interesting tasks.

Dexterous Part Handling

Robots have long been used to remove completed parts and waste sprues from injection molding machines, but they were generally restricted to parts that came away fairly easily from the molds. The latest robots, however, are able to twist and maneuver a part in addition to pulling it, allowing them to ease out difficult-to-remove parts from complex molds. Furthermore, this enhanced dexterity and precision means that the latest robots can also accurately place labels in the molds, assemble products from several components, apply glue and sealant, and package the products when they’re completed.

These robots can generally work much faster than humans: Japanese company Yushin has demonstrated one of its robots removing 16 parts from a mold in 0.27 seconds. In addition, unlike human workers, robots don’t require breaks and are able to continue working 24 hours a day, seven days a week. This all means increased productivity.

Much of the enhanced dexterity and precision comes from the fact that the latest robots boast five, six, or seven axes of movement. Older generations had three axes of movement, corresponding to the three Cartesian directions of x, y, and z (or left and right, forward and backward, and up and down) and so are known as Cartesian, or linear, robots. Although these robots are still popular for simple tasks (because they’re quick and comparatively inexpensive), newer models with more axes of movement are required for more intricate tasks.

These extra axes of movement come from the robots possessing joints that can rotate like a wrist. Not only does this provide the robots with a much greater range of movements, but it also means they can conveniently fold themselves out of the way when not in use, which is useful, given that space is usually at a premium among large injection molding machines.

Smaller Footprints

So despite having a longer reach, greater strength, and increased flexibility to be able to reach into confined spaces, the latest robots take up less room than previous models. This was certainly an important design criteria for the new “KR CYTEC nano” range of robots from the German company KUKA Robotics, which develops robots for a range of industrial applications, including injection molding.

“The most important thing for us was to significantly improve the robot’s compactness and performance,” explains Markus Hollfelder-Asam, product manager for the new KR low-payload class at KUKA. “The volume of the new KR 8 R1620 is 47% less than that of its predecessor (the KR 6-2), despite the greater payload capacity and longer reach. We have significantly reduced the disruptive contours of the robot, while the streamlined design of the wrist ensures utmost accessibility, even in confined workspaces.”

Finer Control

With greater flexibility of movement comes an increased need for the robot “to know” the precision location and orientation of its arm, so that it can perform its task without bumping into the injection molding machines or human workers. This spatial information is provided by a range of sensors incorporated into new robots. These sensors both ensure that the robot arm doesn’t get too close to another object while moving, and also track where the arm is in space.

If the robot arm is powered by servo motors, rather than pneumatics, then the feedback-driven positional encoders that control the servo motors can conduct this tracking, as they continually monitor the position of the drive shaft. The new “7X Line” of five-axis robots from Sepro use servo motors to power movement in each of the five axes and a system control that can integrate positional information from all five encoders, allowing it to know the exact position at all times. According to Sepro, this allows the robot to complete very complicated motions in all axes simultaneously and do it very precisely and with perfect repeatability.

This kind of fine control also extends to the implements on the end of the robot arm that actually perform the functions, whether extracting, transferring, or trimming parts. These implements are collectively known as end-of-arm tooling (EOAT), and encompass everything from simple grippers and suckers to complex systems containing multiple tools for performing several different functions. Whatever the EOAT, however, it needs to be able to pick up, maneuver, and, if necessary, modify the part without damaging it, hence the need for fine control. As with the robot arm, this control is often provided by servo motors and sensors, which can also allow the EOAT to conduct quality testing of the molded part.

Easier Programming and Integrated Communication

Despite becoming increasingly sophisticated in their abilities, robots are becoming ever easier to program. The latest robots, such as the range of six-axis robots developed by the Danish company Universal Robots for a wide range of industrial and research applications, can be programmed by essentially moving the robot arm itself into the desired positions. Other manufacturers such as Sepro use simple graphical interface-based control systems for their robots, making it easy to program them for different tasks, while using a joystick to fine-tune their movements.

Following a trend seen in many other manufacturing sectors, the latest robots can communicate with injection molding machines, helping them to work seamlessly together. This is obviously easiest to do for companies that make both injection molding machines and robots, such as Wittmann. It recently introduced a single control system that can link injection molding machines with several peripheral devices, including robots and temperature controllers, allowing the single system to coordinate the entire manufacturing process.

What’s more, it has developed a smartphone app that links with this control system, allowing the status of the injection molding machines and robots to be monitored remotely. “Machines and production will [be] more linked and ‘talking to each other’ like never before,” says Barry Hill, managing director of Wittmann Battenfeld UK.

Even companies that focus purely on robots, however, are now ensuring that their robots possess the drivers required for them to communicate with other manufacturing machines, including injection molding machines. In November 2015, KUKA announced that its robot software will readily integrate with machine controllers developed by various other companies, including Siemens, CoDeSys, and Beckhoff.

More Specialization

As more and more injection molding companies see the benefits of investing in robots, more and more models are being developed for this application, in a kind of “virtuous” circle. Companies that have long produced robots for injection molding are expanding their ranges, with Sepro showing off 19 different models at the recent NPE 2015, while companies such as Stäubli are launching their first models designed specifically for use in the plastics industry.

Companies are also realizing that different types of injection molding require robots with quite different abilities, which they are now able to provide. “We are able to see how differentiated the user market actually is: heavier payloads for automotive; cleanroom conditions for med-tech molding; and fast cycling systems—including in-mold labelling—for packaging,” says Wittmann’s Hill. “All of these injection molding circumstances require a different approach, and very often a different robot.”