Colorants & Pigments Get More Versatile

What you see isn’t all you get when it comes to new grades of pigments, which meet a range of needs beyond aesthetics

Previous Article Next Article

By Pat Toensmeier

Colorants & Pigments Get More Versatile

What you see isn’t all you get when it comes to new grades of pigments, which meet a range of needs beyond aesthetics

Previous Article Next Article

By Pat Toensmeier

Colorants & Pigments Get More Versatile

What you see isn’t all you get when it comes to new grades of pigments, which meet a range of needs beyond aesthetics

Previous Article Next Article

By Pat Toensmeier

Chemist Mas Subramanian inspects sample of YInMn Blue, a pigment with high UV absorbance and IR reflectivity developed by his university research team and licensed to Shepherd Color. Courtesy of Mas Subramanian, Oregon State University

Consumer product makers rely on colorant advances to highlight their packaging from competitors. Courtesy of Clariant

Clariant has set aggressive near-term sustainability goals for pigment production. Courtesy of Clariant

Among the sustainable raw materials in use by Clariant is succinic acid, which is synthesized from natural sugars and added to quinacridone pigments. Courtesy of Clariant

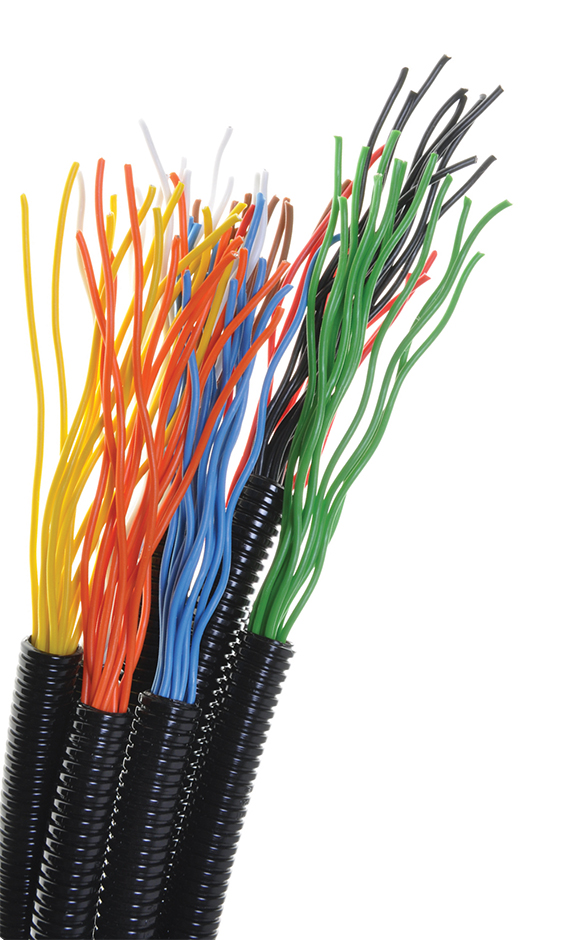

UL certified 14 new wire-and-cable colorants from Teknor Apex for use in halogen-free compounds. Courtesy of Teknor Apex Co.

A self-contained system from Riverdale Global automatically meters liquid pigment into process machines. Courtesy of Riverdale Global

Recent developments in pigments are redefining the role these materials play in plastics well beyond that of appearance. The latest versions of these additives increasingly address such needs as process efficiency, waste reduction, sustainability and regulatory compliance.

Some colorants and pigments are even touted as essential components of “green” building design, for the synergies they provide in the reduction of energy use and thus the carbon footprint of structures ranging from single-family houses to apartment buildings and office towers.

These and other developments stem from ongoing advances in formulation chemistry—some serendipitous—and from enhancements in delivery techniques that promote increasingly precise levels of use and thus, in many colorants and pigments, a finer tailoring of properties.

Designers, compounders and end-users, as a result, can increasingly work with color additives that are not only key to product aesthetics, but to manufacturing productivity and functionality.

Following are representative examples of recent developments in these areas, many of which were on display at the K 2016 trade fair in Düsseldorf, Germany, in late October.

‘YInMn’ = True Blue

Shepherd Color Co. is commercializing a vivid blue pigment that was discovered by researchers at Oregon State University seven years ago. The material, which Shepherd is licensing from the university, is called “YInMn Blue” and will be used in pigments (and coatings) for plastics.

The name derives from its chemical content, which includes yttrium, indium, manganese and oxygen. Unlike many bright blue pigments, the material is extremely stable, probably owing to its accidental discovery after a researcher heated manganese oxide to about 1,200°C (or 2,192°F) to test its electronic properties.

Importantly for its use as a pigment, tests by an Oregon State research team led by chemist Mas Subramanian found that YInMn Blue has high ultraviolet absorbance and high reflectivity in the near-infrared region compared with conventional cobalt blue pigments.

Additionally, according to information from the research team, the pigment has a crystal structure in which the chromophore that produces its intense blue is in a trigonal bipyramidal site, which means that the color can be tuned by adjusting the ratio of indium to magnesium.

This means that in building design the pigment can be used to formulate dark blue roofing that stays cooler in sunlight than conventional blue roofs, thereby creating energy benefits. So-called “cool roofs” that use dark blue colors to reflect solar heat are design features of new and retrofit buildings. They limit the amount of heat that is absorbed by roofs and enters structures, thus eliminating the need for excess air conditioning as well as costly roof-deck insulation or attic venting systems.

The optimum color for a cool roof is white, which might not be a problem for commercial buildings, but homeowners prefer darker colors such as blue that resemble the black or dark grey of conventional roofing shingles.

Exposure tests conducted by Shepherd Color show that a standard blue roof generated much more heat than a roof colored with the YInMn Blue pigment—191°F compared with 168°F. The tests also demonstrated that the total solar reflectance of the pigment was more than three times greater than that of a conventional dark blue pigment.

Most residential roofing shingles are asphalt, but polymer alternatives fabricated from recycled plastics are growing in popularity for their low weight and economy, and could become one of many important markets for the pigment.

Cool-roof design is integral to initiatives in the United States such as Energy Star from the Environmental Protection Agency, the U.S. Green Building Council’s LEED certification program, and California’s Title 24 building code.

Lead-Free Enhancements

While the YInMn pigment represents one extreme on the development scale—a new formulation with exceptional properties—most additive enhancements are geared toward incremental advances in pigments and colorants that meet immediate needs.

One example is PV Fast Yellow H4G, an organic yellow pigment from Clariant Corp. that replaces lead chromate-based materials. Lead chromate pigments have been banned from consumer plastics in Europe since 2015, and users elsewhere are under pressure to find nontoxic alternatives, especially for toys, food-contact applications, and other consumer products.

Clariant describes the material as having two to three times greater color strength in polyethylene and PVC as conventional lead chromate yellows, and adds that in combinations with inorganic pigments H4G achieves a close match to the color and opacity of lead chromates.

The material has good opacity, as well as lightfastness and weather resistance. It has high dispersion, and can be used for indoor and outdoor applications with polyolefins, styrenics, thermoplastic elastomers and polyurethanes. The impact of H4G on part warping is minimal, and the pigment is suitable for such applications as crates, caps and closures. The material is also FDA, EU (10/2011) and GB 9685 compliant for food contact in the U.S., Europe and China, respectively.

Clariant, meantime, has set ambitious sustainability goals. The company seeks to improve the value of colorants and pigments in a number of ways: increasing the use of renewable raw materials; resource savings from improved production processes; devising high-process-efficiency formulations; longer product lifecycles; and greater recyclability.

By 2025, Clariant wants to reduce energy consumption and carbon emissions by 30% per metric ton of pigment produced; achieve 35% reductions in greenhouse gas emissions, water consumption and waste; and reduce waste water by 40%.

Wire and cable is a major user of color. One concentrate supplier, the Color Division of Teknor Apex Co., recently received UL certification that a series of 14 new grades for wire and cable and other electronics are halogen-free and acceptable for use in halogen-free compounds.

The pelletized concentrates use ethylene-vinyl acetate (EVA) and PE as carrier resins. The materials can be used with either EVA or polyolefin-based, halogen-free, flame-retardant compounds.

They were developed with customer input. Compliance with halogen-free requirements in compounds is a key requirement for applications in North America, among them public transit, marine and military installations, as well as office buildings and automotive.

Flexible Carbon Black

Regulation and sustainability influenced the recent development of carbon black masterbatches by Cabot Corp. At K 2016, the company showed an expanded range of universal masterbatches for use with a variety of polymers. New to the Plasblak line are UN2015, UN2017 and UN2019. Together with a previous grade, UN2010, the materials are formulated with low levels of impurities to meet European Union food-contact requirements. UN2019, additionally, complies with FDA regulations for U.S. food-contact applications.

The line includes three grades for non-food applications that meet a growing need for greater levels of recyclate in raw materials in Europe and elsewhere. UN2014, UN2016 and UN6289 are described by Cabot as cost-effective masterbatch options.

All of these masterbatches achieve high jetness (or degree of blackness) and tinting strength at low addition rates. The company adds that just one masterbatch grade can be used effectively with a number of engineering resins, among them ABS, polyamide and polyoxymethylene.

Other new or enhanced grades include Black Pearls 630, a specialty carbon black that balances jetness with blue tone, and adds color without a tradeoff in dispersibility. The pelletized grade, which originated from an effort to fine-tune the properties of another carbon black, says George Haines, global segment manager, is primarily for general-purpose moldings of consumer goods, electronic parts and automotive components.

Cabot has certified more than 20 specialty carbon black grades using International Carbon Black Association and other standards. The objective is to show that certified grades comply with an update to the EU’s REACH regulations that further limits the use of polycyclic aromatic hydrocarbons in applications with prolonged or frequent skin contact. This, in addition to its work in demonstrating masterbatch compliance with FDA and EU food-contact rules, means customers can be certain that materials they specify from Cabot “meet performance and regulatory compliance needs,” Haines says.

Cost-Effective Liquids

Liquid pigments are a small proportion of the color additives market, but offer benefits over pellets and powders, says Paul Maguire, president of Riverdale Global.

Chief among these are: greater accuracy in metering; minimal — even no — waste during operations and thus little, if any, waste-disposal concerns; efficient dispersion in compounds; cleaner machine-side operations and storage; no worker exposure to pigments; and cost savings over dry versions.

Riverdale supplies an innovative liquid pigment system called Pump-in-a-Drum (PIAD). Using a peristaltic pump and gravimetric dispensing system designed by sister company Maguire Products, which builds auxiliary processing equipment, the company supplies single pigments in sealed containers that compounders, molders and others connect to machines for automatic dispensing.

Using a single pigment in the dispenser maximizes color strength, brightness and uniformity, Maguire says. The system can, as a result, achieve full color effects at lower letdown rates than with conventional liquid pigments.

When a container is empty, Riverdale replaces it. The company returns used containers to a central or satellite facility and cleans and refills them for reuse with a processor’s exact color formula.

“We mix color in the container using an in-house coloring system,” Maguire explains. “There is no wasted material.” Containers usually come in 5- and 30-gal. sizes. Samples come in 1-gal. containers, and special totes in a 200-gal. size.

Leftover material—typically 1 to 3% of content—is reused, which saves money. The PIAD’s color-delivery tolerance is within 0.1%, which prevents over-coloring and helps reduce costs.

Overall, users can save 20 to 40% on color costs alone compared with conventional liquid pigments.

Maguire says Riverdale is adding satellite facilities to improve turnaround time for pickups and deliveries. Up to 20 are planned in the U.S. Satellites are also slated for Europe and China. In some cases, refilling operations can be set up next door to a customer, or within a plant.

Future developments include addition of a software tracking system, now in beta testing, which provides information about color formulations and how efficiently dispensing systems and pigments are used, along with compliance information and traceability of components. This type of collection is not unusual for gravimetric blenders that meter dry colors, but is “relatively unusual” for liquids, according to Maguire.