Obi feeds more than the imagination

A decade in the making, this self-dining robot offers a taste of freedom & independence to millions of disabled

Previous Article Next Article

By Robert Grace

Obi feeds more than the imagination

A decade in the making, this self-dining robot offers a taste of freedom & independence to millions of disabled

Previous Article Next Article

By Robert Grace

Obi feeds more than the imagination

A decade in the making, this self-dining robot offers a taste of freedom & independence to millions of disabled

Previous Article Next Article

By Robert Grace

Jon Dekar (left) has been working on the concept of a robotic dining device for 10 years, and enlisted the support of senior engineer Grey Parker (center) and the Sundberg-Ferar design firm to help refine his working prototype. The finished product — called Obi — hit the market late this summer.

Jon Dekar (left) has been working on the concept of a robotic dining device for 10 years, and enlisted the support of senior engineer Grey Parker (center) and the Sundberg-Ferar design firm to help refine his working prototype. The finished product — called Obi — hit the market late this summer.

Jon Dekar (left) has been working on the concept of a robotic dining device for 10 years, and enlisted the support of senior engineer Grey Parker (center) and the Sundberg-Ferar design firm to help refine his working prototype. The finished product — called Obi — hit the market late this summer.

The commercial version of Obi on sale now consists of 33 parts. PTI Engineered Plastics in Michigan made the aluminum tools and molded all of the plastics components.

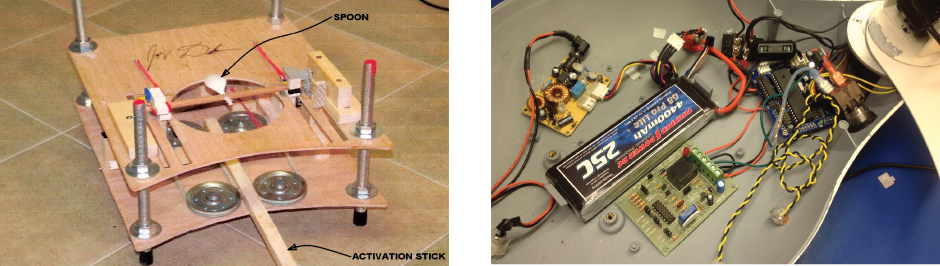

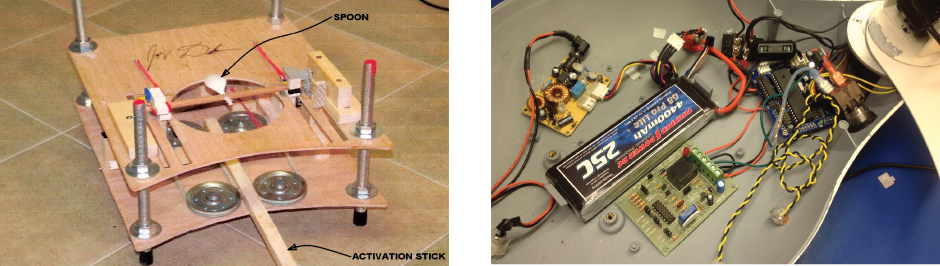

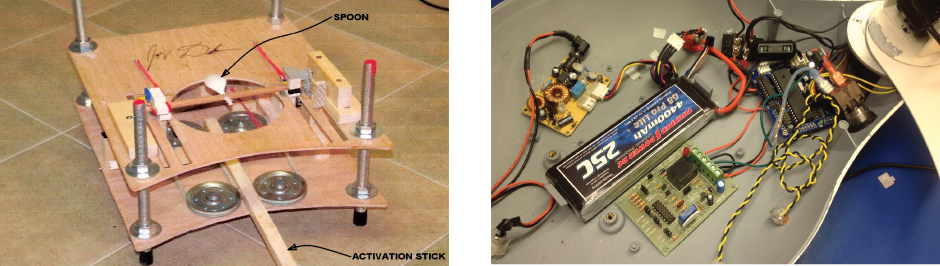

As a mechanical engineering student at the University of Dayton, Jon Dekar pieced together an early prototype of his self-feeding robot (left) using materials he found around his school’s lab. One of the project’s main challenges was finding flame-rated, food-contact-grade.

As a mechanical engineering student at the University of Dayton, Jon Dekar pieced together an early prototype of his self-feeding robot (left) using materials he found around his school’s lab. One of the project’s main challenges was finding flame-rated, food-contact-grade.

As a mechanical engineering student at the University of Dayton, Jon Dekar pieced together an early prototype of his self-feeding robot (left) using materials he found around his school’s lab. One of the project’s main challenges was finding flame-rated, food-contact-grade.

Jon Dekar describes the act of eating as “an intimate experience” and says the ability to feed oneself is both a basic human need and a fundamental freedom. Those beliefs have inspired his efforts over the past decade and have now yielded a new product — a robotic self-dining device called Obi.

As a child, Dekar — now a 28-year-old entrepreneur with a mechanical engineering degree from the University of Dayton in Ohio — saw his paternal grandfather begin to lose that freedom due to a serious, degenerative disease similar to Parkinson’s. His grandfather became bedridden, and eventually could not eat under his own power.

In his high school years, meanwhile, Dekar said in a recent interview, “I also was volunteering at nursing homes and hospitals, and I saw this issue there, as well.” He soon realized there were many people who needed this type of assistance.

Dekar always wanted to build products. “I felt that that represents the pinnacle of what we can do, and the problems we can solve — from the Saturn rocket to your iPhone,” he said. “That drove my interest in engineering.”

Dekar’s father, Tom, also trained as an engineer, but worked professionally as a management consultant. Together, Tom and Jon built stuff — lots of stuff. “That was how we bonded,” Jon recalled.

Motivated to find a solution to this self-feeding problem, in his first year in college the younger Dekar began by piecing together a prototype with Legos, rubber bands and rope — basically whatever materials he could find lying around the school’s engineering lab. He also began doing research into what products were out in the market, and how many people might need this type of help. He said, “I was appalled that in the 21st century, there was not a sophisticated, effective product to address this basic human need.”

Clearly a design problem

“It became apparent right away that this was not a functional problem of taking food and moving it from Point A to Point B. This was very clearly a design problem,” Dekar recounted. “It wasn’t just about the engineering solution, it was about ‘how do we create an inspiring experience with a product that is extremely simple, extremely intuitive — and cool?’ This was about creating an appliance that people would actually want to use, and want in their lifestyle every day.”

Dekar entered the engineering co-op program at his university, which enabled him to work for a semester at a time — for a total of about two years — in Columbus, Ohio, at Battelle Memorial Institute, the world’s largest nonprofit research and development organization. While there, he learned much about product development, including about the processes, procedures and regulatory implications related to medical devices.

By the time he was a junior in college, he began writing a business plan, and engaged the help of his father. “We probably did 15 revisions of this plan before we ever went out and started talking with potential investors.” The tremendous diversity in individuals’ conditions and needs made it very difficult to accurately assess the market size and potential sales opportunity.

They talked with perhaps 100-150 occupational therapists, attended trade shows, visited rehab centers, and eventually estimated that 3 million to 6 million people in the U.S. alone likely needed feeding assistance.

Dekar’s father retired the same week that Jon graduated from university, in 2011, by which time Jon estimates he personally had 2,000-3,000 hours invested in the project already. The two of them formed a company, called Desin LLC (pronounced “design”). With father Tom funding the firm at the outset, they continued to refine the prototypes and quickly earned their first patent.

By then, Dekar said, they already had a fairly robust, aesthetically pleasing, working prototype that looked about 85% like the final version today. This allowed others to better visualize the product, and helped the Dekars to secure funding early. Jon estimates they had about a 40% success rate in convincing potential investors to come on board.

“We were prepared for a 5-10% hit rate,” but the really robust business plan and well-developed prototype helped a lot, as did his father’s extensive business experience.

Dekar approached the Robotics Lab at the University of Dayton, and paid $8 an hour to a Ph.D. or Master’s student to help. “I focused on the human factors, the usability and the mechanical design of the system, and then had this other person work on assembling the electronics, and we both worked on the software together.”

They bought an off-the-shelf Arduino board and programmed it using Arduino’s development tools. They used items such as a model-airplane battery and a garage-door opener, along with a bunch of 22-gauge wires from Radio Shack and “just rigged the system together.” Dekar said he made all the enclosures from simple sheet metal, and modeled all of the aesthetic, surface parts in SolidWorks software, and had them 3D printed at a local shop. They then sanded, primed and painted those parts with a nice automotive-quality gloss paint.

A child-like personality

For the device’s arms, Dekar said, “I was inspired by the Disney Pixar lamp.” The aim was to inject some whimsy. “For people to really engage with robotics, I believe that [the device] has to have a subtle personality, to make it more approachable … so that instead of being fearful of the robot, you become charmed by the child-like personality of the robot.” Indeed, if you push the arm in a way that is not designed, it shakes its head at you gently, as if saying, “don’t do that.”

The Dekars then looked for a design house to help them fine-tune the prototype. The College for Creative Studies in Detroit connected them in April 2014 with Sundberg-Ferar, a multidisciplinary design firm in Walled Lake, Mich., that dates back to 1934.

Grey Parker, a senior engineer at Sundberg-Ferar who began his career designing seating systems for Honda, helped the Dekars to polish up Obi’s overall aesthetics while also assisting with a lot of wire harness work and with several mechanical issues, such as how to clamshell the housing together to provide a seal. The design firm also provided guidance through the labyrinth of regulatory compliance, both with UL and ISO, in addition to providing its core services of refining the product’s aesthetics, user interface and ergonomics.

“The medical standards for electronics are tremendously burdensome — hundreds of pages of regulations,” Dekar said, “so we needed a group who knew what they were doing, and was familiar with the ISO 13485 quality system regulation for medical devices.” Obi is UL-approved, and is considered a home healthcare appliance.

Parker, who has 11 years of industry experience, said, “This was definitely the most emotional product that I’ve had a chance to work through. It was an incredible opportunity to see how a device can really connect man and machine.” Sundberg-Ferar also participated in the research, taking prototypes out in the field for testing, with end users of all ages.

“It was often that we would have people crying,” Parker recalled. “The impact that this would have on their lives was dramatic.” Obi allowed people to “get this little ounce of freedom back, and it made all the difference in the world. It was pretty incredible.”

Jon Dekar knew of PTI Engineered Plastics in Macomb, Mich., liked them, and involved the custom injection molder early in the project, to include doing design reviews of the prototype plastic parts. PTI ended up doing all of the injection molding and aluminum tooling for the project.

Material challenges

“We needed a material that was very food safe,” and that would withstand users putting the bowls into the refrigerator, freezer, microwave and dishwasher.

They had difficulty finding a suitable food-grade, B-rated, flame-retardant plastic. They even struggled to find independent, consistent data on how dishwasher- and microwave-safe different types of plastics were.

Several of the parts required one or more overmolds, which created production challenges. It took a year to resolve all of the problems associated with Obi’s 33 different components.

Dekars considering using Sabic’s Ultem polyetherimide resin, but it required production steel tooling, and became too expensive as an option. They eventually settled on two different grades of polypropylene. RTP Co. is supplying a food-grade, custom PP compound for the plate and four food bowls, and Total Plastics is providing a slightly softer, off-the-shelf PP resin for the utensils.

They used Sabic’s Cycoloy CX2244ME medical-grade, flame-retardant PC/ABS for non-food-contact enclosure parts, and a grade of Sabic’s Lexan LUX polycarbonate resin for the surfaces and rings around its LED lights and switches.

Obi also uses PolyOne’s soft-durometer Versollan OM1255NX thermoplastic elastomer on the overmolded bottom piece, which leverages the material’s high surface energy to help the device grip the table, to keep it from sliding. Uniform Color Co. supplied the additives for the appliance’s all-white plastic parts.

Desin LLC officially launched Obi — whose name comes from the word “obeisance,” which refers to a gesture of respect or deference — this past July. With the goal of keeping costs low, a lot of Dekar’s efforts now are going into building his own distribution network.

Obi carries a $4,500 price tag, but Dekar said he is trying hard to remove any obstacles to potential customers obtaining the device. “We want to keep the price as low as possible, and we want anyone who needs or wants this, to be able to have it.” Desin offers a two-week, risk-free, free trial, as well as 12-month rentals and a lease with payment plan that offers an option to buy at the end. He also will even develop crowd-funding pages for people who want to go that route.

By December 2016, Dekar expects to be making 30 to 50 units a month, and his goal is to sell 1,200 units in 2017. He expects to generate a lot of sales overseas, since in Europe, for example, the cost of such a device is largely covered by health insurance — which is not the case in the United States.

Applying robotics to healthcare

Beyond helping individuals to feed themselves, Jon Dekar also has a grander goal.

“One of the things that we want to do as a company is to help change the [U.S.] healthcare system.” He sees artificial intelligence and robotics as having the potential to improve productivity and the efficiency of delivering healthcare services. Consider the savings, he suggests, if an Obi-like device can allow trained healthcare caregivers in hospitals or nursing homes to perform more value-added tasks by freeing them from having to spend so much of their time hand-feeding patients.

Over the next 10 to 20 years, “We intend to be a company that plays in that area, and helps to transform the healthcare industry and reduce costs with other robotics products.”

ABOUT THE AUTHOR

A 36-year B2B media veteran, Robert Grace was the founding editor of Plastics News in 1989. An ardent design advocate, he struck out on his own in 2014 and founded RC Grace LLC (www.rcgrace.com), a consultancy through which he offers a variety of services – from content creation, freelance editing, marketing and PR, event organizing, and business development. He also now serves at managing editor of Plastics Engineering.

A 36-year B2B media veteran, Robert Grace was the founding editor of Plastics News in 1989. An ardent design advocate, he struck out on his own in 2014 and founded RC Grace LLC (www.rcgrace.com), a consultancy through which he offers a variety of services – from content creation, freelance editing, marketing and PR, event organizing, and business development. He also now serves at managing editor of Plastics Engineering.