Compounding: Efficient Equipment, Lean Trends

New designs and controls allow for faster, more efficient, and even safer compounding extrusion

Previous Article Next Article

By Jennifer Markarian

The B&P TriVolution- 120 tri-kneader can compound PVC and thermoplastics (photo courtesy of B&P Process Equipment).

The B&P TriVolution- 120 tri-kneader can compound PVC and thermoplastics (photo courtesy of B&P Process Equipment).

A modular, turnkey compounding system can be built in modules that are shipped to a customer’s site for installation (photo courtesy of Coperion).

A modular, turnkey compounding system can be built in modules that are shipped to a customer’s site for installation (photo courtesy of Coperion).

The Coperion ZSK Mc18 “smart” features an easy-to-clean exterior (photo courtesy of Coperion).

The Coperion ZSK Mc18 “smart” features an easy-to-clean exterior (photo courtesy of Coperion).

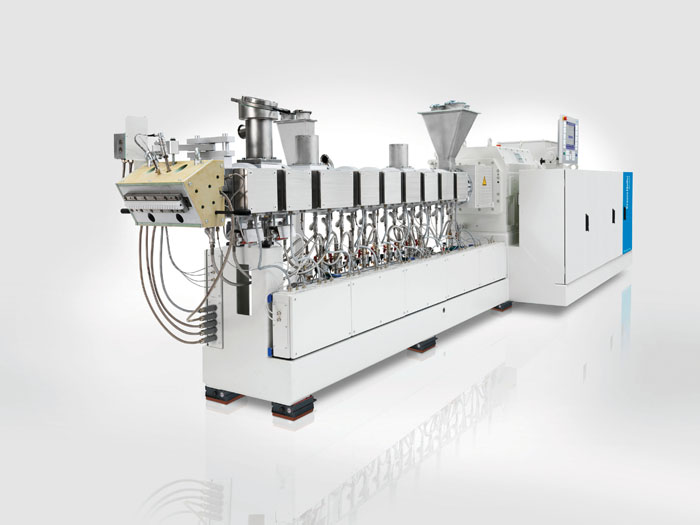

KraussMaffei’s ZE BluePower twin-screw extruder reportedly improves output and lowers energy consumption (photo courtesy of KraussMaffei).

KraussMaffei’s ZE BluePower twin-screw extruder reportedly improves output and lowers energy consumption (photo courtesy of KraussMaffei).

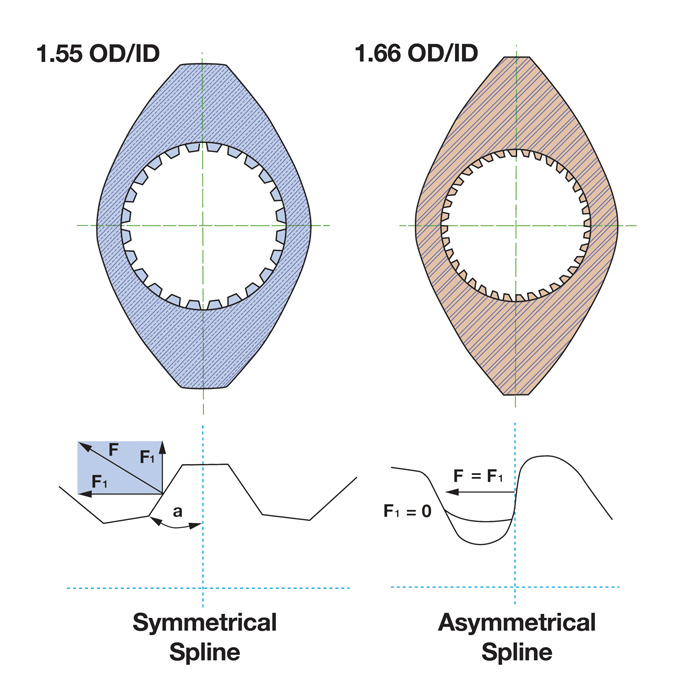

An asymmetrical splined screw shaft allows a higher free volume with an outer/inner diameter (OD/ID) ratio of 1.66, up from the traditional standard of 1.55 possible with a symmetrical splined shaft (diagram courtesy of Leistritz; see also p. 34 of the February 2014 Plastics Engineering for more about a related topic).

An asymmetrical splined screw shaft allows a higher free volume with an outer/inner diameter (OD/ID) ratio of 1.66, up from the traditional standard of 1.55 possible with a symmetrical splined shaft (diagram courtesy of Leistritz; see also p. 34 of the February 2014 Plastics Engineering for more about a related topic).

“At the SPE continuous compounding TopCon held in March 2014, presenters gave examples of how process-control tools are currently being used in compounding applications.”

Thermoplastic compounding— whether performed by a resin producer, toll compounder, specialty compounder, masterbatch compounder, or processor using direct compounding of raw materials to finished part—is a crucial step in creating a material with the performance required for an application. Additives such as antioxidants, property modifiers, fillers, colorants, and fiber reinforcements must be accurately dosed and effectively blended without damaging the additive.

Equipment suppliers continue to provide improvements in output rate and energy consumption and to optimize features such as gentle mixing for sensitive materials, feeding for low bulk-density fillers, and easy access for cleaning and quick changeovers. Other trends include ongoing demand for turnkey or direct extrusion systems, and increasing use of advanced process control and simulation technologies.

Efficient TSEs

Although various types of blenders and compounding extruders are used (depending on the type of polymer, additives, and output), co-rotating, intermeshing twin-screw extruders (TSEs) are widely used because of their dispersive mixing characteristics and the ability to dose additives downstream of the feed-zone into the melted polymer. These TSEs are also known for their modular, segmented screw design that allows the design to be optimized for a formulation by changing, for example, the types of mixing elements or locations of downstream feeding or venting ports.

In the past decade, advances in shaft design and metallurgy have resulted in step changes in the output possible with co-rotating, intermeshing, segmented TSEs. Leistritz’s asymmetric splined shaft design, developed in 2004, enabled an increased free volume with an outer/inner diameter (OD/ID) ratio of 1.66, up from the traditional standard of 1.55. Subsequent improvements in metals used for the shaft allowed manufacturers to also increase the torque possible with a given shaft size, boosting specific torque up to 15 Nm/cm3.

At the K 2013 trade fair, Leistritz displayed its ZSE 50 XX concept extruder, which reportedly allows specific torque of 20 Nm/cm3 for even higher throughputs in torque-limited processes. The higher torque is enabled by the smartXX screw, which is a one-piece, solid screw rather than a modular, segmented screw. Leistritz expects that the production extruder will be built in 2015.

Coperion launched its high-torque ZSK Mc18 series, with a specific torque of 18 Nm/cm3, at K 2010 and, at the most recent K show, introduced several improved features. The ZSK Mc18 “smart” is designed to be more easily accessible for cleaning; its screw shaft axes are low, and ancillary units can be mounted by a swivel arm and operated from floor level, rather than from a raised platform, to improve operator safety. “This design was driven by customer requests for easier accessibility and improved ergonomics,” explains Peter von Hoffmann, general manager for the compounding business unit at Coperion. “Eliminating stairs makes the operator’s job easier and reduces injury risk.”

Customers are also increasingly looking for manufacturing equipment that is easier to keep clean on the outside as well as the inside. “In medical-grade compounding and also in markets such as automotive, compounding facilities are more frequently being audited by customers. The production facility is now also a showroom, and companies want to show that their equipment is clean and in good condition,” says von Hoffmann. Compounding plants can be dusty places, but designs such as the ZSK Mc18 smart, in which the electrical and water supply systems are integrated into the base frame of the machine, make the exterior easy to clean.

The “smart” design can also improve feeding; locating the feeder directly above the extruder throat minimizes the length of the drop into the extruder, which can minimize the amount of air added to low bulk-density fillers and thus improve feeding efficiency. The design is available for the ZSK Mc18 series (with screw diameters of 18, 26, and 32 mm) and for the ZSK MEGAvolume Plus series (screw

diameters of 27 and 34 mm). Coperion also redesigned the heating system for the SK 58 and SK 70 extruder die heads to ensure a homogenous temperature across the die plate, even at high throughput rates.

All models of the ZSK series can be retrofitted with a high-precision, high-resolution torque measurement unit. Conventionally, overall torque is measured indirectly through the motor power, but the new unit directly measures the torque on each individual shaft. This instrument enables a more accurate calculation of specific energy input and provides valuable information on the dynamic behavior of the two screw shafts. This information can be used as a quality-control check, because changes in torque can indicate a potential problem. It can also be used in scale-up calculations and in experiments to evaluate changes in parameters, such as screw design or pellet size and shape.

Meanwhile at K 2013, KraussMaffei Berstorff launched its ZE Blue Power TSE, with increased free volume (an OD/ID of 1.65) and specific torque (up to 16 Nm/cm3) to provide higher output with lower energy consumption. The new design optimizes the tooth profiles of the screw shaft and screw elements, the screw preloading system, and the geometry of the connecting sleeves to safely exploit the high torque, explains the company. A new base-frame concept allows peripheral equipment and control systems to be integrated into the base frame if desired.

And ICMA San Giorgio’s new HP (high-performance) extruder family combines increased torque (16 Nm/cm3) and a higher free volume (OD/ID ratio of 1.65) with a series of technology solutions to improve energy efficiency. These include a high-efficiency water-cooled AC motor and an insulation system that reduces heat losses at the barrel. A clam-shell barrel type is also available.

Next-Generation Kneading

Kneading extruders are reciprocating single-screw extruders that employ mixing flights that interact with stationary pins on the barrel wall. Known for low-temperature, low-shear mixing, kneading extruders have traditionally been used for compounding PVC. In the past few years, developments in kneading extruders have increased output, optimized control, and expanded the realm of applications for kneading technology.

The TriVolution next-generation compounder from B&P Process Equipment is a tri-kneader that can compound more than just PVC and is crossing over into thermoplastic compounding and reactive extrusion, says Michael Lazorchak, global product manager for B&P.

TriVolution can be used, for example, to compound bio-based fibers into polypropylene for RheTech’s RheoVision compounds. In this application, it was found to have better distributive and dispersive mixing control compared to a TSE, without excessive heat generation. TriVolution can use up to 80% less overall energy consumption than a comparable TSE, reports the company, and has about half the footprint of a conventional twin-screw system.

The tri-kneader technology, introduced in 2010, increases the flight-to-pin interactions compared to a legacy co-kneader, which improves mixing and allows uniform dispersion at lower melt temperatures. It also runs at a slower screw speed, which reduces downtime and maintenance and increases the life of wear components.

In reactive extrusion, the TriVolution is proving to have better degassing, reaction, and grafting efficiencies by creating more exposed polymer chains and renewed surface in the melt, adds Lazorchak. Several commercial units have been built, with sizes including 30-, 60-, and 120-mm screw diameters. Others, including an 80-mm size, are currently being manufactured. B&P is planning to build two TriVolution-160 machines in 2014; this is the largest standard size in the product line with rates projected up to 13,000 kg/hr.

At K 2013, Buss introduced its quantec G3 compounder, a third-generation version of the Buss four-flight kneader. The quantec G3 offers a larger processing window and

higher throughput than earlier generations. The G3 has a longer process section with a process section-length (L) to screw-diameter (D) ratio of 14 L/D, and a larger outer screw-to-shaft-diameter ratio (1.62) that increases the available throughput volume.

The screw flights use a patented surface geometry that ensures a constant shear gap between the flights and kneading pins over the entire length of the screw flight. This geometry maintains a constant shear force to eliminate localized overheating and allow gentle kneading and mixing for heat and shear-sensitive materials, notes the company.

The quantec G3 is delivered as an integrated compounding line that incorporates a feed system, pelletizer, and fully piped heating and cooling units. The control cabinet, mounted directly on the machine, is fully wired and tested before leaving the factory. This integrated design is engineered to save the customer several weeks of on-site manpower for installation and commissioning, the company adds. Many customers today run leaner and do not have internal engineering support, thus the market is looking to the equipment manufacturer to supply a system that will quickly move through commissioning to production, Buss explains.

Direct Extrusion

The demand for direct compounding extrusion systems, in which raw materials are compounded and processed directly into a product rather than pellets, continues to evolve.

An advantage of direct compounding is that it eliminates an extra heat history (i.e. pelletizing and remelting), which is particularly important for materials sensitive to degradation. It may also allow higher levels of reclaim.

Commercial direct-extrusion applications include packaging films, PVC flooring, and wood-plastic composite profiles, notes Coperion’s von Hoffmann. Equipment reliability is especially important in direct extrusion, in which downtime directly affects the downstream process.

Process Control & Simulation

Although the overall compounding industry is generally basic in its approach to process control—typically monitoring only temperature and pressure—there is a trend towards more closely monitoring product attributes and controlling the associated process parameters, says Joseph Golba, manager of process development at PolyOne. Achieving what Golba calls “product control” has the advantages of increasing product quality and consistency and reducing waste and cost.

At the SPE Continuous Compounding TopCon held in March 2014, presenters gave examples of how process-control tools are currently being used in compounding applications. On-line viscometry measurements can be used, for example, in blending resins with differing molecular weights, or in reactive extrusion, as a quality-control tool or as a process-control input, notes Golba. As an input to a control system, the viscosity measurement could be used to adjust either feed composition or process parameters to keep the final product within specification.

Another example is measuring color on-line during compounding, to monitor and control the color of the compounded product. “Increased control gives you the opportunity to make every pellet within specification,” says Golba.

One-dimensional process simulation, which can help engineers optimize screw designs and operating conditions using a virtual software program rather than physical plant trials, is another tool seeing increased acceptance. “The costs of raw materials, labor, energy, and lost production time have skyrocketed over the past 15 years, while the cost of the software remains basically the same. Software cost can be justified by the savings from running for as little as a few hours on a production line,” says Adam Dreiblatt, director of process technology at CPM Century Extrusion, who presented at the March 2014 SPE Continuous Compounding TopCon.

The biggest limitation for one-dimensional simulation is the time and cost to characterize raw materials. As compounders know, small formulation changes, such as adding a lubricant, can have a large effect on processing. “In optimization and scale-up, however, it is not necessary to have the exact material characteristics,” adds Dreiblatt. “In these two cases, as long as the same materialsare used to compare both screw designs or to compare two different size extruders, then the modeling approach is valid.” Thus, in the ongoing drive for increased productivity, compounders can benefit from new equipment technology and from process control and simulation tools.