Forming the Future of Thermoforming

Processors urged to get creative & push the envelope

Previous Article Next Article

By Nancy D. Lamontagne

Forming the Future of Thermoforming

Processors urged to get creative & push the envelope

Previous Article Next Article

By Nancy D. Lamontagne

Forming the Future of Thermoforming

Processors urged to get creative & push the envelope

Previous Article Next Article

By Nancy D. Lamontagne

A portion of the crowd that attended the 25th annual SPE Thermoforming conference. Courtesy of Ellen Dallager Photography

A portion of the crowd that attended the 25th annual SPE Thermoforming conference. Courtesy of Ellen Dallager Photography

Ken Griep (center), VP at Portage Casting & Mold, emphasized that understanding the client’s needs and expectations as well as carefully planning all production steps can greatly help eliminate costly down-time during thermoforming. Courtesy of Ellen Dallager Photography

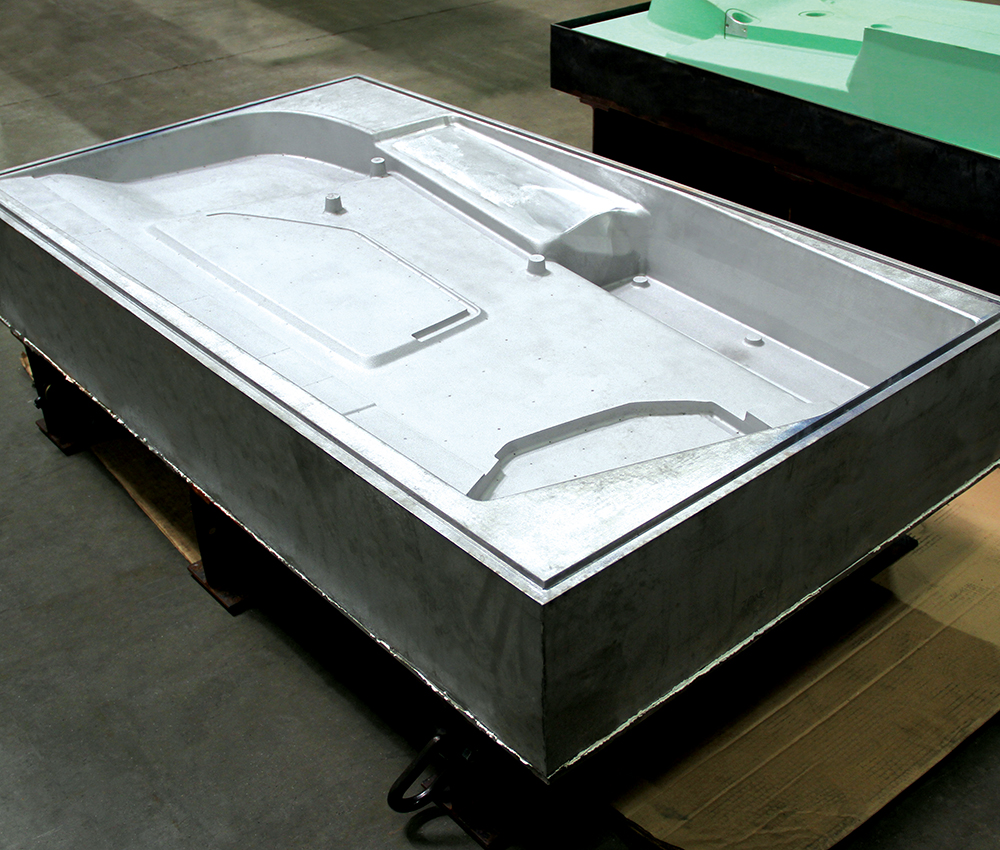

While developing tooling for a heavy-truck interior dash panel, Kienle and her team looked for ways to control variables. Courtesy of Brentwood Industries

Danielle Kienle, Product Engineer at Brentwood Industries, presented a case study outlining the company’s challenges and successes when developing tooling for a heavy-truck interior dash panel. Courtesy of Ellen Dallager Photography

Danielle Kienle

As thermoformers look to the future, they continue to seek new ways to keep costs down while producing as many parts as possible. New technologies, processes and materials are allowing thermoforming to meet customer demands for parts with increasingly complex designs and tight tolerances. But processors need to have an open mind and look to apply the process creatively in new and challenging projects.

Those were some of the key messages from the SPE Thermoforming Division’s 25th anniversary conference, which took place in Schaumburg, Ill., in late September.

The conference theme, “Forming the Future,” captured the bright outlook ahead for process. The global market for thermoformed plastics is projected to hit 8.3 billion pounds this year, according to a June 2016 BCC Research market report called “Thermoformed Plastics: Global Markets.” That amount is expected climb to 10.2 billion pounds by 2021, for a compound annual growth rate of 4.3% during that five-year period, the report projects.

In addition to celebrating its silver anniversary event, the division also served up a full day of workshops on the fundamentals of thermoforming and troubleshooting processes, followed by two days of technical sessions and exhibits, capped by an awards dinner.

Among those honored were Ian Strachan, a South African native and 45-year industry veteran, who was named Thermoformer of the Year, and Noel Tessier, a materials scientist who helped found CMT Materials Inc. and who earned a Lifetime Achievement Award. The division also announced the winners of the popular parts competition. (See sidebar for more on the award winners.)

Try Something New

Some of the industry veterans who spoke at the event urged their industry brethren to continually look for new ways to improve and to not be afraid to take on challenging projects.

Ken Griep, vice president at Wisconsin-based Portage Casting & Mold Inc., presented practical changes that his company implemented to save money and time. Portage Casting & Mold can handle all facets of thermoforming from start to finish – including prototyping, part design, pattern and fixture building, making the tooling itself, and part finishing. “The ability for a customer to leave with a fully trimmed, fully assembled part at the end of a cycle limits a multitude of errors and problems that can arise from going to different shops,” he said.

Griep’s aim was to motivate conference attendees to try something new. “You always want to challenge yourself, find out what could I do to make this a little easier for our workforce,” he said. “Ask yourself: What could I do to eliminate wasted man hours, wasted machine hours? What could I do to help improve preventative maintenance? Just because we did it this way last week, last month, last year, it may not be the best approach – always strive to improve.”

Clear communication with the client from the very beginning will help ensure that everyone understands the client’s needs and that expectations match the thermoformers capabilities. “Sometimes the client has expectations or goals that are unachievable with thermoforming,” said Griep. “In those cases, it becomes our job to educate them about what is achievable and to find out if they can change some of their expectations to match what can be done.”

Another key aspect of upfront planning is examining how fast a part can it be made and then looking downstream to make sure that there aren’t any bottlenecks. “There’s no sense in making 20 to 25 parts per hour if the trimming machine can only handle 5 or 6 parts per hour,” Griep explained. “If you do have a bottleneck at a certain step, if might require buying a better piece of equipment that can handle more parts. You don’t want to find yourself in a situation where you have to move parts from position to position more than once.”

Griep also presented some important tips for reducing downtime when getting ready to run a new part. “Every hour wasted on a mold-machine setup is a wasted production hour,” he said. “You want to put as many people as you possibly can on changing your mold and machine and have all your items ready to go so that you can literally plug and play.”

When setting up the machine for a new run, Griep said it is important to have the mold and process program ready to be installed and all auxiliary equipment such as cooling fixtures in place, so that the changeover can happen very quickly. Using quick disconnects with the air, vacuum and water hookups and using quick locks as much as possible will also cut down on time spent manually connecting and fastening components.

Standardized tool heights will keep the process moving along as quickly as possible as will preheating the mold outside the machine. Heating the mold from room temperature to 150 degrees, then doing the last bit of heating in the machine will save two to three hours of waiting for the mold to reach 180 degrees after installation.

Griep also emphasized the importance of preventative maintenance for keeping machines running. “When you’re running full production, it is very difficult to schedule a 10-hour day or a shift out of that cycle for preventative maintenance, but you have to leave time for it,” he said. “Because when something breaks all production will stop, and you’ll never get that time back.”

Learn from Past Mistakes

Danielle Kienle, product engineer at Reading, Pa.-based Brentwood Industries, presented a case study outlining the two-year process of developing tooling for a heavy-truck interior dash panel, with an emphasis on improvements that proved to be key for delivering a high-quality part. Brentwood focuses on manufacturing highly specialized parts for the medical and transportation industries with the latest materials. “We’ve also served as a product incubator, spinning off a number of proprietary product lines,” Kienle said.

She said she wanted conference attendees to realize that they don’t have to be afraid to fail as long as they learn from their mistakes. “Taking on a challenging project is really the best way to grow,” she said. “It pushes you out of your comfort zone and forces you to think outside the box. If you’re never willing to take that risk, you really won’t progress.”

The dash panel was the largest and most challenging part of a larger project that included more than 50 finished parts for the full interior and a few exterior parts of a heavy truck. The parts were primarily pressured formed thermoplastic polyolefins and featured an acid-etched texture applied to the tooling. In addition to being one of the largest-scale projects the company has tackled, the customer’s timeline for getting the truck fully designed and into production was compressed from five to three years. This meant that Kienle and her colleagues had to work through design changes while also developing tooling.

“There was a lot going on all at once; it really showed us the importance of working with your customer during the early stages of the project,” she said. “If we would have been involved at the prototyping phase, we would have worked through a lot of the tooling development earlier in the process.”

Kienle said that Brentwood Industries’ knowledge and experience allowed them to deliver the high-quality tooling that was key to this project’s success. It was important to identify materials that were the most appropriate for the application and to understand how long the project would last so that the tools could be made to last that long.

“There are so many new materials that weren’t available 10 years ago,” she said. “We have to keep up to date with these new products and how they work while also thinking about the best way to apply them.”

Controlling variables was another important aspect that contributed to the project’s success. Kienle and her colleagues accomplished this by optimizing the tools and with forming machine upgrades, which included adding a vertical sag eye and temperature monitors. They also replaced all the oven elements. “Typically, we would check the oven elements weekly or monthly and replace any that were burnt out, but we decided to replace all of them to ensure consistent output.”

Another contributor to the success of this project was a concerted effort to increase the education of the forming operators. Brentwood brought in Robert Browning from the McConnell Co. to conduct training sessions that increased the awareness and knowledge of the operators and forming specialists, giving them better troubleshooting skills.

Kienle says that Brentwood Industries is seeing increasing demand for more intricate designs, more complex geometries and tighter tolerances in thermoformed parts as well as more requests to use specific raw materials. She also pointed to advances in syntactic foam as having made a big difference in allowing them to achieve greater uniformity in material thickness.

“The technology is evolving and while it has been a learning process, we are able to produce the much more complex parts that are being demanded by the market.”