An Antiblock Alternative

Previous Article Next Article

An Antiblock Alternative

Previous Article Next Article

An Antiblock Alternative

Previous Article Next Article

Miners of a less-familiar mineral filler claim it has some advantages over traditional talc and diatomaceous earth (DE) fillers in term of antiblocking and other properties. Trinity Resources Ltd. in Newfoundland, Canada, offers a product named Altiblock™, produced from the company’s deposits of pyrophyllite (a hydrous aluminum silicate).

Among the additives options that prevent thin plastic layers from sticking to each other, “Talc, nepheline syenite, and DE have been the incumbent high-performance antiblock minerals in plastic films,” says John Hurley, president and CEO of Trinity Resources. Altiblock’s morphology combines the best attributes of these three mineral additives, he explains.

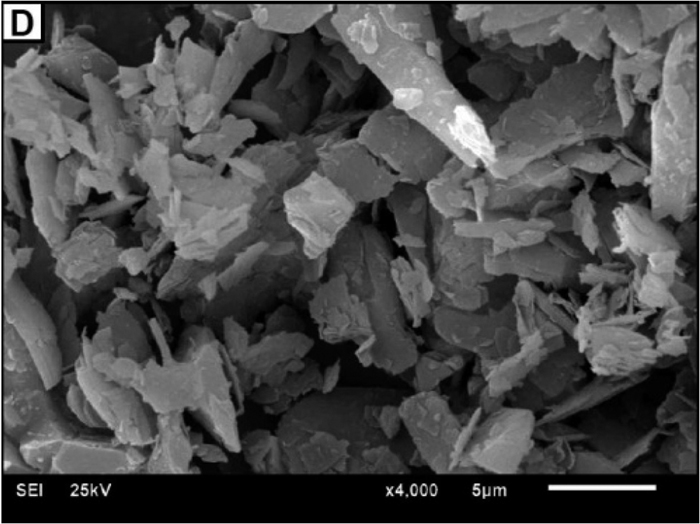

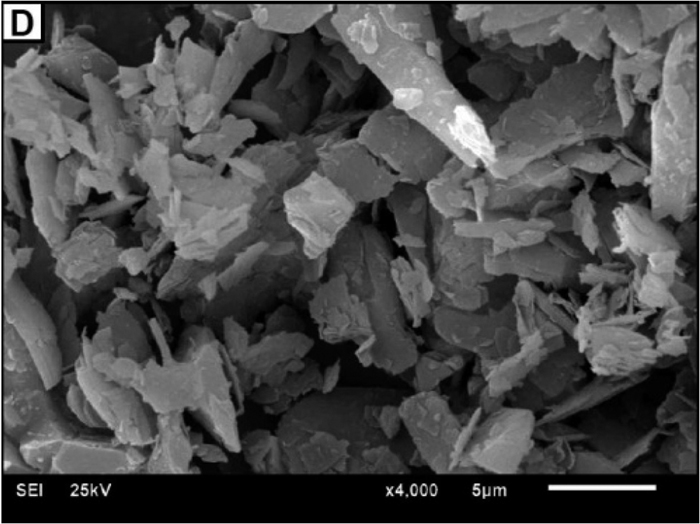

The pyrophyllite product is described as a natural blend of talc-like platy particles and irregular, blocky particle shapes. The combination is said to provide not only optimum antiblocking, but also optimum film strength, barrier resistance, and thermal efficiency. The product also has very low (<0.2%) iron content, which at higher levels can help degrade the film resin or its organic components. And it has a refractive index close to that of nepheline syenite, while outperforming talc and DE in terms of clarity, according to its producer.

The product is available in 2-, 4-, 6-, and 9-micron sizes, with the grade Altiblock D400 specified as a talc replacement, and D900 as a DE replacement. “By focusing on our logistics and manufacturing costs, we are able balance the cost-to-performance equation for film processors throughout the NAFTA region,” Hurley adds.