Additives Annual 2014: Feeling the Heat

Previous Article Next Article

By Michael Tolinski

Photo courtesy of Plastics Color Corp.

Taking a broad view of some of the hottest issues with plastics—that is, issues of special interest to both the plastics industry and the general public—you’ll find that plastics additives have many roles to play. Whether providing “hot,” attention-getting colors for products, addressing sustainability issues related to recycling or bioplastics, or facing literally hot issues related to heat resistance and flame retardants—new additives answer the industry’s needs and public’s concerns. This yearly review will present just a sampling of these kinds of product developments.

Color Concerns

Colorants for plastics have to fulfill several requirements—not only must they help support the marketed features of a product visually, but they must also be consumer-safe and resist the heat of processing, among many other musts.

Regarding appearance, there always seem to be new shades of color that are said to be trending in popularity. Each year colorant producers make their new “top color picks,” colors whose names and descriptions can often be as aesthetically inspired as the colors themselves. For example, Plastics Color Corp. has offered two top picks for 2014, “Oceanana” (“a plant-derived deep blue that inspires calm…”) and “Copperico” (a “copper-like” tone “supplanting grays and yellow/gold tones as a preferred warm/neutral tone around the house”).

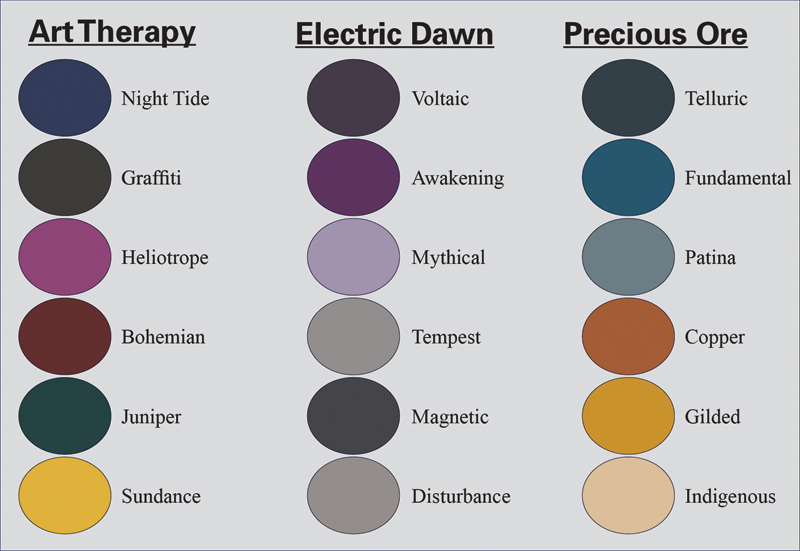

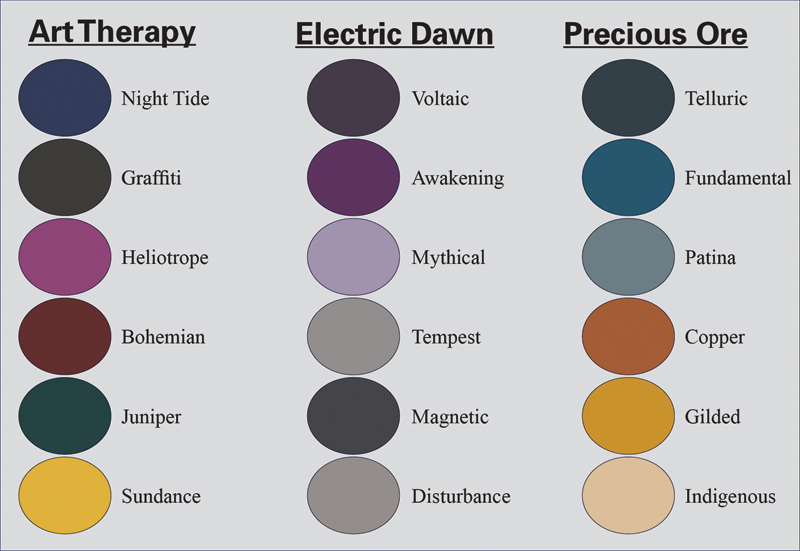

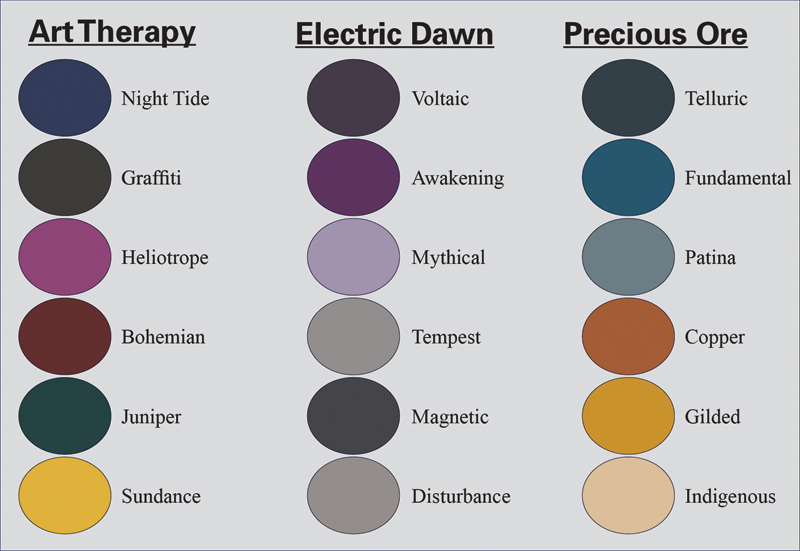

In September, Americhem Inc. announced its forward-looking “2015– 2016 Color Trends.” The company describes six color palettes: “Art Therapy” (“an enlivened palette of crimson, jewel-toned blues, fuchsia and gold that stimulates aesthetic sensibilities and feeds the soul”), “Electric Dawn” (“colors of the pre-dawn sky”), “Precious Ore” (natural landscape colors), “Transcend” (blues, beiges, grays, and “daring blue-violets”), “Venetian Style” (“gold, apricot, warm grays and subtle mauves”), and “Alchemy” (“transforming colors” of nature). There popular trends are based on global cultural influences, demographic trends, and “fashion-forward color predictions,” explains the company.

Some new trending colors identified by Americhem’s researchers.

Special effects colorants are likewise evolving. PolyOne has released liquid color concentrates that provide “shimmer and frost effects” for PET containers, as part of the company’s InVisiOSM suite of color services. The new colorants produce “iridescent color movements” that can “enhance brand presence and deliver differentiated shelf impact across beverage, personal care, and household product packaging applications,” the company says.

As Gary Fielding of PolyOne ColorMatrix adds, “These new, eye-catching formulations give our customers the freedom to push design boundaries and react to global color trends, without disrupting their existing processes.” The formulations are said to be usable with conventional gloss pre-form and blow molds.

PolyOne’s liquid colors offer “shimmer and frost” effects for PET.

Colorants also have to hold up under processing heat. For Fakuma 2014, BASF Color Solutions announced demonstrations of masterbatch applications for coloring plastics—higher-temperature engineering plastics in particular. For processing temperatures up to 350°C, the business unit’s Sicoversal® X masterbatches are optimized for coloring BASF Ultradur® polybutylene terephthalate grades, as shown in example applications of colorful coffee capsules and fiber-optic cables.

Safe Shades

And colorants and other additives have to be safe. These issues were laid out in a detailed 2013 presentation by Ricard Vandellos, vice president, Plastic Additives Europe, BASF Espanola S.L. Vandellos noted that in the face of increased regulation, “BASF is offering comprehensive analytical support for 160 of its pigments,” supporting safe uses of these products in sensitive plastic applications.

Whether talking about colorants, antioxidants, foaming agents, or flame retardants, safety is a hot issue for plastics additives (photo courtesy of BASF).

“Nowadays the plastics converting industry is serving a wider market and application scope where sensitive applications play a key role,” reported Vandellos. “Colored and stabilized plastics are replacing heavier materials driven by cost, weight, design, and consumer safety… At the same time, brand owners are requiring the plastics converting industry to ensure full compliance and minimize cross contamination risk potentially incurred when producing products for sensitive applications in the same sites where non-sensitive application materials are produced.”

Recent regulations in the European Union have made things even more challenging. “New laws such as the EU regulation on toys stipulate the maximum permissible limits for impurities or tighten those that already exist.” Non-EU countries’ laws have likewise stiffened; “China too has launched new food contact regulations,” Vandellos noted. And these laws apply to pigments, even though, being non-migrating, they come “out of a plastic only with difficulty and moreover can rarely be converted to a bio-available form.”

Thus, getting colorants approved for food-contact applications may only get more challenging. But it can be done. Milliken & Co. this year reported U.S. FDA food-contact approval for its PP and HDPE ClearTint®liquid polymeric colorants. The company argues the approval will help manufacturers of food containers avoid the “time and cost required to calculate use levels and conditions for non-migration of new ClearTint colorant blends, making it easier to adopt the latest color trends.”

Colorants for coffee canister materials face high temperatures; BASF offers Sicoversal® X masterbatches as a solution.

Approval will help the colorants broaden their application areas into repeat-use containers like baby bottles and sippy cups. “Our ClearTint colorants were already compliant with FDA food-contact requirements and have now earned agency approval across broad conditions of use, including sterilization in boiling water,” explains Melissa Copeland, Milliken global product line manager.

Food-Friendly Antioxidants

Producers of antioxidants, which protect the polymer from degradation during production and use, are being pressured similarly. In response, in one example, Addivant announced this year that its Weston® 705 liquid antioxidant, a nonylphenol-free phosphite additive, received food-contact approval from the U.S. FDA.

The 705 is a secondary antioxidant for linear low-density polyethylene and HDPE, and the company says toxicology testing shows it’s safer and higher-performing than conventional solid phosphite antioxidants. The liquid antioxidant was developed “with the future in mind,” overcoming the drawbacks of conventional solid phosphites, says Peter Smith, Addivant president and CEO.

The company says the product “looks, handles, and functions” like Weston tris(nonylphenyl) phosphite (TNPP) AOs but is higher in phosphorous, so lower loadings (up to 18% lower) provide equivalent performance. The FDA approval reportedly allows the 705 product to be used in deli wrap, snack food bags, carton liners, and boil-in bags.

“Cool Innovations for Hot Applications”

The above heading was the title of a paper by Cytec Industries authors at the 2014 SPE International Polyolefins Conference earlier this year. It indicates a particular growing need of automotive manufacturers: stabilizing additives that help plastics in automotive interiors (and elsewhere) resist heat and UV light, without fogging. The paper discusses Cytec’s Cyasorb Cynergy Solutions V Series stabilizers for auto interiors, additives which reportedly more than fulfill these goals by protecting physical properties and part appearance and extending service life.

“Applications traditionally designed with glass, metal, and other materials are increasingly replaced with polyolefins, bringing on new application challenges for our customers,” says Francois Jacob, global marketing director for Cytec Additive Technologies.

Photo courtesy of Songwon.

Songwon likewise released its own stabilizers for thermally stable, non-fogging auto interior applications earlier this year. Songxtend™ 2121, 2122, and 2123 stabilizers, by containing at least 30% less sulfur (the 2123 stabilizer is 100% sulfur-free), also reportedly reduce VOC and odor issues in cars.

Songwon global technical service director Thomas Schmutz says the stabilizers “enable manufacturers and OEMs to respond successfully to the increasingly stringent industry standards regarding VOC- and fog-related deposits on interior windscreens.”

Flame Retardants: The New Normal

Auto interiors can get hot, but the highest heat that plastic products could ever encounter is, of course, the heat of burning. Regulatory shifts continue to motivate flame-retardants producers to offer more halogen-free options, as summed up in an August 2014 blog entry by Plastics Color Corp. (PCC; plasticscolor.com/blog): “The plastics industry lost its most versatile and effective flame retardant (FR) when decaBDE was phased out over environmental and health concerns in 2012.”

The bromine-saturated “deca” was more than popular (“Deca was to the FR plastics business what type-O negative is to a blood bank,” the blog entry added). But given the anti-halogen push, the U.S. Environmental Protection Agency has identified 29 potential alternatives for “polyolefins, styrenics, engineering thermoplastics, thermosets, elastomers, or waterborne emulsions and coatings,” reports PCC.

In response, the company reportedly is addressing the difficulties of using some non-halogenated FRs in masterbatches, given the high loading rates typically required. PCC development engineer David Witt is cited as the developer of the company’s FlamaSol® decaBDE-replacement FRs. Witt stresses the importance of FR/resin compatibility, saying that given changing regulations, an FR should fit the required standard (UL, ISO, ASTM), as well as the resin.

Meanwhile, applications for halogen-free FRs can sometimes be surprising; oyster shell fillers in flame-retardant PP, for example, is one focus of Clariant. In research led by the Unité Matériaux et Transformations (UMET) at the University of Lille in France, researchers reported that it’s possible to achieve effective flame retardancy for oyster shell-reinforced PP composites, saying a “significant increase in the thermal stability of the PP compound” was found using Clariant’s phosphate-based Exolit®AP760.

Eurostar Engineering Plastics developed the oyster shell/PP compound, choosing the shells as a “green” source of mineral filler that avoids the negatives of mining processes while contributing to landfill reduction. The Exolit FR supports the environmental profile of the material, says Clariant, with no toxic effects or environmental accumulation.

“The project results herald a breakthrough in the feasibility of using bio-based materials in high-end application areas, such as the automotive and building and construction industries, where effective flame retardancy is required,” says Prof. Sophie Duquesne, leader of the UMET research group. “In addition to oyster shells, we are also actively researching the viability of achieving flame retardancy when vegetal fillers such as flax are used, to further extend possibilities for more environmentally friendly materials in demanding environments.”

Keen on “Green”

Speaking of bio-friendly alternatives… interest remains steady. As with bioplastics producers, additives producers can tout their own environmental awards. This year Arkema received the Chairman’s Award from the Plastics Environmental Division of the Society of Plastics Engineers for the development of its Biostrength® impact modifiers, which improve a range of properties of the biopolymer polylactic acid (PLA). The impact modifiers and process aids reportedly counteract the deficiencies of PLA, which is normally brittle and has low melt strength.

Biostrength impact modifiers are designed to increase PLA toughness by several orders of magnitude, expanding PLA’s range of applications. They also can increase melt strength by as much as 100%, the company adds, helping PLA break into the textile fiber application sector. Manny Katz, global group president of Arkema’s Functional Additives business, says the modifiers “will undoubtedly contribute to the growth of the biopolymer industry by enabling PLA to tap into new markets.”

In plastics recycling, additives play big roles too. Earlier this year, Struktol Co. of America announced the launch of several additives products supporting recycled plastics. For use in various resin families, they’re targeted for compounds containing 100% recycled materials or those with varying degrees of recycled content.

The company’s RP 28 is a compatibilizer and blending aid for incorporating regrind or recycled material, serving also as an alloying agent, the company says. For engineering plastics, the company combines compatibilizers with lubricants in additives that aid the incorporation of mineral or glass fillers, for example. One product, Struktol® TR 219, is said to perform well in nylon 6 and 6,6 and polyethylene terephthalate (PET) compounds—especially in recycled applications or in cases where PET is contaminated with other plastics.

Other products reportedly offer better processing for recycled plastics. Struktol RP 11 is a lubricant that reduces viscosity and improves mold release for PP at loading levels of 0.2%. The company says it allows the greater use of regrind or recycled content “without sacrificing certain properties or performance,” replacing peroxide modifiers and internal or external mold releases.

Foaming: Safe & Efficient

Resin reduction is one sustainability goal lying behind the use chemical foaming agents (CFAs)—and sustainability is supported even more when a non-hazardous CFA is used to create blown cells. To this end, Reedy International introduced a line of high-temperature endothermic chemical foaming agents as alternatives for azodicarbonamide, whose decomposition products have led to some regulations limiting its use in food-related applications.

The company says its Safoam® HT is formulated with FDA-approved foaming agents and “produces no potentially hazardous degradation byproducts.” With a decomposition temperature of 210°C, it can be used without modifying the process conditions for materials traditionally foamed with azodicarbonamide. It’s available in powder and masterbatch form, the company adds.

Wire insulation is one application that benefits from foaming. PolyOne recently announced a new chemical foaming additive for fluoropolymer wire insulation that preserves electrical properties “while reducing insulation thickness and raw material consumption through a consistent closed-cell structure.”

“It’s difficult to minimize the tradeoffs between thermal stability, foaming control, and high processing temperatures when applying wire insulation,” explains Barto du Plessis, general manager, PolyOne Colorant Chromatics. “This new technology balances all three performance requirements and boosts productivity without the need for additional equipment investment.”

The additive reportedly restricts premature foaming (enabling maximum gas generation), produces a consistent cell structure of 200 microns or less, and resists temperatures of 340-380°C, “supporting effective homogenization of the foaming agent with high-performance polymers,” the company adds.

Additives Annual 2014: Feeling the Heat

Previous Article Next Article

By Michael Tolinski

Photo courtesy of Plastics Color Corp.

Taking a broad view of some of the hottest issues with plastics—that is, issues of special interest to both the plastics industry and the general public—you’ll find that plastics additives have many roles to play. Whether providing “hot,” attention-getting colors for products, addressing sustainability issues related to recycling or bioplastics, or facing literally hot issues related to heat resistance and flame retardants—new additives answer the industry’s needs and public’s concerns. This yearly review will present just a sampling of these kinds of product developments.

Color Concerns

Colorants for plastics have to fulfill several requirements—not only must they help support the marketed features of a product visually, but they must also be consumer-safe and resist the heat of processing, among many other musts.

Regarding appearance, there always seem to be new shades of color that are said to be trending in popularity. Each year colorant producers make their new “top color picks,” colors whose names and descriptions can often be as aesthetically inspired as the colors themselves. For example, Plastics Color Corp. has offered two top picks for 2014, “Oceanana” (“a plant-derived deep blue that inspires calm…”) and “Copperico” (a “copper-like” tone “supplanting grays and yellow/gold tones as a preferred warm/neutral tone around the house”).

In September, Americhem Inc. announced its forward-looking “2015– 2016 Color Trends.” The company describes six color palettes: “Art Therapy” (“an enlivened palette of crimson, jewel-toned blues, fuchsia and gold that stimulates aesthetic sensibilities and feeds the soul”), “Electric Dawn” (“colors of the pre-dawn sky”), “Precious Ore” (natural landscape colors), “Transcend” (blues, beiges, grays, and “daring blue-violets”), “Venetian Style” (“gold, apricot, warm grays and subtle mauves”), and “Alchemy” (“transforming colors” of nature). There popular trends are based on global cultural influences, demographic trends, and “fashion-forward color predictions,” explains the company.

Some new trending colors identified by Americhem’s researchers.

Special effects colorants are likewise evolving. PolyOne has released liquid color concentrates that provide “shimmer and frost effects” for PET containers, as part of the company’s InVisiOSM suite of color services. The new colorants produce “iridescent color movements” that can “enhance brand presence and deliver differentiated shelf impact across beverage, personal care, and household product packaging applications,” the company says.

As Gary Fielding of PolyOne ColorMatrix adds, “These new, eye-catching formulations give our customers the freedom to push design boundaries and react to global color trends, without disrupting their existing processes.” The formulations are said to be usable with conventional gloss pre-form and blow molds.

PolyOne’s liquid colors offer “shimmer and frost” effects for PET.

Colorants also have to hold up under processing heat. For Fakuma 2014, BASF Color Solutions announced demonstrations of masterbatch applications for coloring plastics—higher-temperature engineering plastics in particular. For processing temperatures up to 350°C, the business unit’s Sicoversal® X masterbatches are optimized for coloring BASF Ultradur® polybutylene terephthalate grades, as shown in example applications of colorful coffee capsules and fiber-optic cables.

Safe Shades

And colorants and other additives have to be safe. These issues were laid out in a detailed 2013 presentation by Ricard Vandellos, vice president, Plastic Additives Europe, BASF Espanola S.L. Vandellos noted that in the face of increased regulation, “BASF is offering comprehensive analytical support for 160 of its pigments,” supporting safe uses of these products in sensitive plastic applications.

Whether talking about colorants, antioxidants, foaming agents, or flame retardants, safety is a hot issue for plastics additives (photo courtesy of BASF).

“Nowadays the plastics converting industry is serving a wider market and application scope where sensitive applications play a key role,” reported Vandellos. “Colored and stabilized plastics are replacing heavier materials driven by cost, weight, design, and consumer safety… At the same time, brand owners are requiring the plastics converting industry to ensure full compliance and minimize cross contamination risk potentially incurred when producing products for sensitive applications in the same sites where non-sensitive application materials are produced.”

Recent regulations in the European Union have made things even more challenging. “New laws such as the EU regulation on toys stipulate the maximum permissible limits for impurities or tighten those that already exist.” Non-EU countries’ laws have likewise stiffened; “China too has launched new food contact regulations,” Vandellos noted. And these laws apply to pigments, even though, being non-migrating, they come “out of a plastic only with difficulty and moreover can rarely be converted to a bio-available form.”

Thus, getting colorants approved for food-contact applications may only get more challenging. But it can be done. Milliken & Co. this year reported U.S. FDA food-contact approval for its PP and HDPE ClearTint®liquid polymeric colorants. The company argues the approval will help manufacturers of food containers avoid the “time and cost required to calculate use levels and conditions for non-migration of new ClearTint colorant blends, making it easier to adopt the latest color trends.”

Colorants for coffee canister materials face high temperatures; BASF offers Sicoversal® X masterbatches as a solution.

Approval will help the colorants broaden their application areas into repeat-use containers like baby bottles and sippy cups. “Our ClearTint colorants were already compliant with FDA food-contact requirements and have now earned agency approval across broad conditions of use, including sterilization in boiling water,” explains Melissa Copeland, Milliken global product line manager.

Food-Friendly Antioxidants

Producers of antioxidants, which protect the polymer from degradation during production and use, are being pressured similarly. In response, in one example, Addivant announced this year that its Weston® 705 liquid antioxidant, a nonylphenol-free phosphite additive, received food-contact approval from the U.S. FDA.

The 705 is a secondary antioxidant for linear low-density polyethylene and HDPE, and the company says toxicology testing shows it’s safer and higher-performing than conventional solid phosphite antioxidants. The liquid antioxidant was developed “with the future in mind,” overcoming the drawbacks of conventional solid phosphites, says Peter Smith, Addivant president and CEO.

The company says the product “looks, handles, and functions” like Weston tris(nonylphenyl) phosphite (TNPP) AOs but is higher in phosphorous, so lower loadings (up to 18% lower) provide equivalent performance. The FDA approval reportedly allows the 705 product to be used in deli wrap, snack food bags, carton liners, and boil-in bags.

“Cool Innovations for Hot Applications”

The above heading was the title of a paper by Cytec Industries authors at the 2014 SPE International Polyolefins Conference earlier this year. It indicates a particular growing need of automotive manufacturers: stabilizing additives that help plastics in automotive interiors (and elsewhere) resist heat and UV light, without fogging. The paper discusses Cytec’s Cyasorb Cynergy Solutions V Series stabilizers for auto interiors, additives which reportedly more than fulfill these goals by protecting physical properties and part appearance and extending service life.

“Applications traditionally designed with glass, metal, and other materials are increasingly replaced with polyolefins, bringing on new application challenges for our customers,” says Francois Jacob, global marketing director for Cytec Additive Technologies.

Photo courtesy of Songwon.

Songwon likewise released its own stabilizers for thermally stable, non-fogging auto interior applications earlier this year. Songxtend™ 2121, 2122, and 2123 stabilizers, by containing at least 30% less sulfur (the 2123 stabilizer is 100% sulfur-free), also reportedly reduce VOC and odor issues in cars.

Songwon global technical service director Thomas Schmutz says the stabilizers “enable manufacturers and OEMs to respond successfully to the increasingly stringent industry standards regarding VOC- and fog-related deposits on interior windscreens.”

Flame Retardants: The New Normal

Auto interiors can get hot, but the highest heat that plastic products could ever encounter is, of course, the heat of burning. Regulatory shifts continue to motivate flame-retardants producers to offer more halogen-free options, as summed up in an August 2014 blog entry by Plastics Color Corp. (PCC; plasticscolor.com/blog): “The plastics industry lost its most versatile and effective flame retardant (FR) when decaBDE was phased out over environmental and health concerns in 2012.”

The bromine-saturated “deca” was more than popular (“Deca was to the FR plastics business what type-O negative is to a blood bank,” the blog entry added). But given the anti-halogen push, the U.S. Environmental Protection Agency has identified 29 potential alternatives for “polyolefins, styrenics, engineering thermoplastics, thermosets, elastomers, or waterborne emulsions and coatings,” reports PCC.

In response, the company reportedly is addressing the difficulties of using some non-halogenated FRs in masterbatches, given the high loading rates typically required. PCC development engineer David Witt is cited as the developer of the company’s FlamaSol® decaBDE-replacement FRs. Witt stresses the importance of FR/resin compatibility, saying that given changing regulations, an FR should fit the required standard (UL, ISO, ASTM), as well as the resin.

Meanwhile, applications for halogen-free FRs can sometimes be surprising; oyster shell fillers in flame-retardant PP, for example, is one focus of Clariant. In research led by the Unité Matériaux et Transformations (UMET) at the University of Lille in France, researchers reported that it’s possible to achieve effective flame retardancy for oyster shell-reinforced PP composites, saying a “significant increase in the thermal stability of the PP compound” was found using Clariant’s phosphate-based Exolit®AP760.

Eurostar Engineering Plastics developed the oyster shell/PP compound, choosing the shells as a “green” source of mineral filler that avoids the negatives of mining processes while contributing to landfill reduction. The Exolit FR supports the environmental profile of the material, says Clariant, with no toxic effects or environmental accumulation.

“The project results herald a breakthrough in the feasibility of using bio-based materials in high-end application areas, such as the automotive and building and construction industries, where effective flame retardancy is required,” says Prof. Sophie Duquesne, leader of the UMET research group. “In addition to oyster shells, we are also actively researching the viability of achieving flame retardancy when vegetal fillers such as flax are used, to further extend possibilities for more environmentally friendly materials in demanding environments.”

Keen on “Green”

Speaking of bio-friendly alternatives… interest remains steady. As with bioplastics producers, additives producers can tout their own environmental awards. This year Arkema received the Chairman’s Award from the Plastics Environmental Division of the Society of Plastics Engineers for the development of its Biostrength® impact modifiers, which improve a range of properties of the biopolymer polylactic acid (PLA). The impact modifiers and process aids reportedly counteract the deficiencies of PLA, which is normally brittle and has low melt strength.

Biostrength impact modifiers are designed to increase PLA toughness by several orders of magnitude, expanding PLA’s range of applications. They also can increase melt strength by as much as 100%, the company adds, helping PLA break into the textile fiber application sector. Manny Katz, global group president of Arkema’s Functional Additives business, says the modifiers “will undoubtedly contribute to the growth of the biopolymer industry by enabling PLA to tap into new markets.”

In plastics recycling, additives play big roles too. Earlier this year, Struktol Co. of America announced the launch of several additives products supporting recycled plastics. For use in various resin families, they’re targeted for compounds containing 100% recycled materials or those with varying degrees of recycled content.

The company’s RP 28 is a compatibilizer and blending aid for incorporating regrind or recycled material, serving also as an alloying agent, the company says. For engineering plastics, the company combines compatibilizers with lubricants in additives that aid the incorporation of mineral or glass fillers, for example. One product, Struktol® TR 219, is said to perform well in nylon 6 and 6,6 and polyethylene terephthalate (PET) compounds—especially in recycled applications or in cases where PET is contaminated with other plastics.

Other products reportedly offer better processing for recycled plastics. Struktol RP 11 is a lubricant that reduces viscosity and improves mold release for PP at loading levels of 0.2%. The company says it allows the greater use of regrind or recycled content “without sacrificing certain properties or performance,” replacing peroxide modifiers and internal or external mold releases.

Foaming: Safe & Efficient

Resin reduction is one sustainability goal lying behind the use chemical foaming agents (CFAs)—and sustainability is supported even more when a non-hazardous CFA is used to create blown cells. To this end, Reedy International introduced a line of high-temperature endothermic chemical foaming agents as alternatives for azodicarbonamide, whose decomposition products have led to some regulations limiting its use in food-related applications.

The company says its Safoam® HT is formulated with FDA-approved foaming agents and “produces no potentially hazardous degradation byproducts.” With a decomposition temperature of 210°C, it can be used without modifying the process conditions for materials traditionally foamed with azodicarbonamide. It’s available in powder and masterbatch form, the company adds.

Wire insulation is one application that benefits from foaming. PolyOne recently announced a new chemical foaming additive for fluoropolymer wire insulation that preserves electrical properties “while reducing insulation thickness and raw material consumption through a consistent closed-cell structure.”

“It’s difficult to minimize the tradeoffs between thermal stability, foaming control, and high processing temperatures when applying wire insulation,” explains Barto du Plessis, general manager, PolyOne Colorant Chromatics. “This new technology balances all three performance requirements and boosts productivity without the need for additional equipment investment.”

The additive reportedly restricts premature foaming (enabling maximum gas generation), produces a consistent cell structure of 200 microns or less, and resists temperatures of 340-380°C, “supporting effective homogenization of the foaming agent with high-performance polymers,” the company adds.

Additives Annual 2014: Feeling the Heat

Previous Article Next Article

By Michael Tolinski

Photo courtesy of Plastics Color Corp.

Taking a broad view of some of the hottest issues with plastics—that is, issues of special interest to both the plastics industry and the general public—you’ll find that plastics additives have many roles to play. Whether providing “hot,” attention-getting colors for products, addressing sustainability issues related to recycling or bioplastics, or facing literally hot issues related to heat resistance and flame retardants—new additives answer the industry’s needs and public’s concerns. This yearly review will present just a sampling of these kinds of product developments.

Color Concerns

Colorants for plastics have to fulfill several requirements—not only must they help support the marketed features of a product visually, but they must also be consumer-safe and resist the heat of processing, among many other musts.

Regarding appearance, there always seem to be new shades of color that are said to be trending in popularity. Each year colorant producers make their new “top color picks,” colors whose names and descriptions can often be as aesthetically inspired as the colors themselves. For example, Plastics Color Corp. has offered two top picks for 2014, “Oceanana” (“a plant-derived deep blue that inspires calm…”) and “Copperico” (a “copper-like” tone “supplanting grays and yellow/gold tones as a preferred warm/neutral tone around the house”).

In September, Americhem Inc. announced its forward-looking “2015– 2016 Color Trends.” The company describes six color palettes: “Art Therapy” (“an enlivened palette of crimson, jewel-toned blues, fuchsia and gold that stimulates aesthetic sensibilities and feeds the soul”), “Electric Dawn” (“colors of the pre-dawn sky”), “Precious Ore” (natural landscape colors), “Transcend” (blues, beiges, grays, and “daring blue-violets”), “Venetian Style” (“gold, apricot, warm grays and subtle mauves”), and “Alchemy” (“transforming colors” of nature). There popular trends are based on global cultural influences, demographic trends, and “fashion-forward color predictions,” explains the company.

Some new trending colors identified by Americhem’s researchers.

Special effects colorants are likewise evolving. PolyOne has released liquid color concentrates that provide “shimmer and frost effects” for PET containers, as part of the company’s InVisiOSM suite of color services. The new colorants produce “iridescent color movements” that can “enhance brand presence and deliver differentiated shelf impact across beverage, personal care, and household product packaging applications,” the company says.

As Gary Fielding of PolyOne ColorMatrix adds, “These new, eye-catching formulations give our customers the freedom to push design boundaries and react to global color trends, without disrupting their existing processes.” The formulations are said to be usable with conventional gloss pre-form and blow molds.

PolyOne’s liquid colors offer “shimmer and frost” effects for PET.

Colorants also have to hold up under processing heat. For Fakuma 2014, BASF Color Solutions announced demonstrations of masterbatch applications for coloring plastics—higher-temperature engineering plastics in particular. For processing temperatures up to 350°C, the business unit’s Sicoversal® X masterbatches are optimized for coloring BASF Ultradur® polybutylene terephthalate grades, as shown in example applications of colorful coffee capsules and fiber-optic cables.

Safe Shades

And colorants and other additives have to be safe. These issues were laid out in a detailed 2013 presentation by Ricard Vandellos, vice president, Plastic Additives Europe, BASF Espanola S.L. Vandellos noted that in the face of increased regulation, “BASF is offering comprehensive analytical support for 160 of its pigments,” supporting safe uses of these products in sensitive plastic applications.

Whether talking about colorants, antioxidants, foaming agents, or flame retardants, safety is a hot issue for plastics additives (photo courtesy of BASF).

“Nowadays the plastics converting industry is serving a wider market and application scope where sensitive applications play a key role,” reported Vandellos. “Colored and stabilized plastics are replacing heavier materials driven by cost, weight, design, and consumer safety… At the same time, brand owners are requiring the plastics converting industry to ensure full compliance and minimize cross contamination risk potentially incurred when producing products for sensitive applications in the same sites where non-sensitive application materials are produced.”

Recent regulations in the European Union have made things even more challenging. “New laws such as the EU regulation on toys stipulate the maximum permissible limits for impurities or tighten those that already exist.” Non-EU countries’ laws have likewise stiffened; “China too has launched new food contact regulations,” Vandellos noted. And these laws apply to pigments, even though, being non-migrating, they come “out of a plastic only with difficulty and moreover can rarely be converted to a bio-available form.”

Thus, getting colorants approved for food-contact applications may only get more challenging. But it can be done. Milliken & Co. this year reported U.S. FDA food-contact approval for its PP and HDPE ClearTint®liquid polymeric colorants. The company argues the approval will help manufacturers of food containers avoid the “time and cost required to calculate use levels and conditions for non-migration of new ClearTint colorant blends, making it easier to adopt the latest color trends.”

Colorants for coffee canister materials face high temperatures; BASF offers Sicoversal® X masterbatches as a solution.

Approval will help the colorants broaden their application areas into repeat-use containers like baby bottles and sippy cups. “Our ClearTint colorants were already compliant with FDA food-contact requirements and have now earned agency approval across broad conditions of use, including sterilization in boiling water,” explains Melissa Copeland, Milliken global product line manager.

Food-Friendly Antioxidants

Producers of antioxidants, which protect the polymer from degradation during production and use, are being pressured similarly. In response, in one example, Addivant announced this year that its Weston® 705 liquid antioxidant, a nonylphenol-free phosphite additive, received food-contact approval from the U.S. FDA.

The 705 is a secondary antioxidant for linear low-density polyethylene and HDPE, and the company says toxicology testing shows it’s safer and higher-performing than conventional solid phosphite antioxidants. The liquid antioxidant was developed “with the future in mind,” overcoming the drawbacks of conventional solid phosphites, says Peter Smith, Addivant president and CEO.

The company says the product “looks, handles, and functions” like Weston tris(nonylphenyl) phosphite (TNPP) AOs but is higher in phosphorous, so lower loadings (up to 18% lower) provide equivalent performance. The FDA approval reportedly allows the 705 product to be used in deli wrap, snack food bags, carton liners, and boil-in bags.

“Cool Innovations for Hot Applications”

The above heading was the title of a paper by Cytec Industries authors at the 2014 SPE International Polyolefins Conference earlier this year. It indicates a particular growing need of automotive manufacturers: stabilizing additives that help plastics in automotive interiors (and elsewhere) resist heat and UV light, without fogging. The paper discusses Cytec’s Cyasorb Cynergy Solutions V Series stabilizers for auto interiors, additives which reportedly more than fulfill these goals by protecting physical properties and part appearance and extending service life.

“Applications traditionally designed with glass, metal, and other materials are increasingly replaced with polyolefins, bringing on new application challenges for our customers,” says Francois Jacob, global marketing director for Cytec Additive Technologies.

Photo courtesy of Songwon.

Songwon likewise released its own stabilizers for thermally stable, non-fogging auto interior applications earlier this year. Songxtend™ 2121, 2122, and 2123 stabilizers, by containing at least 30% less sulfur (the 2123 stabilizer is 100% sulfur-free), also reportedly reduce VOC and odor issues in cars.

Songwon global technical service director Thomas Schmutz says the stabilizers “enable manufacturers and OEMs to respond successfully to the increasingly stringent industry standards regarding VOC- and fog-related deposits on interior windscreens.”

Flame Retardants: The New Normal

Auto interiors can get hot, but the highest heat that plastic products could ever encounter is, of course, the heat of burning. Regulatory shifts continue to motivate flame-retardants producers to offer more halogen-free options, as summed up in an August 2014 blog entry by Plastics Color Corp. (PCC; plasticscolor.com/blog): “The plastics industry lost its most versatile and effective flame retardant (FR) when decaBDE was phased out over environmental and health concerns in 2012.”

The bromine-saturated “deca” was more than popular (“Deca was to the FR plastics business what type-O negative is to a blood bank,” the blog entry added). But given the anti-halogen push, the U.S. Environmental Protection Agency has identified 29 potential alternatives for “polyolefins, styrenics, engineering thermoplastics, thermosets, elastomers, or waterborne emulsions and coatings,” reports PCC.

In response, the company reportedly is addressing the difficulties of using some non-halogenated FRs in masterbatches, given the high loading rates typically required. PCC development engineer David Witt is cited as the developer of the company’s FlamaSol® decaBDE-replacement FRs. Witt stresses the importance of FR/resin compatibility, saying that given changing regulations, an FR should fit the required standard (UL, ISO, ASTM), as well as the resin.

Meanwhile, applications for halogen-free FRs can sometimes be surprising; oyster shell fillers in flame-retardant PP, for example, is one focus of Clariant. In research led by the Unité Matériaux et Transformations (UMET) at the University of Lille in France, researchers reported that it’s possible to achieve effective flame retardancy for oyster shell-reinforced PP composites, saying a “significant increase in the thermal stability of the PP compound” was found using Clariant’s phosphate-based Exolit®AP760.

Eurostar Engineering Plastics developed the oyster shell/PP compound, choosing the shells as a “green” source of mineral filler that avoids the negatives of mining processes while contributing to landfill reduction. The Exolit FR supports the environmental profile of the material, says Clariant, with no toxic effects or environmental accumulation.

“The project results herald a breakthrough in the feasibility of using bio-based materials in high-end application areas, such as the automotive and building and construction industries, where effective flame retardancy is required,” says Prof. Sophie Duquesne, leader of the UMET research group. “In addition to oyster shells, we are also actively researching the viability of achieving flame retardancy when vegetal fillers such as flax are used, to further extend possibilities for more environmentally friendly materials in demanding environments.”

Keen on “Green”

Speaking of bio-friendly alternatives… interest remains steady. As with bioplastics producers, additives producers can tout their own environmental awards. This year Arkema received the Chairman’s Award from the Plastics Environmental Division of the Society of Plastics Engineers for the development of its Biostrength® impact modifiers, which improve a range of properties of the biopolymer polylactic acid (PLA). The impact modifiers and process aids reportedly counteract the deficiencies of PLA, which is normally brittle and has low melt strength.

Biostrength impact modifiers are designed to increase PLA toughness by several orders of magnitude, expanding PLA’s range of applications. They also can increase melt strength by as much as 100%, the company adds, helping PLA break into the textile fiber application sector. Manny Katz, global group president of Arkema’s Functional Additives business, says the modifiers “will undoubtedly contribute to the growth of the biopolymer industry by enabling PLA to tap into new markets.”

In plastics recycling, additives play big roles too. Earlier this year, Struktol Co. of America announced the launch of several additives products supporting recycled plastics. For use in various resin families, they’re targeted for compounds containing 100% recycled materials or those with varying degrees of recycled content.

The company’s RP 28 is a compatibilizer and blending aid for incorporating regrind or recycled material, serving also as an alloying agent, the company says. For engineering plastics, the company combines compatibilizers with lubricants in additives that aid the incorporation of mineral or glass fillers, for example. One product, Struktol® TR 219, is said to perform well in nylon 6 and 6,6 and polyethylene terephthalate (PET) compounds—especially in recycled applications or in cases where PET is contaminated with other plastics.

Other products reportedly offer better processing for recycled plastics. Struktol RP 11 is a lubricant that reduces viscosity and improves mold release for PP at loading levels of 0.2%. The company says it allows the greater use of regrind or recycled content “without sacrificing certain properties or performance,” replacing peroxide modifiers and internal or external mold releases.

Foaming: Safe & Efficient

Resin reduction is one sustainability goal lying behind the use chemical foaming agents (CFAs)—and sustainability is supported even more when a non-hazardous CFA is used to create blown cells. To this end, Reedy International introduced a line of high-temperature endothermic chemical foaming agents as alternatives for azodicarbonamide, whose decomposition products have led to some regulations limiting its use in food-related applications.

The company says its Safoam® HT is formulated with FDA-approved foaming agents and “produces no potentially hazardous degradation byproducts.” With a decomposition temperature of 210°C, it can be used without modifying the process conditions for materials traditionally foamed with azodicarbonamide. It’s available in powder and masterbatch form, the company adds.

Wire insulation is one application that benefits from foaming. PolyOne recently announced a new chemical foaming additive for fluoropolymer wire insulation that preserves electrical properties “while reducing insulation thickness and raw material consumption through a consistent closed-cell structure.”

“It’s difficult to minimize the tradeoffs between thermal stability, foaming control, and high processing temperatures when applying wire insulation,” explains Barto du Plessis, general manager, PolyOne Colorant Chromatics. “This new technology balances all three performance requirements and boosts productivity without the need for additional equipment investment.”

The additive reportedly restricts premature foaming (enabling maximum gas generation), produces a consistent cell structure of 200 microns or less, and resists temperatures of 340-380°C, “supporting effective homogenization of the foaming agent with high-performance polymers,” the company adds.