Sikora’s X-RAY 6000 system ensures quality in production extrusion.

Photo courtesy of NVision

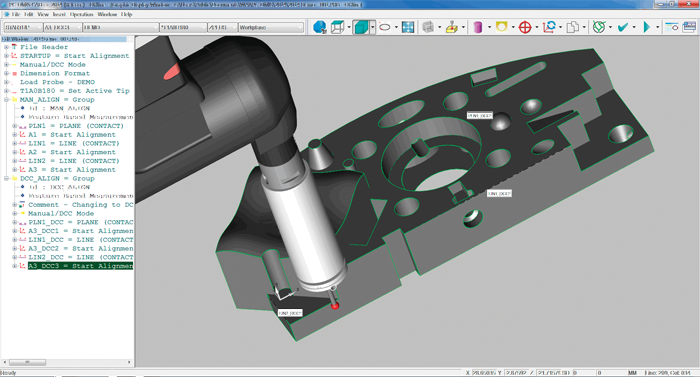

Photo courtesy of Hexagon Metrology

Photo courtesy of Norton

Versatile X-ray Measurement Devices for Extrusion QC

Versatility is the hallmark of Sikora’s X-RAY 6000. In extrusion lines where hoses and tubes are produced, the X-ray measuring device provides continuous compliance with the required specifications regarding wall thickness, eccentricity, and inner and outer diameter. With this device, quality control is carried out directly during the production process.

With two models—X-RAY 6000 for the quality assurance of single-layer products and the X-RAY 6000 PRO for the measurement of single- and multi-layer products—the X-ray measuring system can be individualized to suit every application and requirement. This makes it perfect for different customer demands because the application field of the system is so diverse: both single- or multi-layer tubes; aluminum composite tubes; pressure hoses with textile reinforcement; and small or large diameter hoses made of PE, HDPE, or PVC, as well as foamed products (or products made of EPDM, nylon, rubber, or silicone), are reliably measured by the system. Moreover, it’s suitable for quality control of medical and cosmetic tubes, the company says.

Depending on the requirements (hot or cold measurement), the X-RAY 6000 may be installed in any position in the production line. Directly with the online measurement, the measuring values for wall thickness, eccentricity, inner and outer diameter, and ovality are displayed at the processor system Ecocontrol 6000. Wall thickness values are shown at eight points, while allowing the operator to center the crosshead. Production data are clearly displayed on a 22” (56 cm) vertical widescreen monitor.

With the use of the X-RAY 6000 as measuring head at the hot end, directly after the extruder or after a first vacuum tank/cooling trough, it is possible to rapidly center the crosshead and to control the line speed or extruder RPM. An additional diameter gauge after the vacuum tank/cooling trough, combined with a hot-cold control, considers the material shrinkage. In combination with the processor system Ecocontrol 600, 1000, or 6000, an automatic control of the line is possible. By controlling the line speed or extruder RPM, the product parameters are adjusted to the nominal dimension. The typical return time (ROI) for the investment is 6 to 8 months, the company adds.

www.sikora.net

Kraton Performance Polymers, Inc., a leading global innovator and producer of styrenic block copolymers (SBCs) and other engineered polymers, has announced the opening of its new Kraton Innovation Center in Belpre, Ohio, USA. This pilot facility allows Kraton to manufacture a wide range of SBC-type materials in quantities ranging from 25 kilograms to 50 metric tons.

The facility and its high-technology process equipment broadens the company’s abilities in polymeric chemistry by leveraging unique, less-traditional monomers and building blocks to meet customer needs and create innovative applications. This new ability to generate developmental polymer and processing technologies also opens the door to applications and industries where traditional SBCs were unable to participate.

As the first asset of its kind built by Kraton, the pilot plant is located within the company’s flagship commercial manufacturing facility in Belpre. This allows the new facility to capitalize on the existing plant’s technical skills, talents and infrastructure. Its fit-for-purpose volume scale-up bridges the gap between laboratory and full-scale production of products within the development cycle, enhancing the company’s ability to

deliver developmental polymers in customizable quantities in record time. It will also reduce reliance on the company’s commercial manufacturing plants for test runs, resulting in fewer type changes and improved utilization of its manufacturing facilities.

“By making this additional investment in innovation, we are accelerating our time to market and improving our supply chain capabilities, which enables us to meet the needs of our global customers. This new facility has garnered significant interest on the part of those customers and our development partners around the world,” says Kevin Fogarty, president and CEO. “It also underscores our long-term commitment to the Mid-Ohio Valley and its economic growth.”

Combined, the new pilot facility and the existing Belpre manufacturing plant employ nearly 600 employees and contractors, making Kraton one of the largest employers in the region. Additionally, the modular design of the new pilot plant allows room for future expansion, and it’s able to capitalize on the technical skills and product feedstocks of its on-site manufacturing plant, the company adds.

A heavy-equipment manufacturer with facilities throughout the world has improved the dimensional accuracy of its ground engagement tools. Measuring these tools is challenging because of the complexity of their shapes, tight dimensional tolerances, and harsh manufacturing environment, but using the NVision HandHeld laser scanner to measure tooling and finished products reportedly offers the company a higher degree of accuracy than was possible in the past.

“We have significantly lowered our reject rate and improved our ability to hold close tolerances by using the HandHeld laser scanner to generate complete 3-D geometry at all stages of the product development process,” says a 3-D scan technician for the manufacturer.

The company is a leading manufacturer of buckets, teeth, edges, and other products for construction and mining equipment. Teeth produced for earth-moving equipment typically have organic shapes that are difficult to measure because they have relatively few flat surfaces that can be used for traditional gauge measurements. Inspection is difficult even with coordinate measuring machines, because such a large number of points need to be captured to fully inspect a 3-D surface.

The manufacturer first considered laser scanning about a decade ago as a possible inspection technology. It looked at three or four service bureaus and chose NVision because it offered the best combination of service and price. NVision scanned a few of the company’s parts and tools, and the manufacturer decided that it needed to bring the technology in-house and purchased the HandHeld scanner.

The portable scanning device is attached to a mechanical arm that moves about the object, freeing the user to capture data rapidly and with high resolution. An optional tripod provides complete portability in the field. Intuitive software allows full model editing, polygon reduction, and data output for all standard 3-D packages.

“NVision’s HandHeld scanner has consistently demonstrated the ability to provide accurate results even when used in a dusty manufacturing plant,” the scan technician adds. “Another advantage is its portability—it is light and compact so that we can, when necessary, take it right to a customer’s job site for inspection work.

“The HandHeld scanner has also proven to be extremely reliable, operating for nine years in difficult conditions with virtually no downtime.”

The USDA has approved Bylox® Concentrated Additive from Genarex™ as a USDA Certified Biobased Product. USDA test results indicate that Bylox has a biobased content of at least 98%.

“Bylox is a game-changer. We’ve combined the latest in processing technology and material science to create a new, affordable threshold of performance that gives companies a cost-effective, profitable way to tap into the rapidly growing consumer demand for affordable ‘green’ products,” says Genarex V.P. of sales and product development Bob Montgomery. “The USDA certification gives Bylox critically important credibility in a marketplace that’s grown wary of ‘green’ claims that turn out to be false.”

Bylox offers significant performance and processability advantages other bio-additives don’t, including selective processing temperature design, a

thermal processing window that can reach 250°C, compatibility with an unprecedented number of polymers, and an ability to increase finished-product ductility.

In most cases, Bylox can be added up to 10-30% without sacrificing material performance and properties. Genarex offers the materials at no charge for capability sampling in specific market applications and products, as well as for product evaluations, cost-out, and cost/benefit models. “We’re working very closely with our customers to ensure smooth adoption and integration with their existing and tooling processes,” adds Montgomery.

Hexagon Metrology has launched PC-DMIS 2014, a major release of the world’s most popular measurement software used for the collection, evaluation, management, and presentation of manufacturing data. The software release introduces tools and technologies that will help measurement devices perform better than ever, increase the effectiveness of inspection planning time, and make it easier to complete complex inspection routines.

The new software includes a number of productivity advancements to improve the speed of common programming tasks and the overall user experience. “PC-DMIS 2014 delivers new and improved capabilities based on real-world user feedback from the PC-DMIS forum and our technical support teams,” says Ken Woodbine, president of Hexagon Metrology’s software division. “This release is focused on productivity, and sets the stage for future user experience enhancements already in the planning stage and moving forward.”

Highlights of PC-DMIS 2014 include a new one-click “QuickFeature” feature creation from CAD models, where users can also create features by hovering their mouse over a CAD model to highlight CAD elements. Contact auto features are created from a single click on the CAD model without using any menu options or dialog boxes.

There is also a one-click “QuickAlign” capability where users can now select valid combinations of one, two, or three features to create a quick alignment. The QuickAlign feature will also initiate manual and DCC alignments when used at the beginning of a part program.

These new productivity tools are packaged in a new QuickMeasure toolbar giving drop-down access to common measurement features, providing more screen real estate for the graphics and the measurement routine.

The new software version also includes “Copy Parameters” and “Paste Parameters” functions, which copy parameters from one feature or dimension, and paste them to another feature(s) or dimension(s) in the “Edit” window, making block changes much faster.

PC-DMIS 2014 also rolls out a new “Mini Routines” feature which can be used to measure a selected dimension or group of dimensions from a long part program. Mini Routines offer characteristic-based measurement and the ability to measure a part of a complete measurement routine.

PC-DMIS is the flagship software package for Hexagon Metrology measurement devices and a wide range of other measurement equipment in the marketplace.

Effective June 1, 2014, The M. F. Cachat Company was appointed by Zeeospheres Ceramics, LLC, as exclusive distributor for its complete line of Ceramic Microspheres in most U.S. states (complete list at www.zeeospheres.com/

distributors).

Zeeospheres Ceramics is the new owner and producer of Zeeospheres™ Ceramic Microspheres. The company acquired this business from the 3M Energy and Advanced Materials Division in late April 2009. These innovative inert functional extenders have a very fine particle size and very high (60,000 psi/ +400 MPa) compressive strength. They’re engineered to help formulators reduce costs, enhance properties, and improve processability in a wide range of coatings, adhesives & sealants, construction, plastics, and advanced materials applications, the company explains.

Norton/Saint Gobain Abrasives,the world’s leading manufacturer of metal fabrication abrasives products for over 125 years, has recently introduced a new line of resin fiber discs—Norton Neon F726. The new line of aluminum oxide (AO) fiber discs offers a proprietary aluminum oxide and organic grain blend, resulting in up to three times the normal AO cut rate, life, and overall performance—at an economical price.

“New Norton Neon F726 discs bring superior overall value and increased diversity to the Norton product line,” says Patrick Carroll, senior product manager, Norton/Saint Gobain Abrasives. “Regardless of what the customer is looking for—performance or price—Norton offers the broadest range of products to fit that need.”

An improved resin bond system and heavy-duty fiber backing provide enhanced grain adhesion in the Neon F726 line. When compared to competitive AO products, Neon’s unique AO blend allows for a significantly faster initial cut rate, which is sustained throughout the life of the disc, providing up to three times the overall value. The new Neon fiber discs are primarily used in the metal fabrication and welding sectors and are ideal for light to moderately demanding right-angle grinding applications.

The new fiber discs, positioned in the Norton “GOOD” product tier, are available in grits 24 through 120, which makes them suitable for a number of metal fabrication applications. The new product will be launched in ten-per-package units, making it adaptable for vending or low quantity orders to help minimize inventories, reduce consumption, and increase productivity. Packaging is also convenient for carrying to the jobsite and for smaller jobs.

All of Norton/Saint Gobain Abrasives’ fiber products, including the Neon F726, are made in the USA with consistent abrasive manufacturing processes for maximum quality assurance.