Process Engineering for Recycled Polymers: Life-Cycle Assessment

Previous Article Next Article

By Donald G. Baird and Dimitris I. Collias

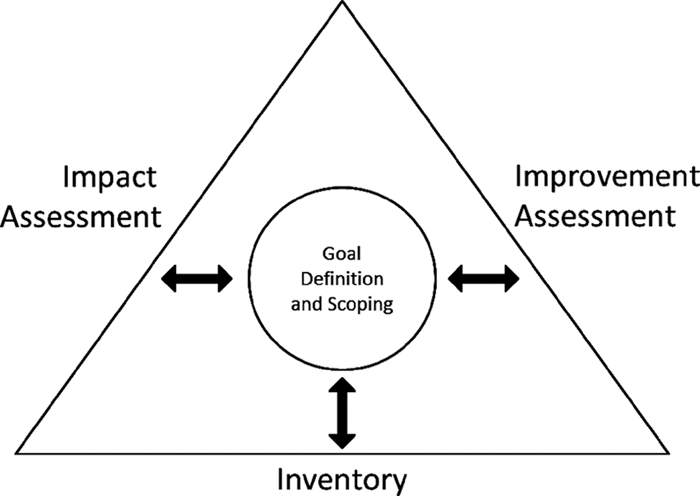

Figure 1: Life-cycle assessment conceptual model (data from Curran1).

Figure 1: Life-cycle assessment conceptual model (data from Curran1).

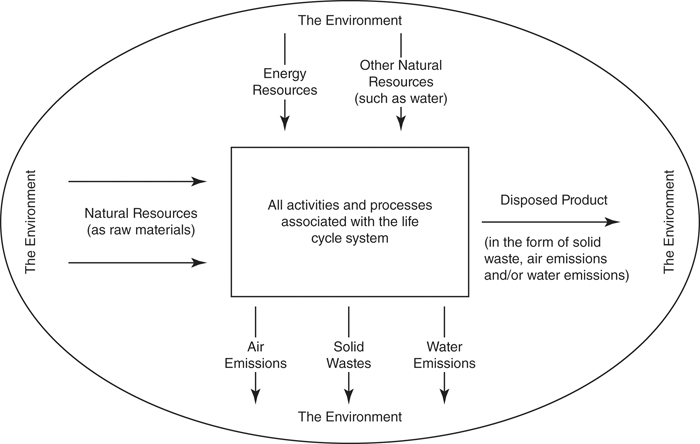

Figure 2: Life-cycle system concept showing the boundaries on which the life-cycle assessment must be performed (reprinted by permission of the publisher from Curran1).

Figure 2: Life-cycle system concept showing the boundaries on which the life-cycle assessment must be performed (reprinted by permission of the publisher from Curran1).

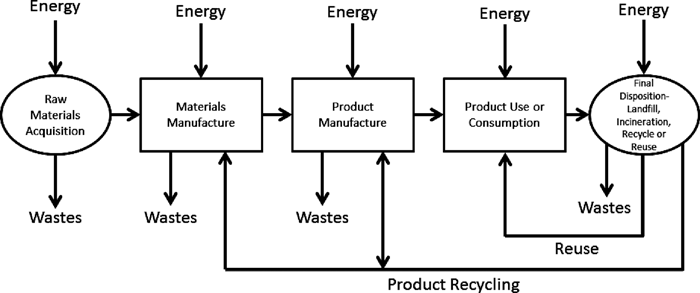

Figure 3: The flow diagram, sometimes referred to as a cradle-to-grave materials flow diagram, of a recycling scheme showing both materials and energy flow in and out of the system for a product life cycle (reprinted with permission of the publisher from Curran1).

Figure 3: The flow diagram, sometimes referred to as a cradle-to-grave materials flow diagram, of a recycling scheme showing both materials and energy flow in and out of the system for a product life cycle (reprinted with permission of the publisher from Curran1).

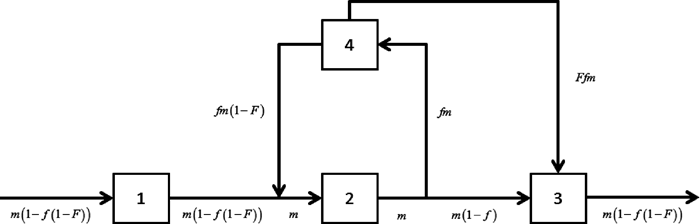

Figure 4: Simple closed-loop recycling when the reprocessing stage produces waste materials (reprinted with permission of the publisher from Brandrup et al.3).

Figure 4: Simple closed-loop recycling when the reprocessing stage produces waste materials (reprinted with permission of the publisher from Brandrup et al.3).

Note:

Below is an excerpt from Chapter 11 of the book Polymer Processing: Principles and Design, 2nd ed., by Donald G. Baird and Dimitris I. Collias (2014, John Wiley & Sons).

The decision to recycle polymers is by no means straightforward. In some instances, recycling polymers can lead to more energy usage and more pollution than merely disposing of them in landfills. The decision to recycle polymers depends on the ultimate goal. Is it to reduce consumption of raw materials (i.e., feedstock)? Is it to reduce the consumption of fuel? Is it to reduce the generation of solid waste?

To determine whether recycling is the appropriate option and what type of recycling option should be selected, one turns to a systems analysis which accounts for all energy and raw materials used to produce a product or process and all wastes produced. This type of analysis is referred to here as life-cycle assessment (LCA), but other names are often used, such as ecobalance, cradle-to-grave analysis, and lifecycle analysis.

LCA is used defensively to justify recycling and offensively to improve products and processes and help select the appropriate polymers and processes for various applications. Although considerable discussion of the technique and its application is given in the books by Curran1 and Horne et al.2, we present an overview of the topic with enough detail to hopefully make the concept useful to the process engineer.

Life-Cycle Concepts

The LCA conceptual model is shown in Figure 1. At the center of LCA is initiation or scoping, in which the goals of the study and the system boundaries are defined. All operations that contribute to the life cycle of the product or process fall within the system boundaries as shown in Figure 2. The environment is the surroundings for the system. Inputs to the system are the natural resources, including energy resources. Outputs of the system are the collection of releases to the environment (i.e., land, water, or air) as well as discarded product.

The quantification of energy and raw material requirements, air emissions, waterborne effluents, solid waste, and other environmental releases throughout the life cycle of a product is referred to as life-cycle inventory (LCI). Impact analysis is an attempt to quantify the effects of the environmental loadings identified in the inventory phase. It mainly refers to the pollution of the ecosystems and the effects on human health. Improvement assessment is a systematic evaluation of the opportunities to reduce the environmental burden associated with energy and raw materials use and environmental releases throughout the whole life cycle of the product or process. This assessment may include both quantitative and qualitative measures of improvement, such as changes in the product or process design, use of raw materials, consumer use, and waste management.

The life-cycle system concept for a product life cycle is illustrated in Figure 3. This diagram is often referred to as a cradle-to-grave materials flow diagram. The boundaries for the LCI encompass the acquisition of raw materials, manufacture of intermediate materials, manufacture of the product being studied, use of the product, and the final disposition.

Recycling or reuse of the product is part of the LCI analysis. Reuse here means the direct reuse of the product for its initial intended use, such as a beverage bottle being placed back into service. The product could be separated from a mixed stream, ground, and returned to the product manufacturing step. In the figure is also shown the return of the product all the way back to the materials manufacturing step, which is referred to as feedstock recycling. Furthermore, the product can be incinerated to recover the inherent energy associated with the polymer.

In the diagram various types of recycling options are illustrated. The use of energy, as shown for each step in Figure 3, carries with it the input of energy resources as well as the inputs and outputs for processing these energy resources into usable fuels. The inputs and outputs for transportation of materials between process steps are implied by the arrows showing the flow of materials between steps.

Mass & Energy Flow in Recycling

Before any recycling scheme is introduced, it is essential that the ultimate goal be specified. If the goal is not specified, then it is impossible to judge whether the recycling scheme has achieved its purpose. If the goals are to reduce the consumption of raw materials or the generation of solid waste, then it is clear that recycling should be practiced. If the goal is to reduce energy consumption, then the process must be examined very closely. The basis for making the decision is centered on the use of material and energy balances.

Several types of recycling schemes exist: (1) closed-loop recycling with no losses in the recycling loop; (2) closed-loop recycling when losses occur in the recycling loop; and (3) open-loop recycling. To illustrate how mass and energy balances are employed in the analysis of recycling schemes, we consider closed-loop recycling with losses as shown schematically in Figure 4. Unit operation 1, or stage 1, in this figure represents the conversion of raw material to product (e.g., polyethylene milk bottles). Stages 2 and 3 represent the consumer and the disposal phase, respectively. Stage 4 is the reprocessing operation for converting the waste back into useful product.

Consider that a single mass, m, of 1 kg of product is passed initially to the consumer. Our goal is to determine with an infinite number of recycles how much material is passed by the consumer. A fraction f of the material leaving the consumer is now fed into the recycling loop, and the recycling loop is responsible for a loss of a fraction F of the material passing through the reprocessing stage 4. The amount of material returned to the main production sequence will be of mass mf(1 − F). The amount of material sent to the disposal stage after the first pass consists of the sum of the material disposed of directly after consumer use, m(1 − f), plus the amount lost from the reprocessing step, mFf (total = m((1 − f) + fF) or = m(1 − f(1 − F))). The amount of mass that passes the consumer after the first recycle is reduced to mp1 = mf (1 − F)(Eq. 1)

After a second recycle the mass of original product, mp2, passing the consumer will be reduced to mp2 = mf2(1 − F)2(Eq. 2) and so on. If the material is continually recycled under the same conditions, then after a large number of cycles the total mass of the original product that will have passed the consumer, Mp, is Mp = m + mf(1 − F) + mf2(1 − F)2 + mf3(1 − F)3 + · · ·(Eq. 3)

Summing Eq. 3, assuming there is an infinite number of terms, gives Mp = m / (1 − f(1 − F))(Eq. 4)

For example, if there is a loss of 20% of the recycled materials (i.e., F = 0.2) and the recycle rate f is 50%, then the product flow past the consumer will be 1.67 kg. From this equation it is obvious that F should be as small as possible if we are to minimize the amount of raw material used. This is further illustrated by referring to Figure 4. The amount of raw material required from operation 1 to provide a mass m to the customer increases as F increases.

We are primarily interested in the amount of energy that is required to execute a particular recycling scheme. Following Figure 4, the energies per unit mass associated with each operation are, respectively, E1, E2, E3, and E4. The total energy requirement for the overall system, Es, is the sum of the energies for each operation:

Es = E1m(1 − f (1 − F)) + E2m

+ E3m(1 − f (1 − F)) + E4mf (1 − F)(Eq. 5)

Equation 5 can be rearranged to emphasize various contributions to the energy requirements:

Es = m(E1 + E2 + E3) + mf (E4 − E1 − E3)

− mfF(E4 − E1 + E3)(Eq. 6)

It is now easier to see the significance of the energy balance, as the first term on the right side of Eq. 6 represents the energy requirements when no recycling is employed. The second term represents the energy associated with the recycling loop if no losses occur. It is obvious if the amount of energy associated with the reprocessing of the polymer is less than the energy required to process the virgin resin, then the amount of energy consumed would be less than with no recycling. The third term represents the energy requirements associated with losses in the recycling loop. Hence, energy savings in the recycling step will be reduced as a result of the loss of material.

References

- Curran, M. A., Ed. 1996. Environmental Life-Cycle Assessment (McGraw Hill, New York).

- Horne, R., T. Grant, and K. Verghese. 2009. Life Cycle Assessment: Principles, Practice and Prospects (CSIRO Publishing, Collingwood, Australia).

- Brandrup, J., M. Bittner, W. Michaeli, and G. Menges. 1996. Recycling and Recovery of Plastics (Hanser/Gardner, Cincinnati, Ohio).

Note:

For information about Polymer Processing: Principles and Design, go to www.wiley.com/WileyCDA/.