Photo courtesy of Wittmann

Photo courtesy of Steer

Photo courtesy of PolyShield

Photo courtesy of Milliken

Wittmann Battenfeld Inc. reports that at NPE2015 it will feature six injection molding machine work cells with integrated robots, automation, material handling, and auxiliary equipment. In addition, the company will display extrusion-related machinery and auxiliaries in its booth.

The six molding-machine work cells on display will include:

- a new SmartPower machine molding a jeweler’s loupe (a magnifying glass for viewing miniature parts being molded on a MicroPower machine at the Burteck LLC booth);

- a two-shot EcoPower machine molding a two-component (glass-filled PA and HDPE) automotive fuel flange;

- a MicroPower micromolding machine producing a liquid silicone rubber two-component tear duct plug;

- a MacroPower 650/8800 machine molding a single-cavity PP box;

- Variotherm and Cellmould molding demonstrated on an EcoPower 240 machine, molding an ABS automotive bezel; and

- an EcoPower 240/1330 machine with in-mold labeling station for molding and labeling stadium cups.

All of the molding machine work cells will feature integrated Wittmann robots. Several new Pro series robots will be on display and operating in the booth, including the W832 and W843. The new Pro series provides even more stiffness of the axis, an AmbiLED indicator lamp for simple display of the robot’s operating mode, the latest R8.3 control system and software, and the new high-performance/high-efficiency ProDrive.

At NPE2015, Gala Industries will introduce its new Rotational Valve, which has a single inlet and multiple outlets. Here, pellet and fluid slurry flows into a rotating nozzle which directs the slurry to a hopper connected to an outlet. The rotating nozzle is connected to an encoder which indicates to the power control system which hopper is being used.

The outlets are connected to different tanks in Gala’s Pellet Conditioning System (PCS). The PCS consists of multiple tanks that are gravity-fed a slurry of pellets and fluid in a sequential pattern. The pellets in this slurry may be tacky and can stick together if the pellets are not kept moving. A pipe manifold controlled with full port ball valves has been used in the past, but pellets sometimes lay stagnant in a line not currently being filled, causing a blockage; Gala engineered the Rotational Valve to solve this problem.

The Rotational Valve has many possible applications, one being use with a bagging process for pressure sensitive adhesive. After pellets are cut and exit the dryer, they need to be directed to different bagging systems. Because the pellets are also gravity fed, the Rotational Valve is a good fit for this application, and it moves at a constant speed to evenly distribute product to the bagging systems.

Gala has been awarded a patent in the USA and has foreign patents pending, the company also reports.

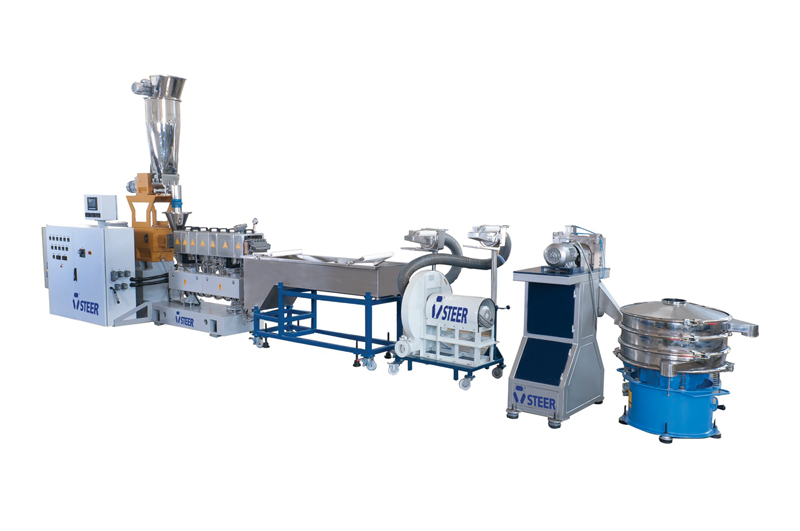

Steer announced that Japanese company Kohwa Kasei Chemicals Inc. has procured a Mega Special 40 extruder line for its plant in Nara (near Osaka), Japan. Kohwa Kasei will use the Do/Di 1.55 Mega Special 40 for its engineering plastics applications with glass-filled nylon, and reportedly has selected Steer for long-term collaboration, as it’s witnessing a surge in demand for nylon/glass-fiber filled polymers in Japan.

The Steer Mega Special 40 is designed for high process compatibility, enhanced compounding, improved wear and corrosion performance, and reduced cost of operations and maintenance. A team of experts from Kohwa Kasei, led by its chairman Shigenori Mochida, visited Steer’s facilities in Bengaluru and foundry in Coimbatore, India, to understand Steer’s technology and to then deploy it gainfully in production.

As Dr. Babu Padmanabhan, managing director and chief knowledge officer of Steer Engineering, reports, “We have gained a leadership position by having a complete range of products to cater to all types of market and application requirements in terms of production capacity—such as lab extruders, pilot production extruders, or large extruders—and varied applications from commodity plastics to highly [engineered] material.”

Engineers increasingly are using Tepex® performance composites from Lanxess subsidiary Bond-Laminates to significantly improve the mechanical strength of components made of fiber-reinforced thermoplastic compression molding compounds.

The latest example is a cover on the rear muffler of the BMW i8 sports car. It’s fabricated in a direct long fiber thermoplastic (DLFT) process from a PP compression molding compound reinforced with long glass fiber rovings. An insert made of Tepex dynalite 104-RG601 is used as the surface layer.

“With its stiffness at high temperatures, it ensures that the cover undergoes no deformation or failure in the hot environment of the rear muffler,” explains Harri Dittmar, composites expert at Bond-Laminates. “What’s more, our composite improves the strength and impact resistance of the component in freezing temperatures.”

In penetration tests (DIN EN ISO 6603-2), the Tepex dynalite formulation used has proved to be eight to nine times more impact resistant at room temperature than a DLFT compression molding compound based on polypropylene. “At temperatures of -30°C, the impact resistance is even ten times higher; DLFT based on polypropylene will splinter under these conditions in a crash—our Tepex will not,” Dittmar says.

The material is also an attractive option for locally reinforcing components made of other thermoplastic compression molding compounds and forming materials. “The combination of Tepex with the DLFT process opens up considerable savings potential, for instance in the fabrication of underbody components,” Dittmar explains. Polypropylene-based, low-weight reinforced thermoplastics, which are used to manufacture underbody panels due to their high sound absorption, can also be significantly stiffened with Tepex surface layers. Using a single-layer Tepex component reportedly preserves the acoustic effect.

Medical enterprises are said to be turning to PolyShield, a manufacturer of multi-layered and tear-off face shield protectors such as laminated medical films, for assistance in fighting Ebola. The shield protectors from PolyShield are of the highest quality and created specifically for use in medical and surgical operating rooms, as well for various other critical medical applications.

The gear that healthcare workers and other medical professionals fighting the deadly Ebola virus are wearing has become an important weapon in the battle to contain the largest-ever outbreak of the disease. However, once the mask is soiled, the protective gear must be removed in order to be replaced. This requires valuable time and unnecessary exposure for the medical professional.

PolyShield makes laminated medical films from highly durable, thin polymer materials. The materials can beused as an integral face shield or as an add-on to strengthen existing face shields. They are designed for easy installation and leave absolutely no air bubbles. In fact, they’re said to be bacteria-proof, as there are no air gaps between layers where bacteria and other infection-spreading bacteria could possibly accumulate.

DSM Dyneema, the manufacturer of ultra-high molecular weight polyethylene (UHMWPE) fiber (branded as Dyneema® life-protection materials and high-performance fibers), has announced that the U.S. Army has chosen a new body armor system that incorporates Dyneema Force Multiplier Technology. It reportedly delivers unparalleled ballistics protection combined with unprecedented weight reduction, the company says. Point Blank Enterprises, a leader in the production of soft body armor, designed the advanced ballistics package incorporated in the new system—the Generation II Soldier Plate Carrier System (SPCS).

Using Dyneema Force Multiplier Technology, Point Blank developed the core ballistics package for the SPCS to create what’s said to be the lightest soft-armor system ever to be fielded by the U.S. Army. The lighter-weight ballistics package meets the army’s requirement for the SPCS to provide protection equal to its current Improved Outer Tactical Vest (IOTV), but in a stand-alone capacity that reduces the soldier’s load and provides optimum mobility.

Built on the company’s “Radical Innovation Platform,” Dyneema Force Multiplier Technology combines breakthroughs in polymer science, next-generation UHMWPE fiber technology, and unique unidirectional engineering. Compared with body armor made from traditional materials such as aramid, protective vests engineered with the technology reportedly can reduce weight by up to 30% while enhancing comfort and agility with fewer layers of material.

Even in our connected world, a conventional cable is not always handy for charging a drained mobile phone or tablet. So the founders of Nomad set out to design a cable as mobile as their own lives. Knowing when an electronic device will need a charge can be unpredictable, but Nomad needed a predictably high-performing and impact-resistant plastic to protect its charging products.

Makrolon® 2207 polycarbonate, from Bayer MaterialScience LLC, is a high-flow thermoplastic material suitable for thin-wall molding. This PC grade has easy-release properties and is an excellent choice for applications that require a durable, heat-stable material.

“We chose Makrolon 2207 polycarbonate for its predictable, consistent quality from batch to batch and high-impact resistance,” says Nomad founders Noah Dentzel and Brian Hahn. “We use the highest-grade materials to ensure we have built a product that can handle virtually anything, but that is still flexible enough to work in hard-to-reach places.”

Developed for people who want a mobile charger without dragging around a three-foot cable, Nomad charging products make clever use of the ubiquitous USB ports commonly found on computers, most modern TVs, printers, keyboards, TV-boxes, stereos, game consoles, cash registers, cars, and airplanes.

“When combined with Nomad’s charging products, durable, lightweight Makrolon polycarbonate helps deliver a mobile charger that’s fit for on-the-go lifestyles,” says Kevin Dunay, Electrical Market segment leader, Polycarbonates, Bayer MaterialScience.

Milliken & Company’s technical expertise and performance-enhancing additive solutions for polyolefins will be among the highlights at ANTEC® Orlando and NPE2015 in Florida, March 23-27. On NPE’s exhibit floor, Milliken will showcase new benefits of its advanced additive technologies that respond to four key industry demands: clarity and aesthetics, productivity improvements, sustainability, and property optimization.

Clarified polypropylene with a glass-like clarity and bright appearance provided by Milliken’s Millad® NX™ 8000 clarifying agent is steadily replacing traditional PET and polystyrene as the material of choice in thermoformed packaging. At its booth, Milliken says it will provide comparisons between “Ultra Clear PP” and these other materials, including the weight reductions that can be achieved by using lower-density PP resin.

A major focus of Milliken’s exhibit will be its newly launched Hyperform® HPN 210M nucleating agent for injection-molded high-density polyethylene used in material handling applications. This technology features a unique crystalline orientation that allows for higher productivity, increased stiffness, reduced warpage, and a higher heat deflection temperature compared to traditional HDPE—elevating its performance to levels approaching those of PP impact copolymers. In addition to demonstrating its many performance benefits, Milliken will display the new industrial applications where this versatile nucleating agent can be used.

For PE, Milliken’s Hyperform HPN 20E nucleating agent will be on display, showcasing its improved barrier performance and physical properties, as well as productivity gains. For PP, the HPN 20E nucleating agent’s unique orientation of polymer crystal growth, superior dimensional control, optimal balance of physical properties, and exceptional modulus in three-dimensional parts makes it the best choice for injection molding in automotive, appliance, and industrial applications, the company says.

BASF reports that its spray polyurethane foam has achieved U.S. Environmental Protection Agency (EPA) Seal & Insulate certification from the International Code Council Evaluation Service (ICC-ES) with Energy Star. This EPA residential program certification highlights products for their energy efficiency and construction.

“Securing a Seal & Insulate certification from ICC-ES and the U.S. EPA is yet another demonstration of BASF’s commitment to residential energy efficiency and building safety. We provide high-quality products that achieve multiple, independent performance requirements,” says Eric Banks, BASF technical specialist, Testing, Approvals & Certifications. “The Seal & Insulate certification confirms the value our products bring to creating more comfortable, energy-efficient homes.”

The EPA Seal & Insulate Program requires independent, third-party testing and certification by technical evaluation providers such as ICC-ES. Certification addresses thermal resistance and surface-burning characteristics that establish compliance with the International Residential Code and International Energy Conservation Code requirements. Energy Star certification requires manufacturers to provide installation instructions and application diagrams. The program applies to insulation intended for use in whole wall, ceiling, roof deck, and floor systems sold in the USA.

3-D laser scanning from NVision helped a certified Federal Aviation Administration (FAA) repair station document its work on a passenger jet part with such precision that the station was able to obtain the necessary FAA approval for the repair in much less time than is usually required.

Due to the stress and strain of normal usage, the aircraft component—part of a key system—will eventually require repair after a certain number of hours. By law, the FAA must approve any modification or repair made to an aircraft component in order to ensure it doesn’t degrade structural integrity, which could impair its performance and jeopardize the safety of passengers and crew.

The repair station, which specializes in the repair and overhaul of aerospace components and systems, needed to first remove corrosion from the part in order to make necessary repairs prior to reassembling the system. However, before commencing the repairs, station users knew they would need to submit a report for FAA approval showing exactly how much metal was removed in the corroded areas. The station brought the part to NVision, a leader in 3-D laser scanning and reverse engineering for over 25 years, so engineers could 3-D map its exact geometry both before and after the corrosion was removed.

For this project they utilized the HandHeld 3-D laser scanner, which is very accurate and capable of capturing 60,000 separate measurements per second. The scanner is highly versatile and quickly obtains dimensions from objects of almost any size or shape. Using the HandHeld Scanner, it reportedly took technicians about half a day to scan the part before corrosion was removed and another half-day to scan it after the removal of the defects.

NVision then created an inspection report with a color deviation chart precisely documenting the exact amount and location of any corrosion and associated metal that had been removed from the part. The report was reviewed and approved by the FAA, the company says.