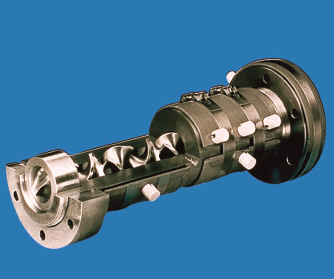

Gunther Niedermoser, plant manager at AgruAmerica, was looking at an economical way to upgrade his 90-mm pipe extrusion line, utilizing existing equipment on the line and blending equipment received from Process Control GmbH (PCC). The 90-mm line was already equipped with a Gravitrol® (gravimetric extrusion control) system from PCC; this system was designed to control the weight per unit length of the pipe by monitoring extruder output and adjusting the puller speed.

With the assistance from PCC’s service manager, Jonathan Phelps, the PCC continuous blender was mounted on a mezzanine above the extrusion line, and the existing Gravitrol system was combined with the PCC blender control system. With the addition of hardware and software for the control of the extruder output, the material blending and full gravimetric extrusion control were integrated into one system.

With the new online blending capability, in addition to gravimetric control of both the puller and extruder, the materials feed and total line yield were now fully automated and accurate to within +/-0.5% by weight. This resulted in faster line startup, reduced overall scrap and improved product quality. Gunther and Jon were successful in adding a significant level of automation and process improvement to the line, with minimal capital expenditure and utilization of surplus equipment. www.process-control.com

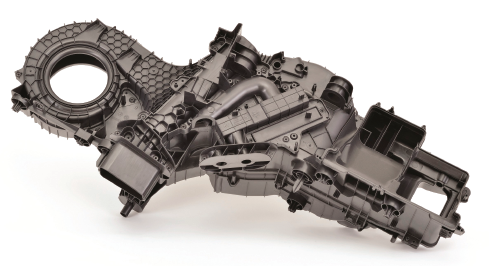

SABIC’s Innovative Plastics business enabled mobile internet company Xiaomi to develop its Mi2A smartphone that addresses growing consumer requirements such as thinner, more durable walls and an antenna-integrated frame.

Since the devices’ inception, manufacturers have worked to make smartphones increasingly thin, compact, and lightweight to keep pace with growing consumer demands. In addition, an emphasis on aesthetics has led consumers to increasingly value the look and feel of a device, alongside its functionality, further challenging OEMs to design a phone that is smaller yet visually appealing.

SABIC’s new LNP™ Thermocomp™ compound and its Thermocomp LDS compound were selected by Xiaomi to create a new smartphone frame which required strength, stiffness, and impact resistance, as well as an integrated antenna (this feature is attractive because it can reduce the size of the smartphone device and eliminate the secondary process of incorporating a separate antenna into the phone, both of which may help the manufacturer to reduce assembly time and cost). Additionally, the company’s Lexan™ EXL resin was selected to allow for rich, jewel-toned colors for the backing of the device.

As consumers continue to seek out smaller, thinner smartphone devices that are multi-functional, manufacturers are increasingly looking for new ways to consolidate parts while ensuring that the materials comprising the more compact device remain compatible,” says Matthew Gray, global marketing director, Consumer Electronics, SABIC Innovative Plastics.

Photo courtesy of SABIC

“SABIC delivered a combination of materials which enabled Xiaomi to integrate the antenna into the frame of the phone, which helped to reduce the part space and weight of the phone without sacrificing design or performance. Additionally, SABIC’s ability to offer all three materials used in the phone saved the customer time in validating compatibility, enabling them to develop this industry-leading smartphone at an excellent value.” www.sabic-ip.com

Smart Machineries and Moulds Pvt. Ltd. has launched its new fully automatic blow molding machine with automatic de-flashing and in-mold labeling: the AD+IML Series. The AD+IML machine is acclaimed for its low power consumption and simple, user-friendly operation, the company says. With a robust design and higher efficiency, these machines are suitable for producing HDPE, PP, and LDPE containers with consistency and good quality.

Photo courtesy of Smart MMPL

Shreeram Rane, managing director of Smart MMPL, acknowledges that the industry needs more innovations and new technology at affordable prices. He says the Smart team is confident about the technical capability within the group and the team is focusing on innovative ideas for new developments in extrusion blow molding machines. The team emphasizes that the company is the only blow molding machine manufacturer that has developed a preferred brand in a very short time because of their compact, fast, consistent, and reliable machines and the excellent after-sales service support to their customers.

Due to consistent quality output with lower weights and fully automatic operation, Smart AD+IML Series machines have great potential in the local as well as international market. The company says it has been following stringent quality norms at all stages of pre-production, production, and post- production, delivering a range of machines at very cost-effective prices. www.smartmmpl.com

General Motors (GM) worked with Continental Structural Plastics (CSP) as the need for a composite electrical vehicle battery enclosure was identified to meet a number of rigorous performance requirements. These included meeting 30° offset-barrier, side-impact, and rear-barrier crashes; 50-G impulse shock (x,y,z); post-crash package integrity; fire-resistance testing; 3-m drop testing (bottom/end); 1-m water-submersion test; and vibration/shock testing.

To satisfy all criteria, a new material, production process, post-mold finishing, and non-destructive test methods were needed. CSP therefore turned to Cytec Industrial Materials for a materials solution as well as engineering support. Cytec studied CSP requirements and developed MTM® 23, a tailored, self-releasing, rapid-cure vinyl ester resin system.

Cytec and CSP also worked together on data generation, ply design, and press production technology. That close collaboration enabled CSP to manufacture parts in less than ten minutes at a 150°C cure (although MTM 23 has the capability to be rapid-cured in less than three minutes, the company says).

The result is the industry’s first application of a volatile organic compound-free (VOC-free) thermoset vinyl ester resin with woven glass-reinforced prepreg. This new material enabled CSP to create a complex-shaped enclosure that protects the EV’s battery components in the event of a catastrophic event.

The tough compression-molded composite reportedly is 40% lighter than metallic solutions, helping the vehicle achieve extended range and enhanced performance. And since it’s non-conductive, it protects occupants and first responders at an accident scene. Moreover, the specially formulated resin is free of styrene emissions, making it safer for workers and the environment.

Selective pattern layups allow for localized reinforcement. The MTM 23 application also features a large structural joint of composite-to-steel. www.cytec.com

Nomacorc, a leading producer of alternative wine bottle closures, is said to be the first to create a plant-based closure, Select® Bio, using Braskem’s “I’m green™” polyethylene. “Green” PE is made from sugarcane ethanol, a 100% renewable material. Its major advantage is the fact that it’s made from raw materials derived from renewable resources, which helps reduce greenhouse gas emissions.

I’m green polyethylene not only removes CO2from the atmosphere due to its renewable feedstock but also contributes to reducing the use of fossil fuel. For each ton produced, “green” PE sequestrates more than two tons of CO2, a significant gain compared to traditional PE, the manufacturer estimates.

As PE, Select Bio closures are also 100% recyclable. And the closures mirror Nomacorc’s current Select Series portfolio in oxygen management performance. As with other Select Series products, Select Bio minimizes the environmental impact of wines by preventing spoilage and waste from wine faults, such as oxidation and reduction. By consistently delivering the right amount of oxygen into the bottle using a carbon-neutral closure, sustainability-minded wineries will now be able to deliver their wines just as they intend.

Braskem has been making I’m green polyethylene since 2010 in its Triunfo Plant in the state of Rio Grande do Sul, in the south region of Brazil. The plant’s capacity is 200 kton/year and the total investment amounts to U.S. $290 million, the company reports.

Using agricultural products as a sustainable alternative to fossil fuel to produce materials has great potential in Brazil, which has approximately 330 million hectares of arable land, of which 67% is in use. Sugarcane cultivation uses 9.2 million hectares, which is highly concentrated in the state of Sao Paulo (which is located more than 1,200 miles (2,000 kilometers) from the Amazon region). The expansion of sugarcane fields is highly regulated, so as to be done in a sustainable way. Brazil is producing annually more than eight billion gallons (30 billion liters) of bio-alcohol, of which only 2.3% is used to make I’m green polyethylene. www.braskem.com

Victrex plc, whose Polymer Solutions division is a specialist manufacturer of PAEK (polyaryletherketone) polymers, has achieved the No. 15 position in a survey of the most-admired 250 companies in the UK, beating a number of FTSE 100 companies. The survey, “Britain’s Most Admired Companies,” was conducted by experts in corporate reputation at Birmingham City Business School, part of Birmingham City University. (It was published in the December 2013 edition of Management Today.)

Photo courtesy of Victrex

Each major business within its sector was voted on by its industry peers, according to a number of criteria, including quality of management; financial soundness; quality of goods and services; ability to attract, develop, and retain top talent; value as a long term investment; capacity to innovate; quality of marketing; community and environmental responsibility; and use of corporate assets. Victrex scored 69.50, beating many larger FTSE 100 companies such as Centrica and GlaxoSmithKline.

Victrex was formed from ICI in 1993, and has grown significantly to serve five strategic markets, including aerospace, automotive, energy, electronics and medical. Today, Victrex is a global company with operations in the USA, Europe, and Asia, and employs over 650 people, with over 300 at its UK headquarters in Thornton Cleveleys. Victrex‘s flagship offering is its Victrex® PEEK (polyetheretherketone) polymer, a lightweight, high-performance plastic used typically as a metal replacement across a range of industries in over 40 countries. www.victrex.com

Minnesota Wire, a specialist in the custom design and production of cable assemblies for medical devices, has replaced the thermoplastic vulcanizate (TPV) elastomers that are standard in such applications with new styrenic thermoplastic elastomer (TPE-S) compounds from Teknor Apex Company, citing better performance initially and after autoclaving, superior processing, and an enhanced look and feel in the end product.

The TPE-S compounds, Medalist® MD-8421, MD-8431, and MD-8451, comprise a series within Teknor Apex’s Medalist product range, a diversified family of high-purity medical elastomers that also includes other TPE types, among them TPVs. At the 2014 MD&M West trade show, Teknor Apex presented data on the new compounds in a new whitepaper. Also exhibiting at the show, Minnesota Wire answered questions about its use of the new materials.

Enhanced electrical properties is another advantage of the new Medalist compounds cited by Minnesota Wire engineer Jeff Lewison. “We can run cables with thinner walls, which enables them to coil better, and the improved electricals enable us to use these compounds in insulation as well as jacketing.”

The whitepaper by Teknor Apex provides test data comparing the three new Medalist compounds with a standard medical-grade TPV used in wire and cable. In tests measuring tensile strength and elongation, the company says all three grades exhibited greater values for these properties prior to autoclaving, and greater property retention after as many as 15 autoclave cycles.

Photo courtesy of Teknor Apex

The three MD-8421, -8431, and -8451 elastomer grades can be used for insulation, jacketing, and molded fittings and connectors. They have Shore ‘A’ hardness levels of 92, 69, and 82, respectively, a flammability classification of HB (UL-94), and a maximum continuous operating temperature rating of 105°C (UL-1581). Besides superior performance in autoclaving, the three compounds also retain high levels of tensile strength, tensile modulus, and elongation after gamma irradiation and EtO sterilization. And they reportedly are resistant to the cleaning and antimicrobial solutions commonly used in medical facilities.

The new TPEs are manufactured in an ISO-13485 facility dedicated to Medalist medical elastomers, passing ISO-10993-5 cytotoxicity testing. They are RoHS- and REACH- compliant and are free of animal-derived materials, phthalates, and latex proteins, the company adds. www.teknorapex.com and www.mnwire.com

Designed and manufactured by Polymer Char, Crystex® QC is an innovative approach designed for soluble fraction determination in quality control laboratories at polypropylene manufacturing plants. The analysis of the amorphous fraction in polypropylene is considered a fundamental parameter in the production of the resins; among other uses, it provides a measurement of the rubber content incorporated when producing high-impact copolymers, which has significant influence on polymer properties and processing. The amorphous fraction is required for certain production applications, such as in the case of high-impact PP copolymer resins.

Traditionally, this test (also known as “xylene solubles measurement”) is performed through gravimetric and wet chemistry methods that involve constant human interaction and result in a tedious and time-consuming operation. Performing this test through a traditional method requires the analyst to weigh a sample, dissolve it using hot xylene, cool down the solution for precipitation and filtrate it, obtain an aliquot of solution to later evaporate it, dry it, and finally weigh the sample once more. The entire operation can last approximately six hours. Not only is this approach very inconvenient, but it also has safety implications for the operator because it requires manipulating solvent at high temperature.

Crystex QC is an innovative instrument that fully automates the process of obtaining the soluble fraction in PP samples (one at a time) through a temperature rising elution fractionation (TREF) procedure that is much simpler and safer to use. The instrument speeds up the analysis process and eliminates major steps usually performed manually. All the analyst is required to do is put an approximate amount of sample into a bottle, place it in the instrument, and lower a handle to pierce the bottle with a needle that will inject the solvent.

The remaining steps in the process are completely automated, including solvent dispensing into the bottle for dissolution, filtration, and rinsing of the lines and needle at the end of each analysis cycle. There is no need for weighing the sample or for handling solvent manually at any point of the analysis. High sample representativeness is obtained because the instrument allows using up to four grams of polymer.

Furthermore, Crystex QC provides a unique and comprehensive analysis because it measures not only the soluble or amorphous fraction percentage, but it provides additional information on ethylene content through an infrared detector (which ensures high-precision results) for the whole sample—the soluble fraction and the crystalline fraction. An integrated viscometer delivers intrinsic viscosity also for all three parts of the sample. All this information is obtained in a single analytical process that lasts, in total, two hours, the company adds. www.polymerchar.com/CRYSTEX_QC

Nypro Healthcare, a Jabil Company, showcased its advanced healthcare device design, development, and commercialization capabilities at MD&M West 2014. Scheduled highlights included a presentation on the company’s use of 3D X-ray computed tomography (CT) scanning to develop next-generation healthcare devices, and on its New Design and Product Introduction Center in Dallas for single-use and electro-mechanical Class I, II, and III devices.

3D ProScan’s X-ray CT scanning capabilities give customers the ability to conduct first article inspections (FAI), compare products with their computer-aided design (CAD) drawings, or compare parts made by two different facilities or tools. The technology is highly accurate, provides detailed images of internal features without disassembly or destruction, and can significantly shorten the time required for part metrology, validation, and qualification for production, the company says.

Nypro Healthcare’s New Design and Product Introduction Center provides a wide range of customer support services for medical device manufacturers to quickly innovate next-generation healthcare products. Each step of the facility’s product introduction process is supported by a qualified team of Nypro Healthcare specialists with expertise in processing, tooling, packaging, quality engineering, procurement, and supply chain management. Additional capabilities include in-house rapid prototyping, a full-service metrology center, engineering test labs, and a 1,500 square-foot Class 10,000 clean room. Regulatory and quality support is also provided. www.nypro.com

The sixteenth-annual SPE® TPO Automotive Engineered Polyolefins Conference, the world’s leading automotive engineered-polyolefins forum, returns to the Troy Marriott in the Detroit suburbs on October 5-8, 2014. This year’s theme is “TPOs: Gateway to Innovations. ”The organizing committee also has issued its annual call for papers and presentations, with abstracts due by April 18, 2014, and non-commercial papers or presentations due by July 31 (email both to TPOpapers@auto-tpo.com).

Bill Windscheif, president of Advanced Innovative Solutions, Ltd. and conference co-chair, notes: “As automakers work very hard to reduce mass and cost while maintaining or improving aesthetics, safety, functionality, and other customer-desired features, they increasingly find that rigid and ductile thermoplastic polyolefins (TPOs) allow them to do more with less—quite literally, thanks to the low specific gravity of these materials. In concert with flexible thermoplastic vulcanizates (TPVs) and thermoplastic elastomers (TPEs), these workhorse materials are being used in more challenging environments on the vehicle, thanks to the tremendous advances made in polymer modification, compounding, additives technologies, and process enhancements.

“For 16 years, SPE has highlighted the latest technologies for automakers and their supply base at our annual TPO Automotive Engineered Polyolefins Conference,” he adds. “Our show’s continued focus remains to provide practical knowledge that can be implemented to improve first-pass yield and offer more value to customers.”

Conference co-chair, Jeffrey Valentage, global market developer, Polyolefins, Specialty Compounding Automotive, ExxonMobil Chemical, adds: “TPOs, TPVs, and TPEs truly can be gateways to innovation for many important applications on passenger vehicles. Each year our conference attracts a larger and more international group of speakers, exhibitors, and attendees, which serves to underscore the growing demand for these versatile families of materials.”

This year’s technical program is co-chaired by Dr. Norm Kakarala, Inteva Products LLC, and Peter Grelle, Plastics Fundamentals Group LLC. Sessions currently planned for the event include:

- “Advances in Automotive Polyolefins,”organized by Neil Fuenmayor, LyondellBasell, and Laura Soreide, Ford Motor Co.;

- “Rigid Polyolefin Compounds,”organized by Mike Balow, Asahi Kasei North America, and Ermanno Ruccolo, Mitsui Plastics, Inc.;

- “Bio-Based Polyolefin Materials,” organized by Susan Kozora, International Automotive Components (IAC) Group, and Dr. Ellen Lee, Ford Motor Co.;

- “Interior Soft Trim & Sealing Systems,” organized by Dave Helmer, General Motors Corp., and Robert Eller, Robert Eller Associates;

- “Surface Enhancements,”organized by Dr. Rose Ryntz, IAC, and Jim Keller, United Paint Co.;

- “Lightweight Polyolefin Parts,” organized by John Haubert, Fiat Chrysler Automobiles, and Normand Miron, Milliken Corp.;

- “Adhesives & Coatings for TPOs,”organized by Hoa Pham, Avery Dennison, and Dr. Pravin Sitaram, Haartz Corp.; and

- “Thermoforming of TPO Materials,”organized by Ed Bearse, Advanced Plastics Consultants, and Rob Philip, Mytex Polymers.

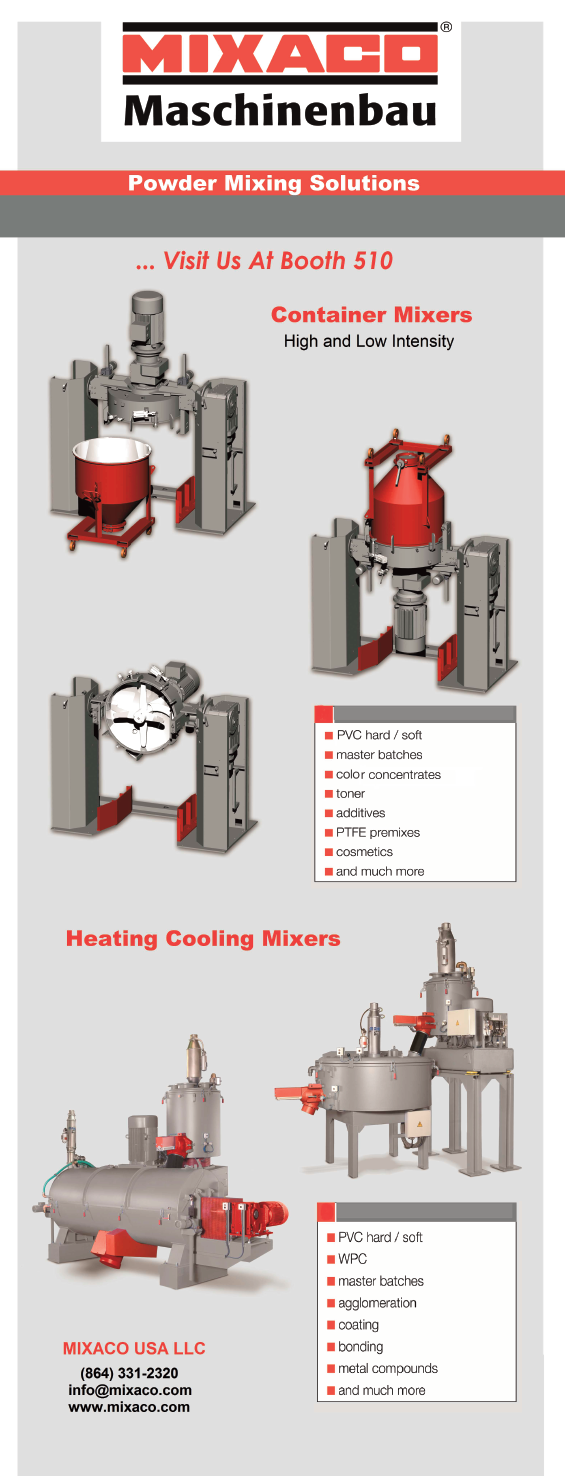

Product features include the following: Kenics Heat Exchangers require less space, energy, and time to process than other designs. Meanwhile, Kenics Static Mixer technology exclusively offers the highest available heat transfer coefficients for fast, uniform heat transfer. With their unique edge-sealed mixing elements, the heat exchangers provide heat transfer rates of four to seven times greater than conventional empty tubes. The result is polymer cooling with minimum space and pressure drop.Chemineer, Inc. offers Kenics® Heat Exchangers for efficient, cost-effective handling of heat transfer applications requiring precise cooling of viscous polymers. Equipped with streamlined Kenics Static Mixer elements, the heat exchangers are reportedly the most efficient units available today.

Product features include the following: Kenics Heat Exchangers require less space, energy, and time to process than other designs. Meanwhile, Kenics Static Mixer technology exclusively offers the highest available heat transfer coefficients for fast, uniform heat transfer. With their unique edge-sealed mixing elements, the heat exchangers provide heat transfer rates of four to seven times greater than conventional empty tubes. The result is polymer cooling with minimum space and pressure drop.Chemineer, Inc. offers Kenics® Heat Exchangers for efficient, cost-effective handling of heat transfer applications requiring precise cooling of viscous polymers. Equipped with streamlined Kenics Static Mixer elements, the heat exchangers are reportedly the most efficient units available today.

The photo on p. 7 of the February issue’s cover story should have been credited to Sonics & Materials, with the caption reading: “Developments in automat ion permit the welding of complex parts such as thisautomotive assembly. Sonics & Materials supplies robot attachments for rapid and precise welding (photo courtesy of Sonics & Materials).

The photo on p. 7 of the February issue’s cover story should have been credited to Sonics & Materials, with the caption reading: “Developments in automat ion permit the welding of complex parts such as thisautomotive assembly. Sonics & Materials supplies robot attachments for rapid and precise welding (photo courtesy of Sonics & Materials).