“It is good to have an end to journey toward; but it is the journey that matters, in the end,” according to Ernest Hemingway.

With performance fabrics, the end is an exciting destination not only within the textile industry, but for the entire universe of outdoor living. But as Hemingway states, the journey itself also matters. Begun decades ago, the creative journey of performance fabrics has taken a dynamic path through stages, processes and an ever-changing landscape of outdoor living.

Today, the path to performance includes yarn development to design creation, precision weaving and printing to marketing and final selection. All culminate in adding style and durability to outdoors everywhere. Exploring this journey from key drivers in the outdoor textile field can provide us with an onboard experience of just why it matters. Buckle up; it is going to be an exciting, colorful and informative ride.

Are we there yet? Timing from yarns to swatch books

“The performance fabric process truly takes 18 months as there is a lot of fine-tuning in the process,” said Natalie Scott, vice president sales and marketing, casual furniture, Sattler Corp., manufacturer of the Outdura brand. “We’re constantly asking: How does this new yarn work in our construction? Does the size or feel work? Can it weave properly? There are trials, warping and tweaking at every stage and once construction is right, we start on colors. It is also a balancing act being fashion forward and making the fabric applicable to our customers and the market.”

A seemingly unending number of stops occur along the journey for performance textiles involving points, plans and processes. All are executed in varying time frames by those within the industry with focus on individual capabilities and targeted customers always in sight.

For textile manufacturer Phifer, the development process is designed around a single selling cycle. “Our designers begin developing new looks and designs early in the calendar year and continue this process through the end of June,” said Hugo Benitez, national market manager, Phifer. “As new designs are entered, we are weaving prototypes throughout the first and second quarters to have fabrics to show our customers in the fall.” Phifer is then able to fabricate its marketing materials and begin presentations to customers worldwide by late August through year’s end.

The process for the Sunbrella brand by Glen Raven involves a lengthier time frame. “We factor in time for color trend research, the actual color development process that ensures pigments are precise and the stringent testing that ensures our new colors meet the toughest Sunbrella performance standards,” said Greg Voorhis, design manager, decorative fabrics, Glen Raven. “Between the development of a new yarn color to its appearance in fabrics in a Sunbrella swatch book and in the marketplace it is usually a total of three to four years.”

Nonstop journey

If there is one area in which multiple textile producers concur, it is in the unending nature of design introductions. When asked how often new designs are created, replies included “constant,” “ongoing,” “continuously” and “weekly.”

Glen Raven’s Voorhis put it simply. “Every day. We are always working on new fabrics and collections for our upholstery, awning, marine and contract lines,” he said. For Glen Raven and others, the magnitude of the design process is driven not only for the brands’ collections, but also for the creation of multiple customer or market exclusive lines.

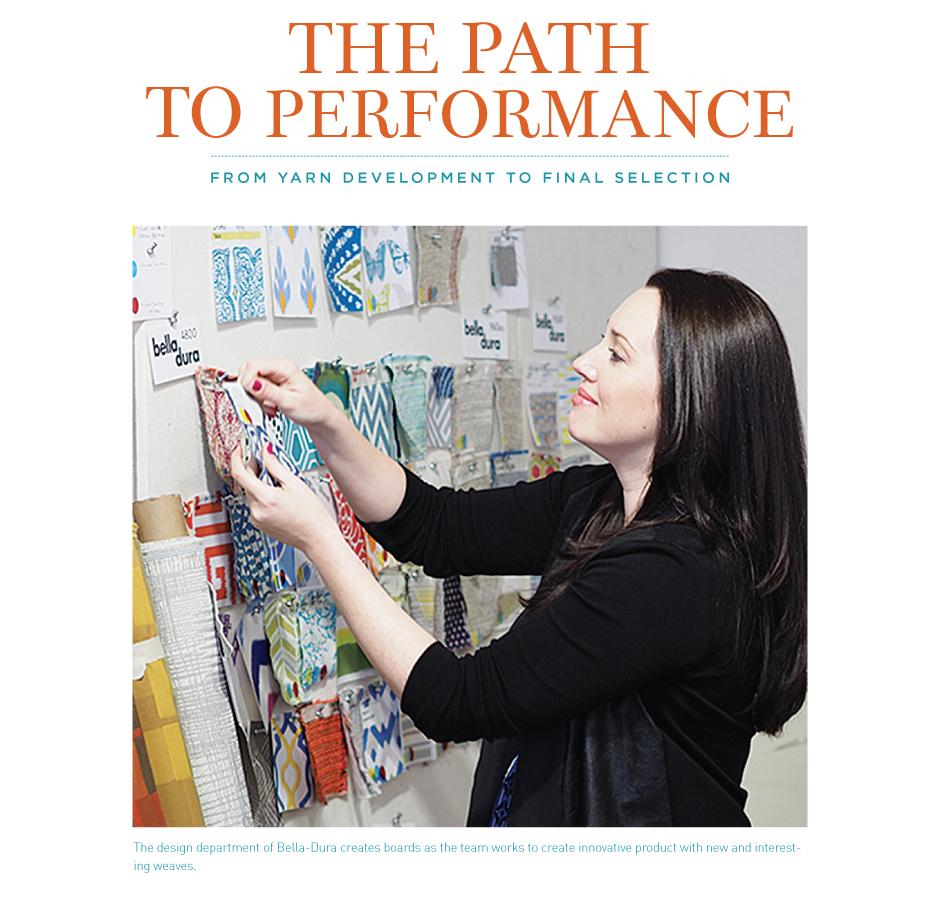

“We are developing artwork all day, every day to service the contract, residential, hospitality, furniture manufacturing and jobber markets,” said M.J. Ramos, senior merchandiser, Bella-Dura. “We have a full-time New York City-based studio with CAD designers and stylists, along with multiple art studios, that help facilitate the development of all new products and fulfill customer requests.”

Wendy Haithcox, Abercrombie Textile’s director of design, shared a similar perspective. “(We design) annually for open line products and weekly for customer projects. Designing customs for the hospitality industry is a big part of our business and we carry that infrastructure over into the outdoor market.”

With printed polyester designs, companies like the Solarium division of the Richloom Fabrics Group, work within a shorter production time frame of approximately six months. Client-specific designs, however, still are a continuous process. “We introduce an Open Stock Line twice a year, in June and December,” said Lori-Jo Shea, design director, Solarium. “We also work with specific accounts on an ongoing basis throughout the year designing for their specific needs.”

Beginning with a spin

For the woven performance textile journey, its beginnings are found in yarn development. Along with lasting durability, considerations abound for this initial stage.

“Color accuracy is incredibly important,” Voorhis said. “Because the addition of a new yarn color is such a time-intensive process, we want to be sure the color meets our performance expectations across all markets and in multiple applications.”

Environmental responsibility is a consideration for the developers at Abercrombie Textiles. “The yarns always have to perform in the outdoors,” Haithcox said. “But getting them to perform for the outdoors is equally high on our to-do list.”

Yarn meets the roll

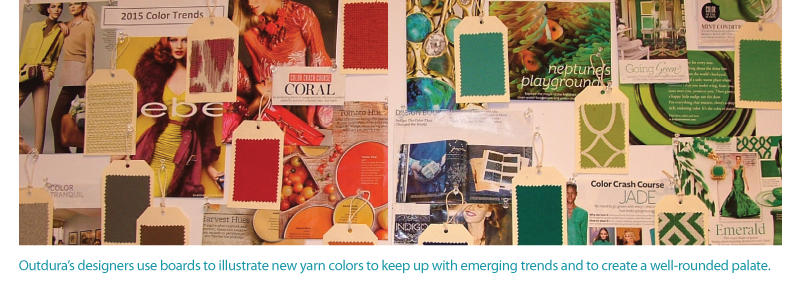

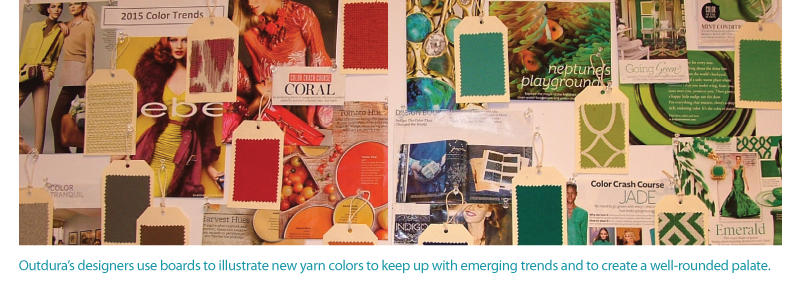

Yarn development, as an initial stage in the woven textile journey, has substantial impact within the design process. “In an effort to develop innovative, new constructions, new yarn development is critical,” Scott said. “We develop new yarn colors each year to keep up with emerging trends. We want to have a well-rounded palate that supports a variety of customers.”

Responsiveness to outdoor customers holds an important position throughout the performance textile journey with each manufacturer creating a balance among constructions, capabilities and customer preferences.

“We try to be unique in what we offer into the market in regards to design,” Benitez said. “That can be new weaves or new colors that follow our design trends. Before deciding what will be selected into our stock line, we listen to our customers as to what fabrics they would like to see in the line.”

Driving design

Inspiration within the design phase of the performance journey can range from global and cultural trends to fashion and art or to colors and concepts from a wide range of consumer goods.

“Inspiration for new fabric designs comes from many places,” Voorhis said. “From looking at fashion trends and colors to different furniture design trends, paying attention to pop culture and just keeping up with what innovative people are creating and doing in the world around us.”

“Textile design is an art form and is therefore subjective to each designer,” Ramos said. “I’m influenced by what surrounds me whether at home or traveling. I’m sensitive to colors, geography, architecture or even a museum visit.”

Manufacturing and weaving

In performance textiles, it is difficult to determine which step along the path is most important. The fact that each step is vital is especially true as the journey enters the manufacturing stage. The elements of the processes involved in taking the inspired designs and creating yardage are essential and the result of considerations from every stage to this point.

Bella-Dura’s Executive VP Ira Gasner sees manufacturing not only in relation to capabilities, but also in the dedication of the artisans in getting the designs correct. “It’s an enormous part of it,” Gasner said. “The main beauty of Bella-Dura is our ability to be so fashion forward, and that comes from the proprietary yarn, Bella-Dura polyolefin. It is produced with minimum usage of water, is energy efficient, requires smaller extrusion lots and therefore allows us more color choices. And of course, without our full-time CAD designers, the teams of people at the mill organizing the production schedule, getting the technical specs together and the dedicated weavers doing their thing, we would have nothing to sell or be able to stand behind.”

A unique perspective on the cooperation of the design process and weaving is provided by designer and textile chemist Laurie Jenkins, co-owner of the Laurie Bell brand. “We want something fresh and new and fashion forward, but also something that works for our production format,” Jenkins said. Her designs are crafted with focus and knowledge of capabilities offered by individual mills considered for the production of Laurie Bell fabrics. “I look at the designs I want and then work with the specific mill’s parameters including common warps they are running,” she said. “Manufacturing is a big part of the design process. The more you understand what each mill can do, you leverage that strength in the creation of the desired end product.”

Textile marketing

The next stop along the performance journey may require additional skills, but is equally creative. Sales and marketing efforts have been instrumental in attaining the position and prominence the category commands today.

“Marketing is key when new constructions or programs are launched and we find that if done well, the message translates through down to the retailer,” Scott said. “With new products, it can start as early as the conception of the product.”

“We begin the thought process on how to market new designs and fabrics the instant we see them,” Benitez said. “Especially those fabrics that leave little doubt they will be part of our line.” Marketing tools utilized by Phifer include all types of promotional literature from point of purchase materials to catalog pages.

Bella-Dura is proud of the team effort connecting the design studio and those creating the messaging. “We want to get across that Bella-Dura is a performance fabric – great for both outdoor and indoor use,” said Susan Lobel, VP, marketing and brand development, Bella-Dura. “We have just completed a total re-branding of Bella-Dura with great new photography that really shows the fabrics in their best light – both in use and as fabric.”

For Twitchell, as soon as sample work is completed and product lines are chosen, decisions are made concerning the best ways to present and showcase its new line of fabrics. A similar process is practiced at Laurie Bell. The brand works continuously to deliver its story of design and innovation through electronic news blasts, publicity and professional lifestyle photography. “We work to create a pretty picture to compel folks to embrace the brand,” Jenkins said. She also views involvement in trade shows, community functions and regional idea homes as ways of garnering attention with trade customers and consumers.

Marketing also is an early consideration in new product development for Solarium. “As soon as we have colorways of a pattern in work, we can share our vision with our PR department,” Shea said. “That way we can work as a team.” She notes those marketing efforts include trade magazine ads, hang tags and sewn-in labels as well as social media.

Next stop, backyards

The success of marketing efforts is realized in the ultimate selection process by manufacturers or jobbers for their customers.

Artistry, innovation and expertise make up the journey being taken today across the textile industry as many work to define what it is that matters for performance fabrics and the end consumer. ![]()