Determination of sulfur, phosphorus and manganese in high purity iron

Yasuyuki Shikamori and Kazumi Nakano

Agilent Technologies, Japan

Keywords

phosphorus, sulfur, manganese, iron, steel, JSS 001-6, JSS 003-6, abundance sensitivity, oxygen mass-shift

Introduction

ICP-MS is the analytical technique of choice for the analysis of trace elements in iron and steel. However, the sensitivity and interference removal performance of quadrupole ICP-MS (ICP-QMS) is not sufficient for the determination of difficult analytes such as phosphorus (P) and sulfur (S) at the low levels required. Furthermore, the determination of manganese (Mn) in an iron matrix is extremely challenging for ICP-QMS due to overlap (or tailing) from the very intense 54Fe and 56Fe peaks that occur either side of the single isotope of manganese at m/z 55.

The Agilent 8800 Triple Quadrupole ICP-MS (ICP‑QQQ) provides more effective and reliable removal of polyatomic interferences, such as 14N16OH on 31P and 16O2 on 32S, using controlled chemical reaction in the CRC. This note describes the performance of the 8800 ICP‑QQQ operating in MS/MS mode, for the determination of the trace elements S, P and Mn in two high purity iron CRMs (JSS 001-6 and 003-6).

Experimental

Instrumentation: Agilent 8800 #100.

Plasma condition: Preset plasma/HMI-mid.

Ion lens tune: Soft extraction tune:

Extract 1 = 0 V, Extract 2 = -175 V.

CRC and acquisition conditions:

- MS/MS O2 mass-shift method to remove the 14N16OH+ and 16O2+ interferences on 31P+ and 32S+ respectively: O2 gas at 0.3 mL/min, Octopole bias = -5 V and KED = -7 V.

- MS/MS He on-mass mode to measure 55Mn+: He gas at 5.0 mL/min, Octopole bias = -18 V and KED = 4 V.

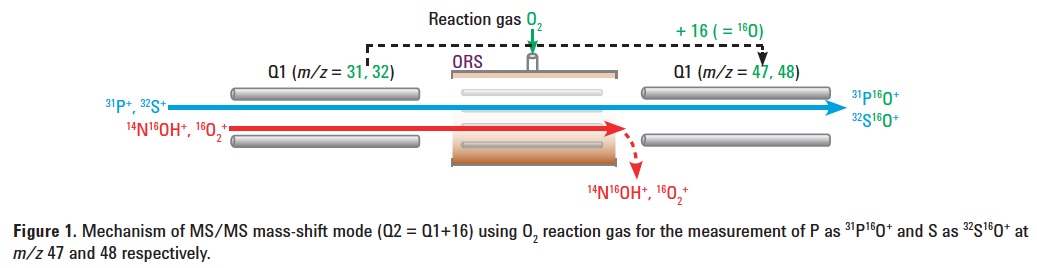

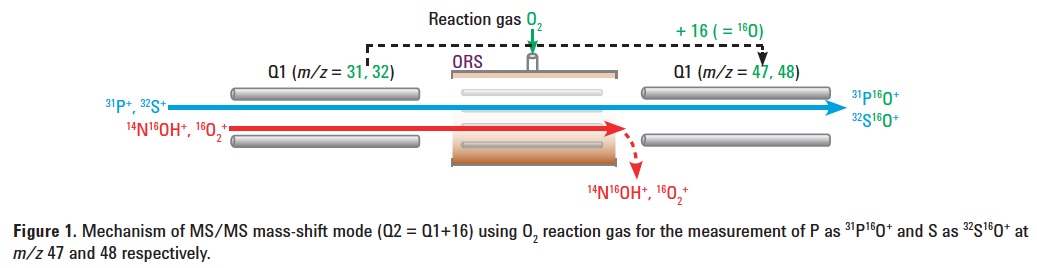

All other parameters were optimized by Autotune in the MassHunter software. Figure 1 shows the mechanism used on the 8800 ICP-QQQ to avoid the 14N16OH+ and 16O2+ interferences on 31P+ and 32S+ by mass-shift mode (Q1≠Q2) using O2 reaction gas.

Sample preparation: Two Steel CRMs, JSS-001 and JSS-003 were purchased from The Japan Iron and Steel Federation (Tokyo, Japan). 0.1 g of each Steel CRM was digested in a mixture of

1 mL HCl and 2 mL HNO3 and diluted to 100 mL with UPW. No further chemical matrix separation, e.g., solvent extraction, ion exchange, etc. was applied. The digested CRM samples containing 0.1% (1000 ppm) Fe were analyzed directly on the ICP-QQQ using the robust plasma conditions provided by Agilent’s HMI aerosol dilution system.

Results and discussion

BEC and DL of P and S

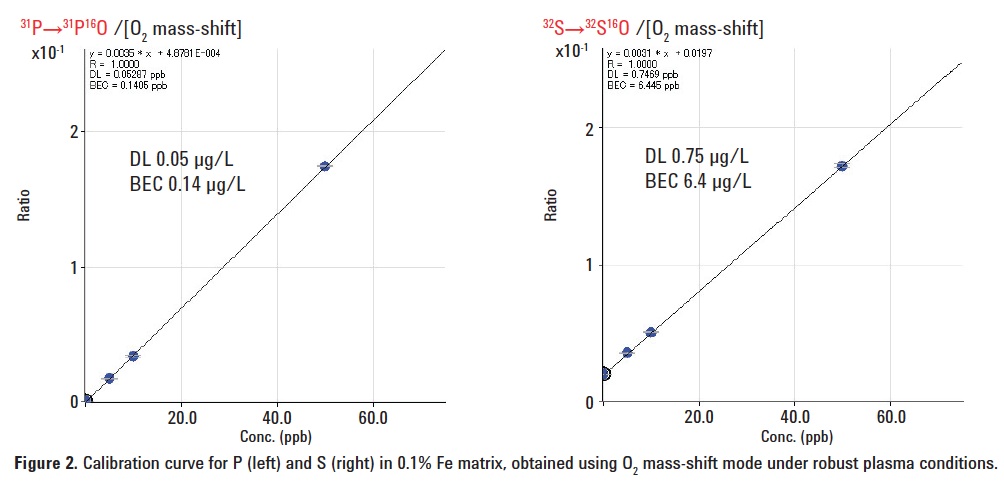

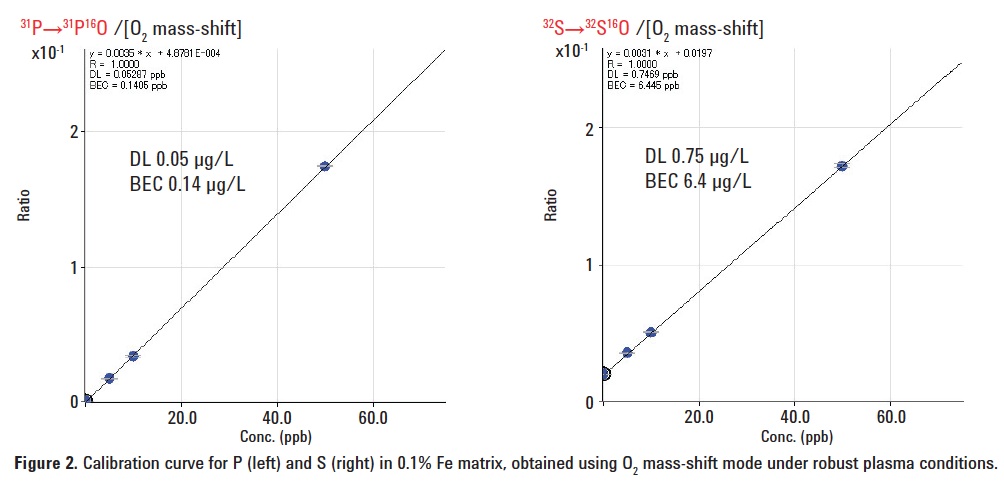

The calibration plots shown in Figure 2 demonstrate that the 8800 ICP-QQQ with MS/MS mass-shift mode can successfully perform the trace level (single ppb) quantitation of P and S in 0.1% Fe solutions. The BEC and DL achieved for P were 0.14 ppb and 0.05 ppb respectively, and the BEC and DL for S were 6.45 ppb and 0.75 ppb respectively.

Trace Mn analysis in Fe matrix

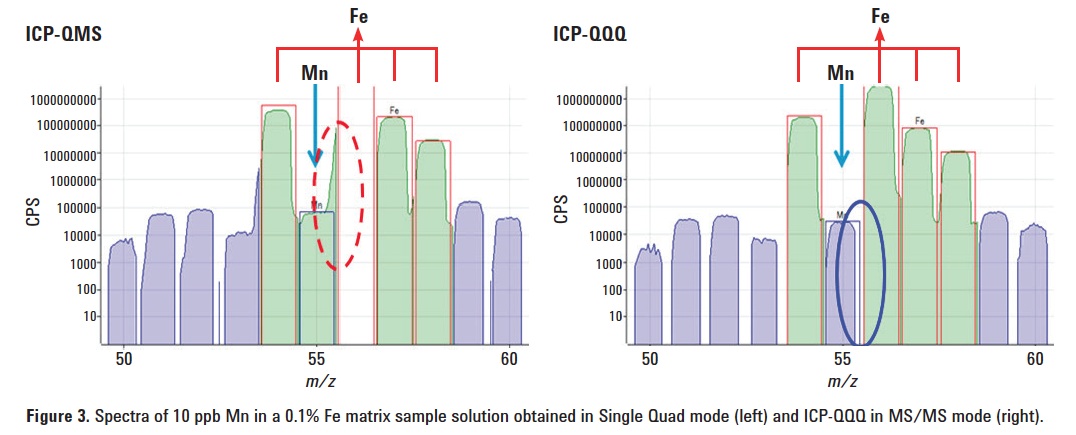

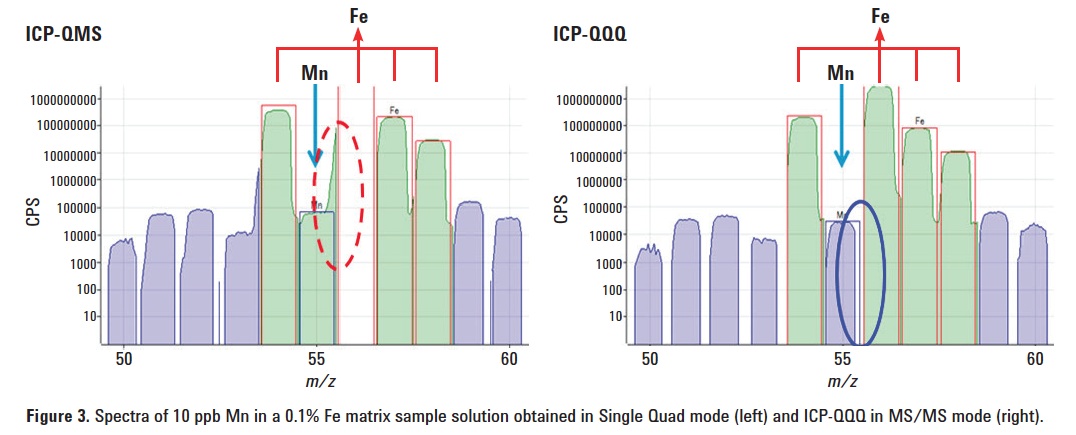

The abundance sensitivity (AS, a measure of peak separation) of ICP-QQQ in MS/MS mode is the product of the Q1 AS x Q2 AS. This means the AS of the 8800 ICP-QQQ is theoretically about 2x that achievable on ICP‑QMS, and the ICP-QQQ is therefore able to successfully separate the 55Mn peak from the very intense overlaps from 54Fe and 56Fe in a high iron matrix. This is demonstrated in Figure 3 which shows the spectra of 10 ppb Mn in a 0.1% Fe matrix sample solution measured in Single Quad mode (left) and MS/ MS mode on the ICP-QQQ (right). Helium was used as the cell gas in both cases to remove 54FeH+ and ArNH+ interferences by KED.

Determination of P, S and Mn in high purity iron CRMs

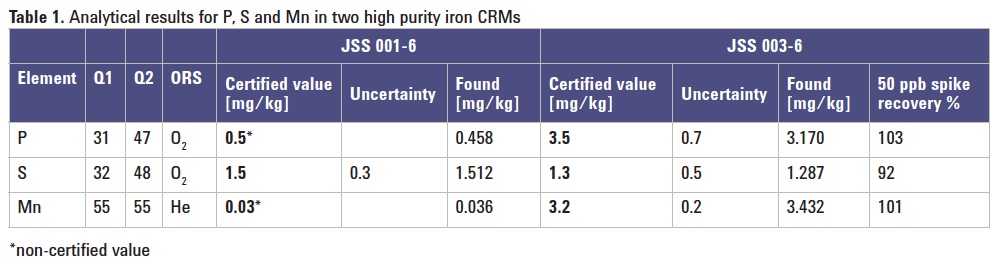

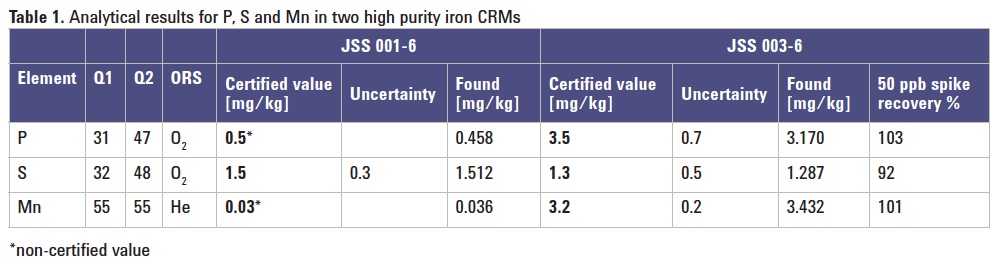

Trace elements including P, S and Mn were determined by ICP-QQQ in high purity iron CRMs: JSS 001-6 and 003-6, using O2 mass-shift mode (for P and S) and He mode (for Mn). As summarized in Table 1, excellent agreement was obtained between the measured (found) and certified values for all three elements, indicating the effective interference removal offered by the 8800 ICP‑QQQ in MS/MS mode. Excellent spike recovery at the 50 ppb level was also confirmed with JSS 003.