High Style for Automotive Interiors

Vehicle interiors are moving into the fast lane of fashion and performance with innovative plastics

Previous Article Next Article

By Pat Toensmeier

Customer demands for comfort and connectivity require more diverse plastic materials and processes. Shown here is the interior of the Buick LaCrosse (original photo courtesy of Darren Brode, Motor City Images).

Automotive interiors are fertile areas of plastics innovation. Recent developments in materials address critical interior needs in such areas as performance, manufacturing efficiency, electronics integration, lightweighting, sustainability, and, of course, consumer styling preferences.

Consumers increasingly want vehicles with stylish interiors. This stems from high buying expectations, and it’s a global trend, especially among young purchasers who view fashionable interiors and accessories like connectivity as mandatory features, even in economy models.

Interior quality, in fact, often closes sales. “Many consumers are willing to upgrade to higher-trim models for the superior interior quality,” says Scott Fallon, general manager of the automotive industry team at SABIC Innovative Plastics.

In particular, OEMs are also looking to plastics to promote the appeal of alternative vehicles. Resins and compounds with properties such as electromagnetic shielding, conductivity, heat dissipation, and flame resistance are among materials that enhance the functionality and aesthetics of hybrid and electric car interiors. Structural plastics that replace metal and offset the weight of large batteries are specified to maximize the range of these platforms.

Plastics additionally play a role in an important environmental issue—interior emissions, which include the vaunted “new-car smell.” Emissions are produced by outgassing of volatile and semi-volatile organic compounds, which stem mostly from coatings but are also released by some polymers, fabrics (including leather), and other materials. Emissions are reduced with polymers and processing techniques that enhance the aesthetics of parts without coatings.

The growing performance needs of interiors are such that OEMs are considering a broader range of plastics. “They are taking the handcuffs off when it comes to materials selection, although cost is still important,” says Jeff Helms, corporate OEM accounts director at Celanese Corp.

As a result, automakers are specifying more engineering resins, high-performance compounds, thermoplastic composites, and specialty materials for interiors, and are increasingly receptive to formulations and process techniques that provide part benefits ranging from higher mechanical properties to enhanced cosmetics.

Shaving Weight

OEMs in key global markets balance performance and aesthetics with regulatory needs, the most common of which involve fuel consumption. In the USA, efforts are directed at meeting CAFE average fuel efficiency rates of 54.5 mpg in cars and light trucks by the 2025 model year, almost double the current 27.5-mpg standard.

Plastics are, of course, critical in extending fuel economy by weight reduction. One expert says automakers are so focused on this that they will specify materials even if they only shave grams off a component—the stakes are that high. Estimates vary, but a 10% reduction in vehicle weight generally yields a 6-7% improvement in fuel economy, says Bob Akins, vice president of sales and marketing at DSM Engineering Plastics–Americas.

From the outside, Ford’s F-150 light truck is a tough vehicle suitable for harsh driving conditions. But on the inside, the truck is plush and equipped with multiple electronic systems, backlit touchpoints, and other amenities. (Photos courtesy of Ford Motor Co.)

So the more plastics applications possible for a vehicle, the greater the potential for weight reduction. But to maximize plastics use, materials must meet the design and performance criteria of increasingly challenging interior parts.

To do this, many applications are being converted to engineering plastics from metal and lower-performing thermoplastics. DSM, for example, cites the successful use of its Akulon polyamide 6 (PA-6) grades in parts in which the resin, in neat and glass-reinforced versions, combines the strength, light weight, and design flexibility necessary to replace metal. Examples include airbag containers, where molded PA-6 simplifies the system’s complex metal design and yields major weight savings—2 kg in passenger-side units alone.

A high-flow grade, Akulon Ultraflow, reduces the thickness of air vanes in dashboard vents. The resin reportedly achieves Class-A surface quality in molded parts, and resists warping. Its thin-wall capabilities also lower material cost and speed molding cycles.

Helms of Celanese predicts that automakers will reduce the mass of vehicle components even more by thin-walling to meet 2025 CAFE requirements and other fuel-efficiency standards in NAFTA, Europe, and China. Celanese, for one, is formulating materials for this need.

For example, Helms notes that 2 mm was, until recently, the limit for thin-walling instrument panels (IPs) and door panels. Now, using the company’s long-fiber-reinforced thermoplastics (LFRT) formulations, which boost mechanical properties, these components can be molded in thicknesses down to 1.4 mm. A glass-fiber/PP version can be used in non-structural applications, where its low specific gravity contributes to a reduction in part weight. In parts with higher mechanical requirements, such as IPs, a carbon-fiber/PA grade might be specified.

Another development from Celanese addresses the need to replace metal components with plastics that look and feel like metal without painting or plating. MetaLX metal-effect materials are produced primarily with the supplier’s Hostaform acetal copolymer. The materials are targeted at interior hard trim, door handles, and speaker grilles and knobs, among other applications.

The grades are colored with aluminum pigments, with high- or low-gloss finishes. Parts molded from the resins are said to be emissions-free, UV-stable, and scratch-resistant. Since there’s no painting or plating, a Celanese analysis states that automakers can save $1-$4 per part with MetaLX resins.

The polymers also improve the haptics, or “feel,” of molded plastics, compared with metal. For example, a lack of “heft” has been a drawback for consumers with previous metal replacements. “Every OEM is interested in haptics,” Helms notes. “We can deliver the feel they want with this material.”

An airbag container molded of Akulon PA-6 from DSM replaced a heavier, multicomponent metal version (photo courtesy of DSM).

BMW’s new 7 Series sedan reflects consumer preferences for comfort, productivity, and entertainment in vehicles (photo courtesy of BMW).

Lighter Subassemblies

One growing approach to weight reduction is subassembly design. Automakers and suppliers are forming consortia to advance techniques addressing this area.

The benefit of this approach, says Levi Kishbaugh, vice president of engineering at Trexel, is that rethinking how subassemblies are designed can lead to substantial reductions in vehicle weight. “Single parts are important for weight reduction, but the way to make a significant impact on weight is with subassemblies,” he remarks.

Trexel works with consortia to apply its MuCell® microcellular, gas-induced foam molding process for subassemblies such as IPs, door modules, and spare-tire wells—anywhere stiffness is a key property, Kishbaugh says. The process, which targets components with wall thicknesses to 3 mm, provides dimensional benefits and uniform stress patterns, as well as weight savings.

The MuCell process is also specified for less-visible interior parts such as lower trim panels and console components. This is because foamed parts generally don’t achieve high cosmetic finishes. Trexel is working to change this. One initiative involves resin supplier Asahi Kasei, which is developing a filled-PP grade that uses a special formula and modified feedstocks to yield an aesthetic finish when foamed. Another effort is through the use of injection molds with induction heating capabilities that cycle the mold temperature to create cosmetic part finishes (see more about this below).

Subassemblies like this Merecedes-Benz center console optimize weight reduction. The interior parts are molded in a variotherm mold with Trexel’s MuCell foam process (photo courtesy of Trexel).

EVs & Electronics Surge, Quietly

Electronics are important interior components. Most vehicles have, in recent years, added an array of sensors (visual and otherwise) that increase operational safety; touchscreens that extend the driver-vehicle interface; diagnostics to monitor operations; GPS navigation; infotainment and Bluetooth systems; console, steering-wheel, and door controls; and ambient lighting, some of which can be programmed to “emotionalize” interior spaces.

There is additionally the impact of electric vehicles on interior design. These vehicles are quiet during operation as well as when idling, so plastics must be noise-free.

SABIC is among the suppliers that tailor resins for these needs. Thermocomp NXCY620 is a polycarbonate (PC)/ABS compound with inherent lubricity that resists friction and sticking, “effectively addressing buzz, squeak, and rattle issues in interior applications,” Scott Fallon says. “This is particularly important in cases where two components are in close proximity to each other and a tight gap is required, whether the contact is plastic-on-metal or plastic-on-plastic.”

Also of interest when designing interiors for electric vehicles is the heating, ventilation, and air-conditioning (HVAC) system. Since an electric vehicle relies on batteries to power HVAC systems, effective interior insulation is necessary to avoid battery drain.

SABIC has long promoted Lexan PC as an alternative to conventional automotive glazing. In electric vehicles, however, the benefits it provides in terms of thermal insulation are especially critical, Fallon says. “The improved performance is due to the lower inherent thermal conductivity of PC glazing relative to tempered glass, which can reduce steady-state total heat transfer between the inside and outside of the vehicle in hot and cold climates,” he says.

To reduce heat buildup in vehicles, infrared-blocking grades of Lexan PC are available for glazing. Recent developments in the material also reduce the skin sensitivity of occupants to heat and sun.

Last October, SABIC announced the results of a program in Germany to develop a lightweight electric concept vehicle for city driving. Working in a consortium with automakers BMW and Daimler, the Technical University of Munich, and others, the Visio.M car, which weighs 450 kg without a battery, used Lexan glazing instead of glass. The insulation of the PC glazing reduced the HVAC load, extending vehicle range by 15 km. The glazing also reduced vehicle weight more than 13 kg compared with glass, which added 2 km of range per charge.

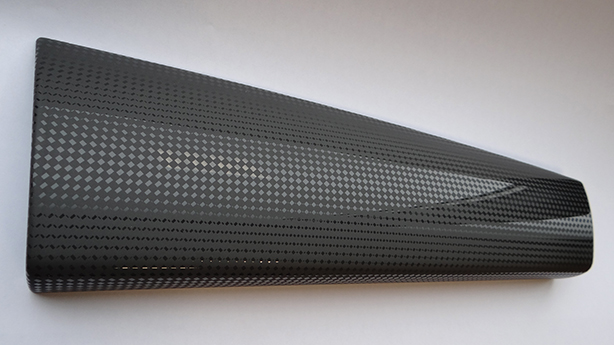

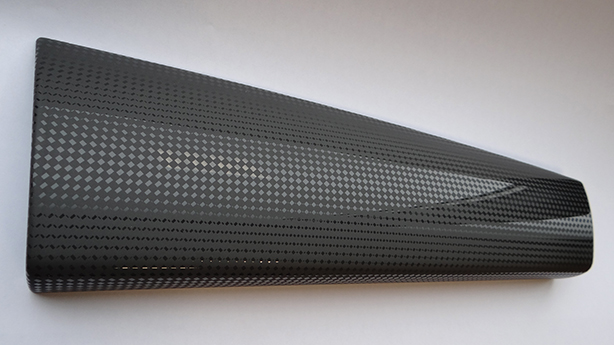

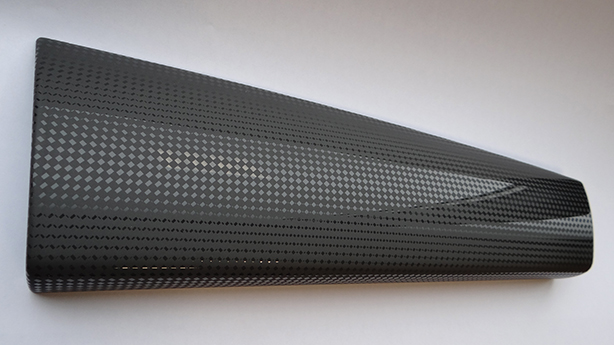

An injection mold with induction-heating components from RocTool produces a high-gloss/low-gloss pattern on this IP compartment for the BMW Mini Cooper (photo courtesy of RocTool).

Appearance Enhancements

One color that gets a lot of attention from automakers is “piano black”—a deep, glossy hue, which can be achieved in plastics without paint or clear coat. BASF supplies such a material, a grade of Ultramid A3L PA 66 called BK7793. The grade was formulated in a “crash program” with Ford to replace painted metal rear-door switch bezels on the 2013 Fusion and Mondeo models. The metal bezels had problems with scratching and marring.

The BK7793 grade uses molded-in color and a special rapid heating and cooling (variotherm) molding technology called E-Mold, developed in South Korea, to bring out the deep black gloss. This and similar molding technologies (e.g., induction and steam) inject resin and rapidly raise in-mold temperature, which causes the viscosity to change. The resin—even a reinforced grade—will flow evenly into the mold and replicate its surface texture. Rapidly cooling the mold freezes the finish in place and a part emerges with a deep, glossy surface.

The grade has outstanding scratch and mar resistance, says Cameron Recknagel, market segment specialist for automotive interiors at BASF. And with no paint or coatings needed, parts don’t contribute to emissions.

In fact, variotherm molding techniques have been around for years. But only recently have they made headway as a process alternative, and then usually for cosmetic benefits. As the market slowly grows, vendors are capitalizing on demand. RocTool, for one, is a French company that started U.S. operations two years ago to sell induction-heating components for molds. President Mathieu Boulanger confirms the process yields a “resin-rich surface” that optimizes piano-black resins and other plastic types, including foams. At least ten European car models use the process for parts, and he expects to see initial North American applications soon.

RocTool supplies copper heating coils that are embedded near the surface of a mold, along with a generator and control to rapidly cycle mold temperature. Although the heat range of the equipment is 60 to 450°C, most operations take place between 130 and 200°C. The process reportedly has no effect on resin properties. There is, however, a 10-30% cycle-time penalty and 10-15% premium on mold cost with the equipment.

The process has a functional value, as well. Volvo licensed the technology to mold the housing of the IntelliSafe body on the new XC90 luxury SUV. The housing attaches to the top of the interior compartment and contains radar that scans for obstacles—including distracted pedestrians—that might cause collisions. The housing needs a textured surface similar to that of the steel part it replaces, to prevent sunlight from blinding the radar. RocTool helped develop a mold surface and heating cycle to achieve this texture.

Despite its benefits, acceptance of induction mold heating has been slow in North America. “It is growing,” Boulanger says, “but the auto industry is conservative and it’s a battle to get to production.”

Consolidated Seating

BASF promotes parts consolidation with overmolded thermoplastic composites. Ultracom materials incorporate laminates of woven glass fiber impregnated with Ultramid PA, or unidirectional reinforced glass- or carbon-fiber tape within a matrix of Ultradur polybutylene terephthalate (PBT) resin. These composites are molded into semi-finished forms and then overmolded into finished components. The result is strong, lightweight parts, in which reinforcements are precisely placed at key points for enhanced mechanical properties.

An Ultracom composite replaces a multicomponent metal seat pan in GM’s Opel Astra in Europe, for example. The new version installs in one piece, which simplifies assembly and saves money, and weighs less than the metal pan.

Another supplier of materials for overmolded thermoplastic composites is Lanxess. The company’s Tepex dynalite composites combine continuous reinforcing fibers with Durethan PA-6 or -66 and Pocan PBT or PET resins. The materials are fabricated as sheet, then molded into a semi-finished form and overmolded into a finished part.

Applications include a seat shell specified for the Opel Astra OPC in late 2013. The matrix in the seat shell is PA-6, with two layers of glass-fiber reinforcement at a 47% loading. The sheet is molded to shape, then overmolded with reinforced PA-6 to integrate reinforcing ribs and other features. The one-shot process reportedly takes less than 60 seconds.

Three views of a one-piece seat pan made with Ultracom thermoplastic composite from BASF. It replaced a multicomponent metal version in GM’s Opel Astra (photo courtesy of BASF).

Reduced-Emission Materials

The issue of emissions has influenced the development of a polyurethane (PUR) seating foam by Dow Automotive Systems. Specflex Activ is an amine-emission-free formulation. Rather than using conventional amine catalysts to promote foaming between polyols and isocyanate, the material incorporates a new additive polyol with high and balanced catalytic activity, the company says.

The formulation reportedly also provides a broader process window, and improves mechanical and aging properties of the PUR foam. In addition to seating, the material can be used in headrests and consoles, says Kyle Wojan, performance solutions field marketer for the NAFTA region at Dow Automotive.

Reducing emissions is also an objective of DuPont Performance Polymers, which recently commercialized low-emission grades of Delrin acetal. Lauren Coleman, regional product manager, says the materials rely on additive and process technology to achieve this. They’re primarily used in safety and gearing components in interiors, and are drop-in replacements for previous Delrin resins.

Among the offerings is the Delrin 300TE family, which “was quickly adopted by the automotive industry, because it offers a good combination of strength and toughness that allows significantly smaller, thinner components that deliver the mechanical performance required for safety systems,” Coleman says. Applications include interior touchpoints (such as knobs and handles), motors, and safety-belt system components.

A “Golden Age” to Come?

As consumers demand higher styling and improved amenities in the vehicles they buy, automakers seek to differentiate models from competitors while holding the line on cost and reducing weight. Thus automotive interiors will flourish as an outlet for plastics innovation—as much as (if not more than) exteriors and underhood applications. This, in turn, will result in numerous developments in materials and processing that could affect all levels of the plastics industry. The golden age of driving may yet be ahead.

High Style for Automotive Interiors

Vehicle interiors are moving into the fast lane of fashion and performance with innovative plastics

Previous Article Next Article

By Pat Toensmeier

Customer demands for comfort and connectivity require more diverse plastic materials and processes. Shown here is the interior of the Buick LaCrosse (original photo courtesy of Darren Brode, Motor City Images).

Automotive interiors are fertile areas of plastics innovation. Recent developments in materials address critical interior needs in such areas as performance, manufacturing efficiency, electronics integration, lightweighting, sustainability, and, of course, consumer styling preferences.

Consumers increasingly want vehicles with stylish interiors. This stems from high buying expectations, and it’s a global trend, especially among young purchasers who view fashionable interiors and accessories like connectivity as mandatory features, even in economy models.

Interior quality, in fact, often closes sales. “Many consumers are willing to upgrade to higher-trim models for the superior interior quality,” says Scott Fallon, general manager of the automotive industry team at SABIC Innovative Plastics.

In particular, OEMs are also looking to plastics to promote the appeal of alternative vehicles. Resins and compounds with properties such as electromagnetic shielding, conductivity, heat dissipation, and flame resistance are among materials that enhance the functionality and aesthetics of hybrid and electric car interiors. Structural plastics that replace metal and offset the weight of large batteries are specified to maximize the range of these platforms.

Plastics additionally play a role in an important environmental issue—interior emissions, which include the vaunted “new-car smell.” Emissions are produced by outgassing of volatile and semi-volatile organic compounds, which stem mostly from coatings but are also released by some polymers, fabrics (including leather), and other materials. Emissions are reduced with polymers and processing techniques that enhance the aesthetics of parts without coatings.

The growing performance needs of interiors are such that OEMs are considering a broader range of plastics. “They are taking the handcuffs off when it comes to materials selection, although cost is still important,” says Jeff Helms, corporate OEM accounts director at Celanese Corp.

As a result, automakers are specifying more engineering resins, high-performance compounds, thermoplastic composites, and specialty materials for interiors, and are increasingly receptive to formulations and process techniques that provide part benefits ranging from higher mechanical properties to enhanced cosmetics.

Shaving Weight

OEMs in key global markets balance performance and aesthetics with regulatory needs, the most common of which involve fuel consumption. In the USA, efforts are directed at meeting CAFE average fuel efficiency rates of 54.5 mpg in cars and light trucks by the 2025 model year, almost double the current 27.5-mpg standard.

Plastics are, of course, critical in extending fuel economy by weight reduction. One expert says automakers are so focused on this that they will specify materials even if they only shave grams off a component—the stakes are that high. Estimates vary, but a 10% reduction in vehicle weight generally yields a 6-7% improvement in fuel economy, says Bob Akins, vice president of sales and marketing at DSM Engineering Plastics–Americas.

From the outside, Ford’s F-150 light truck is a tough vehicle suitable for harsh driving conditions. But on the inside, the truck is plush and equipped with multiple electronic systems, backlit touchpoints, and other amenities. (Photos courtesy of Ford Motor Co.)

So the more plastics applications possible for a vehicle, the greater the potential for weight reduction. But to maximize plastics use, materials must meet the design and performance criteria of increasingly challenging interior parts.

To do this, many applications are being converted to engineering plastics from metal and lower-performing thermoplastics. DSM, for example, cites the successful use of its Akulon polyamide 6 (PA-6) grades in parts in which the resin, in neat and glass-reinforced versions, combines the strength, light weight, and design flexibility necessary to replace metal. Examples include airbag containers, where molded PA-6 simplifies the system’s complex metal design and yields major weight savings—2 kg in passenger-side units alone.

A high-flow grade, Akulon Ultraflow, reduces the thickness of air vanes in dashboard vents. The resin reportedly achieves Class-A surface quality in molded parts, and resists warping. Its thin-wall capabilities also lower material cost and speed molding cycles.

Helms of Celanese predicts that automakers will reduce the mass of vehicle components even more by thin-walling to meet 2025 CAFE requirements and other fuel-efficiency standards in NAFTA, Europe, and China. Celanese, for one, is formulating materials for this need.

For example, Helms notes that 2 mm was, until recently, the limit for thin-walling instrument panels (IPs) and door panels. Now, using the company’s long-fiber-reinforced thermoplastics (LFRT) formulations, which boost mechanical properties, these components can be molded in thicknesses down to 1.4 mm. A glass-fiber/PP version can be used in non-structural applications, where its low specific gravity contributes to a reduction in part weight. In parts with higher mechanical requirements, such as IPs, a carbon-fiber/PA grade might be specified.

Another development from Celanese addresses the need to replace metal components with plastics that look and feel like metal without painting or plating. MetaLX metal-effect materials are produced primarily with the supplier’s Hostaform acetal copolymer. The materials are targeted at interior hard trim, door handles, and speaker grilles and knobs, among other applications.

The grades are colored with aluminum pigments, with high- or low-gloss finishes. Parts molded from the resins are said to be emissions-free, UV-stable, and scratch-resistant. Since there’s no painting or plating, a Celanese analysis states that automakers can save $1-$4 per part with MetaLX resins.

The polymers also improve the haptics, or “feel,” of molded plastics, compared with metal. For example, a lack of “heft” has been a drawback for consumers with previous metal replacements. “Every OEM is interested in haptics,” Helms notes. “We can deliver the feel they want with this material.”

An airbag container molded of Akulon PA-6 from DSM replaced a heavier, multicomponent metal version (photo courtesy of DSM).

BMW’s new 7 Series sedan reflects consumer preferences for comfort, productivity, and entertainment in vehicles (photo courtesy of BMW).

Lighter Subassemblies

One growing approach to weight reduction is subassembly design. Automakers and suppliers are forming consortia to advance techniques addressing this area.

The benefit of this approach, says Levi Kishbaugh, vice president of engineering at Trexel, is that rethinking how subassemblies are designed can lead to substantial reductions in vehicle weight. “Single parts are important for weight reduction, but the way to make a significant impact on weight is with subassemblies,” he remarks.

Trexel works with consortia to apply its MuCell® microcellular, gas-induced foam molding process for subassemblies such as IPs, door modules, and spare-tire wells—anywhere stiffness is a key property, Kishbaugh says. The process, which targets components with wall thicknesses to 3 mm, provides dimensional benefits and uniform stress patterns, as well as weight savings.

The MuCell process is also specified for less-visible interior parts such as lower trim panels and console components. This is because foamed parts generally don’t achieve high cosmetic finishes. Trexel is working to change this. One initiative involves resin supplier Asahi Kasei, which is developing a filled-PP grade that uses a special formula and modified feedstocks to yield an aesthetic finish when foamed. Another effort is through the use of injection molds with induction heating capabilities that cycle the mold temperature to create cosmetic part finishes (see more about this below).

Subassemblies like this Merecedes-Benz center console optimize weight reduction. The interior parts are molded in a variotherm mold with Trexel’s MuCell foam process (photo courtesy of Trexel).

EVs & Electronics Surge, Quietly

Electronics are important interior components. Most vehicles have, in recent years, added an array of sensors (visual and otherwise) that increase operational safety; touchscreens that extend the driver-vehicle interface; diagnostics to monitor operations; GPS navigation; infotainment and Bluetooth systems; console, steering-wheel, and door controls; and ambient lighting, some of which can be programmed to “emotionalize” interior spaces.

There is additionally the impact of electric vehicles on interior design. These vehicles are quiet during operation as well as when idling, so plastics must be noise-free.

SABIC is among the suppliers that tailor resins for these needs. Thermocomp NXCY620 is a polycarbonate (PC)/ABS compound with inherent lubricity that resists friction and sticking, “effectively addressing buzz, squeak, and rattle issues in interior applications,” Scott Fallon says. “This is particularly important in cases where two components are in close proximity to each other and a tight gap is required, whether the contact is plastic-on-metal or plastic-on-plastic.”

Also of interest when designing interiors for electric vehicles is the heating, ventilation, and air-conditioning (HVAC) system. Since an electric vehicle relies on batteries to power HVAC systems, effective interior insulation is necessary to avoid battery drain.

SABIC has long promoted Lexan PC as an alternative to conventional automotive glazing. In electric vehicles, however, the benefits it provides in terms of thermal insulation are especially critical, Fallon says. “The improved performance is due to the lower inherent thermal conductivity of PC glazing relative to tempered glass, which can reduce steady-state total heat transfer between the inside and outside of the vehicle in hot and cold climates,” he says.

To reduce heat buildup in vehicles, infrared-blocking grades of Lexan PC are available for glazing. Recent developments in the material also reduce the skin sensitivity of occupants to heat and sun.

Last October, SABIC announced the results of a program in Germany to develop a lightweight electric concept vehicle for city driving. Working in a consortium with automakers BMW and Daimler, the Technical University of Munich, and others, the Visio.M car, which weighs 450 kg without a battery, used Lexan glazing instead of glass. The insulation of the PC glazing reduced the HVAC load, extending vehicle range by 15 km. The glazing also reduced vehicle weight more than 13 kg compared with glass, which added 2 km of range per charge.

An injection mold with induction-heating components from RocTool produces a high-gloss/low-gloss pattern on this IP compartment for the BMW Mini Cooper (photo courtesy of RocTool).

Appearance Enhancements

One color that gets a lot of attention from automakers is “piano black”—a deep, glossy hue, which can be achieved in plastics without paint or clear coat. BASF supplies such a material, a grade of Ultramid A3L PA 66 called BK7793. The grade was formulated in a “crash program” with Ford to replace painted metal rear-door switch bezels on the 2013 Fusion and Mondeo models. The metal bezels had problems with scratching and marring.

The BK7793 grade uses molded-in color and a special rapid heating and cooling (variotherm) molding technology called E-Mold, developed in South Korea, to bring out the deep black gloss. This and similar molding technologies (e.g., induction and steam) inject resin and rapidly raise in-mold temperature, which causes the viscosity to change. The resin—even a reinforced grade—will flow evenly into the mold and replicate its surface texture. Rapidly cooling the mold freezes the finish in place and a part emerges with a deep, glossy surface.

The grade has outstanding scratch and mar resistance, says Cameron Recknagel, market segment specialist for automotive interiors at BASF. And with no paint or coatings needed, parts don’t contribute to emissions.

In fact, variotherm molding techniques have been around for years. But only recently have they made headway as a process alternative, and then usually for cosmetic benefits. As the market slowly grows, vendors are capitalizing on demand. RocTool, for one, is a French company that started U.S. operations two years ago to sell induction-heating components for molds. President Mathieu Boulanger confirms the process yields a “resin-rich surface” that optimizes piano-black resins and other plastic types, including foams. At least ten European car models use the process for parts, and he expects to see initial North American applications soon.

RocTool supplies copper heating coils that are embedded near the surface of a mold, along with a generator and control to rapidly cycle mold temperature. Although the heat range of the equipment is 60 to 450°C, most operations take place between 130 and 200°C. The process reportedly has no effect on resin properties. There is, however, a 10-30% cycle-time penalty and 10-15% premium on mold cost with the equipment.

The process has a functional value, as well. Volvo licensed the technology to mold the housing of the IntelliSafe body on the new XC90 luxury SUV. The housing attaches to the top of the interior compartment and contains radar that scans for obstacles—including distracted pedestrians—that might cause collisions. The housing needs a textured surface similar to that of the steel part it replaces, to prevent sunlight from blinding the radar. RocTool helped develop a mold surface and heating cycle to achieve this texture.

Despite its benefits, acceptance of induction mold heating has been slow in North America. “It is growing,” Boulanger says, “but the auto industry is conservative and it’s a battle to get to production.”

Consolidated Seating

BASF promotes parts consolidation with overmolded thermoplastic composites. Ultracom materials incorporate laminates of woven glass fiber impregnated with Ultramid PA, or unidirectional reinforced glass- or carbon-fiber tape within a matrix of Ultradur polybutylene terephthalate (PBT) resin. These composites are molded into semi-finished forms and then overmolded into finished components. The result is strong, lightweight parts, in which reinforcements are precisely placed at key points for enhanced mechanical properties.

An Ultracom composite replaces a multicomponent metal seat pan in GM’s Opel Astra in Europe, for example. The new version installs in one piece, which simplifies assembly and saves money, and weighs less than the metal pan.

Another supplier of materials for overmolded thermoplastic composites is Lanxess. The company’s Tepex dynalite composites combine continuous reinforcing fibers with Durethan PA-6 or -66 and Pocan PBT or PET resins. The materials are fabricated as sheet, then molded into a semi-finished form and overmolded into a finished part.

Applications include a seat shell specified for the Opel Astra OPC in late 2013. The matrix in the seat shell is PA-6, with two layers of glass-fiber reinforcement at a 47% loading. The sheet is molded to shape, then overmolded with reinforced PA-6 to integrate reinforcing ribs and other features. The one-shot process reportedly takes less than 60 seconds.

Three views of a one-piece seat pan made with Ultracom thermoplastic composite from BASF. It replaced a multicomponent metal version in GM’s Opel Astra (photo courtesy of BASF).

Reduced-Emission Materials

The issue of emissions has influenced the development of a polyurethane (PUR) seating foam by Dow Automotive Systems. Specflex Activ is an amine-emission-free formulation. Rather than using conventional amine catalysts to promote foaming between polyols and isocyanate, the material incorporates a new additive polyol with high and balanced catalytic activity, the company says.

The formulation reportedly also provides a broader process window, and improves mechanical and aging properties of the PUR foam. In addition to seating, the material can be used in headrests and consoles, says Kyle Wojan, performance solutions field marketer for the NAFTA region at Dow Automotive.

Reducing emissions is also an objective of DuPont Performance Polymers, which recently commercialized low-emission grades of Delrin acetal. Lauren Coleman, regional product manager, says the materials rely on additive and process technology to achieve this. They’re primarily used in safety and gearing components in interiors, and are drop-in replacements for previous Delrin resins.

Among the offerings is the Delrin 300TE family, which “was quickly adopted by the automotive industry, because it offers a good combination of strength and toughness that allows significantly smaller, thinner components that deliver the mechanical performance required for safety systems,” Coleman says. Applications include interior touchpoints (such as knobs and handles), motors, and safety-belt system components.

A “Golden Age” to Come?

As consumers demand higher styling and improved amenities in the vehicles they buy, automakers seek to differentiate models from competitors while holding the line on cost and reducing weight. Thus automotive interiors will flourish as an outlet for plastics innovation—as much as (if not more than) exteriors and underhood applications. This, in turn, will result in numerous developments in materials and processing that could affect all levels of the plastics industry. The golden age of driving may yet be ahead.

High Style for Automotive Interiors

Vehicle interiors are moving into the fast lane of fashion and performance with innovative plastics

Previous Article Next Article

By Pat Toensmeier

Customer demands for comfort and connectivity require more diverse plastic materials and processes. Shown here is the interior of the Buick LaCrosse (original photo courtesy of Darren Brode, Motor City Images).

Automotive interiors are fertile areas of plastics innovation. Recent developments in materials address critical interior needs in such areas as performance, manufacturing efficiency, electronics integration, lightweighting, sustainability, and, of course, consumer styling preferences.

Consumers increasingly want vehicles with stylish interiors. This stems from high buying expectations, and it’s a global trend, especially among young purchasers who view fashionable interiors and accessories like connectivity as mandatory features, even in economy models.

Interior quality, in fact, often closes sales. “Many consumers are willing to upgrade to higher-trim models for the superior interior quality,” says Scott Fallon, general manager of the automotive industry team at SABIC Innovative Plastics.

In particular, OEMs are also looking to plastics to promote the appeal of alternative vehicles. Resins and compounds with properties such as electromagnetic shielding, conductivity, heat dissipation, and flame resistance are among materials that enhance the functionality and aesthetics of hybrid and electric car interiors. Structural plastics that replace metal and offset the weight of large batteries are specified to maximize the range of these platforms.

Plastics additionally play a role in an important environmental issue—interior emissions, which include the vaunted “new-car smell.” Emissions are produced by outgassing of volatile and semi-volatile organic compounds, which stem mostly from coatings but are also released by some polymers, fabrics (including leather), and other materials. Emissions are reduced with polymers and processing techniques that enhance the aesthetics of parts without coatings.

The growing performance needs of interiors are such that OEMs are considering a broader range of plastics. “They are taking the handcuffs off when it comes to materials selection, although cost is still important,” says Jeff Helms, corporate OEM accounts director at Celanese Corp.

As a result, automakers are specifying more engineering resins, high-performance compounds, thermoplastic composites, and specialty materials for interiors, and are increasingly receptive to formulations and process techniques that provide part benefits ranging from higher mechanical properties to enhanced cosmetics.

Shaving Weight

OEMs in key global markets balance performance and aesthetics with regulatory needs, the most common of which involve fuel consumption. In the USA, efforts are directed at meeting CAFE average fuel efficiency rates of 54.5 mpg in cars and light trucks by the 2025 model year, almost double the current 27.5-mpg standard.

Plastics are, of course, critical in extending fuel economy by weight reduction. One expert says automakers are so focused on this that they will specify materials even if they only shave grams off a component—the stakes are that high. Estimates vary, but a 10% reduction in vehicle weight generally yields a 6-7% improvement in fuel economy, says Bob Akins, vice president of sales and marketing at DSM Engineering Plastics–Americas.

From the outside, Ford’s F-150 light truck is a tough vehicle suitable for harsh driving conditions. But on the inside, the truck is plush and equipped with multiple electronic systems, backlit touchpoints, and other amenities. (Photos courtesy of Ford Motor Co.)

So the more plastics applications possible for a vehicle, the greater the potential for weight reduction. But to maximize plastics use, materials must meet the design and performance criteria of increasingly challenging interior parts.

To do this, many applications are being converted to engineering plastics from metal and lower-performing thermoplastics. DSM, for example, cites the successful use of its Akulon polyamide 6 (PA-6) grades in parts in which the resin, in neat and glass-reinforced versions, combines the strength, light weight, and design flexibility necessary to replace metal. Examples include airbag containers, where molded PA-6 simplifies the system’s complex metal design and yields major weight savings—2 kg in passenger-side units alone.

A high-flow grade, Akulon Ultraflow, reduces the thickness of air vanes in dashboard vents. The resin reportedly achieves Class-A surface quality in molded parts, and resists warping. Its thin-wall capabilities also lower material cost and speed molding cycles.

Helms of Celanese predicts that automakers will reduce the mass of vehicle components even more by thin-walling to meet 2025 CAFE requirements and other fuel-efficiency standards in NAFTA, Europe, and China. Celanese, for one, is formulating materials for this need.

For example, Helms notes that 2 mm was, until recently, the limit for thin-walling instrument panels (IPs) and door panels. Now, using the company’s long-fiber-reinforced thermoplastics (LFRT) formulations, which boost mechanical properties, these components can be molded in thicknesses down to 1.4 mm. A glass-fiber/PP version can be used in non-structural applications, where its low specific gravity contributes to a reduction in part weight. In parts with higher mechanical requirements, such as IPs, a carbon-fiber/PA grade might be specified.

Another development from Celanese addresses the need to replace metal components with plastics that look and feel like metal without painting or plating. MetaLX metal-effect materials are produced primarily with the supplier’s Hostaform acetal copolymer. The materials are targeted at interior hard trim, door handles, and speaker grilles and knobs, among other applications.

The grades are colored with aluminum pigments, with high- or low-gloss finishes. Parts molded from the resins are said to be emissions-free, UV-stable, and scratch-resistant. Since there’s no painting or plating, a Celanese analysis states that automakers can save $1-$4 per part with MetaLX resins.

The polymers also improve the haptics, or “feel,” of molded plastics, compared with metal. For example, a lack of “heft” has been a drawback for consumers with previous metal replacements. “Every OEM is interested in haptics,” Helms notes. “We can deliver the feel they want with this material.”

An airbag container molded of Akulon PA-6 from DSM replaced a heavier, multicomponent metal version (photo courtesy of DSM).

BMW’s new 7 Series sedan reflects consumer preferences for comfort, productivity, and entertainment in vehicles (photo courtesy of BMW).

Lighter Subassemblies

One growing approach to weight reduction is subassembly design. Automakers and suppliers are forming consortia to advance techniques addressing this area.

The benefit of this approach, says Levi Kishbaugh, vice president of engineering at Trexel, is that rethinking how subassemblies are designed can lead to substantial reductions in vehicle weight. “Single parts are important for weight reduction, but the way to make a significant impact on weight is with subassemblies,” he remarks.

Trexel works with consortia to apply its MuCell® microcellular, gas-induced foam molding process for subassemblies such as IPs, door modules, and spare-tire wells—anywhere stiffness is a key property, Kishbaugh says. The process, which targets components with wall thicknesses to 3 mm, provides dimensional benefits and uniform stress patterns, as well as weight savings.

The MuCell process is also specified for less-visible interior parts such as lower trim panels and console components. This is because foamed parts generally don’t achieve high cosmetic finishes. Trexel is working to change this. One initiative involves resin supplier Asahi Kasei, which is developing a filled-PP grade that uses a special formula and modified feedstocks to yield an aesthetic finish when foamed. Another effort is through the use of injection molds with induction heating capabilities that cycle the mold temperature to create cosmetic part finishes (see more about this below).

Subassemblies like this Merecedes-Benz center console optimize weight reduction. The interior parts are molded in a variotherm mold with Trexel’s MuCell foam process (photo courtesy of Trexel).

EVs & Electronics Surge, Quietly

Electronics are important interior components. Most vehicles have, in recent years, added an array of sensors (visual and otherwise) that increase operational safety; touchscreens that extend the driver-vehicle interface; diagnostics to monitor operations; GPS navigation; infotainment and Bluetooth systems; console, steering-wheel, and door controls; and ambient lighting, some of which can be programmed to “emotionalize” interior spaces.

There is additionally the impact of electric vehicles on interior design. These vehicles are quiet during operation as well as when idling, so plastics must be noise-free.

SABIC is among the suppliers that tailor resins for these needs. Thermocomp NXCY620 is a polycarbonate (PC)/ABS compound with inherent lubricity that resists friction and sticking, “effectively addressing buzz, squeak, and rattle issues in interior applications,” Scott Fallon says. “This is particularly important in cases where two components are in close proximity to each other and a tight gap is required, whether the contact is plastic-on-metal or plastic-on-plastic.”

Also of interest when designing interiors for electric vehicles is the heating, ventilation, and air-conditioning (HVAC) system. Since an electric vehicle relies on batteries to power HVAC systems, effective interior insulation is necessary to avoid battery drain.

SABIC has long promoted Lexan PC as an alternative to conventional automotive glazing. In electric vehicles, however, the benefits it provides in terms of thermal insulation are especially critical, Fallon says. “The improved performance is due to the lower inherent thermal conductivity of PC glazing relative to tempered glass, which can reduce steady-state total heat transfer between the inside and outside of the vehicle in hot and cold climates,” he says.

To reduce heat buildup in vehicles, infrared-blocking grades of Lexan PC are available for glazing. Recent developments in the material also reduce the skin sensitivity of occupants to heat and sun.

Last October, SABIC announced the results of a program in Germany to develop a lightweight electric concept vehicle for city driving. Working in a consortium with automakers BMW and Daimler, the Technical University of Munich, and others, the Visio.M car, which weighs 450 kg without a battery, used Lexan glazing instead of glass. The insulation of the PC glazing reduced the HVAC load, extending vehicle range by 15 km. The glazing also reduced vehicle weight more than 13 kg compared with glass, which added 2 km of range per charge.

An injection mold with induction-heating components from RocTool produces a high-gloss/low-gloss pattern on this IP compartment for the BMW Mini Cooper (photo courtesy of RocTool).

Appearance Enhancements

One color that gets a lot of attention from automakers is “piano black”—a deep, glossy hue, which can be achieved in plastics without paint or clear coat. BASF supplies such a material, a grade of Ultramid A3L PA 66 called BK7793. The grade was formulated in a “crash program” with Ford to replace painted metal rear-door switch bezels on the 2013 Fusion and Mondeo models. The metal bezels had problems with scratching and marring.

The BK7793 grade uses molded-in color and a special rapid heating and cooling (variotherm) molding technology called E-Mold, developed in South Korea, to bring out the deep black gloss. This and similar molding technologies (e.g., induction and steam) inject resin and rapidly raise in-mold temperature, which causes the viscosity to change. The resin—even a reinforced grade—will flow evenly into the mold and replicate its surface texture. Rapidly cooling the mold freezes the finish in place and a part emerges with a deep, glossy surface.

The grade has outstanding scratch and mar resistance, says Cameron Recknagel, market segment specialist for automotive interiors at BASF. And with no paint or coatings needed, parts don’t contribute to emissions.

In fact, variotherm molding techniques have been around for years. But only recently have they made headway as a process alternative, and then usually for cosmetic benefits. As the market slowly grows, vendors are capitalizing on demand. RocTool, for one, is a French company that started U.S. operations two years ago to sell induction-heating components for molds. President Mathieu Boulanger confirms the process yields a “resin-rich surface” that optimizes piano-black resins and other plastic types, including foams. At least ten European car models use the process for parts, and he expects to see initial North American applications soon.

RocTool supplies copper heating coils that are embedded near the surface of a mold, along with a generator and control to rapidly cycle mold temperature. Although the heat range of the equipment is 60 to 450°C, most operations take place between 130 and 200°C. The process reportedly has no effect on resin properties. There is, however, a 10-30% cycle-time penalty and 10-15% premium on mold cost with the equipment.

The process has a functional value, as well. Volvo licensed the technology to mold the housing of the IntelliSafe body on the new XC90 luxury SUV. The housing attaches to the top of the interior compartment and contains radar that scans for obstacles—including distracted pedestrians—that might cause collisions. The housing needs a textured surface similar to that of the steel part it replaces, to prevent sunlight from blinding the radar. RocTool helped develop a mold surface and heating cycle to achieve this texture.

Despite its benefits, acceptance of induction mold heating has been slow in North America. “It is growing,” Boulanger says, “but the auto industry is conservative and it’s a battle to get to production.”

Consolidated Seating

BASF promotes parts consolidation with overmolded thermoplastic composites. Ultracom materials incorporate laminates of woven glass fiber impregnated with Ultramid PA, or unidirectional reinforced glass- or carbon-fiber tape within a matrix of Ultradur polybutylene terephthalate (PBT) resin. These composites are molded into semi-finished forms and then overmolded into finished components. The result is strong, lightweight parts, in which reinforcements are precisely placed at key points for enhanced mechanical properties.

An Ultracom composite replaces a multicomponent metal seat pan in GM’s Opel Astra in Europe, for example. The new version installs in one piece, which simplifies assembly and saves money, and weighs less than the metal pan.

Another supplier of materials for overmolded thermoplastic composites is Lanxess. The company’s Tepex dynalite composites combine continuous reinforcing fibers with Durethan PA-6 or -66 and Pocan PBT or PET resins. The materials are fabricated as sheet, then molded into a semi-finished form and overmolded into a finished part.

Applications include a seat shell specified for the Opel Astra OPC in late 2013. The matrix in the seat shell is PA-6, with two layers of glass-fiber reinforcement at a 47% loading. The sheet is molded to shape, then overmolded with reinforced PA-6 to integrate reinforcing ribs and other features. The one-shot process reportedly takes less than 60 seconds.

Three views of a one-piece seat pan made with Ultracom thermoplastic composite from BASF. It replaced a multicomponent metal version in GM’s Opel Astra (photo courtesy of BASF).

Reduced-Emission Materials

The issue of emissions has influenced the development of a polyurethane (PUR) seating foam by Dow Automotive Systems. Specflex Activ is an amine-emission-free formulation. Rather than using conventional amine catalysts to promote foaming between polyols and isocyanate, the material incorporates a new additive polyol with high and balanced catalytic activity, the company says.

The formulation reportedly also provides a broader process window, and improves mechanical and aging properties of the PUR foam. In addition to seating, the material can be used in headrests and consoles, says Kyle Wojan, performance solutions field marketer for the NAFTA region at Dow Automotive.

Reducing emissions is also an objective of DuPont Performance Polymers, which recently commercialized low-emission grades of Delrin acetal. Lauren Coleman, regional product manager, says the materials rely on additive and process technology to achieve this. They’re primarily used in safety and gearing components in interiors, and are drop-in replacements for previous Delrin resins.

Among the offerings is the Delrin 300TE family, which “was quickly adopted by the automotive industry, because it offers a good combination of strength and toughness that allows significantly smaller, thinner components that deliver the mechanical performance required for safety systems,” Coleman says. Applications include interior touchpoints (such as knobs and handles), motors, and safety-belt system components.

A “Golden Age” to Come?

As consumers demand higher styling and improved amenities in the vehicles they buy, automakers seek to differentiate models from competitors while holding the line on cost and reducing weight. Thus automotive interiors will flourish as an outlet for plastics innovation—as much as (if not more than) exteriors and underhood applications. This, in turn, will result in numerous developments in materials and processing that could affect all levels of the plastics industry. The golden age of driving may yet be ahead.