Parting Line Pin Holes in Rotomolded Parts

By Bruce Muller

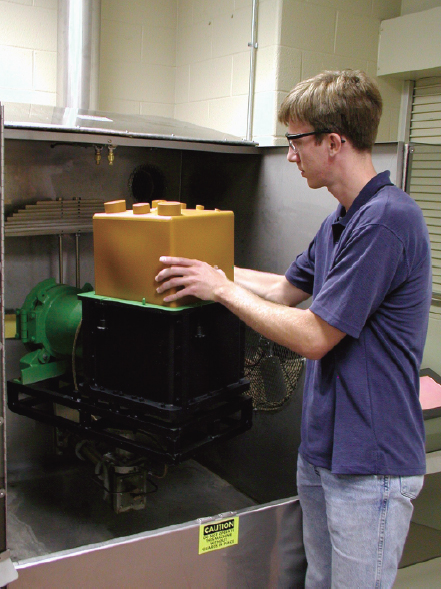

Research rotomolds used at the Pennsylvania College of Technology have two vents—unusual, as most production molds have only one vent.

For preventing scrap in rotational molding, venting is critical, and “Over-venting is better than under-venting.”

Every rotational molder has experienced scrap parts due to pin holes in the parting lines, leaks near inserts, and excessive parting-line flash. One member survey, by the Association of Rotational Molders (ARM), reported pin holes (blow holes and vacuum holes) to be the number-one defect in parts produced by ARM members.

Parting line holes are commonly called pin or blow holes but are often holes created by vacuum. It is important to determine if the holes are blow or vacuum holes in order to correct the problem. A vacuum hole is created by air sucking in through the parting line into the mold during cooling, usually leaving a bubble or funnel-shaped hole on the inside of the part. A hole created from pressure build-up inside the mold escaping through the parting line, during the heating cycle, may blow out through the molten plastic through the mold parting line, creating a blow hole without an internal bubble.

Venting through the parting line is normal until the polymer begins to soften and cover the inside of the parting line. At that point, the vent tubes hopefully become the path of least resistance, allowing the expanding and contracting air to pass through them rather than through the mold parting line or around inserts.

Venting: Air in, Air out

Air moving out of or into the mold, expanding during the heating cycle and contracting during the cooling cycle, will follow the path of least resistance, equalizing to atmospheric pressure. In other words, air must move in and out of the part during the rotational molding process. Using properly placed and sized vents will reduce scrap. Polyethylene molds are routinely vented with one or more Teflon tubes. (The tubes are often packed to prevent powder from falling out of the mold during early rotation, or water entering the part during cooling.)

Venting a new mold often seems to be an afterthought. Often molds are shipped from the mold builder to a rotomolder without the vents placed and drilled. And often, vent placement, size, and tube length may be handled by the maintenance department in a routine, non-scientific manner. According to Roy Crawford, vice chancellor at the University of Waikato (New Zealand) and author of multiple books on rotational molding: “Venting is one of the most important aspects of rotational moulding and yet it is one of the least understood.”

A formula to properly design a vent system is not very straightforward. Some factors affecting the size and number of vents that are necessary are:

- air volume in the mold,

- powder displacement of internal air volume,

- vent tube diameter and length,

- temperature reached by the expanding air inside the mold,

- ramp-up time heating the internal air (rate of the hot air expanding and exiting the mold),

- cooling rate of internal air (rate of air returning into the part),

- material used to pack the vent tube (density and type of packing material used),

- degree of packing or over-packing in the vent tube,

- packing location in the vent tube,

- amount of volatiles in the color and additives (post-molding antistatic additives, for example, typically carry moisture into the mold),

- amount of cooling water (moisture) remaining in the mold at the start of the cycle, and

- mold and powder temperature at the beginning of the oven cycle.

There does not seem to be an industry standard formula for vent tube diameter or length. Considering the factors listed above, the lack of an industry standard is no surprise. There are two vastly different formulas previously used in the industry for sizing vent tube inner diameters:

- The most generous: one inch (25.4-mm) of diameter for each cubic foot (28.3 L) of mold volume (appears too aggressive).

- The least generous: a half-inch (12.7-mm) of diameter for each cubic yard (765 L) of mold volume (a potential problem formula).

If the vent tube is packed, the formula you use should be doubled, as packing may reduce the venting efficiency by 50% or more. The rotomolding research and test molds I build and sell always are designed with two vent tubes. Over-venting is better than under-venting.

Vent Tube Packing, or Not

Many molds don’t require vent tube packing. When possible, vent tubes should extend into the mold, past the powder pool. If the powder pool tumbling in a mold never covers the end of the vent tube, packing may not be required. If cooling water enters a non-packed vent tube, the exterior end of the tube can be shielded to deflect the water in a variety of ways.

Over-packing of vent tubes is extremely common in the rotomolding industry. Packing vent tubes is usually left up to a very busy operator who may not completely understand the problems created by over-packing. A common practice is to roll the packing material tightly in the palms. Variations commonly seen in vent tube packing are:

- using excessive packing material, and packing the vent tube too tightly;

- using an inappropriate packing material; and

- allowing the packing material to stick out of the vent tube.

The most common packing material seen in plants that I visit is steel wool. I’m not enthused about steel wool, as it quickly absorbs heat that may melt the polyethylene, which may block air movement through the packing. When the polyethylene melts, and the steel wool cools, it often blocks the vent tube, creating a vacuum inside the part. This of course increases the chance of premature mold release (warpage) and vacuum holes at the parting line and around inserts, prior to the stiffening of the polymer melt.

Steel wool should not be used when molding crosslinked high-density polyethylene. Pink fiberglass insulation and other fibrous products don’t heat up like steel-wool packing. It is difficult to over-pack vent tubes with die-cut Scotch Brite™, which has a tendency to shrink and fall out of the vent tube. Roughing the inside of larger Teflon tubes and cutting the Scotch Brite slightly larger than the tube will reduce the tendency for it to fall out during rotation.

Silicone Supavents and Smartvents, long vents from Norstar Aluminum Molds, do not require packing, are reusable, and work very well in many molds. The latest offering, Intellivents, used with specially designed Teflon tubes, are reusable and do not require packing.

An old alternative to packing is covering the end of the vent tube on the inside of the mold with PE film using thin wire or a rubber band to hold it on the tube. The PE film usually softens and blows through after all the powder is stuck to the mold. The wire may remain inside the part after removal of the vent tube. (I haven’t had much success with this technique, but I have spoken to molders that have.)

Venting Tips

In conclusion, fifteen mold-venting tips to consider are as follows:

- Maintain mold parting lines to prevent them from becoming the path of least resistance.

- Keep mold parting lines clean when servicing the mold.

- Two or more vents are better than one, when practical.

- Generous over-venting seldom causes problems.

- Clean and repack conventional vent tubes each cycle.

- Vent tubes can be cleaned better and more easily when removed after each cycle.

- Prevent vent tubes from falling out by maintaining molds. (Teflon tubes shrink over time and must be replaced.)

- Poking the vent tube with a properly sized threaded bolt will clean it effectively after each cycle.

- Don’t pack vent tubes, when unnecessary, by extending the vent tubes into the mold beyond the powder pool.

- For consistency have one person pack all vent tubes and supply them to the operators.

- Use coarse steel wool, as it is more difficult to over- pack than a fine grade of steel wool.

- Don’t try to standardize on one size vent tube for all molds for convenience. (Higher volume molds require larger vents.)

- Maintain a vent tube formula based on your products, equipment, cycles and experience. (Include it on all purchase orders when ordering new molds.)

- Request vent tube size and placement recommendations from your designer on each new mold

- Proper venting costs the same as improper venting.

About the author: Bruce Muller, a USA-based consultant, expert witness, and president of Plastics Consulting (www.PlasticsConsulting.org), has sold products or services to companies in 47 countries and is the author of four books on rotational molding; he can be reached via 772-781-6699 or PlasticsC@aol.com.

About the author: Bruce Muller, a USA-based consultant, expert witness, and president of Plastics Consulting (www.PlasticsConsulting.org), has sold products or services to companies in 47 countries and is the author of four books on rotational molding; he can be reached via 772-781-6699 or PlasticsC@aol.com.