• Ferris State University will begin to offer a robotics course for its Plastics and Polymer Engineering Technology students. The course reportedly will teach the students how to integrate a robot into the injection molding process. In addition, the students will learn about end-of-arm tooling (design and build), cavity pressure sensing, vision systems, and other automation equipment. (In partnership with Wittmann Battenfeld Inc., Ferris acquired a new Wittmann W821 robot for its lab.)

“We are excited to offer this course for our students,” says Steve Wolfer, professor with the school’s plastics and rubber programs. “We feel as though the exposure gained from this class will make our students more marketable to our internship and full-time employers.” www.ferris.edu

• Solvay Specialty Polymers has contracted with polymer design, engineering, and injection molding firm Promolding BV to generate several original design concepts for the manufacturing of sterilization instrument cases and trays using Radel® polyphenylsulfone (PPSU) resin instead of stainless steel or aluminum.

Photo courtesy of Solvay Specialty Polymers

The first concept takes advantage of the cost efficiencies of injection molding versus thermoforming, which has been the standard manufacturing method for this application since the mid-1990s. Responding to growing cost pressures from medical OEMs, this injection molding concept uses just five molded components to build full DIN, ¾ DIN, or ½ DIN cases. High hole count, facilitated by injection molding and difficult to achieve after thermoforming, reduces surface area to avoid wet-pack and further lowers overall case weight versus metal. Snap-fit features allow quick assembly, the company adds, and unlike with thermoforming, a matte surface finish can be readily achieved to reduce glare from operating room lights. Meanwhile, the use of colored resins allows for branding opportunities without the added cost of anodizing metal, and material transparency offers another design option.

The second concept offers an innovative strategy for positioning and securing instruments in the inner tray. Instruments are first laid in a pin-bed for positioning. The surface topography is then computer scanned and then replicated using automated CNC equipment onto the surface of a honeycomb insert, which has been molded or extruded from Radel PPSU. The honeycomb structure is said to provide exceptional strength in the vertical direction for supporting large instruments, while inserts with varying cell sizes can be used to accommodate smaller instruments. www.solvay.com

• Clariant announced the commercialization of new Hydrocerol® chemical foaming agents (CFAs) that can help automakers cut the weight of many plastic interior car parts without adversely affecting appearance or performance. Mass reduction, as it is known in the industry, is critical to achieving new, progressive fuel-economy standards.

Foaming has been used in auto parts before, but earlier CFAs made it difficult to achieve the consistent, high-quality surface finish automakers and their customers demand, so applications were limited to parts that were hidden from view. The new-generation Hydrocerol, developed by the Clariant Masterbatches, reportedly creates a finer, more durable foam-cell structure that allows manufacturers to achieve surface quality and mass reduction of between 5 and 20% (depending on part design and application). The results have been demonstrated in components molded from polymers such as thermoplastic olefin, polypropylene, and nylon, and even parts made from up to 30% glass- and mineral-filled materials. Applications under development include door panels, ceiling panels and headliners, and instrument panel sections.

At the same time, the new Clariant CFAs incorporate proprietary scavenging technology that neutralizes the effects of moisture, CO2, and acids that are the natural byproducts of chemical foaming. Uncontrolled, these byproducts can cause corrosion in injection molds and also create surface defects in molded parts. “The Clariant scavenging technology absorbs moisture and acid during foaming,” explains additives product line director Kirk Jacobs. “It means the CFA is not as finicky to implement in a production environment. Corrosion becomes a non-issue, and, in combination with the finer cell structure, the elimination of moisture allows processors to achieve the clean, high-quality surface their automotive customers are looking for.” www.clariant.com

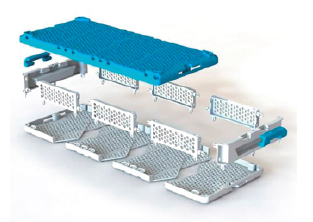

• Under the banner “From Challenge to Benefit,” Victrex Polymer Solutions will be presenting new applications and products based on its high-performance polymers at K 2013. The thermoplastics help reduce weight, energy consumption, and costs in very demanding application areas which are difficult to realize with other materials, the company says. For that reason, Victrex, the manufacturer of polyaryletherketones (PAEK) including Victrex® PEEK, is reportedly focusing its attention during K on topics related to the automotive and aerospace industries, along with metal-replacement.

“Each new product and application development is all about identifying market trends early and taking them into account while facing new challenges at the same time,” explains Rainer Müller, commercial manager, Europe.

The performance of the PAEK product portfolio extends across a broad temperature range—and also under extreme operating conditions, such as damp, chemically aggressive environments or cyclical stresses. “In that way, decisive opportunities can be developed and often make it possible to replace metals, which are much heavier, or to replace other polymers which are unable to stand up over the long term under the specified conditions,” says Müller.

Photo courtesy of Victrex Polymer Solutions

In automotive construction, components made of Victrex WG™ polymers with optimized slip/friction properties reportedly extend the service life and raise the efficiency of components, including electric pumps, for example. As compared to other high-performance plastics, the coefficient of friction exhibited by Victrex polymers is even lower, depending on the requirement profile, and remains stable over the life of the product. The company argues that this is great news for motor vehicle manufacturers, in light of extended warranty periods or the new targets for reduced CO2 emissions recently established by the EU. www.victrex.com

• Zwick Xflow extrusion plastometers, to be exhibited at K 2013, offer raw-material producers a suite of reliable tools to certify flow properties for their customers and to enhance testing efficiency, according to Florian Liebert, Zwick plastics product manager.

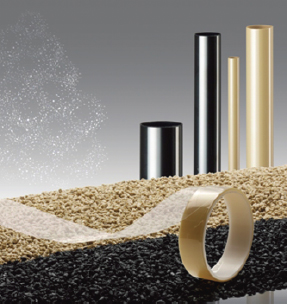

Utilized primarily in support of quality control initiatives, extrusion plastometers characterize the melt mass flow rate and melt volume flow rate of thermoplastics. Quality managers take pelletized samples from live production runs to assess process integrity, as flow properties are essential to material performance in extrusion processes.

“Each system within our line of extrusion plastometers is easy to use,” says Liebert. “We recognize the pace of testing in a quality control environment and have engineered the systems in the Xflow series to offer unprecedented capabilities for raw material producers, compounders and processors,” Liebert says. “Assessing melt flow properties is important to thermoplastic compounders, as the results measured are a key indicator of how well the materials will perform in extrusion or injection molding processes.” www.zwick.com

Photo courtesy of Zwick

• ProTec Polymer Processing is focusing on flexible and cost-effective material handling in plastics processing and plant engineering for PET recycling at this year’s K show. The range of services for material handling includes the planning and construction of complete plants, from silos up to processing machines—complemented by technologically mature and energy-efficient Somos® brand devices and systems for drying, conveying, and dosing pellets and regrind. Presented at K for the first time is a new gravimetric batch dosing system, the Somos BB 500.

The new dosing and mixing system is a batch-dosing device that’s said to be ideal for feeding injection molding machines as well as extruders with multiple component mixtures. It’s designed for dosing up to four free-flowing components with through puts up to about 500 kg/hr (at a bulk weight density of 0.6 kg/L). The device is mounted directly on the material intake of the processing machine—or on a frame next to the machine—and can be equipped with Somos suction conveyors for automatic filling of the material supply tanks. Touchscreen control provides comfortable operation, with a graphic user interface specifically tailored to the range of tasks of a batch dosing device. Up to 50 stored mixture formulas can be called on and immediately applied.

The new BB500 batch-dosing device also provides high dosing precision at an attractive price-performance ratio, the company claims. The individual components are successively dosed in a weighing tank in accordance with the formula, and the total batch is subsequently homogeneously mixed in a mixing tank placed underneath. Depending on the proportion of a component, the batch-dosing device reportedly achieves a precision of ± 1%, up to ± 0.5% of the dosage weight of the corresponding components. www.sp-protec.com

• Styron, a manufacturer of plastics, latex, and rubber, is participating at K under a theme called “Powering ideas. Delivering the future.” The company will feature material solutions in its key strategic markets that address megatrends such as sustainability, lightweighting, energy efficiency, and aesthetics. The company says K 2013 is an ideal platform for Styron to demonstrate its capabilities to solve material challenges for its customers.

“The K show gives us the opportunity to discuss and to listen to our customers’ views and gives us insights into ways in which we can help grow their business while strengthening our relationship,” said Martin Pugh, Styron SVP and plastics business president. “As a global player, we want to continue to optimize our footprint in these strategic markets, while simultaneously focusing on increasing our production capabilities, new product innovations and enhancing our current products.” The “Powering Ideas. Delivering the future.” theme “directs Styron’s focus on our overall objectives to generate powerful solutions that contribute to the success of our customers,” he adds. www.styron.com

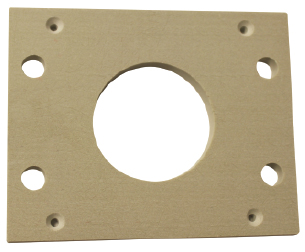

• Moldmakers can now benefit from reduced labor costs with a new line of pre-machined high-temperature insulator sheets from DME. The insulator sheets, designed for standard mold bases, have the highest level of pre-machined features in the marketplace, says the company, with the locating ring clearance hole, assembly screw clearance holes, and insulator sheet mounting holes all pre-machined. By pre-machining the sheet to this extent, DME saves moldmakers labor, time, and machine wear, enabling them to focus their shop time on the high-value machining of core and cavity plates.

The insulator sheets are used on molds and dies between the top clamping plate and the stationary platen and between the bottom of the ejector housing and the movable platen. The newly enhanced sheets are made of high-compression-strength, asbestos-free material with a maximum recommended service temperature of 550°F (288°C), reportedly making them ideal for high-temperature applications. The thermal insulating properties of the glass-reinforced polymer composite material inhibit heat transfer from the mold to the platen, or from the platen to the mold (depending on the application), conserving energy and prolonging machine life. The new line of insulator sheets also has been designed 1/16-inch (1.6-mm) shorter on all sides to prevent damage during mold handling. www.dme.net

Photo courtesy of DME

• Following a successful test phase, Bayer MaterialScience is aiming to commercialize the use of the greenhouse gas carbon dioxide as a new raw material for plastics. The company has started the planning process for the construction of a production facility at its site in Dormagen, Germany, where CO2 will be used to produce a precursor for high-quality foam. The objective is to initially make larger quantities of this precursor available to selected processors in 2015.

The use of carbon dioxide benefits the environment. CO2 replaces a portion of the fossil raw materials, such as petroleum, that would otherwise be used exclusively. At the same time, Bayer expects the new process to provide economic advantages over the conventional production method.

“CO2 is taking on a new light: The waste gas is turning into a useful and profitable raw material,” says Patrick Thomas, CEO of Bayer MaterialScience. “That makes us one of the first companies worldwide to take an entirely different approach to the production of high-quality foams.”

The substance is used for the production of polyurethane foam. This high-quality material can be found in many everyday items, including upholstered furniture, automotive parts, refrigeration equipment, and insulation material for buildings. In internal tests, the new foams show at least the same high quality as conventional material based entirely on fossil fuels, the company reports. www.materialscience.bayer.com

• Royal DSM announced a breakthrough for the use of Stanyl ForTii, its high performance polyamide 4T, in three-dimensional molded interconnect devices (3D-MIDs) in the field of data security in banking. The robust plating performance of Stanyl ForTii, combined with its high strength and stiffness at elevated temperatures, reportedly give designers the freedom to condense their designs.

The devices, which combine mechanical and electronic functionality in a single, highly compact component, are produced by Cicor, a specialist in electronics systems and components. Cicor’s 3D-MID Technology Center focuses on development and customer-specific applications for 3D-MID products. It has the capability for performing all the process steps in 3D-MID production, from injection molding, to direct laser structuring and metallization, through to final assembly.

One particular application concerns a high-security enclosure designed to protect sensitive data against unauthorized access. Cicor’s 3D-MID reportedly delivers enhanced protection, compared with conventional PCB solutions, and meets the latest PCI PTS POI V3 standard (Payment Card Industry/PIN Transaction Security/Point of Interaction Version 3).

Cicor reportedly chose a Stanyl ForTii LDS grade to meet the mechanical and functional properties needed for this highly demanding security application. “Stanyl ForTii has excellent high temperature performance,” says Rui Zhang, application development specialist at DSM. “This, combined with its robust plating performance, provides Cicor’s designers with the freedom they need to make parts that are compact, highly functional, and suitable for large varieties of assembly and use environments.” www.dsm.com

• Tapeswitch Corporation now offers Sentek Solutions’ safety laser scanner, the UAM-02LP-T302, for collision prevention, presence detection, and intrusion detection. The compact, lightweight laser scanner offers a wide area detection zone of 190 degrees and is easily set to a maximum protection range of 2 meters and maximum warning range of 10 meters, depending on the application. Status indicators, located on the front of the scanner, depict a seven segment display and currently selected area and error number in real time.

The UAM-02LP-T302 laser scanner offers a single protection zone with 16 pattern combination, plus two (non-safety) warning zones for complex environment shapes. The easy-to-navigate and -program software offers a beginner mode, flexible configuration protection zone, warning zone, muting configuration capability, reference boundary feature, and direct, numerical, and auto setting drawing method options, plus complex shaped zone set-up (in auto-setting mode). www.tapeswitch.com

Photo courtesy of Tapeswitch

• International Process Plants (IPP) announced that it has several VCM/PVC plant complexes for sale. These plants are available for immediate sale and relocation as complete complexes, or the PVC and vinyl chloride monomer (VCM) plants can be purchased individually.

The first complex is comprised of a nominal capacity 260,000 metric ton (m.t.) per year VCM plant and a 170,000 m.t./year suspension polyvinyl chloride (SPVC) plant. VCM production can reportedly be increased to well over 300,000 tons with modifications; operational technique efficiencies by the previous operators increased production to a maximum of 275,000 m.t./year. Moving from air to pure oxygen in the plant’s EDC section would increase capacity 20%, while other technical modifications could add 15% more. Downstream SPVC production of both rigid and flexible PVC grades can be increased easily by either installing condensers on top of the plant’s Pfaudler reactors and/or providing colder water for the reactor refrigeration.

The second complex has a nominal capacity 120,000 m.t./year VCM plant and a 75,000 m.t./year emulsion polyvinyl chloride (EPVC) plant. Although the EDC section of this VCM plant already uses pure oxygen, capacity can easily reach 160,000 m.t./year and, with additional investment, could be increased to 250,000 m.t./year. The EPVC plant has been continually updated since it started production in 1988, and its capacity can be increased by 15% through grades mix rationalization and other minor improvements. The EPVC plant produces a wide range of high-quality PVC grades covering several applications and, like the SPVC plant of the first complex, is said to include several systems designed to improve quality and safety while reducing operating costs and increasing output. Both complexes use an ethylene-based process, the most common way to produce VCM.

International Process Plants estimates that its plants can be dismantled, shipped, and rebuilt in 18 to 24 months, a significant time advantage compared to building new plants. In addition to these PVC and VCM plant complexes, IPP reportedly is negotiating the purchase of another complex that produces 365,000 m.t./year of VCM and 125,000 m.t./year of SPVC products. www.ippe.com

• The U.S. Nordson Corporation has acquired two of the five companies of the Kreyenborg Group for engineering, automation technology, and software in Muenster, Germany. Managing directors Jan-Udo Kreyenborg and Theodor Bruckmann have sold their shares of Kreyenborg GmbH (which manufactures screen changers and melt filters) and of BKG Bruckmann & Kreyenborg GmbH (which offers special processing technology to produce high-quality plastic pellets). They retired from the management of these companies. Two business managers, Jan Hendrik Ostgathe and Ralf Simon, who have already been working for the companies as managing directors, will also constitute the management after the change in ownership of the company. Nordson, from Westlake, Ohio, USA, is said to be a financially strong mechanical engineering company, operating in more than 30 countries.

According to Kreyenborg, the realignment is necessary for long-term corporate security in world-wide heavily modified markets. In the long run, a medium-sized manufacturer needs a strong global presence to remain competitive with the “big players,” especially in Asia and North America, says the company. As healthy companies, Kreyenborg and BKG reportedly had the chance to negotiate with the new owners and have been able to achieve successful results.

Regarding the employment of the 270 affected staff members, who were informed in July, the situation remains unchanged: The production facilities of the two companies at Coermuehle and at Hessenweg in Muenster have been leased to Nordson for an initial term of ten years. www.kreyenborg.de