3-D Hot Stamping: A New Technology for Decorating Automotive Parts

An economical approach to creating a chrome look on curved plastic parts

Previous Article Next Article

By Ljubisa Drinic

Leonhard Kurz Stiftung & Co. KG, Fürth, Germany

3-D Hot Stamping: A New Technology for Decorating Automotive Parts

An economical approach to creating a chrome look on curved plastic parts

Previous Article Next Article

By Ljubisa Drinic

Leonhard Kurz Stiftung & Co. KG, Fürth, Germany

3-D Hot Stamping: A New Technology for Decorating Automotive Parts

An economical approach to creating a chrome look on curved plastic parts

Previous Article Next Article

By Ljubisa Drinic

Leonhard Kurz Stiftung & Co. KG, Fürth, Germany

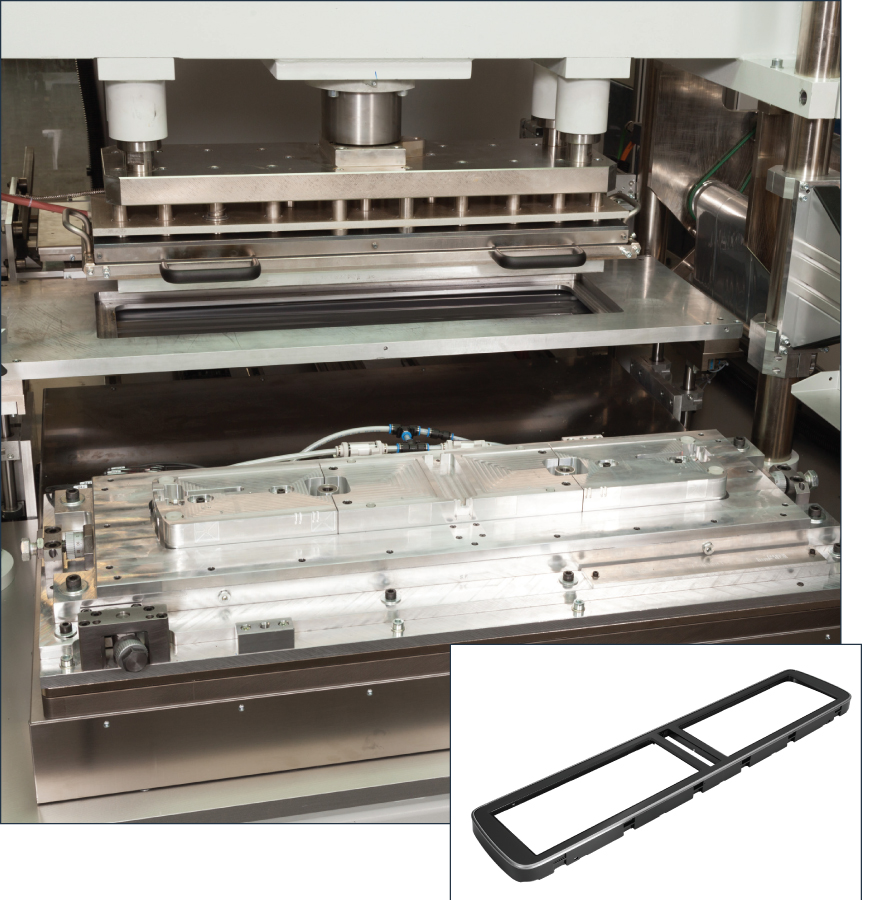

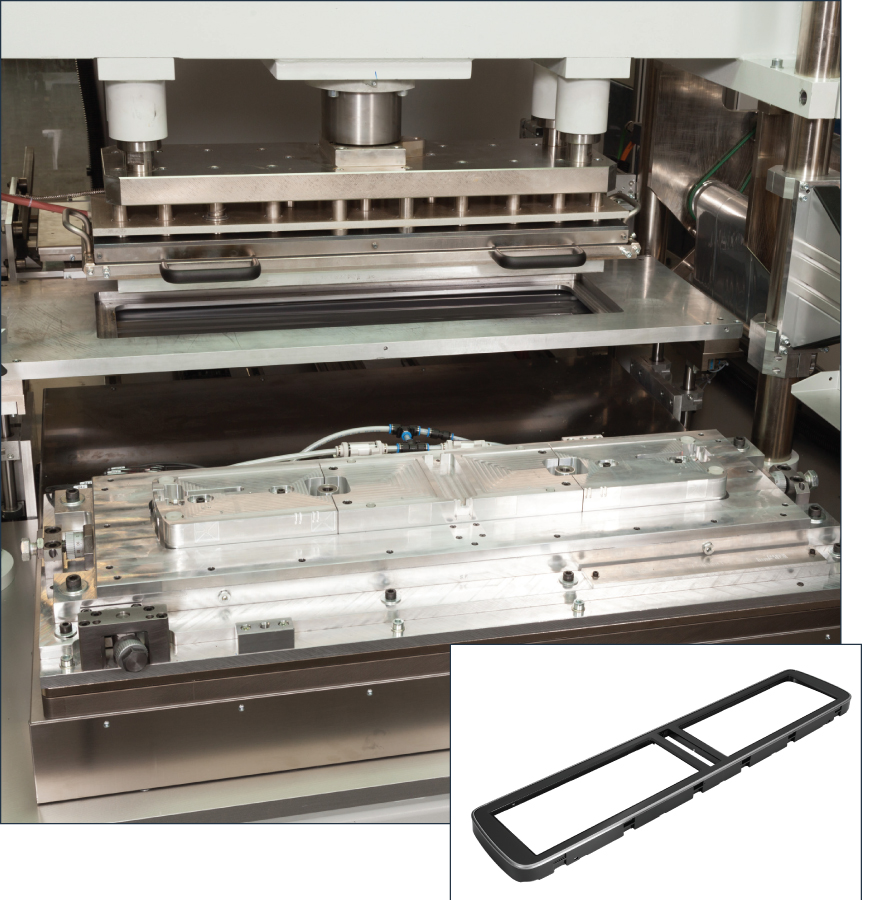

The part fixture for the display trim (inset)

The part fixture for the display trim (inset)

The 3DHS machine

The 3DHS machine

A flat-decorated display trim produced using conventional hot stamping (top), compared with a chromed display trim made using the 3DHS process (middle) and a design variant in a pigment ink color tone (bottom)

Hot Stamping for “Diamond Lattice” Radiator Grilles

Kurz has demonstrated that the hot stamping process can be used to decorate complex geometries. In one case, the requirement from the auto industry was to apply a partial metallic finish to a radiator grille. The plastic part consisted of a lattice structure with 288 individual pins protruding from the nodes on the external face. These pins, which form the visible face of the radiator, were required to have a brilliant and high-quality chrome finish.

The particular difficulty with this application was that the pins all had domed heads and varying shapes that produce a non-uniform refraction, and consequently a diamond-like sparkle, after the metallic coating has been applied. Full-surface galvanic chroming of the plastic part would have adversely affected the appearance of the individual pins. To individually galvanize the pins and then mount them would have required enormous effort.

It was therefore decided to use the environmentally friendly and significantly more economical hot stamping process. In this dry transfer process, the chrome layer, together with top lacquer and adhesive layers, are released from a carrier foil by means of a heated silicone die and permanently bonded to the plastic part.

Besides the pin geometry, a further challenging aspect is the size of the radiator grille, because an injection molded part of this size is required to meet part tolerances within 2 mm. The particular challenge was to ensure that the silicone die, into which the curvature of each individual pin had been incorporated, would contact each pin precisely and transfer the chrome coating accurately and with clean edges. Baier, a company specializing in the construction of technically sophisticated vertical stamping machines and a member of the Kurz Group, developed a custom hot stamping machine especially for this application: a four-head hot stamping machine with four indexed part fixtures that divide the radiator grille into four segments that are coated consecutively.

This division of the part enabled the tolerances to be reduced and the individual pins to be decorated with high contour accuracy. Precise adjustment of the stamping time, stamping temperature, and stamping pressure ensured reliable transfer onto the curved pins. To meet the complex specifications provided by the client, the formulation of the hot stamping foil was tailored to this specific project, thus enabling the permanency of the coating.

Hot Stamping for “Diamond Lattice” Radiator Grilles

Kurz has demonstrated that the hot stamping process can be used to decorate complex geometries. In one case, the requirement from the auto industry was to apply a partial metallic finish to a radiator grille. The plastic part consisted of a lattice structure with 288 individual pins protruding from the nodes on the external face. These pins, which form the visible face of the radiator, were required to have a brilliant and high-quality chrome finish.

The particular difficulty with this application was that the pins all had domed heads and varying shapes that produce a non-uniform refraction, and consequently a diamond-like sparkle, after the metallic coating has been applied. Full-surface galvanic chroming of the plastic part would have adversely affected the appearance of the individual pins. To individually galvanize the pins and then mount them would have required enormous effort.

It was therefore decided to use the environmentally friendly and significantly more economical hot stamping process. In this dry transfer process, the chrome layer, together with top lacquer and adhesive layers, are released from a carrier foil by means of a heated silicone die and permanently bonded to the plastic part.

Besides the pin geometry, a further challenging aspect is the size of the radiator grille, because an injection molded part of this size is required to meet part tolerances within 2 mm. The particular challenge was to ensure that the silicone die, into which the curvature of each individual pin had been incorporated, would contact each pin precisely and transfer the chrome coating accurately and with clean edges. Baier, a company specializing in the construction of technically sophisticated vertical stamping machines and a member of the Kurz Group, developed a custom hot stamping machine especially for this application: a four-head hot stamping machine with four indexed part fixtures that divide the radiator grille into four segments that are coated consecutively.

This division of the part enabled the tolerances to be reduced and the individual pins to be decorated with high contour accuracy. Precise adjustment of the stamping time, stamping temperature, and stamping pressure ensured reliable transfer onto the curved pins. To meet the complex specifications provided by the client, the formulation of the hot stamping foil was tailored to this specific project, thus enabling the permanency of the coating.

Ljubisa Drinic

Ljubisa Drinic

At the K 2013 trade fair, Kurz, an international manufacturer of decorative and functional coatings, presented its patent-pending 3DHS process for decorating three-dimensional plastic parts. This technology allows slightly curved plastic parts, which could previously only be coated by more expensive means, to be decorated using the economical hot stamping process. The new decoration process was demonstrated at K by means of a small, ring-shaped cover. The 3DHS process can, however, now be employed in the series production finishing of large plastic parts incorporated into automotive interiors.

A Chrome Look—from Every Angle

The first series production part decorated using the 3DHS process was a display trim for an automotive cockpit. This involved the application of a true chrome decorative strip to the curved edge of the black pre-lacquered plastic part. In earlier models of the car, this edge decoration did not extend beyond the plane of the front face. The automotive customer’s objective was to implement a seamless chrome finished edging that is not only visible when the cockpit is viewed front-on, but which extends onto the adjacent edge and is visually apparent while passengers get in and out of the car, and from the front-seat passengers’ perspective. Using the new process, this design optimization could be achieved without significant additional expense.

The vertical stamping method of hot stamping decoration has, in the past, always been restricted to flat surfaces. The roll-on process was in addition suitable for stamping cylindrical items. Slightly curved geometries could be decorated by means of in-mold decoration during the injection molding process. And highly three-dimensional parts were decorated using the so-called insert molding process, where pre-formed inserts are placed in the injection mold and bonded to the plastic part during injection molding.

The 3DHS process, which was developed and registered for patent by Kurz, now makes it possible to decorate plastic parts with a mildly 3-D geometry by vertical stamping, thereby lowering the processing costs. Thanks to the additional flexibility this method provides with regards to the coating technology used, the general principle of selecting the most favorable decoration process for each part geometry can be even better accommodated. Through application testing it has been possible to establish which coating methods deliver an optimum stamping result while keeping decoration costs as low as possible (and testing also shows when it is possible to employ the 3DHS process).

A partial chrome finish on a single-piece part, as implemented for the display trim using the 3DHS technology, would have traditionally been accomplished by means of galvanization. This requires the production of two separate plastic parts, one of which is chrome-coated in a galvanic bath and subsequently bonded to the second black, lacquered part. Using the 3DHS process, on the other hand, it is possible to apply a partial chrome coating to a single-piece, pre-lacquered trim, thereby eliminating an injection mold, an injection molding operation, and an assembly step.

In addition to the cost advantages, this process also provides environmental benefits. While true chrome is used in the manufacture of the 3DHS hot stamping foil, it is not the environmentally hazardous hexavalent chromium employed in the galvanization process.

Stamping 3-D Geometries

The 3DHS technology requires the use of a specially tailored system composed of a 3DHS hot stamping foil, a hot stamping die, and a hot stamping machine. A special-purpose hot stamping foil, with a formulation optimized for the requirements of 3-D decoration, has been specially developed for this process. The foil has high elasticity, which enables it to be thermally shaped to match the geometry of the plastic part in a separate work operation performed prior to the stamping process.

The required module for shaping the foil has been integrated into the 3DHS machine (which was developed by the Kurz subsidiary Baier). The corresponding 3DHS die system comprises clamping elements for securing the hot stamping foil to be shaped, and a hot stamping die that has been adapted to suit the 3-D geometry of the part being decorated. At the beginning of the decoration process, the plastic part is loaded into the part fixture of the 3DHS machine and brought into the stamping position. Next, the 3DHS decorative foil is thermally deformed over the part, and then applied to the curved surfaces through the action of the stamping die.

Challenging part geometries: While at K 2013 it was only a small air vent panel that was decorated using the 3DHS process, the current display trim being coated by this process has a length of 715 mm and a width of 148 mm. The part size posed a particular challenge, namely that injection molding parts of these dimensions are subject to manufacturing tolerances. The requirement was to be able to apply a coating beyond the edge, by vertical stamping and in a single machine cycle, despite these variations.

The second difficulty arose as a result of the almost vertical outside edges of the trim. It was necessary to generate a sufficiently high stamping force on these edges to ensure the complete transfer of the chrome coating. These stringent requirements can only be met by using a specialized die that perfectly matches the three-dimensional contour of the part being decorated.

It is also necessary to use a custom-manufactured part fixture that can provide an adequately supportive counter-surface for the die during the pressure buildup phase. To achieve perfect quality when decorating a part of the previously described geometry, the hot stamping machine, hot stamping die, and hot stamping foil must be precisely tailored to one another.

Easy design changeovers:The interior of a vehicle is becoming ever more important to car buyers. People spend a great deal of time in their cars these days, and put considerable emphasis on maximum comfort and sophisticated design. The interior should provide a feel-good space that has been designed to suit personal tastes. This trend towards a personalized fit-out can be optimally satisfied by hot stamping technology in general, and the newly developed 3DHS decoration in particular.

When using the 3DHS technology, changing over the design is as simple as replacing the stamping foil roll. This enables small runs to be produced quickly and economically, thereby catering to individual requirements. In addition to the chrome coating described above, numerous further design directions are possible: other true metal coatings in a wide variety of metallic tones, all kinds of brushed designs, and a large pallet of pigmented colors.

Summary

The new 3DHS process has passed qualification testing. The process can be used to create a perfect finish on plastic parts with complex part geometries, provided the machine, die, and stamping foil have been precisely tailored to one another. 3DHS offers an efficient and environmentally friendly means of decorating curved plastic parts. The technology reduces processing costs and allows economical design changeovers.

About the Author:

Ljubisa Drinic is a degreed mechanical engineer at Leonhard Kurz Stiftung & Co. KG (www.kurz.de), where he acts as head of Kurz’s Business Area Plastic Decoration Sales and Marketing. He’s also CEO of the machine manufacturer Baier GmbH & Co. KG.