Arburg at K Talks Cube Molding, Additive Manufacturing & Industry 4.0

Arburg at K Talks Cube Molding, Additive Manufacturing & Industry 4.0

Arburg at K Talks Cube Molding, Additive Manufacturing & Industry 4.0

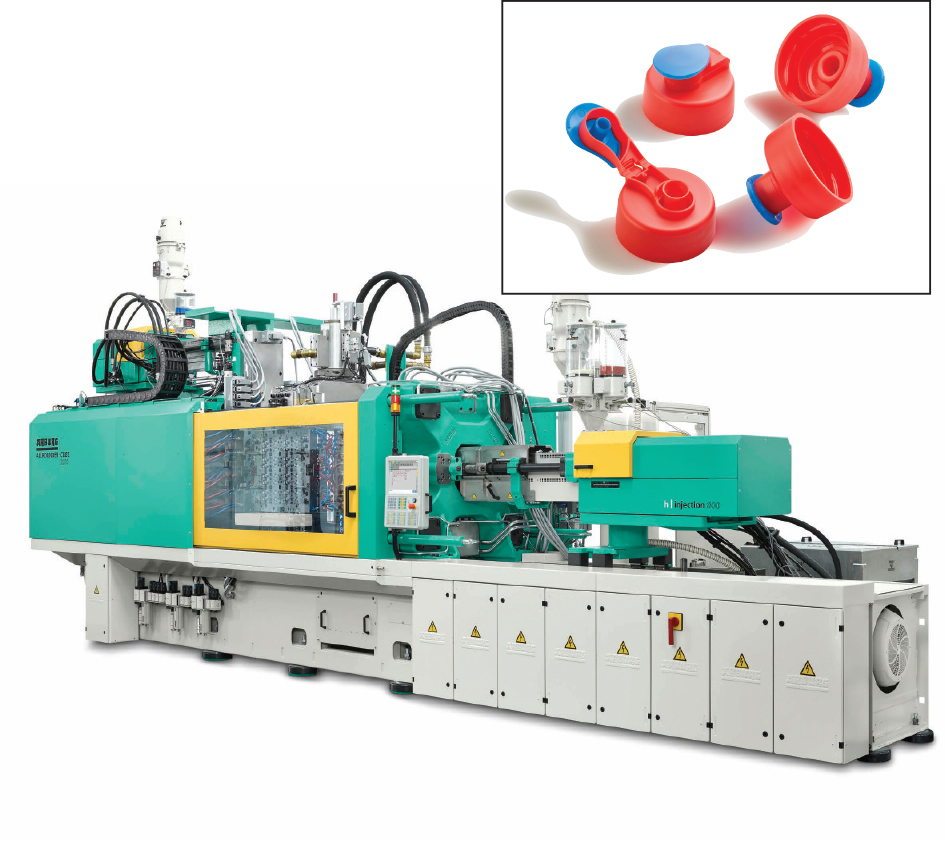

At K, Arburg produced two-part flip-top closures on a 290-tonne Allrounder Cube press. Photos courtesy of Arburg

Arburg GmbH + Co. KG focused on Industry 4.0 at K 2016, while also showcasing Freeformer additive manufacturing machines as well as how it has transformed its cube molding capabilities into high-volume production.

With the Allrounder Cube, a revolving four-faced mold spins between two injection units, and produces a multicomponent part. Running a cube mold from Germany’s Foboha GmbH at the K show, Arburg molded two-component, flip-top closure caps on a 32-by-32 cavity mold, in a 290-tonne press in an 8.5-second cycle. Both parts of the cap were polypropylene, but they were different colors. Arburg also offers an Allrounder Cube in a 460-tonne model.

Regarding Industry 4.0, Heinz Gaub, Arburg’s Managing Director of Technology & Engineering, explained: “We used the example of a ‘smart’ luggage tag to demonstrate the potential of spatially distributed production and the individualization of high-volume parts in batches as small as a single unit. For this purpose, an Allrounder injection molding machine was combined with a Freeformer for industrial additive manufacturing and the product was individualized on a customer-specific basis.”

After Arburg molded the two parts using a vertical Allrounder 375 V and an NFC chip was integrated, the order data for the subsequent production process was stored on the chip and the product thus became an information and data carrier, identifying itself at the various stations and controlling its own further manufacturing process. The subsequent processes included adding the address data of a QR code by laser and the additive application of a 3D graphic using the Freeformer.

The Arburg host computer system stored all process and quality data on a central server. The individual website of the personalized product meant that all process and quality data could be traced at any time. At the central “Industry 4.0” information point, the last of five stations, Arburg also illustrated the benefits of such a system, and suggested some possible business models. In addition to traceability, this includes other data-supported actions using the NFC chip integrated in the luggage tag, such as the online ordering of brochures.

Arburg also demonstrated “smart service” by using a hydraulic Allrounder 270 S press to introduce a new remote maintenance tool that enables fast, efficient and reliable online support. It equipped the injection molding machine with a service router and integrated firewall for this purpose. Users can analyze malfunctions and process sequences through online support. This reduces unnecessary waiting times, machine downtime and cost, the company said. www.arburg.com