End-to-End FE-Based Homogenization of Woven Composites

Previous Article Next Article

By Maxime A. Melchior, Marc Duflot, Jean-Sébastien Gerard, Laurent Adam, and Roger Assaker

e-Xstream engineering, an MSC Software Company, Newport Beach, California, USA

End-to-End FE-Based Homogenization of Woven Composites

Previous Article Next Article

By Maxime A. Melchior, Marc Duflot, Jean-Sébastien Gerard, Laurent Adam, and Roger Assaker

e-Xstream engineering, an MSC Software Company, Newport Beach, California, USA

End-to-End FE-Based Homogenization of Woven Composites

Previous Article Next Article

By Maxime A. Melchior, Marc Duflot, Jean-Sébastien Gerard, Laurent Adam, and Roger Assaker

e-Xstream engineering, an MSC Software Company, Newport Beach, California, USA

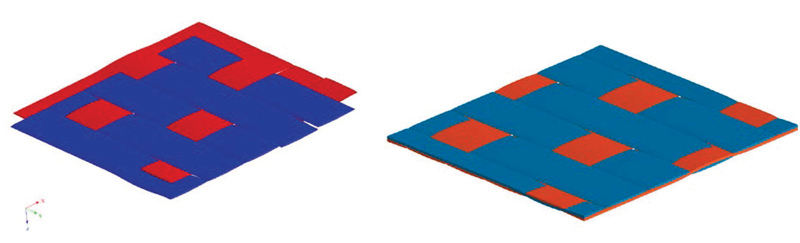

Figure 1: Satin 5HS unit cell (left) and parallelipedic RVE (right)

Figure 2: 2.5D woven

Figure 3: Voxel mesh of 2.5D woven yarn (top) and visualization of the results (bottom)

Figure 4: Heterogeneous material (left) from which its equivalent stiffness is computed from homogenization

Table 1: Elastic Constants of a Balanced Plain Weave Glass/Epoxy Material: Experimental Measurements and Predictions

Figure 5: From the yarn cross-sections to spheroidal inclusions

Figure 6: Voxel mesh used for the balanced plain weave glass/epoxy material and the balanced 5HS T-300 carbon/PPS material

Table 2: Elastic Constants of an Unbalanced Plain Weave Glass/PPS Material: Experimental Measurements and Predictions

Table 3: Elastic Constants of a Balanced 5HS T-300 Carbon/PPS Material: Experimental Measurements and Predictions

Figure 7: Evolution of the CPU time, in function of the number of degrees of freedom, for voxelisation and the iterative solver

Figure 8: Three-point bending on a sub-component to represent a typical pole side crash case5

Ed. note: This paper won the first-place Dr. Jackie Rehkopf Best Paper Award at the SPE Automotive Composites Conference and Exhibition (ACCE) 2014.

Woven composites are represented by interlacing yarns impregnated by a resin matrix. Yarns are made of a resin matrix reinforced by continuous fibers. Homogenization of woven composites therefore requires two levels of homogenization, the one of the yarn and the one of the ply. Finite element (FE) based homogenization at the ply level can be combined with mean-field homogenization at the yarn to predict the mechanical behavior of a single ply. The main difficulty of this approach lies in the generation of a representative volume element (RVE) of a single ply.

An end-to-end FE-based homogenization of woven composites was developed in Digimat®. The developed set of tools allows running finite element simulations on the single ply woven RVE with the use of mean-field homogenization at the yarn level. Generated RVEs are meshed with voxels to avoid meshing troubles in resin rich pockets between yarns or close to yarn crossings. The local fiber orientation used in the yarn homogenization is function of the yarn curvature. A fully analytical framework based on mean-field homogenization has also been developed. The particularity of this framework is that it takes yarn curvature into account.

Background and Motivation

The large amount of woven designs is still found where tailor- made, high-end solutions are needed and a costly solution is acceptable. The applications cover the aerospace, automotive (racing), marine, wind technology, and sport equipment markets. The overall objective is to use lightweight materials with the best stiffness and strength properties possible.

Woven composites are typically draped onto more or less complex surfaces to produce structural parts. The draping process can have significant impact on local warp and weft angles which leads to a local variation of effective material properties. Understanding the connection between the warp/weft microstructure, the resulting material properties and finally their influence on the part performance is crucial knowledge in the design process of woven composite structure.

A key challenge in the predictions of the woven behavior is the modeling of the mechanical behavior of a single ply. The purpose of this paper is to illustrate our ability to predict the linear behavior of single plies of wovens through two different homogenization methods. This paper presents our end-to-end FE based homogenization and our mean-field homogenization for woven, braided and 2.5D woven. Comparison is made with experimental results for three different descriptions of woven.

FE-Based Homogenization of Woven

End-to-end solution

A complete end-to-end solution has been implemented in Digimat. It allows performing all the different steps needed to obtain a complete FE analysis, starting from the material data available in the datasheet of the considered woven fabric. Those steps are:

- Mean-field homogenization of the yarns

- Generation of a geometry of a unit cell

- Generation of a RVE

- Voxelisation

- FE model definition and application of periodic boundary conditions

- Solving the FE analysis

- Post-processing the outputs of the FE analysis.

Generation of the geometry of woven, braided, and 2.5D woven

Based on the description of the woven (weave pattern, yarn cross section dimension, yarn density in the woven), a geometrical model of each yarn is built.1Those geometries are then assembled to create a unit cell; this unit cell is in turn adjusted in order to create a parallelipipedic RVE out of it (Figures 1 and 2). This RVE will then be meshed and used for the FE analysis.

Voxelisation

The geometry is discretized with a regular pattern of eight-node brick finite elements. This pattern is known as a voxel mesh (volume and pixel). Each element is assigned to the material of the phase where its center is located: either in the matrix material or in the homogenized yarn material. In the latter case, the local orientation is mapped from the geometry to the yarn element. Such a voxel mesh is illustrated on Figure 3, where the matrix elements are hidden.

In a voxel mesh, the boundary between the matrix element set and the yarn element set is a patch of rectangular facets that are parallel to one of the RVE faces. It may then be regarded as a less accurate approximation to the RVE inner surfaces than the one that would be obtained with a usual tetrahedral mesh generator with nodes exactly on the surfaces. Still, our approach is more robust than that alternative which leads to badly-shaped tetrahedral elements in areas between yarns or close to yarn crossings.

Moreover, the resulting finite element stiffness matrix has a smaller bandwidth and a better conditioning number than with a conventional mesh generator. The linear systems to be solved are well suited to iterative solvers, which we found to be particularly computationally efficient in this work. Consequently, models with small element edges, which represent the geometry sufficiently well, may be solved in a moderate CPU time.

Mean-Field Homogenization of Woven

Mean-field homogenization theory

Composites are by definition a combination of two or more constituents to obtain an improved material in comparison to the base constituents. As composite properties depend on the material microstructure including fiber amount and orientation, they are adequately modeled from micromechanics. In particular, mean-field homogenization combines the properties of the underlying constituents of a multi-phase material so that the original heterogeneous material is represented by an equivalent homogeneous one (Figure 4). Implemented in the Digimat software,2this technology has proven effective for a broad range of materials.

Application to woven

Woven composites rely on a two-step homogenization scheme. The first step consists in the homogenization of the local behavior of the yarn. The latter is modeled as a UD composite. The second step consists in the homogenization of the ply. The latter is described as a matrix reinforced by a large number of inclusions. The orientation, volume fraction and aspect ratio of these inclusions (Figure 5) are computed from the geometry and orientation of the yarn cross sections.1Therefore, the set of inclusions takes the yarn waviness into account. A current assumption of our model is that inclusions are represented by a spheroid instead of using an ellipsoid. Our current modeling for woven is limited to the elastic behavior.

Validation of Both Homogenization Procedures

The FE and mean-field homogenizations of woven have been validated on three different types of woven: a balanced plain weave, an unbalanced plain weave and a 5HS satin. For each simulation 3D periodic boundary conditions and the Marc iterative solver are used.

The balanced plain weave glass/epoxy material data come from Lomov.3 Our predictions with FE homogenization and voxel mesh and with mean field homogenization are compared to experimental data and the FE predictions with conformal mesh obtained by Lomov (Table 1). The yarn width-to-height ratio is equal to 17. The mesh consists of 50*50*20 voxels (Figure 6).

Predictions obtained with our two methods of homogenization are close to the experimental measurements and to the predictions of Lomov. The larger discrepancy is observed on the shear modulus predicted by mean-field homogenization. Four simulations have been required to compute these properties. They took altogether a total computation time of 88 seconds.

The unbalanced plain weave glass/PPS material data come from Angioni.4The mesh consists also of 50*50*20 voxels. The ratio between the warp and the weft width is 0.91. The yarn width-to-height ratio is equal to 19. Our predictions with FE homogenization and voxel mesh and with mean field homogenization are compared to experimental data (Table 2).

The balanced 5HS T-300 carbon/PPS material data come from Angioni.4The mesh consists in 100*100*20 voxels (Figure 6). The yarn width-to-height ratio is equal to 20. Our predictions with FE homogenization and voxel mesh and with mean field homogenization are compared to experimental data (Table 3).

The balanced plain weave model has been used to perform a study over the computation time for the voxelisation and the iterative solver over increasing number of degree of freedom (Figure 7). Both evolve quasi linearly. Less than hundred seconds are needed to obtain results from an input file when hundred thousands of degrees of freedom are involved in the computation.

Perspectives

Our goal for the conference presentation is to use our woven modeling in the pole side impact of a composite beam (Figure 8). Other goals are to extend our mean-field homogenization method to a non-linear method and to extend our approach to orthogonal 3D woven.

Conclusions

Digimat proposes an end-to end FE based homogenization of woven, braided, and 2.5D woven composites. A single tool allows generating the geometry and the mesh, runs the computation and post-processes the results from material data available in datasheets. The full determination of the elastic constants of a woven material can be obtained in less than 200 seconds when approximately hundreds of thousands of degrees of freedom are involved. The voxel mesh allows obtaining meshes for large width-to-height ratio of yarn cross-sections. The same material description can also be used in mean-field homogenization analysis. Predictions of elastic properties of both homogenization methods have been successfully validated against experimental measurements.

References

- Lomov S. V., Ivanov D. S., Verpoest I., Zako M., Kurashiki T., Nakai H., Hirosawa S., “Meso-FE modeling of textile composites: Road map, data flow and algorithms,” Composites Science and Technology, 67, 1870-1891, 2007.

- e-Xstream engineering, “Digimat documentation Release 5.0.1,” 2014.

- Lomov S. V., Ivanov D. S., Verpoest I., Bogdanovich A. E., Mungalov D., Zako M., Kurashiki T., Nakai H. “Predictive analyses and experimental validations of effective elastic properties of 2D and 3D woven composites,” Proceedings of the 13th European Conference on Composite Materials (ECCM – 13), Stockholm, Sweden, June 2-5, 2008.

- Angioni S. L., Meo M., Foreman A., “A comparison of homogenization methods for 2-D woven composites,” Composites Part B-Engineering, 42 (2), pp. 181-189, 2011.

- Bidaine B., Calmels S., “Progressive failure of CFRP coupons and automotive parts,” Proceedings of SPE-ACCE 2014.

About the authors:

Dr. Maxime A. Melchior, lead author (with co-authors Marc Duflot, Jean-Sébastien Gerard, Laurent Adam, and Roger Assaker), presented this paper at the SPE Automotive Composites Conference and Exhibition (ACCE) 2014. Melchior joined e-Xstream engineering in 2011 and is currently involved in all of the company’s initiatives involving the modeling of woven fabric reinforcements for composites. He received a Ph.D. in Applied Mechanics in 2009 from the Université Catholique de Louvain.