Plastics-Makers Help Drive Recycling Growth

Communication is the key for strengthening recycling efforts nationwide

Previous Article Next Article

By American Chemistry Council (ACC)

Plastics-Makers Help Drive Recycling Growth

Communication is the key for strengthening recycling efforts nationwide

Previous Article Next Article

By American Chemistry Council (ACC)

Plastics-Makers Help Drive Recycling Growth

Communication is the key for strengthening recycling efforts nationwide

Previous Article Next Article

By American Chemistry Council (ACC)

The Recycling Partnership encourages communities to increase curbside recycling using large, rolling bins.

This article continues the series of updates in Plastics Engineering from Plastics Make it Possible®, an initiative sponsored by America’s Plastics Makers® through the ACC.

A recent ACC article in this publication highlighted the growth of plastics recycling in the USA (February 2016), noting that it has been growing steadily, broadly, and expansively:

- The recycling rate for plastic bottles reached nearly 32% in 2014, topping 3 billion pounds (1.4 billion kg) for the year.

- Nearly 1.3 billion pounds (600,000 kg) of rigid plastics (e.g., wide-mouth containers, caps, lids, toys, buckets, and crates) were collected for recycling in 2014, equal to four times the amount collected in just 2007, when measuring began.

- And nearly 1.2 billion pounds (540,000 kg) of plastic wraps and bags were collected for recycling in 2014, an increase of 79% since 2005, when measuring began.

These numbers represent a lot of hard work by municipalities, recyclers, consumers, consumer product companies—and America’s plastics makers.

Since the early 1980s, U.S. companies that make plastics have invested billions of dollars to help establish the plastics recycling infrastructure. Resin-makers’ combined efforts range from supporting innovations in collection and processing, to tracking progress to encourage Americans to recycle more plastics. Here’s a look at a few of these efforts…

Strengthening Curbside Collection

The growth in curbside recycling over the past few decades has driven much of the growth in recycling plastics (and others materials). Since 2012, the ACC has supported The Recycling Partnership, a non-profit organization dedicated to helping communities improve their residential curbside programs by encouraging citizens to recycle.

The Partnership’s approach is simple: make recycling easier. This group works with various stakeholders in recycling (government, private industry, haulers, materials recovery facilities, and more) to identify ways to improve curbside recycling programs through data analysis and education.

The Partnership dramatically improved recycling in more than 70 U.S. communities in 2015 alone. Currently reaching 1.2 million households, this organization has supplied more than 165,000 new, larger recycling carts. Many communities have seen huge advances in recycling rates after moving to single stream recycling, in which all recyclables go into one large bin. And these rising recycling rates are lifting all materials, not just plastics.

Speaking the Same Language

Plastics recycling can be confusing at times. While the very nature of plastics—lightweight yet strong—makes them suitable for all sorts of packaging, the many different types of plastics can make it tricky sometimes to collect and sort the stuff. And unlike aluminum cans, which are fairly uniform in shape, plastic packaging takes so many shapes and forms that communities often struggle when telling residents what to recycle. Do we look at the number on the bottom of a package? Is a plastic cup the same as a recyclable container? Should we just throw anything plastic in the bin and let the recyclers figure it out? (By the way, the answer to that last one is a definite no.)

To help cut through some of this confusion, plastics-makers created a wide-ranging resource for recycling professionals: recycleyourplastics.org.This site provides ready access to no-cost resources on improving plastics collection and recycling, including user-friendly tips and tools and best practices, and access to experts and peers in the recycling world.

To further support these efforts, plastics-makers and recyclers have created a set of common plastics recycling terms to help get everybody in the USA and Canada speaking the same language when collecting, processing, and selling recycled plastics. The common terms (like a glossary or lexicon) are designed to make it easier for consumers to recycle more plastics and to help improve nationwide tracking of the types and amounts of plastics recycled.

This resource is offered free of charge to any community in the USA and Canada, and includes simple tools to make implementation easy. These resources were designed to boost the types and amounts of plastics recycled and to help meet growing demand for recycled plastics.

Putting It Right on the Label

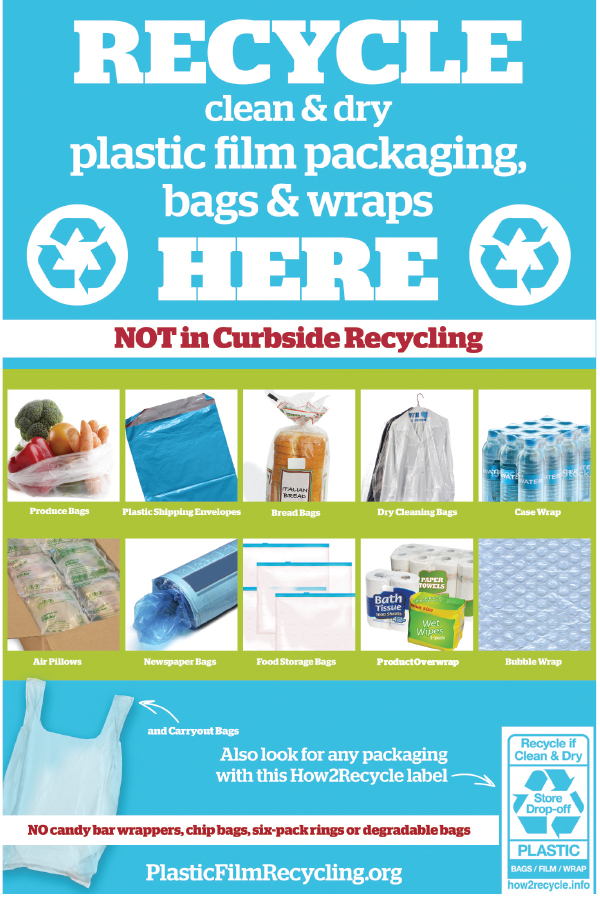

The Sustainable Packaging Coalition has introduced a new “How2Recycle” label that a variety of major brand owners and retailers are using on packaging to provide clear, simple, and nationally harmonized recycling directions. While still fairly new, with support from companies including

Costco, General Mills, Microsoft, and Estee Lauder, the new label has the potential to dramatically increase recycling rates.

Plastics-makers supported the development of the label and worked with the Coalition and others to create a store drop-off version specifically for polyethylene film recycling. This How2Recycle label can help growing efforts to recycle more plastic bags for bread, groceries, and newspapers; dry-cleaning and product wraps; air pillows; and other recyclable flexible plastics.

For years now, plastics makers have been working with municipalities, retailers, and businesses nationwide to develop a widespread collection program for plastic film at thousands of major retailers across the country, including grocery stores, Target, Wal-Mart, Lowe’s, and others. Plastic wraps and bags now are collected at more than 18,000 storefront locations across the USA, and the plastic film recycling rate reached 17% in 2014. (One major end use of this film is composite decking made by Trex.)

Plastics-makers also sponsor annual surveys that measure the amounts of plastics recycled and the percentages of Americans who have access to various types of recycling programs. Efforts to track recycling of plastic bottles began in 1990, with separate studies for film added in 2005 and rigid plastics added in 2007.

Encouraging Consumers to Recycle

Many Americans remember the impact of the iconic litter prevention advertisements featuring an actor playing a Native American (actor Iron Eyes Cody) tearing up at the sight of a polluted landscape. That campaign, sponsored by Keep America Beautiful (KAB) and the Ad Council, helped make it culturally unacceptable to litter the landscape.

KAB and the Ad Council recently teamed up again, this time to motivate Americans to recycle every day. Plastics-makers are helping to sponsor the “I Want to Be Recycled” campaign, which uses TV, radio, online, and outdoor advertising to teach a new generation—and even the older ones—to “give your garbage another life. Recycle.” Whether a plastic bottle or aluminum can, the ads proclaim that all recyclables have the potential to become something important.

And many more efforts are underway. As noted above, most efforts to increase plastics recycling involve broad coalitions of organizations dedicated to sustainably managing post-use plastics. Of particular note is the positive impact of the growing number of large brand companies that have committed to increasing the use of recycled plastics in their products and packaging, which should drive increased future demand.

One of the goals of the ACC’s Plastics Make it Possible initiative (www.plasticsmakeitpossible.com/plastics-recycling/) is to help more people understand the personal and societal benefits of plastics and specifically how plastics contribute to sustainability. Plastics offer so many environmental benefits, from extending food shelf life, to dramatically boosting the energy efficiency of our homes and vehicles, to reducing greenhouse gas emissions. The ability to recycle plastics after use strengthens these benefits. The growing success of plastics recycling—made possible by decades of collaborative efforts—has contributed vastly to the plastics sustainability story.