Close the Loop to Save Water & Energy

An integrated closed-loop process cooling system helps processors achieve sustainability goals

Previous Article Next Article

By Al Fosco

Frigel North America, East Dundee, Illinois, USA

Close the Loop to Save Water & Energy

An integrated closed-loop process cooling system helps processors achieve sustainability goals

Previous Article Next Article

By Al Fosco

Frigel North America, East Dundee, Illinois, USA

Close the Loop to Save Water & Energy

An integrated closed-loop process cooling system helps processors achieve sustainability goals

Previous Article Next Article

By Al Fosco

Frigel North America, East Dundee, Illinois, USA

The Frigel integrated closed-loop process cooling system uses a closed-loop adiabatic fluid cooler, rather than an open cooling tower, to provide clean water at the right temperature to processing machines year round.

The Frigel integrated closed-loop process cooling system uses a closed-loop adiabatic fluid cooler, rather than an open cooling tower, to provide clean water at the right temperature to processing machines year round.

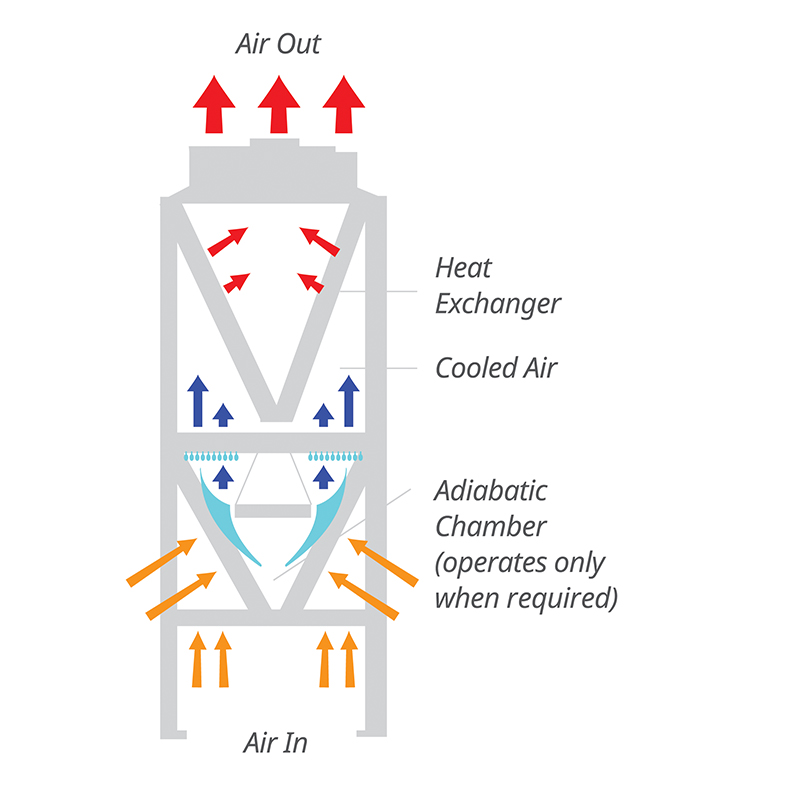

The closed-loop fluid cooler uses heat exchangers and a patented adiabatic chamber to cool water circulated to it from processing machines. The chamber pre-cools ambient air on hotter days before it enters the unit’s heat exchanger compartment. Cooled water is then re-circulated to the facility’s machines.

Housed outside a facility, a Frigel closed-loop fluid cooler offers opportunities to save water and energy—with less maintenance and water-treatment chemicals than with open cooling towers.

Housed outside a facility, a Frigel closed-loop fluid cooler offers opportunities to save water and energy—with less maintenance and water-treatment chemicals than with open cooling towers.

The environment is a chief concern for forward-thinking plastics processors, which is why a growing number are exploring or adopting a process cooling approach that allows them to further their sustainability goals, while also achieving operational efficiencies. The approach replaces the use of open cooling towers and central chillers with an integrated closed-loop system that saves both water and energy.

Processors in Tune with Water & Energy

It’s accepted that processors pay close attention to process cooling, since they rely on it for production. It’s also clear that most are in tune with the need to conserve water and energy.

Based on a survey conducted by Frigel at NPE in 2015, 64.7% of show attendees ranked water conservation as extremely or quite important. The same survey also illustrated the importance of process cooling on the bottom line, since water consumption, as well the energy required to achieve and maintain proper water temperatures, impacts profitability. Additionally, processors are keenly aware of the need to improve operational efficiencies where possible.

The growing emphasis on sustainability and the ongoing need for operational efficiencies led to the evolution of technology that moves beyond conventional methods to provide cooling water to process machines.

Traditional Process Cooling Limitations

A large percentage of processors use a traditional approach to process cooling, whether it’s injection molding, blow molding, thermoforming, or extrusion. While effective for decades, conventional methods offer limited opportunity for water and energy savings.

The conventional approach uses an open cooling tower to feed water to operations. Yet the challenge with an open cooling tower is that it uses an evaporative process to extract heat from process cooling water, making it a notorious water-waster. The open-air system also creates the potential for Legionnaire’s disease, creating safety and ecological concerns.

Some also use a centralized air-cooled chiller to provide cold/chilled water to avoid the introduction of dirty cooling water to machines. The chiller also becomes necessary when a cooling tower cannot supply process-cooling water below the wet bulb temperature that it’s capable of producing. In other words, the more humid the atmosphere, the lower the capacity of the cooling tower and the greater the need for a refrigeration system to provide chilled water to designated process machines.

An Integrated Closed-Loop System

A process-cooling approach widely adopted in Europe and growing in popularity worldwide involves an integrated closed-loop system. Interest in it is driven largely by the need to achieve maximum operational efficiencies and the desire to conserve water and energy.

The primary component of the system is a closed-loop adiabatic fluid cooler, which uses heat exchangers and an internationally patented adiabatic chamber to cool water circulated to it from the machines. Here’s an overview how the fluid cooler works:

- In the adiabatic chamber, a fine mist of water is pulsed into the incoming air stream during high ambient-temperature conditions.

- The mist evaporates instantly, cooling the air before it impinges on the cooling coils that carry the process water.

- The process drops the temperature at or below the set-point. Cooled water is then re-circulated to the facility’s process machines.

- A microprocessor-based controller automatically maintains targeted cooling temperatures.

In addition to the closed-loop fluid cooler, an integrated approach includes the use of a portable, combined chiller/temperature control unit (TCU) machine, rather than a traditional TCU that is without a chiller. The closed-loop fluid cooler supplies water to the combined chiller/TCU located at each process machine. The combined chiller/TCU includes a water-cooled refrigeration system and, depending on the machine, either one or two TCUs housed inside a compact cabinet. Each zone is equipped with a high-flow process pump.

Saving Water & Energy

The use of the closed-loop fluid cooler saves both water and energy when compared with an open cooling tower. The combined chiller/TCU also contributes to energy savings.

Unlike a cooling tower, the closed-loop fluid cooler reuses water without continuous evaporation. Typically, users can save as much as 95% of process cooling water when compared with an open cooling tower.

In various climates, the closed-loop fluid cooler also allows for “free cooling” to achieve energy savings. Free cooling means there’s no need for a processor’s chillers to operate to meet cooling loads when ambient conditions permit, which is typically during winter months. With free cooling, the system automatically shuts down chillers that would otherwise be used for processes and lets the adiabatic cooler provide the chilled water needed. When chillers are offline, energy savings result.

The savings are often significant versus air-cooled chillers, because the chillers use ambient air to remove heat from the refrigerant circuit. In other words, the higher the ambient air temperature, the higher the compressor condensing temperature. In the end, the air-cooled chiller’s compressor must work harder, and more electrical energy is required to provide chilled water.

The use of a combined chiller/TCU can also lead to energy savings since it gives users more control over water temperatures supplied to each process machine. Specifically, the use of a combined chiller/TCU means there’s no need to unnecessarily reheat water that was previously refrigerated when only a limited number of process machines need cold water-wasting energy. Instead, the closed-loop fluid cooler provides water to the combined chiller/TCU, which then provides either chilled or warmer water at the temperature needed to each process machine.

Additional energy savings are achieved via variable-speed fans used on newer closed-loop fluid coolers. The fans reduce fan energy use by as much as 25% compared to typical on/off fans. New fluid coolers also use high-efficiency pumps that consume less energy.

The closed-loop system also avoids the risk of proliferation of harmful bacteria, such as Legionella, due to the absence of stagnant water. Additionally, there are no discharges to municipal sewage systems of process water, and no expensive chemicals required to treat the water. Compared with cooling towers, it also results in significantly reduced maintenance and minimization of water treatment chemicals.

Processors See Results

Plastics processors throughout the world have used the integrated system to achieve both environmental and operational advantages.

In Orchard Park, New York, Polymer Conversions, Inc. replaced an open cooling tower with two closed-loop fluid cooler systems that supply water to combined chiller/TCU units in their injection molding operation. In addition to gaining a higher degree of precision in process cooling, as dictated by the production of high quality thermoplastic products, it saves as much as 95% in process cooling water compared to the former cooling tower. The system also helped the company reduce its ecological footprint.

As with Polymer Conversions, extruder SELA Inc. sought to gain more control of process cooling temperatures—and had its eye on lower energy consumption. The company, in York, South Carolina, opted to replace two five-ton air-cooled chillers with an integrated system that includes two closed-loop fluid coolers and chiller/TCU units. In addition to better temperature control, this drastically reduced the need for municipal water and reduced energy costs. In all, the system saves SELA approximately $10,000 per year in water and energy savings when compared to the alternative of a cooling tower/central chiller setup that it originally considered for the same purpose.

On the opposite side of the world, in Sydney, Australia, Cormack Packaging replaced its cooling towers and central chiller system with a closed-loop fluid cooler, which supplies water to combined chiller/TCUs. In addition to improved production efficiencies, Cormack significantly decreased water loss due to cooling tower evaporation, lowered energy consumption, and eliminated the risk of Legionella bacteria.

No matter the geographic location, progressive-minded processors are always on the lookout for ways to conserve natural resources and improve operational efficiencies. The use of integrated closed-loop systems in place of open cooling towers and central chillers is a proven step in the right direction.

About the author… Al Fosco is global marketing manager for Frigel (www.frigel.com). Prior to joining Frigel in 2009, he spent 16 years with Conair’s Water Products Division; before that, he was with AEC for 14 years. Fosco has a master’s degree in Heat Transfer and Fluid Mechanics Engineering from the University of Illinois.