Efficient, Profitable Recycling

New processes & products are putting plastics recycling in the black

Previous Article Next Article

By Nancy D. Lamontagne

Efficient, Profitable Recycling

New processes & products are putting plastics recycling in the black

Previous Article Next Article

By Nancy D. Lamontagne

Efficient, Profitable Recycling

New processes & products are putting plastics recycling in the black

Previous Article Next Article

By Nancy D. Lamontagne

Cumberland’s CT500 series granulators have a rear hopper door that provides easy access for cleanout and inspection, and a front access that completely opens for quick and easy maintenance, with little downtime (photo courtesy of Cumberland).

Cumberland’s CT500 series granulators have a rear hopper door that provides easy access for cleanout and inspection, and a front access that completely opens for quick and easy maintenance, with little downtime (photo courtesy of Cumberland).

Ecostrate creates a variety of products from old computers, packaging, and carpet waste (photo courtesy of Ecostrate).

Ecostrate creates a variety of products from old computers, packaging, and carpet waste (photo courtesy of Ecostrate).

The NPE2015 Zero Waste Zone will include a recycling demonstration from Rapid Granulator Inc. The company’s Rapid 500-90 granulator will be granulating PET bottles used during the show, with a conveyor supplied by LaRos Equipment feeding the granulator and an Air Wash system supplied by Kongskilde for evacuating and removing dust from the material. Rapid Granulator’s machines provide direct and easy access for rapid cleaning and maintenance, allowing fast production changeovers. The 500 series uses a clean “double scissors” cutting action and a constant cutting circle to produce uniformly sized granules with minimal dust—and lower energy consumption, the company reports.

The NPE2015 Zero Waste Zone will include a recycling demonstration from Rapid Granulator Inc. The company’s Rapid 500-90 granulator will be granulating PET bottles used during the show, with a conveyor supplied by LaRos Equipment feeding the granulator and an Air Wash system supplied by Kongskilde for evacuating and removing dust from the material. Rapid Granulator’s machines provide direct and easy access for rapid cleaning and maintenance, allowing fast production changeovers. The 500 series uses a clean “double scissors” cutting action and a constant cutting circle to produce uniformly sized granules with minimal dust—and lower energy consumption, the company reports.

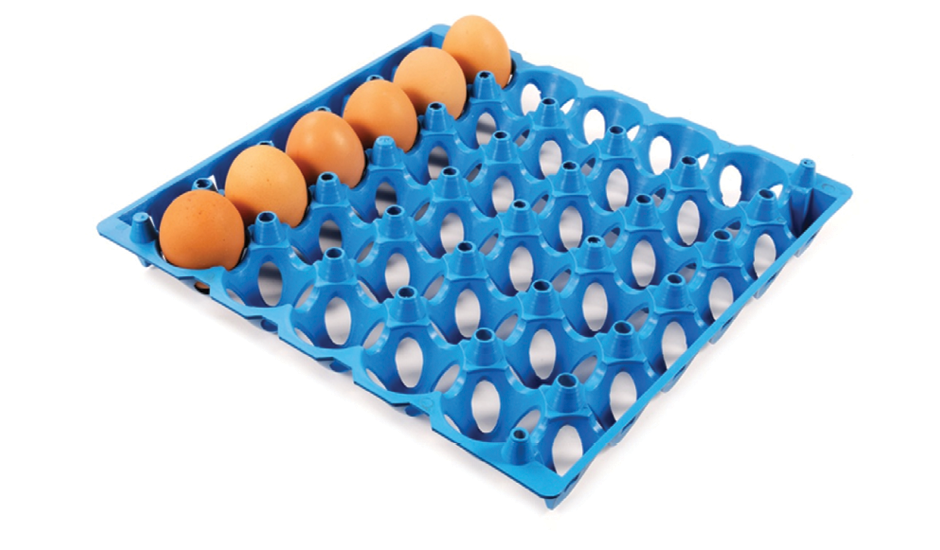

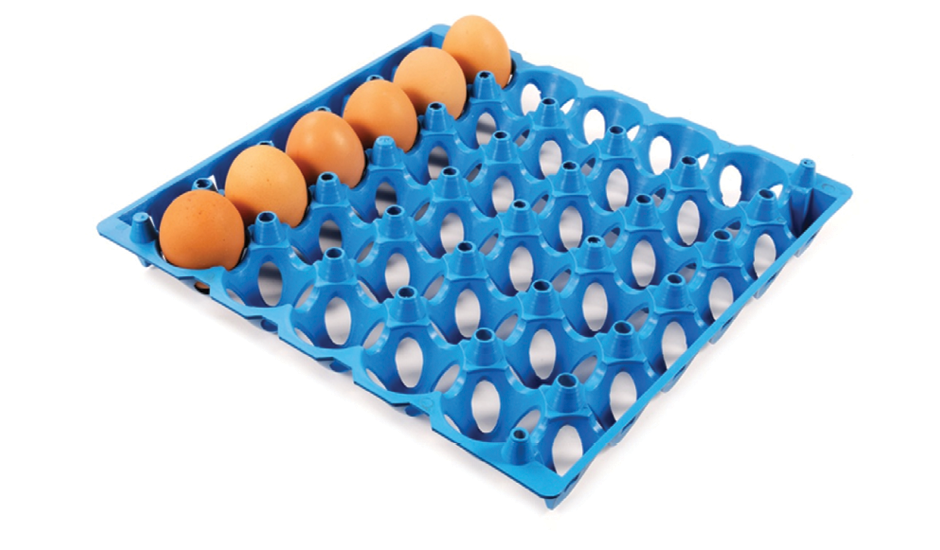

Heng Hiap Industries produces “smart” plastics that can be used for products like this anti-bacterial egg tray made from plastic scrap (photo courtesy of Heng Hiap).

Heng Hiap Industries produces “smart” plastics that can be used for products like this anti-bacterial egg tray made from plastic scrap (photo courtesy of Heng Hiap).

The plastics recycling industry continues to look for ways to improve and grow. Companies are developing more efficient processes that turn out better products, save money, or recycle specialty materials such as bio-based plastics. Education is also helping to unify the industry.

For SPE’s yearly Global Plastics Environmental Conference (GPEC®), which took place during the Plastics Recycling 2015 event in February, John Farney of Cumberland Engineering offered the presentation “Power Consumption Savings and Reduced Operating Expenses in Size Reduction.” Profitability in plastics recycling comes from processing a maximum material volume at high quality while minimizing operating costs. Even though a plastics recycling line can cost 2 to 5 million dollars, power consumption is one of the permanent operating variables that can be controlled.

“People don’t always realize that old equipment can use much more power than newer equipment,” says Farney. “If you’re wasting a lot of power, then you’re wasting a lot of profit. Machinery can, and must, be made to operate to peak possible performance, so the operation becomes more profitable.”

Increasing Efficiency

One way to up efficiency is to find ways to take the strain off of equipment. “PET bottles are usually contaminated with food, cosmetic products, or even oil,” Farney says. “We’ve done some work recently with what is called wet grinding, where you put some water in during grinding to accomplish a pre-rinse that helps remove some of the material dynamically and quickly, so that your downstream washing equipment can run more efficiently and hopefully with less maintenance.”

Cumberland designs and manufactures a broad range of size-reduction and material-recovery systems that are used for scrap reclaim and recycling. “We build quality machines with the premise that they are an investment that can be maintained,” Farney says. The company’s 3200 Series granulators are designed for applications such as heavy extruder purgings, blow-mold flashings, thick sheet, pipe, large blow-molded parts, packaging films, and large-capacity post-consumer products. Its X Series granulators feature low-heat granulation, thanks to a unique rotor and cutting chamber design that helps prevent polymer melting (this virtually eliminates the smearing of material on the sides of the cutting chamber). Cumberland also offers the CT500 Series, with a rear access hopper door that provides easy access for cleanout and inspection, and front access that completely opens for quick and easy maintenance, with little downtime.

Farney says that Cumberland is looking at several emerging markets and trends in the area of recycled materials and reclaimed resins, either post-consumer or post-industrial. He points to recycling of specialty plastics as a mostly untouched market, and to e-waste as another growing, yet challenging, area for plastics recycling. “The electronics technology keeps changing, so any advances in recycling e-waste are short-lived.”

Recovering More

Ron Sherga, CEO of EcoStrate SFS Inc., explains that most recyclers are extracting a small percent of the products they bring in—or they can’t extract enough to be economically sustainable when disposal or shipping costs are taken into account. Most existing processes use energy-intensive separation techniques that only recover 20-40% of a product’s value.

“EcoStrate is able to use many end-of-life products in their entirety and in the form in which they arrive to our plants or those of our partners,” Sherga says. “Using localized waste in most cases, we create products that are purchased and used globally in large volumes.”

The company creates substrate and end-user products from old computers, packaging, and carpet/textile waste by teaming up with existing recyclers that create large waste streams. It offers customers and partners the ability to certify recovery and recycling of a material by its actual verifiable reuse in commercial applications it creates. The company has made prototype products for the transportation industry and has a slate of building-related products. EcoStrate has reportedly also had great success in creating products at large sizes, such as 4 x 8 foot (1.2 x 2.4 m) panels, which it plans to explore further.

The company recently signed a cooperative agreement with DuPont Industrial Biosciences to collaboratively develop and commercialize products using recovered post-consumer carpet made with DuPont™ Sorona® bio-based fiber. EcoStrate is already using Sorona fibers to make products for the traffic sign market and, with DuPont’s support, hopes to develop other large-scale and niche products for flooring, transportation, and promotional markets in the future.

“Bio-based materials offer a unique set of circumstances in regards to their handling and responsible end-of-life solutions,” Sherga says. “We view our use of Sorona recovered fibers not as recycling, but more as prolonging the life of a very sustainable and well-designed material into a new family of products.”

From Scrap to “Smart”

Heng Hiap Industries Sdn Bhd in Malaysia has developed recycling technology that can transform plastic scrap into materials which the company calls “smart plastics” that can be used for highly specialized applications. These plastic resins come in various colors and can be customized to include fire-retardant, fast-cycling, and anti-bacterial properties. The company’s primary customers are top Japanese automotive and home appliance makers, as well as construction and industrial packaging makers in the UK and Germany.

“We are able to achieve high-performance smart plastic materials because we are fully integrated, from curb-side collection to specialized compounding capabilities,” says Kian Hoe Seah, director of Heng Hiap Industries.

The company preserves the quality of plastics scrap by using a frictional washer to remove oxidized flakes and a specialized Zerma crusher to crush the material, with minimal oxidation. Then a 30-ton specialized blending silo creates a homogeneous blend. Testing and quality control checks are conducted to ensure that all requirements are met before the plastic resins are produced. Once the base blend properties are acceptable, the company customizes the resins with an extruder. Finally, an S+S Separation and Sorting Technology GmbH metal separator ensures the product is free of metal contamination.

Heng Hiap recently launched a protein-based plastic. This biodegradable plastic material fully breaks down within two years and can be used in existing injection molding machines, the company says. “We believe in close-loop material design,” says Seah. “If [bio-based] materials are collected and went into the recycling stream, then useful life remains. However, if we missed the collection and the plastic went to landfill… this bioplastic will be degraded through localized microbial activities.”

Ensuring Quality—and Cost Savings

Plastics Forming Enterprises, LLC (PFE) is an independent test lab that uses its 30 years of experience in designing and developing recycling facilities around the world—and its extensive lab to help its clients improve their products and processes.

“We lead brand owners to good product quality design decisions and lead reclaimers to understand the current conditions of their materials and equipment, and assist them in upgrading equipment in good ways or changing process conditions,” explains Kristina Hansen, project manager at PFE. “We also get involved with new materials and innovations that have not hit the market yet.”

In plastics recycling, testing and analysis is important for ensuring quality and cost savings. The company has a pilot line that clients can use to test the recycling of various materials. In addition, its lab can analyze mechanical, color, viscosity, and many other properties of many materials, including, but not limited to, PET, PE, and PP.

Using PET as an example, Hansen points out that there are many things that can negatively affect the quality of a recycled PET stream, including the labels used, adhesives, closures, parts that sink and don’t melt, or other resins that are identified as PET and can’t be separated properly. “There’s definitely an effort to maximize PET resin, so there is a lot more material that can be recovered,” Hansen says. “There’s also an effort going forward with obtaining more thermoforms, but thermoforms have many… materials and challenges that are separate from [those of] the PET bottle stream.”

Lou Tacito, president of PFE, says he sees a need for education, organization, and unification within the recycled plastics industry so that recycled plastics as a whole can better compete with other materials. The company says it’s very active in plastics recycling education, and one of its next outreach efforts is a seminar on recycling at the University of Massachusetts–Lowell this spring.