Eco-Molding: More Power for Less Energy

Previous Article Next Article

By Jan H. Schut

Background photo of the mid-size JSW J450AD-1400H electric injection molding machine is courtesy of JSW Plastics Machinery.

For years injection molding machine makers have touted savings of 30%, 50%, and even more in energy cost. But OEMs typically calculate energy savings by comparing new efficient machine functions to old-fashioned hydraulics in which standard induction electric motors run at constant RPM. These power one or more hydraulic pumps, running constantly, even when the machine is idling. The big energy savings come from reducing that unnecessary motion by adding servo motors to hydraulic pumps and variable frequency drives to electric motors, so they only turn when needed.

These savings are now mainstream. How much more efficient can injection molding machines get? The latest improvements involve power coordinating and sharing across a machine to reduce spikes in energy use and simplify power component size. More efficient barrel heating is also being used, and more efficient hydraulic pumps. The resulting energy improvements aren’t as dramatic as the earlier ones, but every improvement helps.

All-electric injection molding machines still account for only 15-20% of sales in Europe, while hydraulics and hybrids account for 80-85%, industry sources say. In Japan, where all-electric injection molding started in 1984 and has had government incentives, roughly 80% of injection molding machine sales are all-electric, versus 20% hybrid and hydraulic. In the USA, just under 50% are all-electric and the rest hybrid and hydraulic. These numbers have stayed fairly constant for the past five years, largely because of efficiency improvements in hybrids.

Energy Flows in Molding Machines

An injection molding machine has seven main functions that use energy: plastification, barrel heating, platen movement, injection, clamping pressure, ejection, and barrel retraction. All seven can be made more energy efficient.

Energy efficiency, however, isn’t just a machine function. Efficiency, typically measured in kilowatt-hours per kilogram of material (kWh/kg), is different for each molded part, depending on melt temperature, part weight, cycle time, machine size, and machine efficiency. For thin-walled parts with short cycles, specific energy consumption of 0.3 kWh/kg is very efficient; for a thicker part molded more slowly, 0.6 kWh/kg could be efficient.

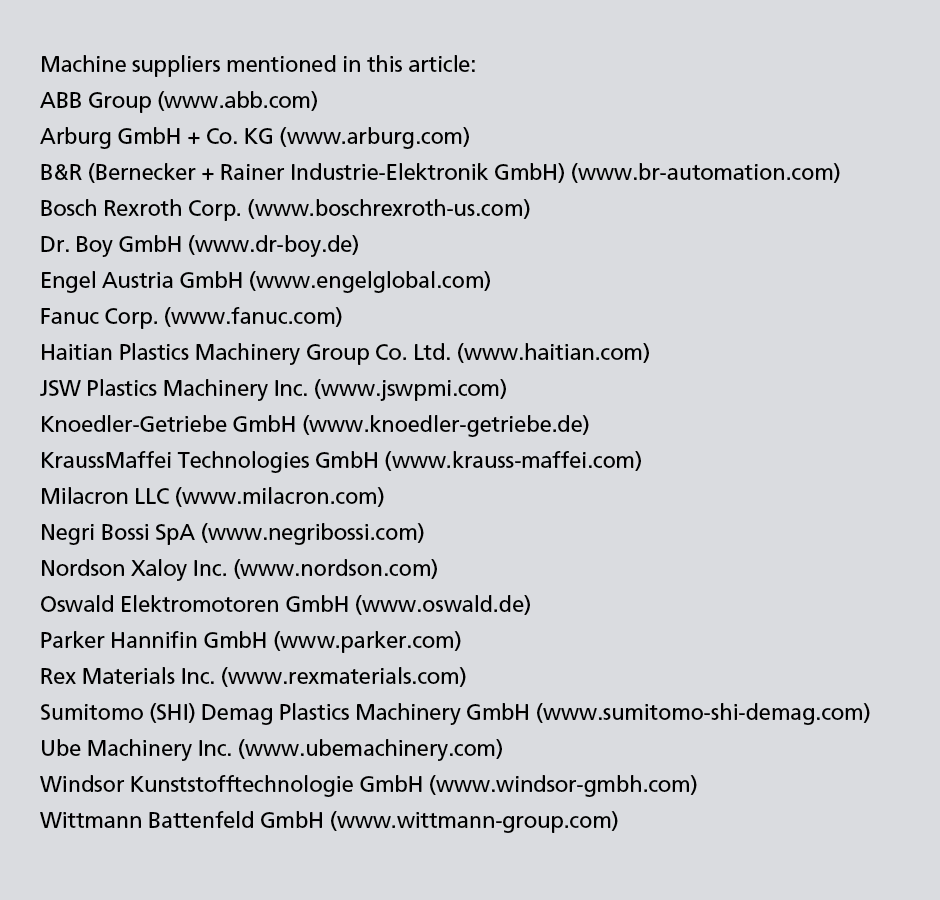

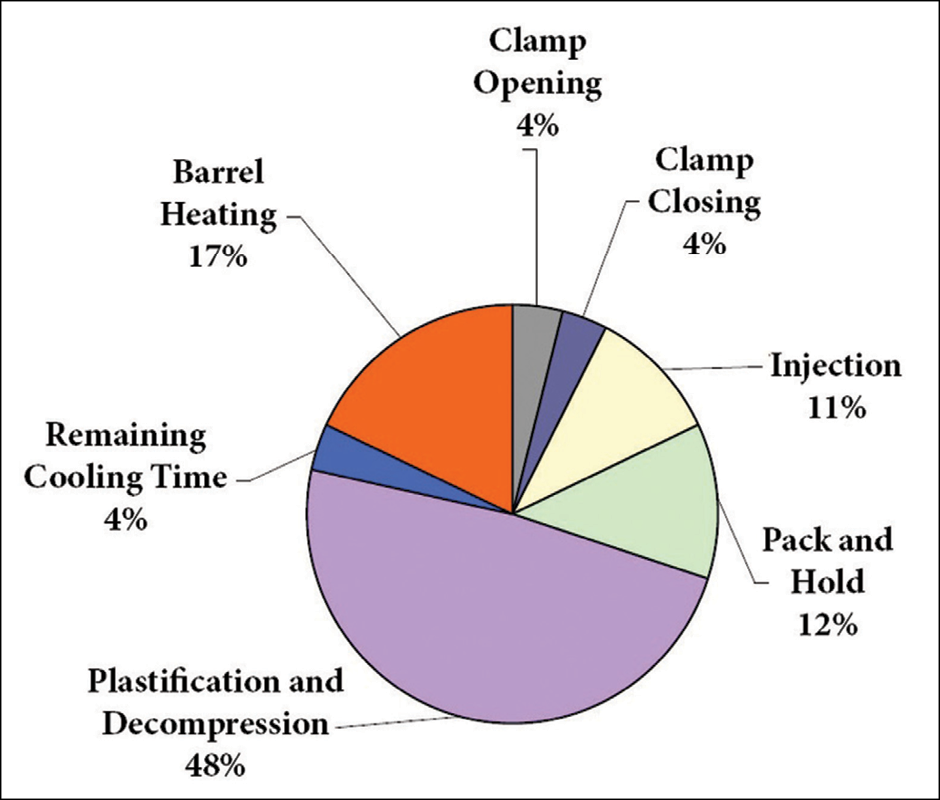

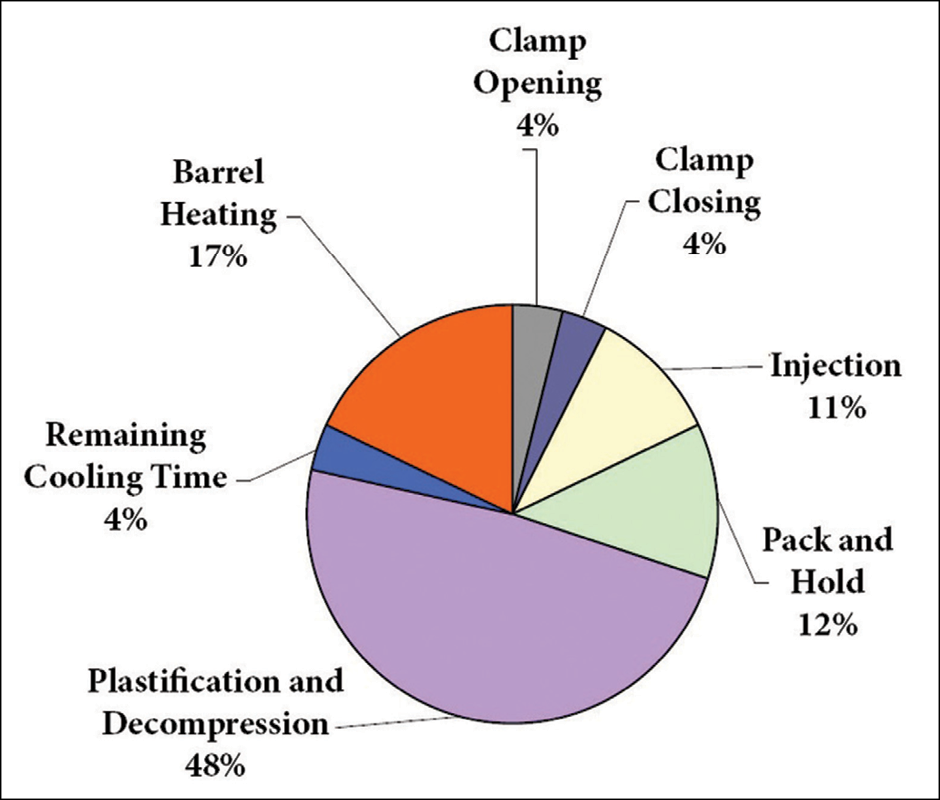

How much energy does each machine function use? This was addressed by the SKZ Plastic Institute (Wuerzburg, Germany), which does R&D on energy saving both for OEMs and processors and conducts audits in the plastics industry for ISO 50001 certification in energy management. SKZ tested a 100-ton all-electric press molding an 83-g ABS tray in 16.9-second cycles. Plastification consumed 48% of the energy; barrel heating, 17%; clamping, 12%; and injection, 11%. Linear movements to open and close molds and retract the barrel for cooling used only 4% each. Specific energy use for the part was 0.384 kWh/kg.

Percentages will vary for different parts made on the same machine, but barrel heating is always a big user. “If you improve only the energy efficiency of drive motors, but do nothing with barrel heaters, the ratio of energy used for barrel heat will rise,” notes Thomas Brettnich, technology development manager at Sumitomo (SHI) Demag Plastics Machinery GmbH (Schwaig, Germany). “In some cases, the ratio of energy for barrel heating in a very efficient all-electric injection molding machine can reach up to 50%.”

Barrel heating is the only energy use that doesn’t involve movement, so the fixes are different. Insulating the barrel saves “an average of about 25% of heat energy,” says Bernhard Lettner, product manager for large two-platen presses at Engel Austria GmbH (Schwertberg, Austria). Andreas Gehring, an engineer in energy certification at SKZ, says barrel insulation should be used if heater bands cycle “on” more than 25% of the time. But it should be possible to disassemble insulation, because some plastics need surplus frictional heat drawn off near the end of the barrel to avoid overheating.

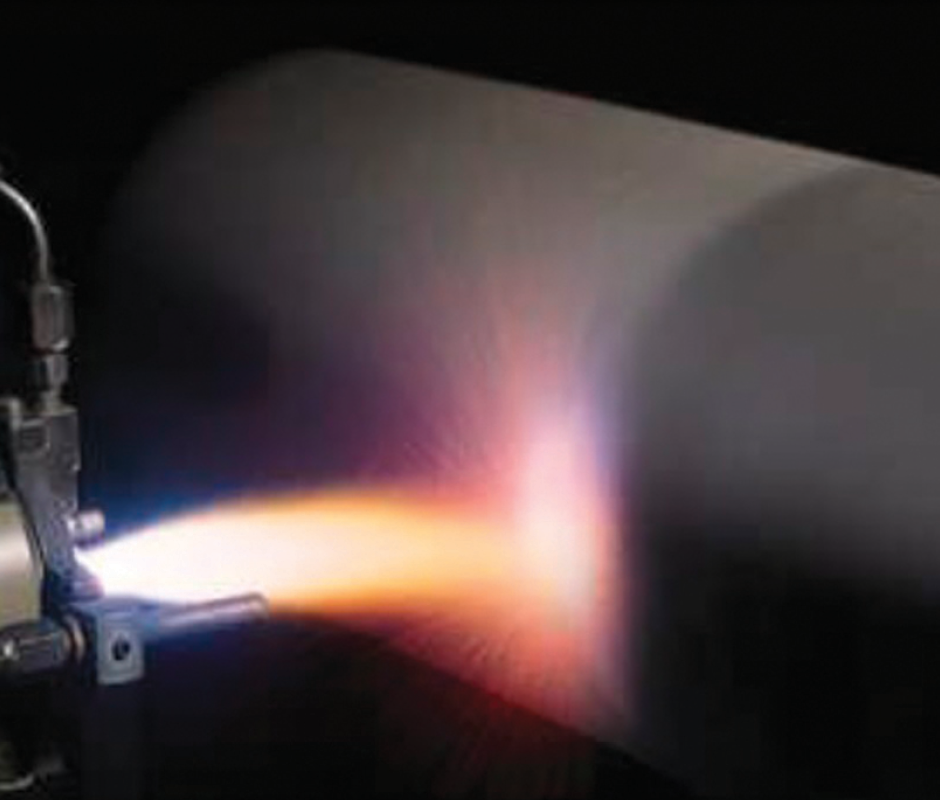

Replacing conventional heater bands with radiant IR heaters adds cost, but saves even more energy. “Based on a complete retrofit of a small machine, we expect IR ceramics to save 45-50% of heat energy—up to twice as much as insulating blankets,” says Dean Francis, president of Windsor Kunststofftechnologie GmbH (Hanau, Germany), which retrofits hydraulic presses for energy saving and sells all-electric presses from JSW Plastics Machinery Inc. in Japan. Infrared elements from Rex Materials Inc. (Fowlerville, Michigan, USA), for example, can be used to convert all heating zones, or only the feed zone, which consumes the most energy.

OEMs are also introducing dramatically more efficient barrel heat. Dr. Boy GmbH (Neustadt-Fernthal, Germany) showed a prototype of its patent-pending EconPlast barrel heating system at K 2013. Its heater bands are located closer to the melt for faster response and 50% less energy than conventional external heater bands. EconPlast barrels don’t need additional insulating sleeves and make feed-throat cooling more efficient. They’re an option on Boy’s 24-48 mm screws and presses larger than 25-tons.

Two OEMs recently introduced barrels heated with patented SmartHeat technology from Nordson Xaloy Inc. (New Castle, Pennsylvania, USA), which is reportedly 30-60% more energy efficient than band heaters. For 18 months, Haitian Plastics Machinery Group Co. Ltd. (Beilun, Ningbo, China) has offered SmartHeat barrels as an option on all its injection molding machines, both all-electric and hybrid.

Ube Machinery Inc. (Ann Arbor, Michigan) will introduce a SmartHeat barrel on a 950-ton all-electric machine at NPE2015, which Ube says will be the most energy-efficient large injection molding machine in the world. Smart-

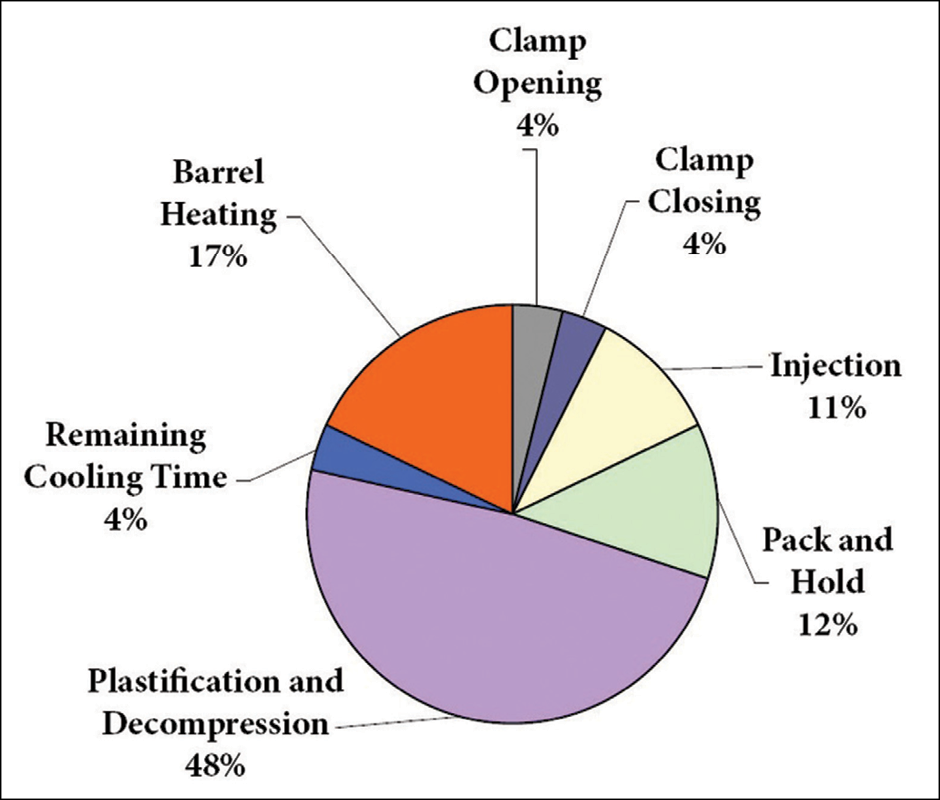

Heat has been commercially available for three years. It uses a very thin (1.6 mm) metallized ceramic coating encapsulating fine nickel chrome wires, plasma-sprayed directly onto the barrel. Last year Xaloy also added SmartHeat coatings for injection nozzles.

Energy consumption ratios for an electric 100-ton injection molding machine with hydraulic injection, making 83-gram ABS storage trays with 2-mm thick walls, in 16.9-second cycles and with specific energy use of 0.384 kWh/kg. The ratios of energy used by modern all-electric molding machines are similar to those of older hydraulic machines, but overall energy use is about 50% less (image courtesy of SKZ).

Optimizing Motor Efficiency

For both OEMs and retrofits, the two big energy-saving devices on injection molding machines are the variable frequency drive, or inverter, on electric motors, and the servo motor on hydraulic pumps. Variable frequency drives can control standard AC motor speed down to zero. A servo motor added to a hydraulic pump also controls pump rotation, allowing the pump to stop almost completely when oil pressure or volume isn’t needed, though very low pressure has to be maintained for restart.

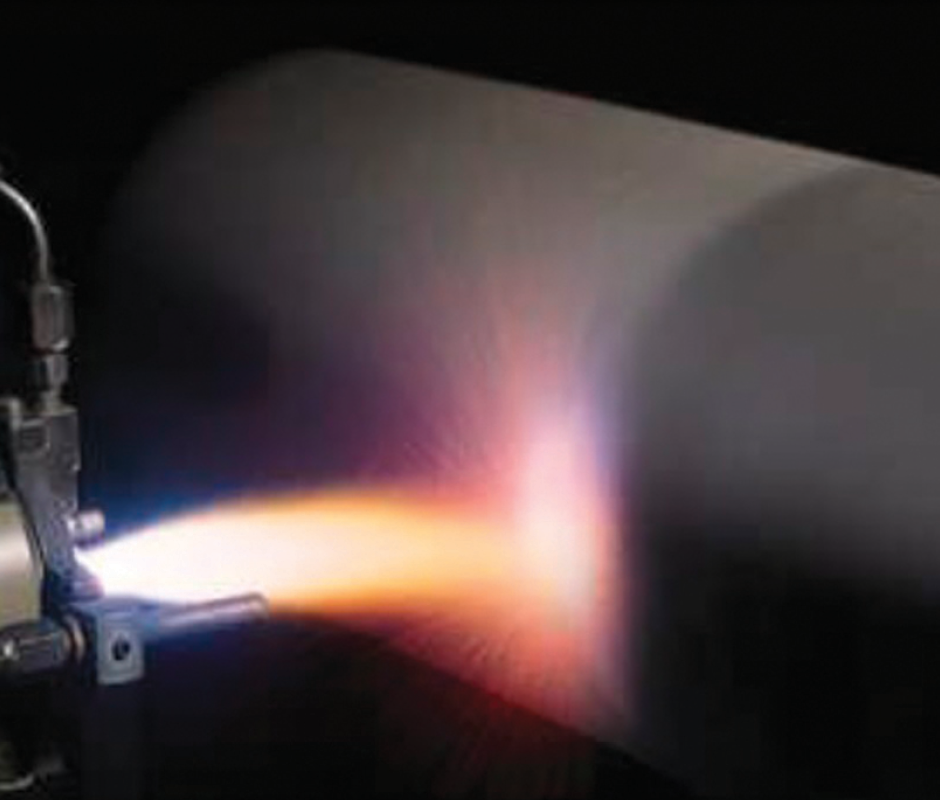

Two OEMs, Haitian and Ube, recently introduced SmartHeat ceramic-coated barrels from Xaloy, reportedly saving 30-50% in heat energy. SmartHeat uses a sixteenth-inch (1.6-mm) metallized ceramic coating plasma-sprayed onto the barrel (at top), encapsulating fine nickel chrome wires.

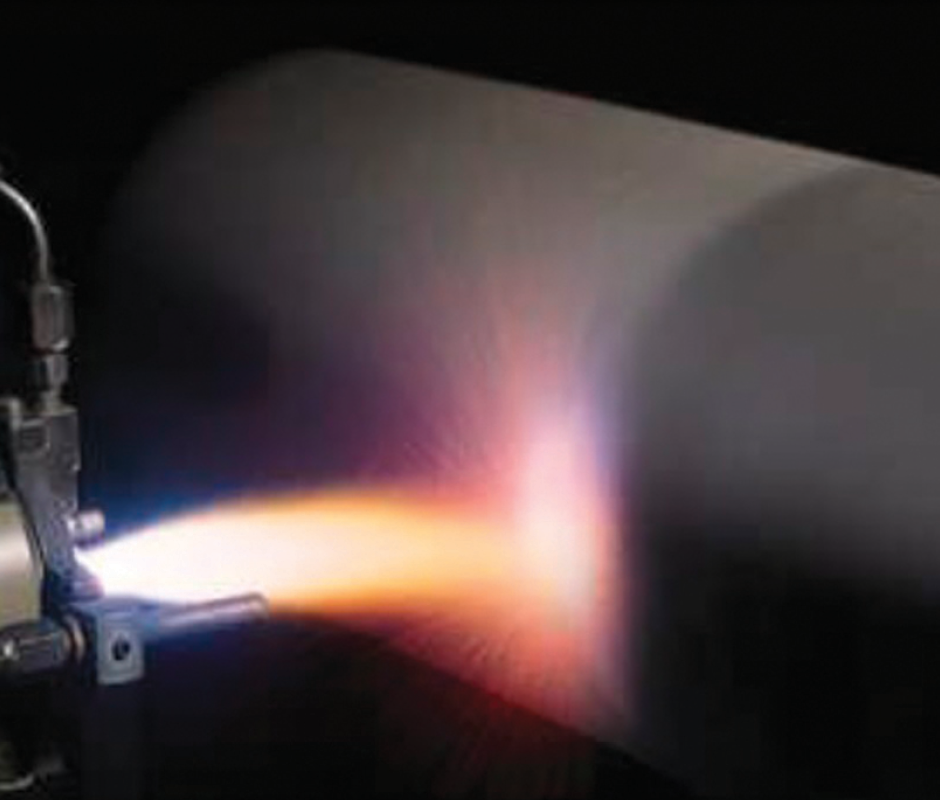

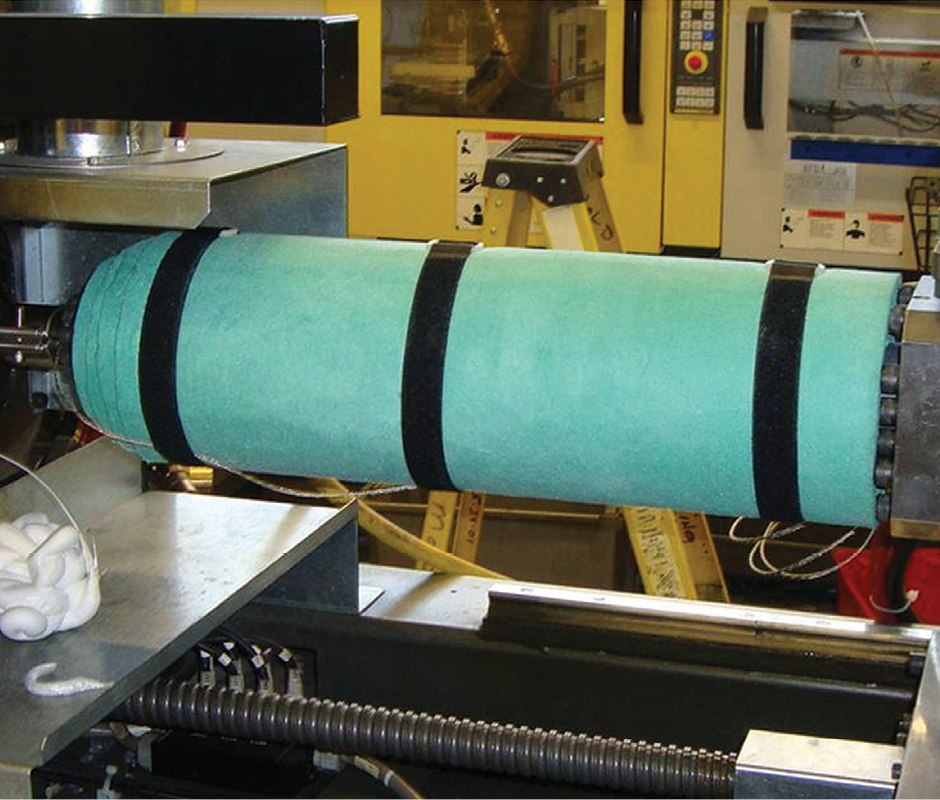

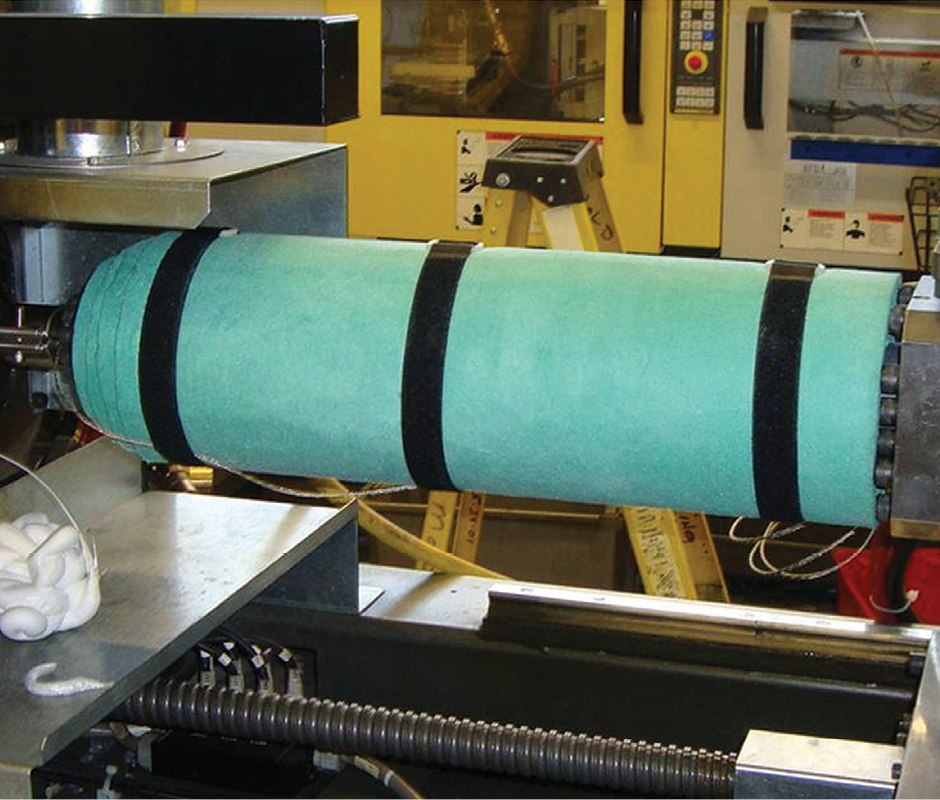

Shown at right is a barrel with tightly wrapped thermal insulating sheets (photos courtesy of Nordson Xaloy).

Electric power with a variable frequency drive on an AC motor will be 50% more energy efficient than old-fashioned hydraulics and 10-30% more efficient than modern servo-controlled hydraulics for any machine function. This is because even efficient hydraulics lose energy in two conversions. First, electric power is converted to hydraulic power; then hydraulic power is converted to mechanical power. Since plastification uses the most energy, converting the screw on a large machine to electric power will save the most energy. It also reduces the size of the remaining hydraulic pumps and the amount of hydraulic oil used in a hybrid machine.

The kind of electric motor on the screw also makes a difference in efficiency. Putting a direct-drive, permanent-magnet torque motor on the screw instead of

an inverter-controlled AC motor with a gearbox saves 1.5-2% more for energy lost in the gearbox. Sumitomo Demag, which builds its own high-torque, permanent-magnet motors, has used them for energy savings on all-electric injection molding machines since 2003.

Oswald Elektromotoren GmbH (Miltenberg, Germany) recently developed the MFS series of highly dynamic, water-cooled permanent magnet motors up to 350 kW and 3500 RPM, with low inertia and high acceleration rates for injection molding. Oswald’s MFS motors up to 75 kW are used on all-electric models from Milacron LLC in Batavia, Ohio, USA.

Servo motors controlled by a servo drive or amplifier can also be used instead of an AC motor controlled by an inverter. Servo motors are more precise and much more energy efficient, but also more expensive. Large servo motors (over 100 kW) and permanent magnet motors are expensive because of the high price of copper and rare earth magnets. The largest all-electric press in the world is a 3850 ton Ube machine, installed last year in North America for automotive applications. The largest servo-hydraulic press is around 7000 tons. To reach 3850 tons electrically, Ube synchronizes four large servo motors from Fanuc Corp. in Japan.

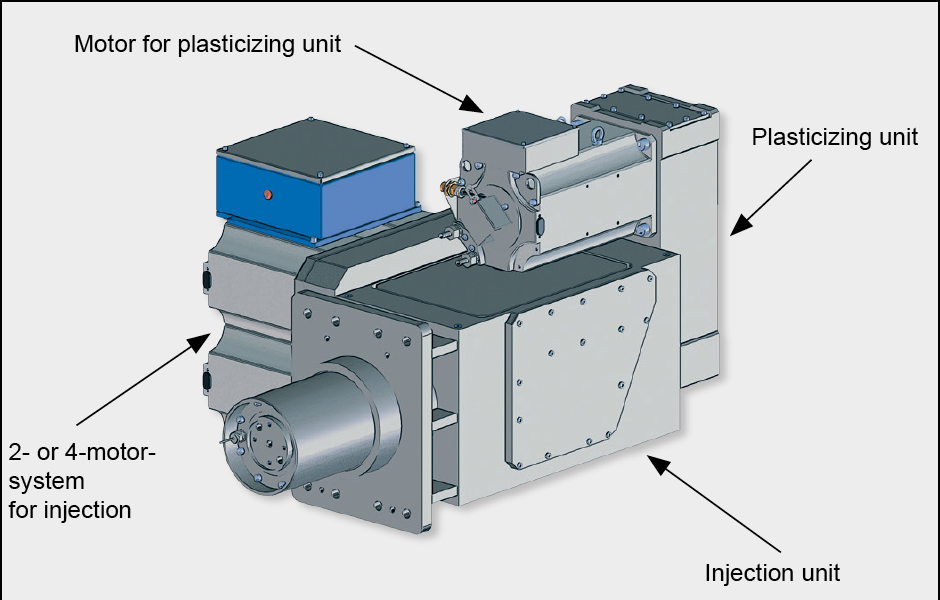

Most all-electric machines, however, are under 350 tons. Electric motors lose about 8% of energy converting rotational power to linear power, typically with a conventional ball screw. Knoedler-Getriebe GmbH (Ostfildern, Germany) offers the alternative ZS rack-and-pinion electric motor, water-cooled with a four-servo-motor drive, which also converts rotation to linear movement. Knoedler’s rack-and-pinion motor can replace a hydraulic cylinder for injection or plastification on molding machines from 200 to 450 tons, and reportedly creates a power density similar to that in hydraulics.

More energy savings are possible with linear “stop/go” movements like clamp-open and -close by regenerating electricity from braking instead of dissipating it as heat. A regenerative inverter/AC motor unit returns braking energy to the grid or applies it to other power uses. Regenerative inverter drives are available from B&R (Bernecker + Rainer Industrie-Elektronik GmbH, Egglesberg, Austria) for all-electric and hybrid machines and for retrofit.

Regeneration can recover 50%-60% of the energy from clamp movement, notes Reinhard Schiffers, head of machine technology at KraussMaffei Technologies GmbH in Munich, Germany. But to reach high recovery rates, a toggle design must be low-friction, like KraussMaffei’s AX toggle machine with linear guides.

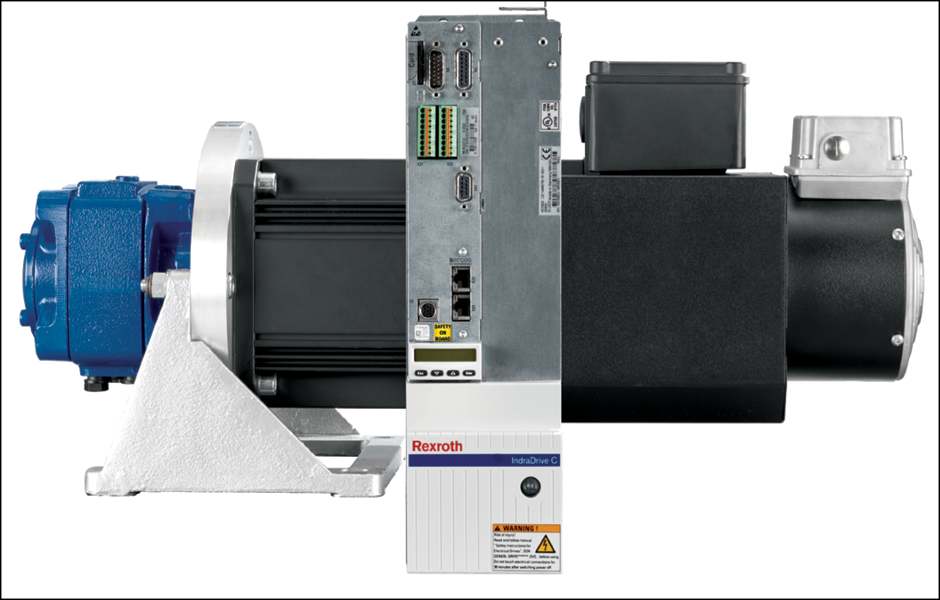

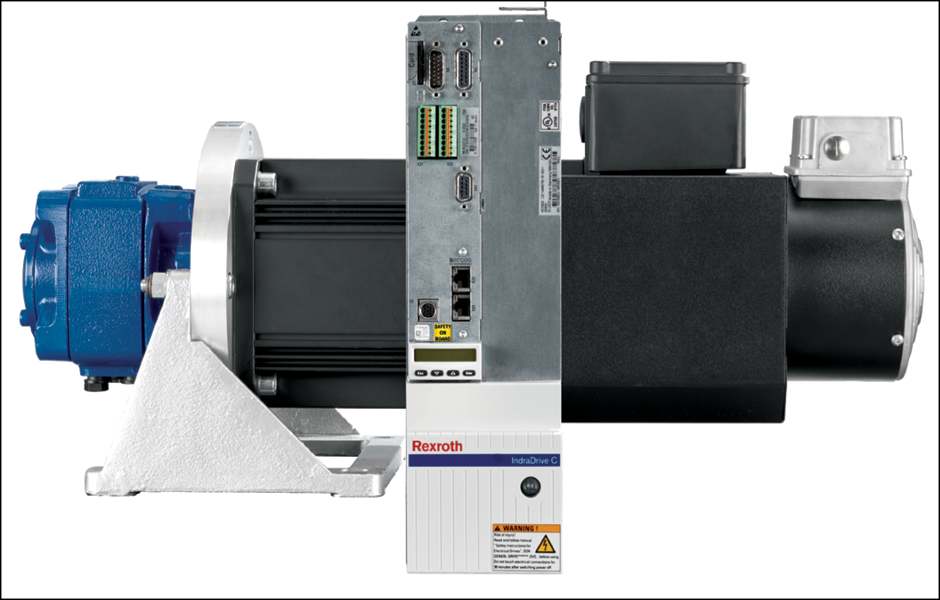

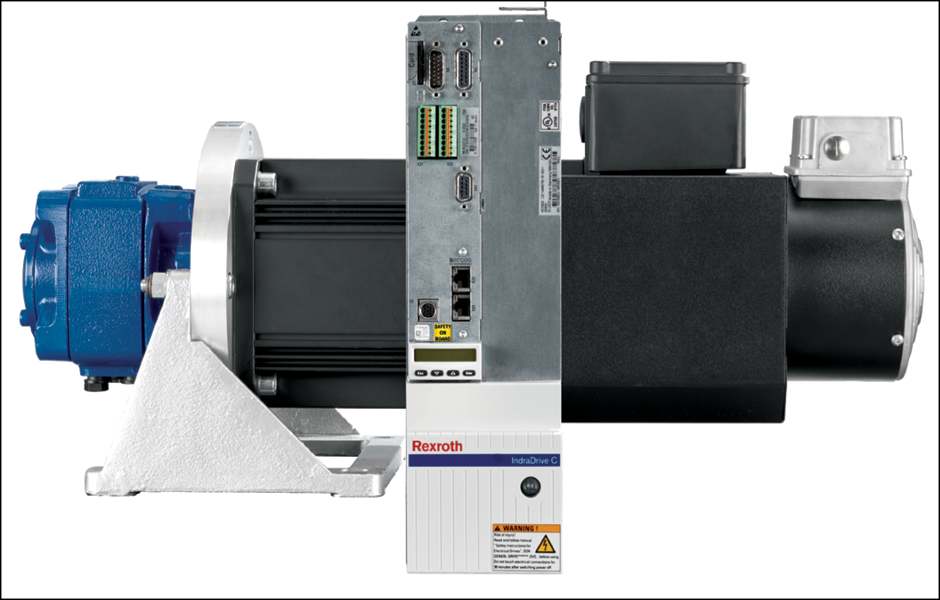

Putting servo motors on hydraulic units brought big energy savings to injection molding. Now Bosch Rexroth is testing variable frequency drives and synchronous torque motors on gear and piston pumps to get much higher RPMs and faster machine response times (photo courtesy of Bosch Rexroth).

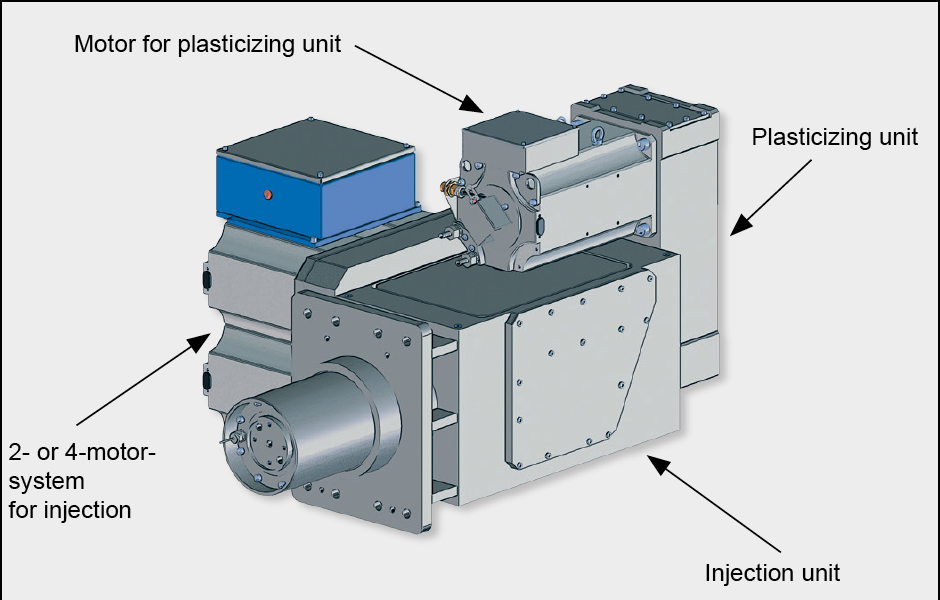

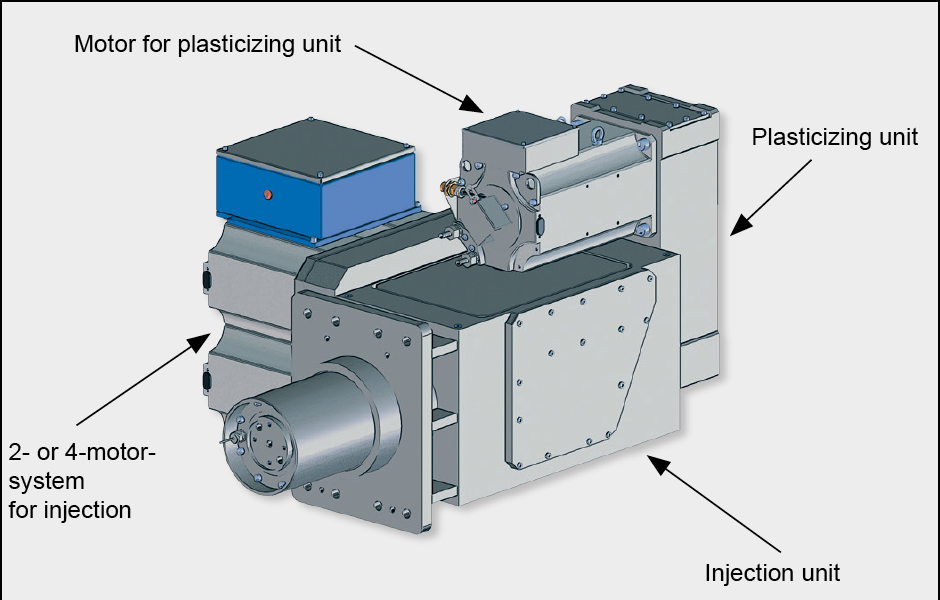

Knoedler’s rack-and-pinion electric motor with up to four servo motors converts rotation to linear power with high power density, similar to hydraulics. It’s used for energy saving for injection and platen movement on all-electric presses from 200 to 450 tons (image courtesy of Knoedler).

Regenerating electricity can also lower spikes in energy demand. Bosch Rexroth AG (Lohr am Main, Germany), developed a patented flywheel motor in 2011 to recover and store braking energy. When an electric motor for mold opening accelerates and decelerates for mold closing, deceleration turns this second flywheel motor. The second flywheel motor stores braking energy and returns it for the next mold opening, reducing peak demand. Bosch Rexroth worked with an injection molding machine OEM to develop software control to improve flywheel efficiency, introduced at K 2013 on a nearly all-electric high-speed packaging machine. Because the flywheel motor adds cost, its main economic advantage is on injection molding machines over 400 tons.

Optimizing Pump Efficiency

The big energy saver on hydraulic units is adding a variable speed servo drive to control the pump, allowing it to stop during part cooling, which for large parts saves a lot of energy. At the Fakuma Show in Germany in 2014, Wittmann Battenfeld GmbH (Kottingbrunn, Austria) introduced a new generation hybrid injection molding machine called SmartPower, with a Bosch Rexroth servo motor coupled to low-noise hydraulic pumps for injection and clamping.

The SmartPower hybrid molding machine uses Wittmann’s patented KERS (kinetic energy recovery system) with servo-hydraulics to recover braking energy and reapply it to barrel heat or to another machine motion. Wittmann has used KERS on its all-electric EcoPower machines since 2010; SmartPower hybrid machines became available in January 2015 in sizes from 25 to 120 tons.

Controlling hydraulic units with servo motors also allows the servo motor to act as a generator and recover energy every time pressure is reduced in the hydraulic pump. Milacron says that it recovers 16% of clamping energy this way on its Maxima two-platen machines, which were converted from hydraulic to servo hydraulic four years ago.

“Under certain circumstances, servo hydraulics and all-electrics can be very close in energy efficiency,” notes Neal Gigliotti, manager of the plastics group at Bosch Rexroth Corp. in Bethlehem, Pennsylvania. “Servo hydraulics will be more energy efficient than electro-mechanical drives when clamp-holding requirements are longer.”

Bosch Rexroth also combines a variable frequency drive with a synchronous torque motor on a hydraulic pump for even more precise pump control, higher RPM, and faster machine response time. Gear pumps, which typically turn at 3000 RPM, are being tested at 4000 RPM with torque motors, while piston pumps, which typically turn at 1800 RPM, now turn as high as 3000 RPM.

Because hydraulic drives have roughly five-times higher energy density than electric motors (in kW/m3), they can accelerate large loads faster, so hydraulic units are sometimes also preferred for high-speed injection. Another reason to keep hydraulic functions on mostly all-electric machines is that many existing molds use hydraulic core pulls. When Arburg GmbH + Co. KG (Lossburg, Germany) introduced its all-electric Allrounder machines back in 2001, Arburg offered the option of integrating a small hydraulic system for molds.

Wittmann Battenfeld introduced SmartPower servo-hydraulic presses in 2014, the first use of its patented kinetic energy recovery system (KERS) on servo-hydraulics. KERS (via the green plug in the close-up photo) recovers braking energy and reapplies it to barrel heating. It’s been commercial on all-electric presses since 2010 (photos courtesy of Wittmann Battenfeld).

Adding servo motors to hydraulic pumps allows less expensive gear pumps to be used instead of variable-displacement piston pumps to control oil pressure, though all OEMs don’t agree. Negri Bossi SpA (Milan, Italy) combines a variable frequency drive with a variable volume hydraulic pump on its Canbio VSE press, introduced in 2011, claiming more consistent output.

Reducing friction in oil lines, manifolds, and fittings also saves energy. Better controlled hydraulics run cooler, and cooler oil lasts longer. KraussMaffei developed a new hydraulic manifold for its GX series, introduced in 2012, with two valves instead of one and bigger oil lines. KraussMaffei claims it uses 30% less energy and lowers oil temperature.

Pump makers are also working on quieter, more energy efficient pumps, including a new vane pump from Parker Hannifin GmbH (Kaarst, Germany). Parker announced its patent pending Drive Controlled Pump in 2014 using an AC drive on either an asynchronous or synchronous motor with either a vane or piston pump, or a combination of the two. The vane pump speed range is said to be from 0 to 3000 RPM for applications including injection molding. Advantages of a beefed up vane pump would be lower energy use, lower cost, and lower noise. But vane pumps, which were used in injection molding decades ago in the ‘70s and ‘80s, aren’t as sturdy as gear or piston pumps.

Another area with recent developments is software and control packages to monitor energy use and optimize machine settings. B&R, which supplies servo pumps for injection molding, introduced EnMon (energy monitoring) software pre-installed in its PC at K 2013 to optimize energy use throughout the molding process. It’s reportedly used by several OEMs, including Milacron. B&R has also added energy-use measurement to the PLC of its X20 series machine controls. Meanwhile, ABB Group (Zurich, Switzerland) introduced energy-monitoring capabilities in its ACS 880 drive motors in 2013.

Arburg has used a commercial inverter for energy recovery from braking on its servo-electric-type clamping mechanisms since 2001, on both all-electric and hybrid machines. The recovered energy goes back to the grid, rather than to other machine motions (photo courtesy of Arburg).

OEMs have also developed energy-optimizing software. KraussMaffei introduced MC6 (motion control) software at K 2013, automatically optimizing screw speed and other settings for energy efficiency. The software asks the operator to check a part after an automatic adjustment, and approve the adjustment manually.

Parker Hannifin announced the patent-pending Drive Controlled Pump using either a vane (front) or piston (rear) pump, or a combination. Vane pumps, used in injection molding in the ‘70s and ‘80s, used to have reliability issues, but should be quieter and less expensive than gear pumps (photo courtesy of Parker Hannifin).

Will processors see the same energy savings that OEMs claim? The short answer is that actual energy savings depend on part and cycle time, not just machine efficiency. An all-electric machine is inefficient running low throughput of small parts, while any machine running high output will see more energy savings on larger parts with slower cycles. So the right configuration of electric and servo-hydraulic motors depends on the part and throughput rate.

Right: Engel’s e-speed 650 high-speed packaging machine at K 2013 introduced flywheel energy-storage technology that’s said to level out spikes in energy demand (photo courtesy of Engel).

It may sound obvious, but it’s also important to check standard machine settings against the needs of a given part. “If only 300 tons of clamp pressure are needed on a 600-ton machine, set pressure for only 300 tons,” cautions SKZ’s Gehring. The same is true for temperature settings, injection pressure, and screw speed. “Screw rotation,” he notes, “can be slowed down to match plastification time to the end of cooling time to save energy.”

Eco-Molding: More Power for Less Energy

Previous Article Next Article

By Jan H. Schut

Background photo of the mid-size JSW J450AD-1400H electric injection molding machine is courtesy of JSW Plastics Machinery.

For years injection molding machine makers have touted savings of 30%, 50%, and even more in energy cost. But OEMs typically calculate energy savings by comparing new efficient machine functions to old-fashioned hydraulics in which standard induction electric motors run at constant RPM. These power one or more hydraulic pumps, running constantly, even when the machine is idling. The big energy savings come from reducing that unnecessary motion by adding servo motors to hydraulic pumps and variable frequency drives to electric motors, so they only turn when needed.

These savings are now mainstream. How much more efficient can injection molding machines get? The latest improvements involve power coordinating and sharing across a machine to reduce spikes in energy use and simplify power component size. More efficient barrel heating is also being used, and more efficient hydraulic pumps. The resulting energy improvements aren’t as dramatic as the earlier ones, but every improvement helps.

All-electric injection molding machines still account for only 15-20% of sales in Europe, while hydraulics and hybrids account for 80-85%, industry sources say. In Japan, where all-electric injection molding started in 1984 and has had government incentives, roughly 80% of injection molding machine sales are all-electric, versus 20% hybrid and hydraulic. In the USA, just under 50% are all-electric and the rest hybrid and hydraulic. These numbers have stayed fairly constant for the past five years, largely because of efficiency improvements in hybrids.

Energy Flows in Molding Machines

An injection molding machine has seven main functions that use energy: plastification, barrel heating, platen movement, injection, clamping pressure, ejection, and barrel retraction. All seven can be made more energy efficient.

Energy efficiency, however, isn’t just a machine function. Efficiency, typically measured in kilowatt-hours per kilogram of material (kWh/kg), is different for each molded part, depending on melt temperature, part weight, cycle time, machine size, and machine efficiency. For thin-walled parts with short cycles, specific energy consumption of 0.3 kWh/kg is very efficient; for a thicker part molded more slowly, 0.6 kWh/kg could be efficient.

How much energy does each machine function use? This was addressed by the SKZ Plastic Institute (Wuerzburg, Germany), which does R&D on energy saving both for OEMs and processors and conducts audits in the plastics industry for ISO 50001 certification in energy management. SKZ tested a 100-ton all-electric press molding an 83-g ABS tray in 16.9-second cycles. Plastification consumed 48% of the energy; barrel heating, 17%; clamping, 12%; and injection, 11%. Linear movements to open and close molds and retract the barrel for cooling used only 4% each. Specific energy use for the part was 0.384 kWh/kg.

Percentages will vary for different parts made on the same machine, but barrel heating is always a big user. “If you improve only the energy efficiency of drive motors, but do nothing with barrel heaters, the ratio of energy used for barrel heat will rise,” notes Thomas Brettnich, technology development manager at Sumitomo (SHI) Demag Plastics Machinery GmbH (Schwaig, Germany). “In some cases, the ratio of energy for barrel heating in a very efficient all-electric injection molding machine can reach up to 50%.”

Barrel heating is the only energy use that doesn’t involve movement, so the fixes are different. Insulating the barrel saves “an average of about 25% of heat energy,” says Bernhard Lettner, product manager for large two-platen presses at Engel Austria GmbH (Schwertberg, Austria). Andreas Gehring, an engineer in energy certification at SKZ, says barrel insulation should be used if heater bands cycle “on” more than 25% of the time. But it should be possible to disassemble insulation, because some plastics need surplus frictional heat drawn off near the end of the barrel to avoid overheating.

Replacing conventional heater bands with radiant IR heaters adds cost, but saves even more energy. “Based on a complete retrofit of a small machine, we expect IR ceramics to save 45-50% of heat energy—up to twice as much as insulating blankets,” says Dean Francis, president of Windsor Kunststofftechnologie GmbH (Hanau, Germany), which retrofits hydraulic presses for energy saving and sells all-electric presses from JSW Plastics Machinery Inc. in Japan. Infrared elements from Rex Materials Inc. (Fowlerville, Michigan, USA), for example, can be used to convert all heating zones, or only the feed zone, which consumes the most energy.

OEMs are also introducing dramatically more efficient barrel heat. Dr. Boy GmbH (Neustadt-Fernthal, Germany) showed a prototype of its patent-pending EconPlast barrel heating system at K 2013. Its heater bands are located closer to the melt for faster response and 50% less energy than conventional external heater bands. EconPlast barrels don’t need additional insulating sleeves and make feed-throat cooling more efficient. They’re an option on Boy’s 24-48 mm screws and presses larger than 25-tons.

Two OEMs recently introduced barrels heated with patented SmartHeat technology from Nordson Xaloy Inc. (New Castle, Pennsylvania, USA), which is reportedly 30-60% more energy efficient than band heaters. For 18 months, Haitian Plastics Machinery Group Co. Ltd. (Beilun, Ningbo, China) has offered SmartHeat barrels as an option on all its injection molding machines, both all-electric and hybrid.

Ube Machinery Inc. (Ann Arbor, Michigan) will introduce a SmartHeat barrel on a 950-ton all-electric machine at NPE2015, which Ube says will be the most energy-efficient large injection molding machine in the world. Smart-

Heat has been commercially available for three years. It uses a very thin (1.6 mm) metallized ceramic coating encapsulating fine nickel chrome wires, plasma-sprayed directly onto the barrel. Last year Xaloy also added SmartHeat coatings for injection nozzles.

Energy consumption ratios for an electric 100-ton injection molding machine with hydraulic injection, making 83-gram ABS storage trays with 2-mm thick walls, in 16.9-second cycles and with specific energy use of 0.384 kWh/kg. The ratios of energy used by modern all-electric molding machines are similar to those of older hydraulic machines, but overall energy use is about 50% less (image courtesy of SKZ).

Optimizing Motor Efficiency

For both OEMs and retrofits, the two big energy-saving devices on injection molding machines are the variable frequency drive, or inverter, on electric motors, and the servo motor on hydraulic pumps. Variable frequency drives can control standard AC motor speed down to zero. A servo motor added to a hydraulic pump also controls pump rotation, allowing the pump to stop almost completely when oil pressure or volume isn’t needed, though very low pressure has to be maintained for restart.

Two OEMs, Haitian and Ube, recently introduced SmartHeat ceramic-coated barrels from Xaloy, reportedly saving 30-50% in heat energy. SmartHeat uses a sixteenth-inch (1.6-mm) metallized ceramic coating plasma-sprayed onto the barrel (at top), encapsulating fine nickel chrome wires.

Shown at right is a barrel with tightly wrapped thermal insulating sheets (photos courtesy of Nordson Xaloy).

Electric power with a variable frequency drive on an AC motor will be 50% more energy efficient than old-fashioned hydraulics and 10-30% more efficient than modern servo-controlled hydraulics for any machine function. This is because even efficient hydraulics lose energy in two conversions. First, electric power is converted to hydraulic power; then hydraulic power is converted to mechanical power. Since plastification uses the most energy, converting the screw on a large machine to electric power will save the most energy. It also reduces the size of the remaining hydraulic pumps and the amount of hydraulic oil used in a hybrid machine.

The kind of electric motor on the screw also makes a difference in efficiency. Putting a direct-drive, permanent-magnet torque motor on the screw instead of

an inverter-controlled AC motor with a gearbox saves 1.5-2% more for energy lost in the gearbox. Sumitomo Demag, which builds its own high-torque, permanent-magnet motors, has used them for energy savings on all-electric injection molding machines since 2003.

Oswald Elektromotoren GmbH (Miltenberg, Germany) recently developed the MFS series of highly dynamic, water-cooled permanent magnet motors up to 350 kW and 3500 RPM, with low inertia and high acceleration rates for injection molding. Oswald’s MFS motors up to 75 kW are used on all-electric models from Milacron LLC in Batavia, Ohio, USA.

Servo motors controlled by a servo drive or amplifier can also be used instead of an AC motor controlled by an inverter. Servo motors are more precise and much more energy efficient, but also more expensive. Large servo motors (over 100 kW) and permanent magnet motors are expensive because of the high price of copper and rare earth magnets. The largest all-electric press in the world is a 3850 ton Ube machine, installed last year in North America for automotive applications. The largest servo-hydraulic press is around 7000 tons. To reach 3850 tons electrically, Ube synchronizes four large servo motors from Fanuc Corp. in Japan.

Most all-electric machines, however, are under 350 tons. Electric motors lose about 8% of energy converting rotational power to linear power, typically with a conventional ball screw. Knoedler-Getriebe GmbH (Ostfildern, Germany) offers the alternative ZS rack-and-pinion electric motor, water-cooled with a four-servo-motor drive, which also converts rotation to linear movement. Knoedler’s rack-and-pinion motor can replace a hydraulic cylinder for injection or plastification on molding machines from 200 to 450 tons, and reportedly creates a power density similar to that in hydraulics.

More energy savings are possible with linear “stop/go” movements like clamp-open and -close by regenerating electricity from braking instead of dissipating it as heat. A regenerative inverter/AC motor unit returns braking energy to the grid or applies it to other power uses. Regenerative inverter drives are available from B&R (Bernecker + Rainer Industrie-Elektronik GmbH, Egglesberg, Austria) for all-electric and hybrid machines and for retrofit.

Regeneration can recover 50%-60% of the energy from clamp movement, notes Reinhard Schiffers, head of machine technology at KraussMaffei Technologies GmbH in Munich, Germany. But to reach high recovery rates, a toggle design must be low-friction, like KraussMaffei’s AX toggle machine with linear guides.

Putting servo motors on hydraulic units brought big energy savings to injection molding. Now Bosch Rexroth is testing variable frequency drives and synchronous torque motors on gear and piston pumps to get much higher RPMs and faster machine response times (photo courtesy of Bosch Rexroth).

Knoedler’s rack-and-pinion electric motor with up to four servo motors converts rotation to linear power with high power density, similar to hydraulics. It’s used for energy saving for injection and platen movement on all-electric presses from 200 to 450 tons (image courtesy of Knoedler).

Regenerating electricity can also lower spikes in energy demand. Bosch Rexroth AG (Lohr am Main, Germany), developed a patented flywheel motor in 2011 to recover and store braking energy. When an electric motor for mold opening accelerates and decelerates for mold closing, deceleration turns this second flywheel motor. The second flywheel motor stores braking energy and returns it for the next mold opening, reducing peak demand. Bosch Rexroth worked with an injection molding machine OEM to develop software control to improve flywheel efficiency, introduced at K 2013 on a nearly all-electric high-speed packaging machine. Because the flywheel motor adds cost, its main economic advantage is on injection molding machines over 400 tons.

Optimizing Pump Efficiency

The big energy saver on hydraulic units is adding a variable speed servo drive to control the pump, allowing it to stop during part cooling, which for large parts saves a lot of energy. At the Fakuma Show in Germany in 2014, Wittmann Battenfeld GmbH (Kottingbrunn, Austria) introduced a new generation hybrid injection molding machine called SmartPower, with a Bosch Rexroth servo motor coupled to low-noise hydraulic pumps for injection and clamping.

The SmartPower hybrid molding machine uses Wittmann’s patented KERS (kinetic energy recovery system) with servo-hydraulics to recover braking energy and reapply it to barrel heat or to another machine motion. Wittmann has used KERS on its all-electric EcoPower machines since 2010; SmartPower hybrid machines became available in January 2015 in sizes from 25 to 120 tons.

Controlling hydraulic units with servo motors also allows the servo motor to act as a generator and recover energy every time pressure is reduced in the hydraulic pump. Milacron says that it recovers 16% of clamping energy this way on its Maxima two-platen machines, which were converted from hydraulic to servo hydraulic four years ago.

“Under certain circumstances, servo hydraulics and all-electrics can be very close in energy efficiency,” notes Neal Gigliotti, manager of the plastics group at Bosch Rexroth Corp. in Bethlehem, Pennsylvania. “Servo hydraulics will be more energy efficient than electro-mechanical drives when clamp-holding requirements are longer.”

Bosch Rexroth also combines a variable frequency drive with a synchronous torque motor on a hydraulic pump for even more precise pump control, higher RPM, and faster machine response time. Gear pumps, which typically turn at 3000 RPM, are being tested at 4000 RPM with torque motors, while piston pumps, which typically turn at 1800 RPM, now turn as high as 3000 RPM.

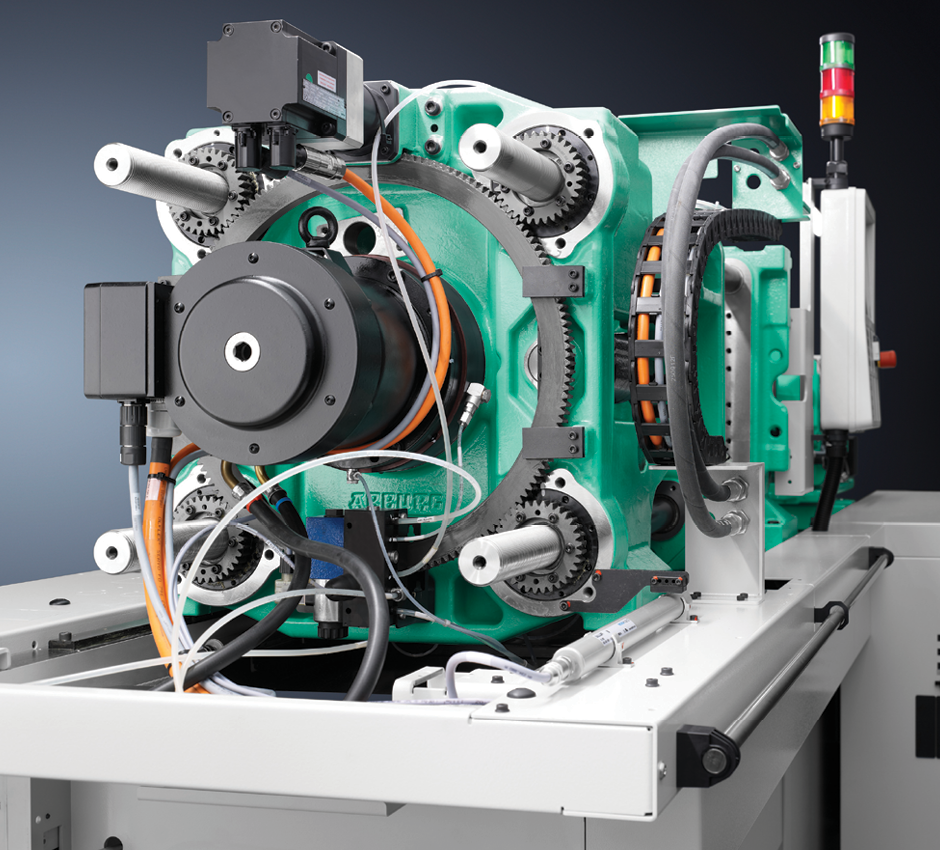

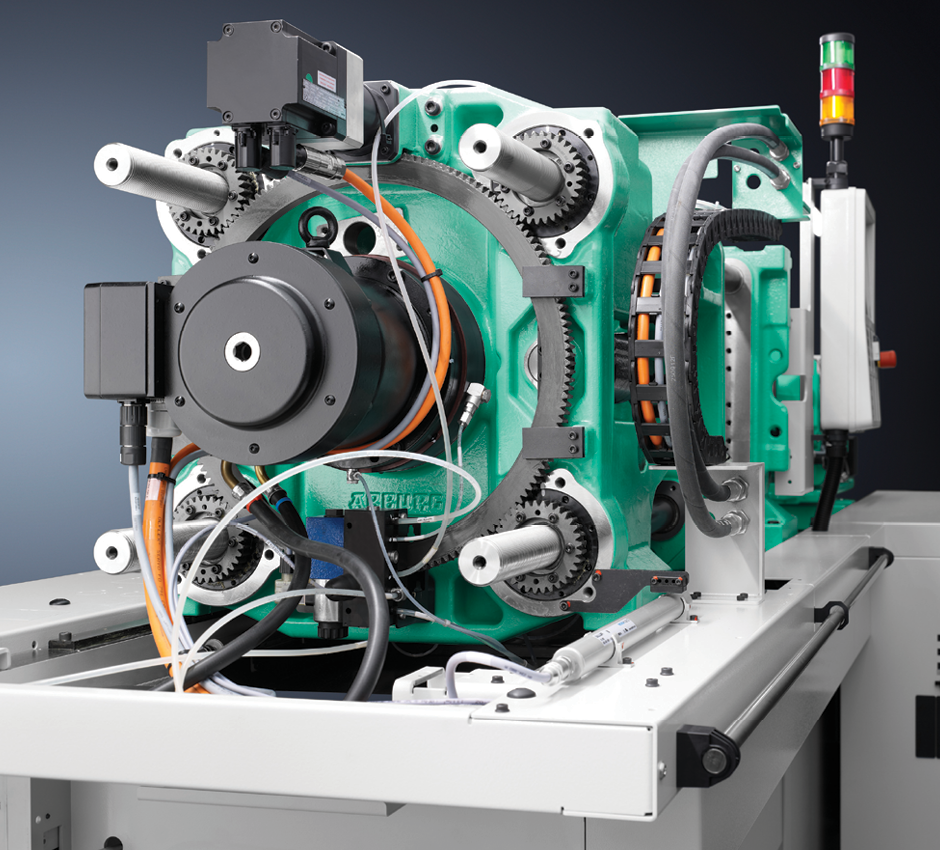

Because hydraulic drives have roughly five-times higher energy density than electric motors (in kW/m3), they can accelerate large loads faster, so hydraulic units are sometimes also preferred for high-speed injection. Another reason to keep hydraulic functions on mostly all-electric machines is that many existing molds use hydraulic core pulls. When Arburg GmbH + Co. KG (Lossburg, Germany) introduced its all-electric Allrounder machines back in 2001, Arburg offered the option of integrating a small hydraulic system for molds.

Wittmann Battenfeld introduced SmartPower servo-hydraulic presses in 2014, the first use of its patented kinetic energy recovery system (KERS) on servo-hydraulics. KERS (via the green plug in the close-up photo) recovers braking energy and reapplies it to barrel heating. It’s been commercial on all-electric presses since 2010 (photos courtesy of Wittmann Battenfeld).

Adding servo motors to hydraulic pumps allows less expensive gear pumps to be used instead of variable-displacement piston pumps to control oil pressure, though all OEMs don’t agree. Negri Bossi SpA (Milan, Italy) combines a variable frequency drive with a variable volume hydraulic pump on its Canbio VSE press, introduced in 2011, claiming more consistent output.

Reducing friction in oil lines, manifolds, and fittings also saves energy. Better controlled hydraulics run cooler, and cooler oil lasts longer. KraussMaffei developed a new hydraulic manifold for its GX series, introduced in 2012, with two valves instead of one and bigger oil lines. KraussMaffei claims it uses 30% less energy and lowers oil temperature.

Pump makers are also working on quieter, more energy efficient pumps, including a new vane pump from Parker Hannifin GmbH (Kaarst, Germany). Parker announced its patent pending Drive Controlled Pump in 2014 using an AC drive on either an asynchronous or synchronous motor with either a vane or piston pump, or a combination of the two. The vane pump speed range is said to be from 0 to 3000 RPM for applications including injection molding. Advantages of a beefed up vane pump would be lower energy use, lower cost, and lower noise. But vane pumps, which were used in injection molding decades ago in the ‘70s and ‘80s, aren’t as sturdy as gear or piston pumps.

Another area with recent developments is software and control packages to monitor energy use and optimize machine settings. B&R, which supplies servo pumps for injection molding, introduced EnMon (energy monitoring) software pre-installed in its PC at K 2013 to optimize energy use throughout the molding process. It’s reportedly used by several OEMs, including Milacron. B&R has also added energy-use measurement to the PLC of its X20 series machine controls. Meanwhile, ABB Group (Zurich, Switzerland) introduced energy-monitoring capabilities in its ACS 880 drive motors in 2013.

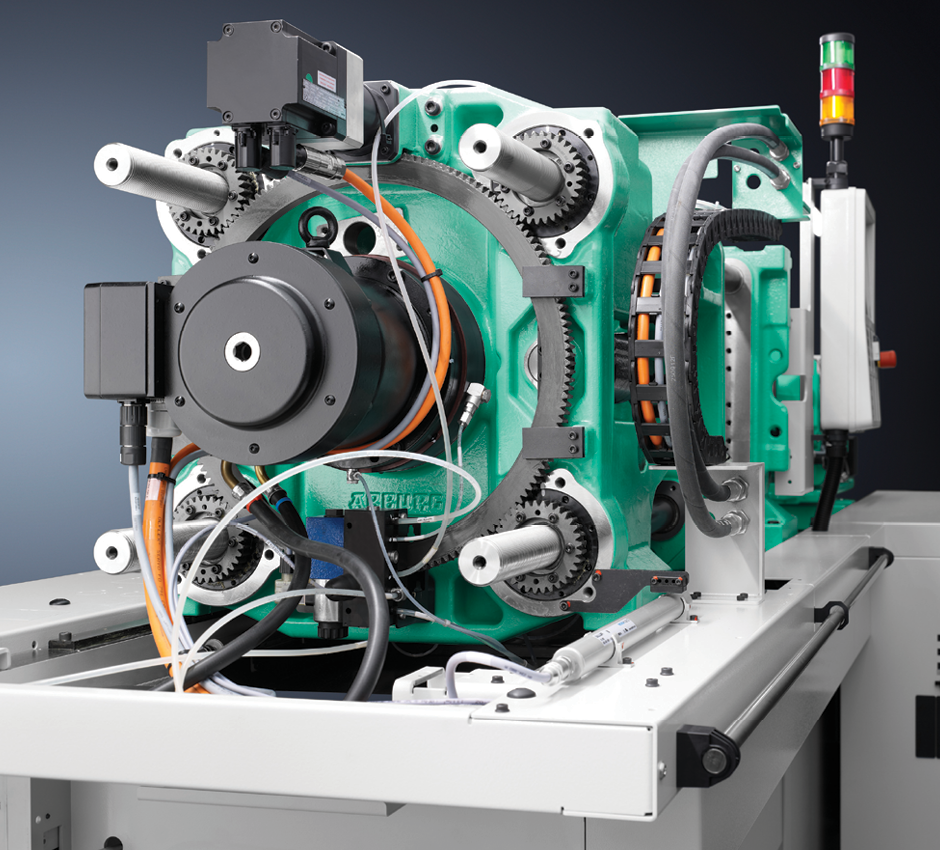

Arburg has used a commercial inverter for energy recovery from braking on its servo-electric-type clamping mechanisms since 2001, on both all-electric and hybrid machines. The recovered energy goes back to the grid, rather than to other machine motions (photo courtesy of Arburg).

OEMs have also developed energy-optimizing software. KraussMaffei introduced MC6 (motion control) software at K 2013, automatically optimizing screw speed and other settings for energy efficiency. The software asks the operator to check a part after an automatic adjustment, and approve the adjustment manually.

Parker Hannifin announced the patent-pending Drive Controlled Pump using either a vane (front) or piston (rear) pump, or a combination. Vane pumps, used in injection molding in the ‘70s and ‘80s, used to have reliability issues, but should be quieter and less expensive than gear pumps (photo courtesy of Parker Hannifin).

Will processors see the same energy savings that OEMs claim? The short answer is that actual energy savings depend on part and cycle time, not just machine efficiency. An all-electric machine is inefficient running low throughput of small parts, while any machine running high output will see more energy savings on larger parts with slower cycles. So the right configuration of electric and servo-hydraulic motors depends on the part and throughput rate.

Right: Engel’s e-speed 650 high-speed packaging machine at K 2013 introduced flywheel energy-storage technology that’s said to level out spikes in energy demand (photo courtesy of Engel).

It may sound obvious, but it’s also important to check standard machine settings against the needs of a given part. “If only 300 tons of clamp pressure are needed on a 600-ton machine, set pressure for only 300 tons,” cautions SKZ’s Gehring. The same is true for temperature settings, injection pressure, and screw speed. “Screw rotation,” he notes, “can be slowed down to match plastification time to the end of cooling time to save energy.”

Eco-Molding: More Power for Less Energy

Previous Article Next Article

By Jan H. Schut

Background photo of the mid-size JSW J450AD-1400H electric injection molding machine is courtesy of JSW Plastics Machinery.

For years injection molding machine makers have touted savings of 30%, 50%, and even more in energy cost. But OEMs typically calculate energy savings by comparing new efficient machine functions to old-fashioned hydraulics in which standard induction electric motors run at constant RPM. These power one or more hydraulic pumps, running constantly, even when the machine is idling. The big energy savings come from reducing that unnecessary motion by adding servo motors to hydraulic pumps and variable frequency drives to electric motors, so they only turn when needed.

These savings are now mainstream. How much more efficient can injection molding machines get? The latest improvements involve power coordinating and sharing across a machine to reduce spikes in energy use and simplify power component size. More efficient barrel heating is also being used, and more efficient hydraulic pumps. The resulting energy improvements aren’t as dramatic as the earlier ones, but every improvement helps.

All-electric injection molding machines still account for only 15-20% of sales in Europe, while hydraulics and hybrids account for 80-85%, industry sources say. In Japan, where all-electric injection molding started in 1984 and has had government incentives, roughly 80% of injection molding machine sales are all-electric, versus 20% hybrid and hydraulic. In the USA, just under 50% are all-electric and the rest hybrid and hydraulic. These numbers have stayed fairly constant for the past five years, largely because of efficiency improvements in hybrids.

Energy Flows in Molding Machines

An injection molding machine has seven main functions that use energy: plastification, barrel heating, platen movement, injection, clamping pressure, ejection, and barrel retraction. All seven can be made more energy efficient.

Energy efficiency, however, isn’t just a machine function. Efficiency, typically measured in kilowatt-hours per kilogram of material (kWh/kg), is different for each molded part, depending on melt temperature, part weight, cycle time, machine size, and machine efficiency. For thin-walled parts with short cycles, specific energy consumption of 0.3 kWh/kg is very efficient; for a thicker part molded more slowly, 0.6 kWh/kg could be efficient.

How much energy does each machine function use? This was addressed by the SKZ Plastic Institute (Wuerzburg, Germany), which does R&D on energy saving both for OEMs and processors and conducts audits in the plastics industry for ISO 50001 certification in energy management. SKZ tested a 100-ton all-electric press molding an 83-g ABS tray in 16.9-second cycles. Plastification consumed 48% of the energy; barrel heating, 17%; clamping, 12%; and injection, 11%. Linear movements to open and close molds and retract the barrel for cooling used only 4% each. Specific energy use for the part was 0.384 kWh/kg.

Percentages will vary for different parts made on the same machine, but barrel heating is always a big user. “If you improve only the energy efficiency of drive motors, but do nothing with barrel heaters, the ratio of energy used for barrel heat will rise,” notes Thomas Brettnich, technology development manager at Sumitomo (SHI) Demag Plastics Machinery GmbH (Schwaig, Germany). “In some cases, the ratio of energy for barrel heating in a very efficient all-electric injection molding machine can reach up to 50%.”

Barrel heating is the only energy use that doesn’t involve movement, so the fixes are different. Insulating the barrel saves “an average of about 25% of heat energy,” says Bernhard Lettner, product manager for large two-platen presses at Engel Austria GmbH (Schwertberg, Austria). Andreas Gehring, an engineer in energy certification at SKZ, says barrel insulation should be used if heater bands cycle “on” more than 25% of the time. But it should be possible to disassemble insulation, because some plastics need surplus frictional heat drawn off near the end of the barrel to avoid overheating.

Replacing conventional heater bands with radiant IR heaters adds cost, but saves even more energy. “Based on a complete retrofit of a small machine, we expect IR ceramics to save 45-50% of heat energy—up to twice as much as insulating blankets,” says Dean Francis, president of Windsor Kunststofftechnologie GmbH (Hanau, Germany), which retrofits hydraulic presses for energy saving and sells all-electric presses from JSW Plastics Machinery Inc. in Japan. Infrared elements from Rex Materials Inc. (Fowlerville, Michigan, USA), for example, can be used to convert all heating zones, or only the feed zone, which consumes the most energy.

OEMs are also introducing dramatically more efficient barrel heat. Dr. Boy GmbH (Neustadt-Fernthal, Germany) showed a prototype of its patent-pending EconPlast barrel heating system at K 2013. Its heater bands are located closer to the melt for faster response and 50% less energy than conventional external heater bands. EconPlast barrels don’t need additional insulating sleeves and make feed-throat cooling more efficient. They’re an option on Boy’s 24-48 mm screws and presses larger than 25-tons.

Two OEMs recently introduced barrels heated with patented SmartHeat technology from Nordson Xaloy Inc. (New Castle, Pennsylvania, USA), which is reportedly 30-60% more energy efficient than band heaters. For 18 months, Haitian Plastics Machinery Group Co. Ltd. (Beilun, Ningbo, China) has offered SmartHeat barrels as an option on all its injection molding machines, both all-electric and hybrid.

Ube Machinery Inc. (Ann Arbor, Michigan) will introduce a SmartHeat barrel on a 950-ton all-electric machine at NPE2015, which Ube says will be the most energy-efficient large injection molding machine in the world. Smart-

Heat has been commercially available for three years. It uses a very thin (1.6 mm) metallized ceramic coating encapsulating fine nickel chrome wires, plasma-sprayed directly onto the barrel. Last year Xaloy also added SmartHeat coatings for injection nozzles.

Energy consumption ratios for an electric 100-ton injection molding machine with hydraulic injection, making 83-gram ABS storage trays with 2-mm thick walls, in 16.9-second cycles and with specific energy use of 0.384 kWh/kg. The ratios of energy used by modern all-electric molding machines are similar to those of older hydraulic machines, but overall energy use is about 50% less (image courtesy of SKZ).

Optimizing Motor Efficiency

For both OEMs and retrofits, the two big energy-saving devices on injection molding machines are the variable frequency drive, or inverter, on electric motors, and the servo motor on hydraulic pumps. Variable frequency drives can control standard AC motor speed down to zero. A servo motor added to a hydraulic pump also controls pump rotation, allowing the pump to stop almost completely when oil pressure or volume isn’t needed, though very low pressure has to be maintained for restart.

Two OEMs, Haitian and Ube, recently introduced SmartHeat ceramic-coated barrels from Xaloy, reportedly saving 30-50% in heat energy. SmartHeat uses a sixteenth-inch (1.6-mm) metallized ceramic coating plasma-sprayed onto the barrel (at top), encapsulating fine nickel chrome wires.

Shown at right is a barrel with tightly wrapped thermal insulating sheets (photos courtesy of Nordson Xaloy).

Electric power with a variable frequency drive on an AC motor will be 50% more energy efficient than old-fashioned hydraulics and 10-30% more efficient than modern servo-controlled hydraulics for any machine function. This is because even efficient hydraulics lose energy in two conversions. First, electric power is converted to hydraulic power; then hydraulic power is converted to mechanical power. Since plastification uses the most energy, converting the screw on a large machine to electric power will save the most energy. It also reduces the size of the remaining hydraulic pumps and the amount of hydraulic oil used in a hybrid machine.

The kind of electric motor on the screw also makes a difference in efficiency. Putting a direct-drive, permanent-magnet torque motor on the screw instead of

an inverter-controlled AC motor with a gearbox saves 1.5-2% more for energy lost in the gearbox. Sumitomo Demag, which builds its own high-torque, permanent-magnet motors, has used them for energy savings on all-electric injection molding machines since 2003.

Oswald Elektromotoren GmbH (Miltenberg, Germany) recently developed the MFS series of highly dynamic, water-cooled permanent magnet motors up to 350 kW and 3500 RPM, with low inertia and high acceleration rates for injection molding. Oswald’s MFS motors up to 75 kW are used on all-electric models from Milacron LLC in Batavia, Ohio, USA.

Servo motors controlled by a servo drive or amplifier can also be used instead of an AC motor controlled by an inverter. Servo motors are more precise and much more energy efficient, but also more expensive. Large servo motors (over 100 kW) and permanent magnet motors are expensive because of the high price of copper and rare earth magnets. The largest all-electric press in the world is a 3850 ton Ube machine, installed last year in North America for automotive applications. The largest servo-hydraulic press is around 7000 tons. To reach 3850 tons electrically, Ube synchronizes four large servo motors from Fanuc Corp. in Japan.

Most all-electric machines, however, are under 350 tons. Electric motors lose about 8% of energy converting rotational power to linear power, typically with a conventional ball screw. Knoedler-Getriebe GmbH (Ostfildern, Germany) offers the alternative ZS rack-and-pinion electric motor, water-cooled with a four-servo-motor drive, which also converts rotation to linear movement. Knoedler’s rack-and-pinion motor can replace a hydraulic cylinder for injection or plastification on molding machines from 200 to 450 tons, and reportedly creates a power density similar to that in hydraulics.

More energy savings are possible with linear “stop/go” movements like clamp-open and -close by regenerating electricity from braking instead of dissipating it as heat. A regenerative inverter/AC motor unit returns braking energy to the grid or applies it to other power uses. Regenerative inverter drives are available from B&R (Bernecker + Rainer Industrie-Elektronik GmbH, Egglesberg, Austria) for all-electric and hybrid machines and for retrofit.

Regeneration can recover 50%-60% of the energy from clamp movement, notes Reinhard Schiffers, head of machine technology at KraussMaffei Technologies GmbH in Munich, Germany. But to reach high recovery rates, a toggle design must be low-friction, like KraussMaffei’s AX toggle machine with linear guides.

Putting servo motors on hydraulic units brought big energy savings to injection molding. Now Bosch Rexroth is testing variable frequency drives and synchronous torque motors on gear and piston pumps to get much higher RPMs and faster machine response times (photo courtesy of Bosch Rexroth).

Knoedler’s rack-and-pinion electric motor with up to four servo motors converts rotation to linear power with high power density, similar to hydraulics. It’s used for energy saving for injection and platen movement on all-electric presses from 200 to 450 tons (image courtesy of Knoedler).

Regenerating electricity can also lower spikes in energy demand. Bosch Rexroth AG (Lohr am Main, Germany), developed a patented flywheel motor in 2011 to recover and store braking energy. When an electric motor for mold opening accelerates and decelerates for mold closing, deceleration turns this second flywheel motor. The second flywheel motor stores braking energy and returns it for the next mold opening, reducing peak demand. Bosch Rexroth worked with an injection molding machine OEM to develop software control to improve flywheel efficiency, introduced at K 2013 on a nearly all-electric high-speed packaging machine. Because the flywheel motor adds cost, its main economic advantage is on injection molding machines over 400 tons.

Optimizing Pump Efficiency

The big energy saver on hydraulic units is adding a variable speed servo drive to control the pump, allowing it to stop during part cooling, which for large parts saves a lot of energy. At the Fakuma Show in Germany in 2014, Wittmann Battenfeld GmbH (Kottingbrunn, Austria) introduced a new generation hybrid injection molding machine called SmartPower, with a Bosch Rexroth servo motor coupled to low-noise hydraulic pumps for injection and clamping.

The SmartPower hybrid molding machine uses Wittmann’s patented KERS (kinetic energy recovery system) with servo-hydraulics to recover braking energy and reapply it to barrel heat or to another machine motion. Wittmann has used KERS on its all-electric EcoPower machines since 2010; SmartPower hybrid machines became available in January 2015 in sizes from 25 to 120 tons.

Controlling hydraulic units with servo motors also allows the servo motor to act as a generator and recover energy every time pressure is reduced in the hydraulic pump. Milacron says that it recovers 16% of clamping energy this way on its Maxima two-platen machines, which were converted from hydraulic to servo hydraulic four years ago.

“Under certain circumstances, servo hydraulics and all-electrics can be very close in energy efficiency,” notes Neal Gigliotti, manager of the plastics group at Bosch Rexroth Corp. in Bethlehem, Pennsylvania. “Servo hydraulics will be more energy efficient than electro-mechanical drives when clamp-holding requirements are longer.”

Bosch Rexroth also combines a variable frequency drive with a synchronous torque motor on a hydraulic pump for even more precise pump control, higher RPM, and faster machine response time. Gear pumps, which typically turn at 3000 RPM, are being tested at 4000 RPM with torque motors, while piston pumps, which typically turn at 1800 RPM, now turn as high as 3000 RPM.

Because hydraulic drives have roughly five-times higher energy density than electric motors (in kW/m3), they can accelerate large loads faster, so hydraulic units are sometimes also preferred for high-speed injection. Another reason to keep hydraulic functions on mostly all-electric machines is that many existing molds use hydraulic core pulls. When Arburg GmbH + Co. KG (Lossburg, Germany) introduced its all-electric Allrounder machines back in 2001, Arburg offered the option of integrating a small hydraulic system for molds.

Wittmann Battenfeld introduced SmartPower servo-hydraulic presses in 2014, the first use of its patented kinetic energy recovery system (KERS) on servo-hydraulics. KERS (via the green plug in the close-up photo) recovers braking energy and reapplies it to barrel heating. It’s been commercial on all-electric presses since 2010 (photos courtesy of Wittmann Battenfeld).

Adding servo motors to hydraulic pumps allows less expensive gear pumps to be used instead of variable-displacement piston pumps to control oil pressure, though all OEMs don’t agree. Negri Bossi SpA (Milan, Italy) combines a variable frequency drive with a variable volume hydraulic pump on its Canbio VSE press, introduced in 2011, claiming more consistent output.

Reducing friction in oil lines, manifolds, and fittings also saves energy. Better controlled hydraulics run cooler, and cooler oil lasts longer. KraussMaffei developed a new hydraulic manifold for its GX series, introduced in 2012, with two valves instead of one and bigger oil lines. KraussMaffei claims it uses 30% less energy and lowers oil temperature.

Pump makers are also working on quieter, more energy efficient pumps, including a new vane pump from Parker Hannifin GmbH (Kaarst, Germany). Parker announced its patent pending Drive Controlled Pump in 2014 using an AC drive on either an asynchronous or synchronous motor with either a vane or piston pump, or a combination of the two. The vane pump speed range is said to be from 0 to 3000 RPM for applications including injection molding. Advantages of a beefed up vane pump would be lower energy use, lower cost, and lower noise. But vane pumps, which were used in injection molding decades ago in the ‘70s and ‘80s, aren’t as sturdy as gear or piston pumps.

Another area with recent developments is software and control packages to monitor energy use and optimize machine settings. B&R, which supplies servo pumps for injection molding, introduced EnMon (energy monitoring) software pre-installed in its PC at K 2013 to optimize energy use throughout the molding process. It’s reportedly used by several OEMs, including Milacron. B&R has also added energy-use measurement to the PLC of its X20 series machine controls. Meanwhile, ABB Group (Zurich, Switzerland) introduced energy-monitoring capabilities in its ACS 880 drive motors in 2013.

Arburg has used a commercial inverter for energy recovery from braking on its servo-electric-type clamping mechanisms since 2001, on both all-electric and hybrid machines. The recovered energy goes back to the grid, rather than to other machine motions (photo courtesy of Arburg).

OEMs have also developed energy-optimizing software. KraussMaffei introduced MC6 (motion control) software at K 2013, automatically optimizing screw speed and other settings for energy efficiency. The software asks the operator to check a part after an automatic adjustment, and approve the adjustment manually.

Parker Hannifin announced the patent-pending Drive Controlled Pump using either a vane (front) or piston (rear) pump, or a combination. Vane pumps, used in injection molding in the ‘70s and ‘80s, used to have reliability issues, but should be quieter and less expensive than gear pumps (photo courtesy of Parker Hannifin).

Will processors see the same energy savings that OEMs claim? The short answer is that actual energy savings depend on part and cycle time, not just machine efficiency. An all-electric machine is inefficient running low throughput of small parts, while any machine running high output will see more energy savings on larger parts with slower cycles. So the right configuration of electric and servo-hydraulic motors depends on the part and throughput rate.

Right: Engel’s e-speed 650 high-speed packaging machine at K 2013 introduced flywheel energy-storage technology that’s said to level out spikes in energy demand (photo courtesy of Engel).

It may sound obvious, but it’s also important to check standard machine settings against the needs of a given part. “If only 300 tons of clamp pressure are needed on a 600-ton machine, set pressure for only 300 tons,” cautions SKZ’s Gehring. The same is true for temperature settings, injection pressure, and screw speed. “Screw rotation,” he notes, “can be slowed down to match plastification time to the end of cooling time to save energy.”