Plastic Parts in Plastics Processing Equipment

Experts are anticipating more roles for plastics in replacing metal parts in thermoforming machinery

Previous Article Next Article

By Pat Toensmeier

Plastic Parts in Plastics Processing Equipment

Experts are anticipating more roles for plastics in replacing metal parts in thermoforming machinery

Previous Article Next Article

By Pat Toensmeier

Plastic Parts in Plastics Processing Equipment

Experts are anticipating more roles for plastics in replacing metal parts in thermoforming machinery

Previous Article Next Article

By Pat Toensmeier

Next-generation versions of the KMD78 “Speedformer” thermoformer from Kiefel could include exterior panels formed from plastics (photo courtesy of Kiefel).

Among the plastic parts ZED Industries uses in machines is this tooling-stacking device made from ultra-high molecular-weight polyethylene (photo courtesy of ZED).

This block of Delrin acetal replaced solid red bronze bearings in supporting 1500-lb (680-kg) sheet rolls during feeding. The part reportedly lasted more than ten years (the same as bronze), cost less than a casting, and required no oil. (Photo courtesy of ZED.)

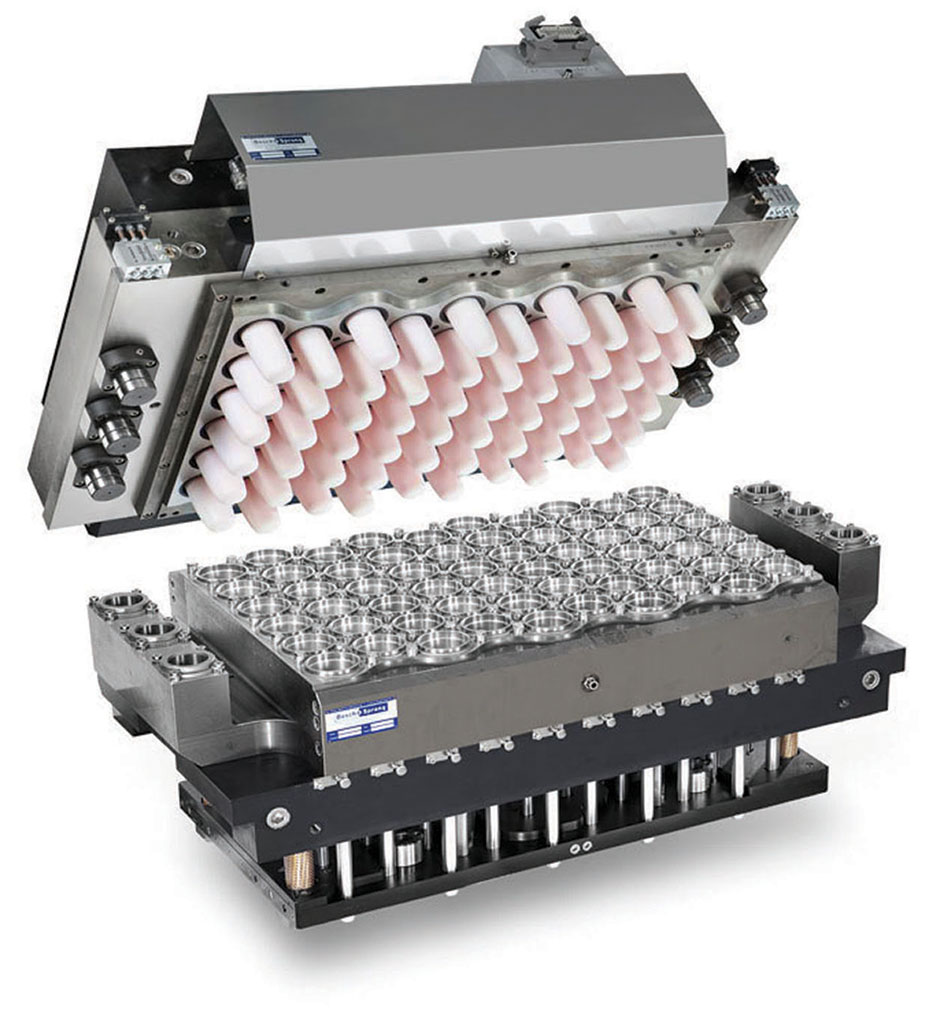

Polymer plug-assists from CMT Materials have microsphere reinforcements that hold dimensional tolerance and provide even pre-stretching of sheet. Shown here is a 60-cavity cup mold built by Bosch Sprange BV (photo courtesy of Bosch Sprange).

Printing Plastic Molds

Plastics might get a boost in process equipment from 3-D printing (or additive manufacturing). Suppliers of polymeric materials and printing systems such as Stratasys say their products are used to print injection molds for prototyping or low-volume production.

They could just as readily print thermoforming molds, though there would be size limits. The largest build area Stratasys provides is 1,000 x 800 x 500 mm on the Objet1000 Plus system. Build times depend on mold size, complexity, and material used.

Processors could also use 3-D printing to produce spare parts or custom polymer machine components.

Plastics are vital to the performance of countless applications. In automotive, aerospace, healthcare, appliances, electronics, and packaging—the uses of plastics are so extensive that most products that consumers and other end-users take for granted would either be impossible, or at least impractical, to make without them.

Except for one broad category: process machinery. This equipment is almost entirely metal, and for good reason: The metals specified for machines offer the best combination of performance, economy, and service life. And if something isn’t broke, why fix it? This is a relevant point, but it’s being challenged by some builders of thermoforming machines, for example.

A Growing Trend?

While metal will continue to dominate thermoforming machine construction, some components are being replaced with plastics like engineering thermoplastics, thermosets, and fiber-reinforced composites. These substitutions are mostly in specialty thermoforming areas such as cleanroom machines for medical and food packaging, where processors must eliminate the potential for contamination from lubricants, wear-induced slivers, and other metals-related problems.

To meet cleanroom operating conditions, some thermoforming machine builders add gears, bushings, brackets, and slides made of plastics to their equipment.

“The trend is starting to accelerate,” says Willem De Vos, CEO of the Society of Plastics Engineers (SPE). In an email interview, De Vos says several machine builders are using more plastic parts to replace smaller functional components. “Typically, these are parts that will be used on all their machine models.”

“The disappointing thing is that bigger parts,” like machine housings, he adds, “could be done in thermoformed plastics…. But no [OEM] has gone this route yet for a complete series” of machines. One reason is that part volumes would be low and thus affect return on investment for the tooling and design work.

De Vos believes that greater use of plastics in machines could increase the awareness and appreciation among end-users of what polymers and composites can achieve in performance, and in machine design. This might help advance the use of plastics in more applications. “The plastics industry tries every day to make more things in plastic; why can’t we start by making the machines that make plastic parts in plastic?”

Attractive Plastics

This would have limits. Nobody believes that plastics and composites can easily or economically replace metal when it comes to clamping force and heat resistance. But there are many areas where polymer components have benefits. Those that De Vos cites include lower energy consumption due to improved insulation, corrosion resistance, noise reduction, and electromagnetic shielding.

And there’s another benefit to plastics, he adds: design. “Why should a car look beautiful and [not] a machine for thermoforming?”

Design, in fact, might be a compelling reason to use plastics in thermoformers, at least for their exteriors. Thomas Huber, packaging industry sales director at Kiefel in Germany (the U.S. office, known as the Brueckner Group, is in Portsmouth, New Hampshire), says the OEM is “looking into” plastics for next-generation machines. One likely application is exterior panels. “Parts with thicknesses of 5 to 8 mm are thermoformable,” including those on Kiefel machines, he notes. “These parts are now painted metal.”

Ten years ago, Kiefel hired industrial designers to upgrade the look of its machines. The new designs, Huber says, “put Kiefel in a good position versus other thermoforming machines on the market.”

Sizzle alone does not sell a machine, he acknowledges, but it might add an aesthetic that could swing a buying decision if all other factors—performance, durability, and cost—were equal.

The engineers who design Kiefel machines understand metal, Huber says, but have little practical experience in plastics. The OEM started a program six months ago to educate its engineers about polymers and their properties, and this could result in the creative use of plastics in future machines.

Metals’ Strengths

The issue of plastics in machinery was raised by De Vos during a question-and-answer session at SPE’s European Thermoforming Division’s conference last year. Several OEMs at the time said they had looked at plastics for select components—electrical cabinets, pillars, vacuum tanks, panels and some platens—but did not find them effective alternatives to metal.

However, De Vos says there are many parts in thermoforming machines, including structural components, where engineering resins can replace metal. Examples include housings, where ABS and ABS/polycarbonate alloys are among the materials that he believes could withstand heat, resist oil and other fluids, and meet mechanical requirements.

Ken Braney, managing director of Plastics Machinery Group International in the UK, was an attendee at the 2014 conference. He says that thermoformers supplying the agricultural industry make panels as large as 12 x 8 ft (3.6 x 2.4 m), so large-part know-how exists. Plastics could replace metals in door panels, and clear materials like ABS or PC are logical replacements for glass, he observes.

“The idea [of using plastics] is something people are considering,” Braney remarks. Overall, though, he hasn’t seen much evidence of plastics substitution and believes the cost benefits of metal are too favorable.

Paul Alongi, CEO of MAAC Machinery Corp., doesn’t see much changeover either. “I’ve looked at it a few times but nothing seemed to make sense,” says Alongi, who was at the conference Q&A session. He adds that MAAC makes machines to order, so sizes are different, which would affect fabrication economics. Alongi hasn’t ruled plastics out as a building material, though. “We would use plastics if our clients requested it.”

Cleanroom Thermoforming

One company that is adding plastics components to its machines is ZED Industries of Vandalia, Ohio, USA. CEO Peter Zelnick says most of the substitution is in thermoformers used in medical and food packaging (form/fill/seal) cleanrooms.

“The potential for plastics to replace stainless steel is extensive,” he says. Among the benefits Zelnick cites for the materials is their ability to resist repeated steam washdowns in cleanrooms and hold dimensional tolerance. Moreover, the use of self-lubricating polymers eliminates airborne contamination from oil particles.

The plastics most used by ZED in bearings, gears, and other components are nylon 66, acetal, filled nylons and acetals, PTFE-impregnated hybrids, polypropylene, polyethylene, and ultra-high molecular-weight polyethylene. Some of these resins can be costly. The price of materials, however, is a fraction of total machine cost. What is important, apart from operational reliability, is that plastics meet the 20- to 30-year lifespan requirements of machines, Zelnick says.

Also important is the availability of plastics. A lot of the materials ZED specifies are machined from forms that can be rapidly sourced from local distributors.

In addition to the packaging and medical sectors, Zelnick sees growing demand in other markets with cleanroom requirements, such as the assembly of computers and robotic electronics.

Plastics often find use in production lines as machinery makers seek innovative solutions for special requirements. Robotic end-of-arm tooling suppliers, for one, began using lightweight composites in place of steel and aluminum years ago to achieve the split-second in-and-out movement necessary to de-mold parts from high-speed injection machines.

Plug-Assists

In heavy-gauge thermoforming, plastics are vital to a key component: the plug-assist. While many are made of aluminum or even wood, one company that uses polymer formulations for these parts is CMT Materials in Attleboro, Massachusetts, USA.

CMT makes plug-assists out of Hytac, an epoxy or thermoplastic resin reinforced with hollow glass microspheres that are 50% air by volume (also known as syntactic foam). Conor Carlin of CMT says benefits of a microsphere-reinforced plug-assist include light weight, high durability, and low thermal conductivity. This last quality maintains the dimensional tolerance of the plug-assist, contributes to finished part appearance, and helps reduce cycle times.

Carlin declines to reveal details about the thermoplastic that CMT uses in plug-assists, or the size and loading of the microspheres. He does say the plug-assist provides savings by producing an even mechanical pre-stretch prior to forming and, as a result, it allows 10-12% reductions in starting sheet thickness while eliminating thin spots in finished products.

“Plastic Making Plastic”

However the use of plastics in thermoform machinery (and other process equipment) turns out, it’s clear that there’s a trend toward integrating the materials in machines. The rationale will continue to be focused on performance, but OEMs and processors should not discount the impact that innovative plastics design features would have on the marketability of machines, and on product manufacturers.

“My dream is to enter an injection molding or thermoforming plant and see machines made from plastic making plastic,” SPE’s De Vos says. “I had a similar dream for a car made out of plastic, and we are coming very close [to that], so who knows?”