Active Packaging Gets Smarter

Embedded sensors and quantum dots help plastics packaging make giant leaps in usefulness

Previous Article Next Article

By Geoff Giordano

Active Packaging Gets Smarter

Embedded sensors and quantum dots help plastics packaging make giant leaps in usefulness

Previous Article Next Article

By Geoff Giordano

Active Packaging Gets Smarter

Embedded sensors and quantum dots help plastics packaging make giant leaps in usefulness

Previous Article Next Article

By Geoff Giordano

AdhereTech’s “smart” pill bottle includes a 3G chip that relays when patients do—and don’t—take their medications (photo courtesy of AdhereTech).

Electronics can be printed on flexible plastic substrates using a combination of printing techniques (photos courtesy of Thin Film Electronics).

Electronics can be printed on flexible plastic substrates using a combination of printing techniques (photos courtesy of Thin Film Electronics).

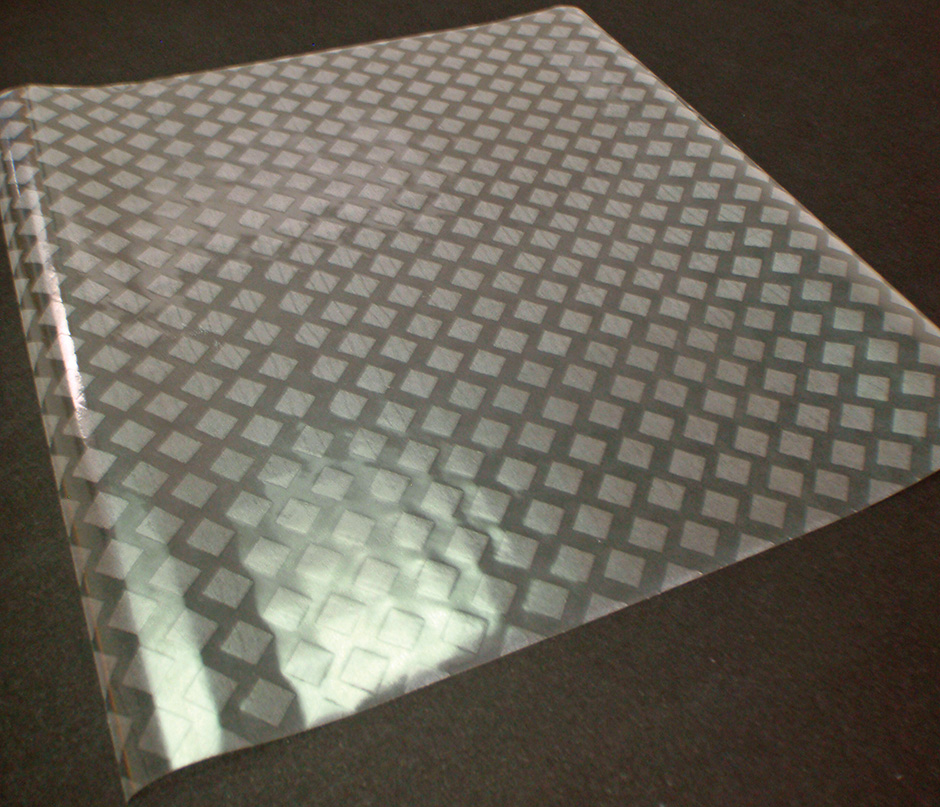

Cellresin flexible film printed with a diamond pattern containing 1-MCP ethylene inhibitor; this structure is a multilayer lamination (photo courtesy of Cellresin Technologies).

A Cellresin label applied to a PP bag featuring ethylene-inhibiting 1-MCP (photo courtesy of Cellresin Technologies).

In this age of information, it’s no wonder that even our packaging is telling us valuable things about what’s inside. “Active” or “intelligent” packaging provides information on practically everything, from the state of its contents to when patients must take medication.

Options include track and trace, featuring RFID tags and printed sensors; condition-monitoring or time/temperature indicators; security alert devices; and anti-microbial properties and shelf-life extension. “Brand owners are also very interested in the marketing opportunities to improve consumer engagement and gathering data,” says Andrew Manly, communications director for the Active and Intelligent Packaging Industry Association (AIPIA).

The food industry benefits greatly from such packaging, assuming 30% food waste along the supply chain, Manly notes. “l bet if one of the major food retailers saved 10% of the food it throws out because it has passed its sell-by [date], that would run into tens of millions” of any given currency.

Active packaging can eliminate cumbersome and expensive labels or informative inserts. “There are huge benefits to be gained from accessing information on, say, pharma products, in your language via a QR code on a smartphone,” Manly suggests. Brand owners can even share special offers, loyalty programs, user tips and audio or visual enhancements.

Medication Adherence

Far too often, medical professionals encounter patients who don’t take medicine at the right time. Medication non-adherence is “the biggest problem in healthcare today,” says Josh Stein, CEO and cofounder of AdhereTech. This problem takes a huge toll, he says: more than 100,000 deaths in the USA every year, $300 billion in increased costs, and $100 billion in lost revenues.

AdhereTech’s solution is injection-molded “smart” pill bottles. These bottles are made with durable medical-grade plastics, Stein says, and are subjected to drop tests to protect the electronics inside.

“We’ve put a 3G chip inside the bottles,” Stein explains. “The bottle is built just like a cell phone,” with a circuit board and rechargeable battery. “Whenever the patient uses the bottle, [the chip] tells us what the patient is doing. You get all that data in real time. We also analyze that data and compare it to what a patient should be doing.” Transmission, storage, and protection of that data is steered by HIPAA regulations.

When patients aren’t taking medication properly, “we intervene in a series of fully customizable ways,” he continues. The bottle lights up and beeps; patients get text messages and automated phone calls; they can even get live intervention from a nurse. The bottles are being used for patients prescribed high-cost medicines—typically for cancer, HIV, hepatitis C, and similar diseases—and also for testing new drugs in clinical trials. “We want this to be a tool that patients ask for,” Stein says.

The bottles—the “Generation 1” version was introduced in 2013—are reportedly being used by top healthcare firms, pharmaceutical companies, hospitals, and a major insurance company. A “Generation 2” bottle is scheduled to go into use this year.

Fortifying Food

Embedded electronics are vital to food packaging as well. At Thin Film Electronics, “our smart label products are impacting key vertical markets such as consumer packaged goods, healthcare, and retail,” says Jennifer Ernst, chief strategy officer. “In food and beverage markets, we’re constantly seeing news of food recalled due to poor handling during production and packaging.”

By adding temperature-sensing technology to disposable items, she says, “a food manufacturer or distributor can track the temperature of perishable goods such as meat, fish, or produce down to the individual package level to monitor freshness and ensure quality upon arrival at its final destination. Manufacturers, wholesalers, retailers, and consumers can be alerted if an individual food item has crossed a pre-set temperature threshold and reduce the risk of food-borne illnesses and costly recalls.”

Thin Film prints electronics on flexible plastic substrates using conventional and new printing techniques, Ernst explains. “We are able to create rewritable memory using roll-to-roll techniques. For example, Thinfilm Memory, the first commercial printed memory, is produced on equipment much like that used for graphics publishing.”

Ernst detailed the process as follows: “We begin with a thin, inexpensive plastic—PET or PEN [polyethylene naphthalate]—for our substrate. On the plastic substrate, we gravure print our bottom electrode, then coat a layer of ferroelectric polymer. Next, we use a second gravure print station to add our top electrodes, followed by screen printing a series of carbon pads. Carbon is a cost-effective way to expand the contact area available on the memory labels.

“Finally, two patent-pending protection layers are printed via rotary screen. The resulting electronic device has been demonstrated to withstand scratch and abrasion tests. Finished rolls are converted to labels via industry-standard methods. On one roll we can create over a million labels. Creating electronics completely without the use of silicon or other relatively expensive electronic materials is an industry first.”

Thin Film’s process delivers significant cost advantages because it is additive. “Where conventional silicon fabrication requires coating a surface with a universal film and etching away what you don’t want, printing allows you to put materials exactly where you want them. This translates to very high materials-utilization rates with little waste.”

Meanwhile, in her presentation at AIPIA’s congress in Chicago last year, Jenneke Heising of Wageningen University in The Netherlands discussed an intelligent packaging concept for fresh cod fillets that communicates freshness “from the moment of packaging until the day the fish is spoiled.” The concept could lead to dynamic pricing with electronic sensors, she says. “When foods becomes older, the price becomes lower automatically. This allows first-expired first-out instead of first-in first-out.”

According to Heising, “Foods that will benefit the most from intelligent packaging are relatively expensive, highly perishable foods.” Specifically, “foods with known or low variation in initial quality can benefit from sensors that monitor the conditions that influence the quality of the packed foods, like storage time and temperature. Foods with an unknown initial quality, or a high variation in initial quality, need sensors that monitor compounds or properties of the food that are directly linked to quality attributes of the food. The initial quality of fresh fish is highly variable, [so] fresh cod fillets require sensors monitoring compounds correlated with the quality of the fish.”

In her research, “We developed a new non-destructive method with electrodes in an aqueous phase inside the headspace of the package to monitor volatile amines—compounds generally used as a freshness indicator of the packed fish.” Her recommendation for commercial use is “a miniaturized sensor integrated into a package for food units [that] should be able to be produced on a large scale at low-cost (relative to the value of the food product), accurate and reliable, easy to read and understand by the user, preferably sustainable, and of course safe for food contact.”

Saving Broccoli

How about protecting produce? Cellresin Technologies has a way to extend the shelf life of post-harvest products, says Will Wood, vice president and general manager. Cellresin incorporates ethylene inhibitor 1-methylcyclopropene (1-MCP) into packaging like overwraps for trays, shrink and lidded films, films for bulk bags and liners, pallet bags, and more.

Ethylene, natural to most fruits, vegetables, flowers,

and plants, tells plants when to grow and mature—and eventually over-ripen and spoil. “The discovery of 1-methylcyclopropene and its use as an ethylene inhibitor, particularly in combination with cold storage rooms, has made it possible to switch off the aging process in horticultural products for a sufficient period of time to result in significant improvements in product shelf life, freshness, and quality,” Wood explains.

“In mid-2002, the EPA approved the use of 1-MCP as a growth regulator in cold storage rooms for a variety of fruits and vegetables, registered under the name SmartFresh,” he says. But there aren’t enough cold storage rooms to handle all the crops harvested globally, so incorporating the ethylene inhibitor into packaging is vital.

“Conventional printing—inkjet, flexographic, or gravure—methods are used to dispose proprietary 1-MCP compositions onto a portion of a packaging material’s surface. Printing techniques are used to deliver precise amounts of 1-MCP-containing compositions to the packaging articles in the form of printed patterns or indicia.”

When moisture released from the packaged produce’s respiration diffuses through the inside layer, it destabilizes the 1-MCP complex, “followed by release and subsequent diffusion through the inside layer and into the package headspace. The release of 1-MCP may continue for several days at reduced storage temperature. The rate of inhibitor release is proportional to the amount of water in the package headspace and, of course, temperature.”

Broccoli tested by Cellresin showed markedly improved longevity when stored in film with a 1-MCP layer for 28 days at 40°F (4.4°C). Wood concludes such film could significantly reduce an estimated $241 million in annual U.S. broccoli spoilage.

Combating Counterfeiting

Protecting consumers from phony products is another benefit of smart packaging, says Daniel Forte, CEO/founder of Quantum Technology Group. Quantum dots are emerging as a “commercially viable product.”

“Often, targeted protection technologies are rapidly defeated because the underlying scientific methods are easily understood or reverse-engineered,” Forte notes. “A fundamental challenge to a counterfeiter starts with the sophistication of the platform technology inherent in quantum dot nanoparticle synthesis.”

Quantum dots range from 2 to 10 nanometers and contain nearly 20 properties, he explains. Synthesis requires extensive knowledge of chemical interaction, various gases, and temperature controls. “With only four known methods to produce quantum dots, and most processes focused on highly toxic cadmium-based materials, the manufacturing process is volatile.”

But the payoff, Forte says, is that “the fluorescent quantum dot nanoparticle produces a photo-luminescent signature that is very precise and may be evaluated to determine additional measurable characteristics such as quantum yield, absorption, fluorescence decay, blink rate, chemical composition, and more. Imagine the challenges to counterfeiters when a precise variety of quantum dots of unique signatures are combined onto various substrates.”

He says Quantum dots work well in inks, lacquers, and laminates and on a wide variety of substrates including paper, polymers, metal, and glass. “The key advantage of the quantum dot materials from Quantum Technology is that they have successfully overcome the issues necessary for commercialization [as we] prepare for market entry with a non-toxic, environmentally friendly product line.”

An “Active” Future

Ultimately, cost and education remain key factors to more widespread active packaging, asserts Manly of the AIPIA.

“Devices such as RFID tags and PE [photoelectric] sensors have come down in price dramatically,” he notes. “Many solutions need a major champion to break through.” The UK’s Marks and Spencer and Walmart in the USA are early adopters, but active and intelligent packaging “needs a more focused effort as the benefits for supply-chain management and shelf extension, anti-theft, and security measures are proven. It is happening—with RFID, particularly in the apparel sector, and Diageo is just rolling out a security tag for one of its premium whisky brands. But we’d like to see more.”