Photo courtesy of Herrmann Ultrasonics

Photo courtesy of Graco

Photo courtesy of Solvay

Photos courtesy of SABIC

Photo courtesy of Mettler Toledo

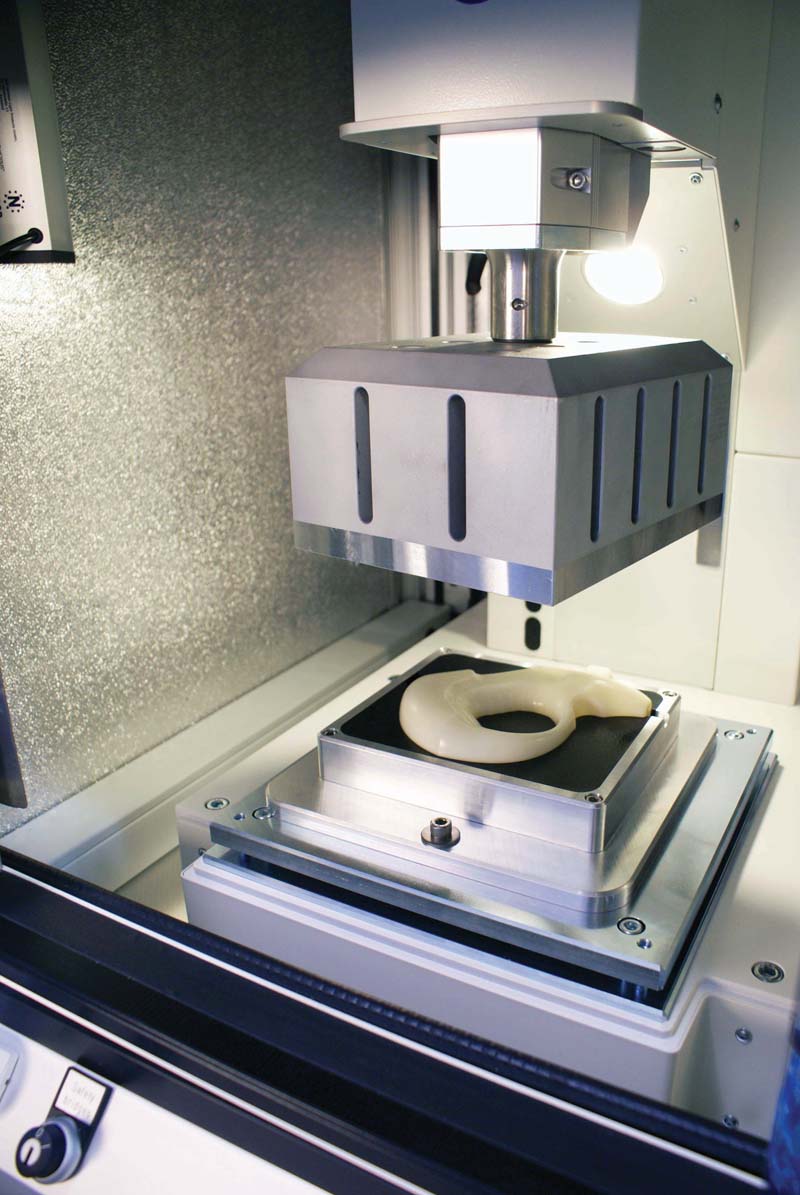

Herrmann Ultrasonics Inc. has worked with Florida-based medical products company Genicon to build one of the largest ultrasonic medical weld tools ever designed. The product being welded—a newly designed suction irrigation handle—was displayed by Genicon at the recent MEDICA 2015 tradeshow in Germany.

The device is used for liposuction. The application was very challenging due to the size of the joining partners and their three-dimensional shapes—especially the 12-mm difference in contour heights, which needed to be matched by the contact surface of the weld tool, called a sonotrode. The team at Herrmann made it work with a 220 x 180 mm aluminum sonotrode.

To meet the increasing requirements for ultrasonic assembly processes in sterile environments, Herrmann Ultrasonics introduced the new Medialog welder, which caters to medical device manufacturers. Together with stainless steel, cleanroom-friendly surfaces, and modified pneumatics, the welder includes a unique FSC operator interface.

FSC stands for “FDA system component,” and it meets the demanding requirements FDA CFR 21 part 11 of the Food and Drug Administration. FSC includes complete documentation of all actions performed by authorized users and records time-stamped audit trails. The creation of customized individual access authorization, in combination with electronic signatures, ensures authenticity, completeness, and confidentiality of all data, Herrmann adds.

To address an industry need for a broader processing filament, Eastman Chemical Co. and colorFabb BV have announced an enhanced product for the 3-D printing industry: nGen, a new product made with Eastman Amphora™ AM3300 3D polymer, adds functional properties and top print quality to the filament line, and has the ability to print within a wide processing range.

The product is made from Eastman’s Amphora range of copolyesters designed specifically for 3-D printing. Like the colorFabb XT filament that came before it, nGen is a tough, low-odor, styrene-free offering that’s suitable for most day-to-day 3-D printing activities. It’s reportedly easy to use and reliable, being designed for a wide range of 3-D printing enthusiasts.

With its ability to work at a large range of processing temperatures, nGen processes at 220-240°C and has an elevated heat resistance of 85°C. Its ability to dissipate heat faster than other types of filaments improves the performance on overhanging surfaces. All of this makes nGen an efficient filament that can print functional, durable, and attractive creations in less time.

The filament “empowers a larger panel of users to create tough and useful items, as the filament is appropriate for anyone who wants to print a variety of objects without compromising quality, performance, color, or strength,” says Ruud Rouleaux, managing director, colorFabb. “This industry is evolving, and the types of consumers and professionals who engage in 3-D printing are increasing, sparking a need for materials that support this growth.”

The Eastman polymer provides maintains many advantages of the Amphora 3D polymer, but with a few differentiating qualities. Amphora AM3300 has good flow properties through the printer nozzle, even at lower temperatures, and is not impacted by humidity and moisture from the environment, resulting in stable printing results with less waste.

“Eastman Amphora AM3300 3D polymer is reliable and easy for people to use, so even casual users can work with an advanced filament,” says Alex Dudal, market development representative, Eastman Chemical Co.

Winsell Inc. has announced the launch of its 2016 Rotational Molding Product Design Competition. The goal of this annual contest is to inspire emerging industrial design students’ talents to create breakthrough consumer products that utilize the latest technologies in rotational molding.

Judging criteria includes: originality, processability, growth potential, beauty and visual appeal, tool-building compatibility, and the use of appropriate Winsell materials.

The entry deadline for this year’s competition is April 29, 2016. The first-place winner of the competition will receive $500, second place, $250, and ten honorable mention participants will each receive $150. The design competition is organized by Winsell, with support from 2016 sponsors Avantech, Diversified Mold & Castings, M. Holland, and Polimeros USA.

Past participants have stated that their product submission “will be a great portfolio piece,” and that “this competition helped me embark on new adventures that I would not have otherwise been exposed to.”

“The rotational molding industry is fueled by the creative ideas of product designers,” adds Fred Shockey, Winsell chairman and CEO. “When we cultivate and celebrate emerging talent in the field, we will thrive. The Product Design Competition gives us a glimpse into the future of rotational molding, while also ensuring that future.”

All entry information, criteria, and forms are available on the Winsell website:

Graco Inc., a leader in fluid-handling products and systems, announced the release of Graco Fluid Automation F4-5 and F4-55 liquid silicone rubber (LSR) dispensing equipment.

The new F4-series systems are reportedly designed to keep the dispensing of two-component LSR consistently precise, with two flow meters ensuring the material remains on-ratio. This is particularly critical in industries like medical device manufacturing, where pharmaceutical properties added to the LSR make materials extremely expensive, and in infant care product manufacturing, where off-ratio dispensing can result in product defects, the company explains.

“The introduction of the Graco Fluid Automation F4-5 and F-4-55 ushers in a new level of precision in the dispensing of LSR,” says David Bordwell, global product manager for Graco’s Advanced Fluid Dispense division. “The equipment’s helical gear and unique flow meter construction allows the F4 series systems to measure material in extremely small increments, which increases the operator’s ability to detect even the smallest anomaly much sooner.”

The Graco Fluid Automation F4-5 and F4-55 dispensing units help reduce costs by eliminating off-ratio dispensing and therefore waste caused by non-cured parts. Additional benefits include a reduced machine footprint and the substitution of programmable logic controllers with the more robust proprietary Graco Control Architecture (GCA).

According to Bordwell, “The move to Graco Control Architecture translates into easy startup and operation for the end user. GCA controls are more user-friendly, thereby saving the user time, service, and support requirements.”

Solvay Specialty Polymers, a leading global supplier of high-performance polymers, announced a new licensing agreement that enables RTP Company, a custom compounder of engineered thermoplastics, to manufacture and sell RTP custom compounds based on Solvay’s ultra-high performance Torlon® polyamide-imide (PAI) polymer.

The new business arrangement expands RTP’s capability to meet growing demand for Torlon PAI-based compounds. Available under the RTP 5000 label, the new offering from RTP Co. will target demanding applications that require high structural strength or excellent wear resistance, as well as the ability to perform reliably at high temperatures, under load, and in harsh chemical environments.

“This new agreement both expands and strengthens our broad and growing portfolio of custom compounds,” says Scott Koberna, global general manager of wear and friction materials for RTP. “Solvay’s advanced Torlon PAI technology will help us explore entirely new and unique solutions for customers in fast-growing markets, such as automotive, industrial, off-road vehicles, building and construction, defense, and aerospace.”

Torlon PAI combines the performance of thermoset polyimides with the melt-processing advantage of thermoplastics to deliver industry-leading strength and stiffness at temperatures up to 275°C. Wear-resistant grades offer unsurpassed performance at elevated pressures and velocities in both dry and lubricated environments.

The RTP 5000 family of compounds will incorporate new and existing additive packages to further extend the performance range of Solvay’s PAI technology. Solvay will continue to manufacture and sell Torlon compounds through its normal direct supply channels.

“RTP Company has been a well-recognized and trusted compounder of Solvay’s advanced materials for many years, and this new agreement improves on that relationship by combining Solvay’s industry-leading PAI polymer chemistry with RTP Company’s world-class compounding and distribution capabilities,” says Chris Wilson, vice president of Ultra Polymers for Solvay Specialty Polymers. “This is a major win for both companies and will expand the competitive solutions of our global customers.”

www.solvayspecialtypolymers.com

With automakers increasingly exploring new ways to use light, SABIC says it’s actively working on developing car window technology with integrated lighting features.

The company first disclosed its efforts to develop polycarbonate (PC) windows with integrated lighting at the International Symposium on Automotive Lighting, held in Darmstadt, Germany, in September 2015. There, the company showed a rear quarter window produced through two-shot injection molding with Lexan™ and Cycoloy™ resins, featuring two sets of decorative lighting components: two blue LED light pipes and a white LED light guide with white laser-etched graphics.

While those elements are largely decorative, SABIC says integrated lighting can serve a variety of functional purposes. To illustrate one potential use, the company released a concept sketch in which a lighting component built into a lightweight polycarbonate window indicates the battery status of an electric or hybrid vehicle, from green for fully charged, to red for a critical condition. This feature could allow the driver to understand the state of battery charge without any need to enter and start the vehicle.

“Our customers are always looking for new ways to surprise and delight consumers,” says Scott Fallon, senior director of SABIC’s automotive business. “Combining PC glazing with lighting technologies opens up a whole new range of possibilities to help them do this. Our long-standing expertise in each application space and our capabilities to support product creation lend themselves perfectly to help automakers develop unique solutions and set new trends in vehicle design.”

Beyond using a car window to indicate battery charge status, SABIC says lighting features in windows could also enable new styling and branding solutions and display other kinds of useful information. Possibilities might include:

- adding signature lighting or side markers on window surfaces to help better distinguish vehicle models and enhance consumer appeal;

- using colored light for brand enhancement;

- using window lighting to put on a show outside of the vehicle when parked, including projecting patterns or imagery on the ground;

- displaying warning messages;

- displaying dynamic turn indicators and hazard light signals;

- enhancing nighttime safety;

- allowing for animated welcome and goodbye gestures; and

- adding ambient lighting features to enhance interiors.

Automakers already are adding lighting touches to various vehicle components like door handle pockets, side mirrors, door interiors, instrument panels, center consoles, and cup holders, the company notes.

Kemgo recently launched a new online platform that enables suppliers and buyers of petrochemicals to source the best deals in a global marketplace. This online marketplace is a new innovation that serves the needs of the petrochemical industry. The company says it’s the only marketplace specifically designed for petrochemical products: polymers, chemicals, and fertilizers.

Kemgo, based in Princeton, New Jersey, with a presence in Germany, makes worldwide market data visible and new markets accessible without increasing costs to buyers and sellers. Ralph de Haan and Joe Naaman founded Kemgo with the aim of creating a world where marketing, sales, and distribution of petrochemicals would be automated.

“In the 21st century, geography and limited information shouldn’t be an obstacle when finding suppliers or buyers,” says Naaman. “We are going to help by creating this trusted worldwide marketplace,” adds de Haan.

Naaman is described as a consultant by training and an entrepreneur at heart, always looking for ways to improve the status quo. Together with Naaman, de Haan drives the company’s vision, strategy, and growth. He’s an industry insider with “a flare for the entrepreneurial.” His previous stint in the German Luftwaffe provided him with the exacting German engineering discipline required to get Kemgo off the ground.

Kemgo creates effective deal-making opportunities by ensuring all trusted petrochemical industry stakeholders have access to global markets at dynamic pricing, 24/7, 365 days a year. It accomplishes this through the use of a web application that provides buyers and sellers worldwide the ability to connect with one another to share and act upon requirements and facilitate transactions.

While the company vets every member to ensure it’s a legitimate player in the petrochemicals industry, the service is free of charge for buyers and sellers to sign up for and post product needs or products for sale. A small commission fee is charged to sellers when a transaction is confirmed.

Kemgo says it enables the petrochemical market to increase revenues and reduce costs by:

- Creating abundance and choice: increasing supply and purchasing options available to buyers and sellers to make the best business decisions for their companies.

- Expanding market presence: making worldwide market data visible and new markets accessible—for easily finding partners, without increasing costs.

- Speeding up the sourcing and ordering process: providing petrochemical suppliers and buyers with the ability to connect with one another globally, facilitating transactions 24/7.

- Building a community around petrochemicals: creating a global trade environment built on trust for the petrochemical community.

Kemgo successfully raised capital in a round led by Marcus Hübel, a former senior executive in the chemicals industry (and most recently an executive committee member of a Middle East-based global market force), and Olivier van Duijn, entrepreneur and current eBay general manager, Benelux.

Within its two first months of operation, Kemgo managed to acquire some strategic members to the platform, including a Fortune 100 company and a major Middle Eastern petrochemical manufacturer. It continues to expand its footprint into new markets and products globally.

After the successful market introduction of its MS-TS and ML-T balances, Mettler Toledo has completed the renewal of its portfolio with the launch of its entry-level balance, the ME-T.

It offers a reliable, high-performance weighing cell, and a large, intuitive 4.5-inch (11.4-cm) color touchscreen, as well as three interface connections for easy data handling. “It’s the perfect choice for day-to-day weighing in any lab or manufacturing environment where affordability is a priority,” the company says.

Built-in applications and an intuitive user interface make the ME-T convenient and easy to use, even for untrained operators. The weighing-in guide and large touchscreen with red and blue digits help users to dose to target, and clearly indicate if sample weights are over or under tolerances. Results, including statistical evaluations, can be sent directly to a printer or transmitted wirelessly to a PC, eliminating transcription by hand and the potential for error that comes with it.

ME-T balances come standard with the company’s “electromagnetic force compensation” weighing cell and overload protection to ensure solid performance and reliable results. This reliability is enhanced by attributes such as passcode protection, which ensures balance settings are not changed accidentally or by unauthorized personnel. Automatic sample ID assignment, with the ability to record up to four IDs per sample, not only saves time and helps improve productivity, it also ensures traceability so applicable regulations can be met.

In addition, ME-T balances offer a variety of connectivity options and are easy to clean. Balance usability can be further improved with Mettler Toledo accessories that help ensure accuracy for less common weighing processes, the company adds.

The 2015 Chem Show, held in November at the Javits Center in New York, welcomed 5,170 registered attendees at the chemical processing industries’ (CPI’s) leading event for processing technology. Thousands of engineers, researchers, corporate managers, and plant personnel from chemical, pharmaceutical, food, and other process industries interacted with the Show’s 282 exhibitors, while capitalizing on a wide scope of free seminars and joining in the 100-year celebration of the biennial Chem Show’s history as a staple event for the North American CPI.

For the first time at the Show, the Kirkpatrick Chemical Engineering Achievement Award was presented by Chemical Engineering Magazine. The 2015 Award went to Dow Performance Plastics for its Intune olefin block copolymers. This technology makes the blending of two previously unmixable polymers—polyethylene and polypropylene—possible through use of parts-per-million levels of catalyst at very specific temperatures.

Additionally, the Show introduced a new “best practices” seminar program that was offered free to all attendees. Industry experts spoke on key and critical issues faced by today’s CPI market, linking strategies and solutions to products and services seen on the show floor.

“We are incredibly pleased with the enthusiastic feedback we have received from seminar attendees,” says Clay Stevens, president of International Exposition Company. “The free seminars and other educational opportunities drew over 600 people and were extremely well-received. We’re already planning more meeting rooms at the 2017 [Chem] Show to accommodate for an even larger program.”